Do you remember the first time you crafted something with your own hands? The joy of creating a wooden toy or a simple tool is unmatched. Now imagine bringing that thrill into your woodworking projects! A wood lathe can make this possible. But did you know the tool rest setup is like a trusty co-pilot? Without it, turning wood isn’t as easy or fun. This story begins with understanding how the right setup makes all the difference.

Think of wood lathe tool rests as the unsung heroes of woodturning. They’re the guide that helps us shape, mold, and create. Once, a group of kids were trying to make a wooden pen as a school project. It was with the right tool rest setup that they succeeded. Imagine the excitement on their faces! The setup impacts precision, helping you avoid mistakes, just like in their story.

Why is it so important? Ever tried drawing without a desk? It’s tricky. Similarly, a tool rest ensures stability and control. This means you can focus on making amazing objects. What’s the secret behind skilled woodturners? Often, it lies in mastering this crucial aspect. Embark with us on this journey to explore how this setup can transform your woodworking crafts!

Mastering Wood Lathe Tool Rest Setup Techniques

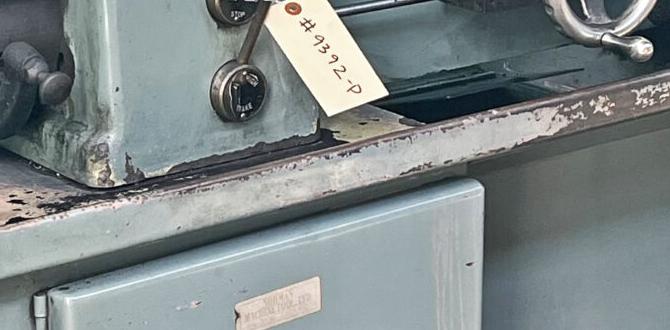

Wood Lathe Tool Rest Setup

Setting up a wood lathe tool rest is simpler than it seems. The tool rest supports your chisel while you shape the wood. First, attach it to the lathe securely. Adjust its height so that it’s level with the center of the wood piece. This helps you make smoother cuts. Did you know that a well-set tool rest can enhance your carving precision? With the right setup, you’ll enjoy turning projects more than ever!Understanding the Importance of a Wood Lathe Tool Rest

Role of the tool rest in woodturning. Impact on precision and safety.Think of a wood lathe tool rest as the stage for a dance show. The dancers are your tools, and precision is key to keep them safe and on point. Setting up a tool rest correctly ensures your tool’s tips glide smoothly, adding sleek precision to your woodturning projects. Did you know: a mere 1-inch shift in tool rest can mean the difference between a stunning vase and a wooden disaster? Plus, it’ll save your fingers from unwanted mishaps, making it not just an art, but a safe practice for wood-turners everywhere!

| Benefit | Description |

|---|---|

| Precision | Proper setup helps mold your design with accuracy. |

| Safety | A secure tool rest reduces risks and promotes safe handling. |

As quoted by woodworkers, “A well-placed tool rest is like having a trusty comrade in your workshop.” So, before starting that spinning masterpiece, give your tool rest the attention it deserves!

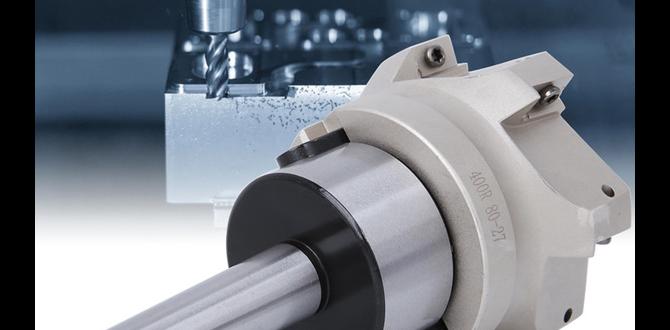

Types of Wood Lathe Tool Rests

Standard tool rest designs and uses. Specialty rests for specific tasks.In the world of woodturning, tool rests act like trusty sidekicks for your lathe adventures. They come in all shapes and sizes! The standard tool rests are your everyday heroes. They give you simple, steady support for basic tasks. Ever feel like you need a superhero? Specialty rests have your back! They’re crafted for specific jobs like bowl turning. Think of them as the Batman of rests. They’ve got the gadgets to tackle specific woodworking tasks with ease and finesse. With the right rest, you’re not far from wood-turning greatness.

| Type | Design | Use |

|---|---|---|

| Standard Tool Rest | Simple, straight | General woodturning |

| Specialty Tool Rest | Curved, angled | Bowl turning, intricate tasks |

Choosing the Right Tool Rest for Your Project

Factors to consider: material, length, and height. Comparing different brands and models.When choosing a tool rest, consider a few things. First, think about the material. Metal is sturdy. Next, check the length. It should fit your project size. Then, look at the height. It should be comfortable to use. Different brands offer various features:

- Strong Metals

- Adjustable Heights

- Durable Models

Read reviews and compare them. This helps you find the best fit. Remember, a good tool rest makes work fun and easy!

