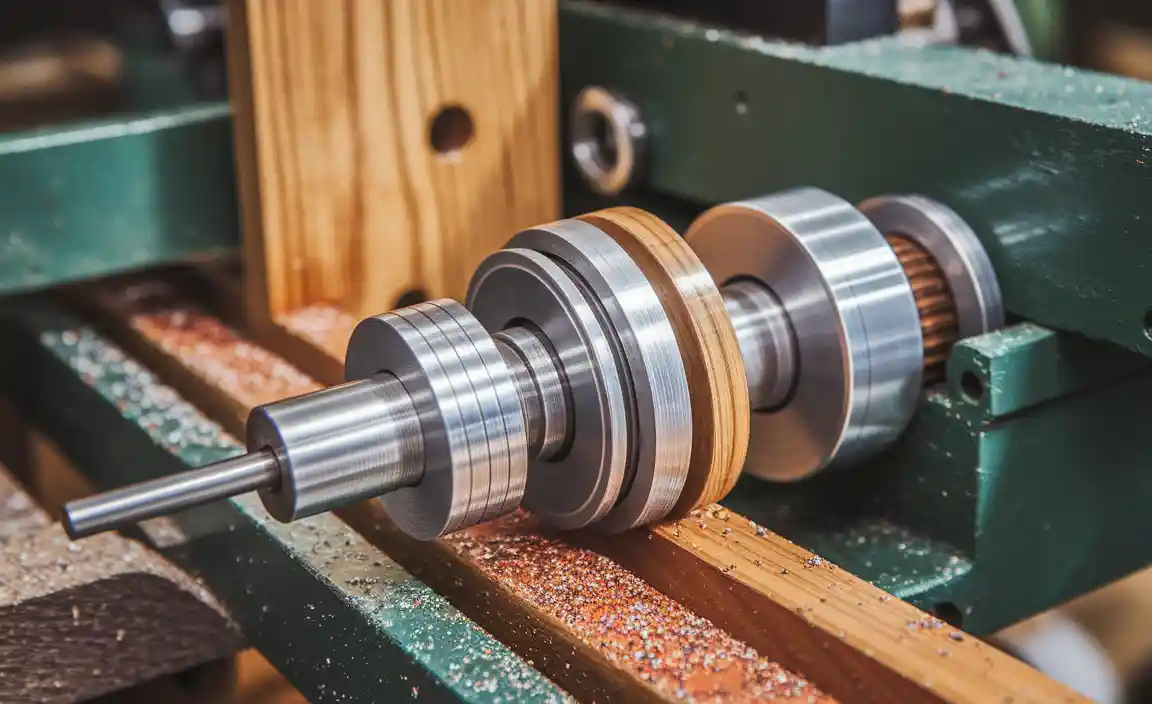

Have you ever watched a wood lathe spin? It’s fascinating to see raw wood transform into beautiful shapes. But have you thought about how important the pulley system is to this process? The pulley system in a wood lathe might seem simple, yet it plays a huge role in how well the machine works.

Imagine trying to ride a bike with a loose chain. Frustrating, right? Just like the bike chain, the wood lathe’s pulley system needs careful inspection. Why? Because a well-maintained pulley system ensures smooth operation and safety. Without it, things can go wrong!

Many woodworkers may not realize that the pulley system may need regular check-ups. Did you know that simple inspections can save time and money? Taking a little bit of time to look over the system can prevent bigger problems later on.

In this article, we’ll dive into the world of wood lathe pulley system inspection. You’ll learn why it’s important and how to do it. So, let’s get started on keeping that lathe spinning smoothly!

Wood Lathe Pulley System Inspection: Essential Tips And Guide

Understanding the Wood Lathe Pulley System

Definition and purpose of a wood lathe pulley system. Key components of the system and their functions.

A wood lathe pulley system helps control the speed and direction of the lathe. It uses several key parts to do this smoothly. Think of it like a puppet show; the pulleys act like puppet strings that make everything move just right! The main components include pulleys, belts, and the motor. Each part works together to keep your lathe spinning like a top and make your woodwork dreams come true! It’s fun to watch, and if something breaks, you’ll know just where to look.

| Component | Function |

|---|---|

| Pulleys | Change direction and speed of the drive |

| Belt | Transfers power from the motor to the lathe |

| Motor | Powers the entire system |

Importance of Regular Inspection

Benefits of maintaining a wood lathe pulley system. Common issues that arise from neglecting inspections.

