Master your wood lathe tools with a proven sharpening system! This guide provides a simple, step-by-step method for beginners to restore razor-sharp edges, ensuring smoother cuts, better results, and increased safety in your woodworking projects. Get ready to make your tools perform like new!

Welcome, fellow makers and woodturners! Daniel Bates here from Lathe Hub, and I’m thrilled you’re joining me today. If you’ve just started turning wood, you’ve probably noticed that your tools, no matter how good they were out of the box, start to feel… well, dull. It’s like trying to carve butter with a spoon instead of a sharp knife. Frustrating, right? This is a super common hurdle for beginners, and honestly, it trips up experienced woodturners too. The good news? Achieving that perfect, smooth cut is entirely within reach, and it all comes down to a reliable tool sharpening system. We’re going to walk through a proven method, step-by-step, that will transform your tools from frustrating blurs to precision instruments. Get ready to unlock a whole new level of control and satisfaction in your turning! We’ll cover everything you need to get those edges singing, and by the end, you’ll feel confident in your sharpening skills.

Why Your Wood Lathe Tools Need a Proven Sharpening System

Turning wood is a dance between you, the lathe, and your tools. When your tools are sharp, they glide through the wood, peeling off thin shavings with ease. This not only makes your work more enjoyable but also dramatically improves the quality of your finished pieces. Smooth cuts mean less sanding later, fewer tear-outs, and a much safer turning experience. Think of it this way: a dull tool requires more force to cut, which can lead to the tool digging in unexpectedly, causing a catch. A catch can be dangerous, potentially sending your workpiece flying or even causing injury. A sharp tool, on the other hand, takes a precise bite, giving you control and confidence.

For beginners, understanding tool geometry and how to maintain it is fundamental. It’s not about magic; it’s about understanding angles and using the right techniques and tools to restore them. A consistent sharpening system removes the guesswork. Instead of randomly grinding away, you’re following a proven process that guarantees predictable, excellent results. This builds muscle memory and confidence, allowing you to focus on the creative aspects of woodturning rather than worrying about your tools.

The Core Components of a Wood Lathe Tool Sharpening System

At its heart, a wood lathe tool sharpening system involves restoring a keen edge by removing material from the tool’s bevel. Think of it as putting a fine point back on a pencil that’s gotten worn down. This requires a few key elements:

- An Abrasive Surface: This is what does the actual sharpening by grinding away metal.

- A Way to Hold the Tool: You need to present the tool’s bevel to the abrasive consistently.

- A Method to Maintain Angles: Keeping the correct angle is crucial for the tool’s performance.

- A Way to Refine the Edge: After grinding, you’ll want to hone the edge to make it even sharper.

While there are many commercial sharpening systems available, the principles are the same. We’ll focus on a versatile approach that uses common tools and techniques, making it accessible for any beginner.

Essential Tools for Your Sharpening Station

Setting up a dedicated sharpening station isn’t complicated, and you don’t need a huge investment to start. Here are the key items you’ll want to gather:

- Bench Grinder: A slow-speed grinder (1750 RPM is ideal for wood tools) with appropriate grinding wheels is the backbone of most sharpening systems.

- Water Stone or Diamond Plate: These are for refining the edge after grinding. Water stones come in different grits, and diamond plates are durable and consistent. A combination stone (e.g., 1000/4000 grit) is a great starting point.

- Sharpening Jig or Guide: This is vital for maintaining consistent angles. Many systems use such a jig, or you can create your own using simple methods. For example, a simple block with an angled slot or a commercially available jig like the Wolverine Grinding Jig.

- Magnifying Glass or Loupe: To inspect your edge for a consistent bevel and to check for burrs.

- Safety Glasses: Absolutely non-negotiable whenever metal is being ground!

- Bench Vise: Helpful for holding chisels or other items securely if you’re grinding non-lathe specific tools as well.

- Shop Rags or Paper Towels: To keep things clean and dry.

- Dressing Stick/Stone: To flatten your water stones and keep them cutting true.

For water stones, think about a coarse grit (around 400-1000) for establishing a new bevel or repairing significant damage, and a finer grit (4000-8000+) for honing the edge to razor sharpness. Diamond plates offer a consistent surface and don’t dish out like stones, making them a very low-maintenance option. A good starting point for diamond plates might be a coarse (around 300 grit) and a fine (around 1200 grit).

Understanding Wood Lathe Tool Grinding Wheels

When using a bench grinder, the type of wheel matters. For woodturning tools, you generally want to avoid high-speed grinders with aggressive, fast-cutting wheels meant for metal sharpening. These can overheat and “blue” the steel, ruining its temper and making it soft. Opt for:

- White Aluminum Oxide Wheels: These are generally preferred for high-speed steel (HSS) tools as they are less likely to overheat the steel compared to silicon carbide or brown aluminum oxide wheels.