### **What materials are tool rests made from?**Tool rests are often made from steel or cast iron. Steel is strong and lasts long. Cast iron is heavy and stable. Both materials help when turning wood neatly.

Step-by-Step Guide to Setting Up a Wood Lathe Tool Rest

Positioning the tool rest correctly. Adjusting for optimal height and distance.Setting up a wood lathe tool rest needs careful handling. Start by ensuring the tool rest is the right distance from the wood. Put it close enough for your tools to reach but not touch. Adjust the height so cutting is easier. Your tool should be horizontal and stable.

- Keep it at the right height.

- Ensure a small gap to avoid vibration.

Being precise helps you work safer and better.

How close should a tool rest be to the wood?

Maintain about 1/8 inch distance between the tool rest and wood surface. This allows you to control your tools without risk of catching.

Common Mistakes and How to Avoid Them

Misalignment issues and solutions. Incorrect tool rest height and its consequences.Setting up a wood lathe can be a puzzle. Misalignment is like a wobbly bicycle wheel—nobody wants that! Keep everything straight by checking if parts fit snugly. As for the tool rest, if it’s too high, you’ll snag wood like fishing in a tree. Too low, and it turns into a splintery surprise party! Aim for a comfy middle ground where cuts glide smoothly.

Here are some pointers to avoid these hiccups:

| Common Mistake | Solution |

|---|---|

| Misalignment | Ensure all parts are aligned properly. |

| Incorrect Tool Rest Height | Adjust height for smooth, easy cuts. |

Remember, even the best woodworkers made mistakes at first. As one wise carpenter said, “Measure twice, cut once.” So, keep calm, fix those errors, and you’ll become a lathe legend in no time.

Maintenance Tips for Longevity

Cleaning and lubrication practices. Inspecting for wear and tear.Is your wood lathe tool rest setup ready for long-lasting use? Keeping it in good shape is easy with a few steps! First, regular cleaning is key. Wipe it down after each use to remove dust and debris. Next, add a bit of oil to lubricate moving parts. This makes everything run smoothly.

But wait, there’s more! Check for signs of wear and tear every now and then. Look for cracks or damages. It’s like giving your tool a health check-up! A small fix today avoids bigger problems tomorrow.

Why is regular cleaning important?

Regular cleaning keeps your tools in top shape. It removes dirt and grime, which helps them last longer. Clean tools work better too!

What should I check for during inspection?

Look at every part. Feel for rough spots and see if anything is loose. If you spot a problem, fix it soon. This keeps your wood lathe safe and reliable.

Enhancing Your Woodturning Techniques

Experimenting with various tool rest setups. Adapting setups for different turning projects.Spice up your woodturning skills by trying out different tool rest setups! Each shape you turn can be as unique as a snowflake, needing its own special approach. For instance, a slender vase might prefer a close and steady rest. On the other hand, a chunky bowl might like a bit more distance. This keeps your work fun and sometimes funny—what works for one project might make another go whizz, kaboom! Adaptation is the name of the game.

| Project Type | Recommended Setup |

|---|---|

| Slender Vase | Close and Steady |

| Chunky Bowl | Slight Distance |

As the saying goes, “Variety is the spice of life.” So, why not let experimentation enhance your woodturning journey? Adjusting your setup based on the needs of your project can turn a task into an adventure. Try different positions until you find the one that feels just right. It’s like being a detective, but instead of finding clues, you’re creating art!

Conclusion

Setting up a wood lathe tool rest is simple with the right steps. Make sure it’s sturdy and adjusted correctly for safe, precise turning. We learned about aligning it properly and keeping tools sharp. Keep practicing and explore more resources to master this skill. Now, let’s create amazing wood projects safely and confidently!FAQs

Certainly! Here Are Five Questions Related To Setting Up A Tool Rest For A Wood Lathe:When you set up a tool rest for a wood lathe, place it close to the wood so your tool can touch it easily. The tool rest should be just above the center of the wood piece for safe turning. Make sure the tool rest is tight and doesn’t wiggle when you touch it. Adjust it if you’re working on a different shape to keep your hands steady.