Regular check-ups on your wooden lathe’s pulley system are crucial. These inspections can help spot problems before they get big, saving you time and money. Think of your lathe like a car; if you ignore the oil change, it won’t run smoothly. Common issues from skipping inspections include worn-out belts and misaligned pulleys. It’s fun to keep things running like a well-oiled machine rather than turning your workshop into a lumberyard disaster!

| Benefits of Inspections | Common Issues from Neglect |

|---|---|

| Increased safety | Worn belts |

| Better performance | Misaligned pulleys |

| Cost savings | Overheating |

Tools Required for Inspection

Essential tools needed for an effective inspection. Safety equipment to consider during the process.

To inspect the wood lathe pulley system, you will need a few important tools. These items help make the inspection safe and effective. Here are some essential tools:

- Wrenches

- Screwdrivers

- Safety goggles

- Gloves

- Tape measure

Always wear your safety equipment. It protects you from any flying debris. Using the right tools ensures the job is done correctly.

What tools do I need for wood lathe pulley inspection?

You need wrenches, screwdrivers, safety goggles, gloves, and a tape measure for wood lathe pulley inspection.

Step-by-Step Inspection Process

Detailed procedure for inspecting the pulley system. Tips for detecting wear and damage.

Inspecting the pulley system is important to keep your wood lathe working well. Follow these steps to check it:

- Start by turning off the machine. Safety first!

- Look for cracks or wear on the pulley wheels.

- Check the belts for fraying or breaks.

- Listen for unusual noises when you run the lathe.

To spot any damage, keep an eye out for:

- Loose screws and bolts.

- Signs of rust or corrosion.

A well-maintained pulley system helps your lathe last longer!

How often should I inspect my wood lathe pulley system?

Inspect your wood lathe pulley system at least once a month to catch any issues early and ensure safety.

Signs of Wear and Tear

Common indicators that your pulley system may be failing. Impact of worn components on lathe performance.

Noticing some odd sounds? Or maybe your lathe is shaking like a maraca? These could be signs your pulley system is wearing out. Common signs include frayed belts, cracks, or wobbling pulleys. If you spot any of these, it’s time to inspect closely. Worn-out parts can make your lathe dance instead of work. Imagine trying to build a table, but the wood keeps flying off! Keeping an eye on your components ensures a smooth operation.

| Signs of Wear | Impact on Performance |

|---|---|

| Frayed Belts | Loss of power transfer |

| Cracked Pulleys | Potential machine damage |

| Wobbling Movement | Increased vibration and noise |

Maintenance Practices for Longevity

Best practices to ensure the pulley system’s longevity. Frequency of inspections and maintenance routines.

Keeping your pulley system in top shape is like caring for a pet. It needs love and attention! Regularly check for wear and tear to help it last longer. Aim for inspections every month; it’s a fun excuse to peek under the hood. When you see a problem, tackle it quickly—delaying could lead to more trouble. Here’s a quick routine:

| Action | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Lubrication | Every 6 months |

| Replace Worn Parts | As needed |

Stick to these habits, and your wood lathe pulley system will thank you. You’ll hear it say, “Wheeee!” or maybe that’s just your imagination! Either way, a little routine goes a long way.

Expert Recommendations and Best Practices

Insights from experienced woodworkers on pulley maintenance. Resources for further learning and support.

Listening to seasoned woodworkers can reveal valuable tips for keeping your pulley system in top shape. One expert suggests checking for wear and tear at least once a month—no one wants their lathe to go “squeak!” during a big project. Also, keep those pulleys clean; dust can be a real party crasher! For more tricks, check resources like woodworking forums or YouTube channels dedicated to lathe maintenance. You can even find funny how-to videos that will keep you smiling as you learn!

| Tip | Description |

|---|---|

| Monthly Inspection | Check pulleys for wear and tear. |

| Keep It Clean | Remove dust and debris regularly. |

| Seek Resources | Explore forums and YouTube for tips! |

Look for advice that dives deeper into pulley care. Following these expert recommendations makes woodwork way more enjoyable. Remember, a well-maintained lathe can be the difference between a masterpiece and a disastrous noodle! Happy turning!

FAQs about Wood Lathe Pulley System Inspection

Common questions regarding inspection and maintenance. Answers to help clarify typical concerns and misconceptions.

Many people wonder about the best ways to inspect wood lathe pulley systems. One common question is about how often you should check them. Regular checks can prevent big problems! Another common query is whether lubrication is necessary. The answer is yes—keeping parts greased helps them work better. Remember: a lube a day keeps the breakage away! Also, folks often ask if unusual noises mean trouble. Yes, strange sounds often signal something is wrong. Be on the lookout!

| Question | Answer |

|---|---|

| How often should I inspect the pulley system? | Regularly, at least every few months! |

| Is lubrication necessary? | Yes, lubrication helps everything run smoothly! |

| What do strange noises mean? | They could signal a problem that needs fixing. |

Conclusion

In conclusion, inspecting a wood lathe pulley system is essential for safety and efficiency. Regular checks help prevent accidents and keep your projects running smoothly. Always look for wear and damage on the pulleys and belts. You can learn more by reading guides or watching videos online. Let’s keep our wood lathe in top shape for better woodworking!