- Slow-Speed Grinder (1750 RPM recommended): This is the most critical factor. A slower wheel removes metal more gradually, reducing the risk of overheating.

- Wheel Selection: A medium grit (e.g., 60-80 grit) is usually sufficient for initial shaping and sharpening.

Many woodturners use specific jigs that hold the tool bevel at a set angle against the grinding wheel. This is where the “system” really comes into play. These jigs ensure that you’re grinding the same flat bevel consistently. You can find various jigs, like the Oneway Wolverine or similar designs, that mount to your grinder and guide the tool.

External Resource: For more on grinder safety and wheel selection, consult the OSHA standard on Abrasive Wheel Machinery (though primarily for industrial use, it highlights crucial safety principles).

Step-by-Step: The Proven Wood Lathe Tool Sharpening System

Let’s get down to business. This system is designed to be repeatable and effective, giving you a consistently sharp edge. We’ll use a common set of tools: a bench grinder with a jig and a water stone for final honing.

Step 1: Prepare Your Grinding Station

First things first: safety and setup. Ensure your bench grinder is securely mounted, and the wheels are clean and in good condition. If you’re using a jig, attach it securely to the grinder rest. Select a medium-grit white aluminum oxide wheel. Make sure you have your safety glasses on! If using water stones, soak them according to the manufacturer’s instructions (usually 10-20 minutes). Have your tool ready, and perhaps a bowl of water nearby to cool the tool if it starts to feel hot.

Step 2: Set Up Your Sharpening Jig

This is where the “system” shines. If you’re using a jig like the Wolverine, you’ll adjust its angle to match the bevel of your tool. For instance, a common skew chisel bevel angle might be around 25-30 degrees. Consult your tool manufacturer or a reliable woodworking guide for the recommended sharpening angles for different tools (like gouges, chisels, scrapers).

Most jigs allow you to slide the tool in and out to control the length of the bevel. When sharpening, you’ll aim to maintain the existing bevel angle without digging too deep or grinding away too much material. The goal is to touch up the edge, not to reshape the entire tool unless it’s severely damaged.

Step 3: Grind the Bevel

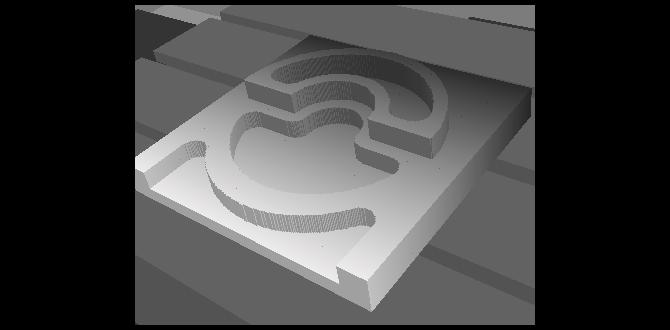

Take your first tool, let’s say a spindle gouge. Mount it in your jig and position the bevel against the grinding wheel. Gently push the tool into the rotating wheel. Move the tool side-to-side slightly as you grind to ensure you’re grinding the entire bevel surface evenly. Don’t press hard; let the wheel do the work. Grind for a few seconds, then pull the tool back and check its temperature. If it’s getting too hot to touch comfortably, dip it in water. Repeat this process, alternating sides if necessary or grinding one side until you just start to feel a small burr forming on the opposite edge. You can check for a burr by gently running your fingernail away from the edge.

Pro Tip: For beginners, aim to grind just enough to remove the dullness and establish a keen edge. Over-grinding wastes tool steel and can change the tool’s geometry too much. A tiny burr is what you’re looking for – it indicates you’ve ground all the way to the edge.

Step 4: Check and Refine the Grinding

Once you’ve established a consistent bevel with a small burr, remove the tool from the jig and examine the edge under magnification if possible. Ensure the bevel is flat and uniform. If there are any hollows or inconsistencies, go back to the grinder and touch them up, always maintaining the same angle. The goal is a consistent, sharp edge running the full length of the cutting edge.

Step 5: Hone the Edge on a Water Stone or Diamond Plate

Now that the grinding is done, it’s time to refine and hone the edge for superior sharpness. This is often the most crucial step for achieving that glass-smooth cut.

Using Water Stones:

- Take your soaked water stone (start with the coarser grit, e.g., 1000).

- Place the bevel of your tool flat against the stone.

- Maintain the same angle you used on the grinder.

- Rub the tool back and forth, using light pressure. Think about “stropping” the edge.

- Work the edge until you no longer feel the burr from grinding and can feel a very fine wire edge.

- Move to your finer grit stone (e.g., 4000+) and repeat the process. This refines the edge to a razor-sharp state.