Sure, here’s an answer: Clouds are like big, fluffy cotton candy in the sky. They form when water vapor (tiny water droplets) up high gets cold and sticks together. When there are a lot of water droplets, we see them as clouds. Different kinds of clouds can bring different weather, like rain or sunshine.

What Are The Key Factors To Consider When Positioning The Tool Rest For Efficient Woodturning?When you position the tool rest for woodturning, make sure it’s close to the wood. This helps you control the tools better. Keep the tool rest at the same height as your cutting tool. Move the tool rest as you shape the wood to stay close. Always check that it’s tight and doesn’t move around.

How Does The Height Of The Tool Rest Affect The Turning Process, And What Is The Recommended Height Relative To The Workpiece?The tool rest’s height is important when turning wood on a lathe. If it’s too high or too low, it can make it harder to work with the wood smoothly. Generally, the tool rest should be at the same height as the middle of the workpiece or slightly above. This position helps you control your tools better and makes the turning process safer and easier.

What Safety Precautions Should Be Taken When Adjusting Or Repositioning The Tool Rest On A Wood Lathe?When changing the tool rest on a wood lathe, always turn the machine off first. Wait until it stops spinning before you touch anything. Make sure your hands and fingers are away from sharp parts. Wear safety goggles to protect your eyes from flying bits of wood. Finally, tighten the tool rest securely before turning the lathe back on.

How Can The Type Of Wood And The Nature Of The Project Influence The Setup Of The Tool Rest?The type of wood and the project you’re doing can change how you set up the tool rest. If the wood is soft, you might keep the tool rest closer to the wood so you have more control. For hard wood, you might set it farther away for smoother cuts. Some projects need special angles, and you can adjust the tool rest to help make the right shapes. Always make sure the tool rest is steady so you have a safe and easy time working.

What Are Some Common Mistakes To Avoid When Setting Up A Tool Rest, And How Can They Be Corrected For Optimal Performance?When setting up a tool rest, you might place it too far from the tool. Keep it close to support the tool properly. Make sure the tool rest is flat, not slanted. Tighten it well so it doesn’t move around. If it’s not working right, adjust it and try again until it’s steady.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Questions Related To Setting Up A Tool Rest For A Wood Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you set up a tool rest for a wood lathe, place it close to the wood so your tool can touch it easily. The tool rest should be just above the center of the wood piece for safe turning. Make sure the tool rest is tight and doesn’t wiggle when you touch it. Adjust it if you’re working on a different shape to keep your hands steady.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure, here’s an answer: Clouds are like big, fluffy cotton candy in the sky. They form when water vapor (tiny water droplets) up high gets cold and sticks together. When there are a lot of water droplets, we see them as clouds. Different kinds of clouds can bring different weather, like rain or sunshine.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Positioning The Tool Rest For Efficient Woodturning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you position the tool rest for woodturning, make sure it’s close to the wood. This helps you control the tools better. Keep the tool rest at the same height as your cutting tool. Move the tool rest as you shape the wood to stay close. Always check that it’s tight and doesn’t move around.”}},{“@type”: “Question”,”name”: “How Does The Height Of The Tool Rest Affect The Turning Process, And What Is The Recommended Height Relative To The Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The tool rest’s height is important when turning wood on a lathe. If it’s too high or too low, it can make it harder to work with the wood smoothly. Generally, the tool rest should be at the same height as the middle of the workpiece or slightly above. This position helps you control your tools better and makes the turning process safer and easier.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Adjusting Or Repositioning The Tool Rest On A Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When changing the tool rest on a wood lathe, always turn the machine off first. Wait until it stops spinning before you touch anything. Make sure your hands and fingers are away from sharp parts. Wear safety goggles to protect your eyes from flying bits of wood. Finally, tighten the tool rest securely before turning the lathe back on.”}},{“@type”: “Question”,”name”: “How Can The Type Of Wood And The Nature Of The Project Influence The Setup Of The Tool Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The type of wood and the project you’re doing can change how you set up the tool rest. If the wood is soft, you might keep the tool rest closer to the wood so you have more control. For hard wood, you might set it farther away for smoother cuts. Some projects need special angles, and you can adjust the tool rest to help make the right shapes. Always make sure the tool rest is steady so you have a safe and easy time working.”}},{“@type”: “Question”,”name”: “What Are Some Common Mistakes To Avoid When Setting Up A Tool Rest, And How Can They Be Corrected For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When setting up a tool rest, you might place it too far from the tool. Keep it close to support the tool properly. Make sure the tool rest is flat, not slanted. Tighten it well so it doesn’t move around. If it’s not working right, adjust it and try again until it’s steady.”}}]}