FAQs

Certainly! Here Are Five Related Questions On The Topic Of Wood Lathe Pulley System Inspection:

Sure! Inspecting a wood lathe pulley system is important. First, you check for any cracks or damage. Next, make sure the belts are tight and not worn out. You should also look at the alignment of the pulleys. Finally, always keep the area clean to avoid accidents.

Sure! Please provide the question you would like me to answer.

What Are The Key Components Of A Wood Lathe Pulley System That Should Be Inspected Regularly?

You should check the belts to make sure they aren’t worn or loose. Look at the pulleys for any cracks or damage. It’s also important to inspect the motor for strange sounds or overheating. Lastly, make sure everything is clean and working well together. Regular checks help keep your wood lathe running smoothly!

How Can You Identify Signs Of Wear Or Damage In The Pulley System Of A Wood Lathe?

To check for wear or damage in the pulley system of a wood lathe, look for cracks or breaks in the pulleys. You can feel if they are loose when you touch them. Also, listen for weird noises when the lathe runs. Finally, check the belts. If they look frayed or worn out, it’s time for a change.

What Maintenance Steps Should Be Taken To Ensure The Longevity And Functionality Of The Pulley System On A Wood Lathe?

To keep the pulley system on a wood lathe working well, you should check it often. First, make sure to clean the pulleys and remove any dust or wood shavings. Next, you can put a little oil on the moving parts to keep them sliding smoothly. Also, be sure to check the belts for wear and replace them if they look damaged. Finally, always store your lathe in a dry place to prevent rust.

How Does The Alignment Of Pulleys Affect The Performance And Safety Of A Wood Lathe?

When pulleys on a wood lathe are aligned correctly, the machine runs smoothly. This helps the wood spin evenly, making your projects better. If the pulleys are not lined up, the lathe can shake or make noises. This can be dangerous because it might cause you to lose control. Keeping the pulleys aligned helps us work safely and make nice wood pieces.

What Safety Precautions Should Be Observed During The Inspection Of A Wood Lathe Pulley System?

When you inspect a wood lathe pulley system, be careful. First, always unplug the machine to avoid accidents. Wear safety glasses to protect your eyes from any small debris. Make sure to check for loose parts and watch for moving pieces. Lastly, keep your hands away from the moving parts while the lathe is running.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Wood Lathe Pulley System Inspection:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Inspecting a wood lathe pulley system is important. First, you check for any cracks or damage. Next, make sure the belts are tight and not worn out. You should also look at the alignment of the pulleys. Finally, always keep the area clean to avoid accidents.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Wood Lathe Pulley System That Should Be Inspected Regularly?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the belts to make sure they aren’t worn or loose. Look at the pulleys for any cracks or damage. It’s also important to inspect the motor for strange sounds or overheating. Lastly, make sure everything is clean and working well together. Regular checks help keep your wood lathe running smoothly!”}},{“@type”: “Question”,”name”: “How Can You Identify Signs Of Wear Or Damage In The Pulley System Of A Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check for wear or damage in the pulley system of a wood lathe, look for cracks or breaks in the pulleys. You can feel if they are loose when you touch them. Also, listen for weird noises when the lathe runs. Finally, check the belts. If they look frayed or worn out, it’s time for a change.”}},{“@type”: “Question”,”name”: “What Maintenance Steps Should Be Taken To Ensure The Longevity And Functionality Of The Pulley System On A Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the pulley system on a wood lathe working well, you should check it often. First, make sure to clean the pulleys and remove any dust or wood shavings. Next, you can put a little oil on the moving parts to keep them sliding smoothly. Also, be sure to check the belts for wear and replace them if they look damaged. Finally, always store your lathe in a dry place to prevent rust.”}},{“@type”: “Question”,”name”: “How Does The Alignment Of Pulleys Affect The Performance And Safety Of A Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When pulleys on a wood lathe are aligned correctly, the machine runs smoothly. This helps the wood spin evenly, making your projects better. If the pulleys are not lined up, the lathe can shake or make noises. This can be dangerous because it might cause you to lose control. Keeping the pulleys aligned helps us work safely and make nice wood pieces.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Observed During The Inspection Of A Wood Lathe Pulley System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you inspect a wood lathe pulley system, be careful. First, always unplug the machine to avoid accidents. Wear safety glasses to protect your eyes from any small debris. Make sure to check for loose parts and watch for moving pieces. Lastly, keep your hands away from the moving parts while the lathe is running.”}}]}