Using Diamond Plates:

- Place your diamond plate on a stable surface (some have non-slip bases).

- Position the tool bevel flat on the plate.

- Maintain your sharpening angle and move the tool with light pressure, a few strokes on each side or as needed to remove the burr.

- Repeat with a finer grit diamond plate if you have one.

Beginner’s Note: The honing step is key to a truly sharp edge. Don’t skip it! It removes the microscopic “teeth” left by the grinder and creates a smooth, polished cutting surface. You should be able to shave hair off your arm with a properly honed tool.

Step 6: Deburr and Test

After honing on your finest abrasive, you’ll want to remove any final microscopic burr. Some turners do this by gently stroking the edge backwards on a piece of scrap wood or leather, or by using a fine-grit sharpening stone as a final polishing step. The goal is a polished, burr-free edge.

Test the sharpness on a piece of scrap wood. A sharp tool will cut cleanly with minimal effort. If it’s dragging, tearing, or requiring significant force, it needs more honing or a touch-up on the grinder.

Sharpening Specific Wood Lathe Tools

While the core system applies to most tools, each type has nuances:

Spindle Gouges

These are often sharpened to a fingernail shape, with a common bevel angle of 30-45 degrees. The jig is crucial for maintaining that curved bevel.

Bowl Gouges

Bowl gouges typically have a more pronounced fingernail grind with varying bevel angles (often 40-55 degrees) depending on the desired cut. The jig helps you maintain the sweeping bevel.

Skew Chisels

Skew chisels require precise bevel angles (around 25-30 degrees) and a keen edge. The flat bevel of a skew is easier to maintain on a jig than a gouge’s curved bevel.

Scrapers

Scrapers are sharpened differently. The edge is burnished to create a tiny burr that does the scraping. This often involves a hardening and tempering process for the burr and then regular burnishing.

Parting Tools and Cut-off Tools

These narrow tools are typically sharpened with a very simple, straight bevel on their cutting face. A jig is still helpful to maintain the correct angle.

A common sharpening jig setup for gouges and skews involves resting the tool on the grinder’s tool rest and using a jig that guides the tool’s bevel against the wheel. For simpler tools like scrapers or parting tools, you might use a straight jig or even freehand sharpen if you’re confident, though a jig is always recommended for consistency.

Maintaining Your Sharpening System

For the system to work, your tools need to be maintained:

- Grinding Wheels: Keep them clean and true. Use a diamond wheel dresser to flatten dished wheels and expose fresh abrasive.

- Water Stones: Regularly flatten them with a flattening stone. This ensures they cut efficiently and that your tool bevels remain flat.

- Diamond Plates: While they don’t dish as much, they can get clogged with metal dust. Clean them with a solvent and a brush.

Regular maintenance ensures your sharpening station is always ready and performing at its best. It’s a small effort that results in a huge payoff in tool performance.

Troubleshooting Common Sharpening Issues

Even with a system, you might run into snags. Here’s how to fix them:

- Tool Overheating: Grind in shorter bursts, use less pressure, and dip the tool in water more frequently. Ensure your grinder is slow-speed.

- Inconsistent Bevel: This usually means the tool is not held steadily in the jig, or the jig itself is not properly secured. Double-check your jig setup and your technique.

- No Sharp Edge After Honing: You might not have removed the grinding burr completely, or you’re not using a fine enough abrasive. Make sure you feel the burr disappear on the finer stones.

- Edge Degrading Quickly: If your edge isn’t holding up, it could be due to overheating during grinding (which softens the steel) or not sharpening to a fine enough polish. Ensure your water stones or diamond plates are clean and effective.

Don’t get discouraged! Sharpening is a skill that improves with practice. Every time you sharpen, you’ll be a little more confident and a little more precise.

Pros and Cons of a Dedicated Wood Lathe Tool Sharpening System

Like any tool or method, there are advantages and disadvantages to using a dedicated sharpening system.

| Pros | Cons |

|---|---|

| Consistency: Jigs and systems ensure repeatable bevel angles and edge geometry. | Initial Investment: Some jigs and specialized stones/plates can be costly. |

| Improved Edge Quality: Leads to sharper tools and better woodworking results. | Learning Curve: Understanding angles and proper technique still takes practice. |

| Safety: Reduces the risk of tool catches by ensuring sharp edges. | Requires Dedication: Needs a dedicated space and regular time commitment. |

| Tool Longevity: Proper sharpening removes minimal material, extending the life of your tools. | Potential for Over-Grinding: If technique is poor, too much steel can be removed. |

| Efficiency: Once set up, can be faster than freehand sharpening. | Setup Time: Initial setup and calibration of jigs can take time. |

For beginners, the pros of a system – especially consistency and improved safety – far outweigh the cons. It builds a solid foundation for good turning habits.