Don’t let a shaky wood lathe ruin your projects! This guide explains the common causes of wood lathe vibration and provides simple, hands-on fixes. Get your lathe running smoothly and confidently turn those stunning creations.

Hey, it’s Daniel Bates from Lathe Hub! If you’re new to woodworking, you’ve probably noticed that sometimes your wood lathe just doesn’t sound or feel right. That buzzing, rattling, or shaking is called vibration, and it can be a real headache. It makes precise work tough, can damage your tools, and frankly, it’s just annoying. But don’t worry, we’re going to break down exactly why this happens. We’ll look at the most common culprits behind wood lathe vibration and, more importantly, how to fix them so you can get back to safely and enjoyably creating beautiful pieces. We’ll cover everything from unaddressed foundational issues to simple setup adjustments.

Understanding Wood Lathe Vibration: Why It Happens

Wood lathe vibration is a common issue, especially for beginners as they get a feel for their machines and the materials they’re working with. Think of it like an unbalanced washing machine during its spin cycle – something isn’t quite right, leading to that unsettling shake. This vibration isn’t just a minor nuisance; it directly impacts the quality of your work, can be hard on your lathe’s components, and is a safety concern. A vibrating lathe makes it difficult to achieve smooth cuts, can lead to tear-out and uneven surfaces on your projects, and can even cause inaccuracies in measurements. Over time, excessive vibration can also contribute to wear and tear on bearings, motors, and other parts of your lathe.

The good news is that most wood lathe vibrations stem from a handful of predictable causes. By understanding these causes, you can systematically troubleshoot and resolve them. We’re going to dive into each of these, explaining what they are and how to address them. From ensuring your lathe is properly set up to checking the condition of your workpiece, we’ve got you covered. Let’s get your lathe running like a dream!

Common Causes of Wood Lathe Vibration & Their Fixes

When your wood lathe starts vibrating, it’s usually a clear sign that something isn’t quite right. These issues can range from simple, quick fixes to more involved checks. Let’s break down the most frequent offenders and how to tackle them, making your turning experience much smoother and safer.

1. Unbalanced Workpiece

This is by far the most common cause of vibration, especially when you’re starting a new piece of wood or turning something irregular. Wood isn’t always perfectly uniform. When the mass isn’t distributed evenly around the center of rotation, the lathe has to work harder, and that imbalance translates directly into shaking. This is most noticeable when you’re turning a square blank or a piece with knots or uneven density.

How to Fix It:

- Rough Turning: Start by roughing out your blank into a basic cylindrical shape. As you turn, try to get the shape as round and symmetrical as possible, even at a lower speed. This process itself helps to balance the mass.

- Speed Adjustment: If you’re turning a piece that you suspect is unbalanced (like a very irregular piece of burl wood), start at a lower RPM. Gradually increase the speed as the workpiece becomes more balanced.

- Centering: Ensure your workpiece is properly centered on the lathe’s drive center and spur center. Minor misalignment can exaggerate the effects of any imbalance.

- Secure Mounting: Double-check that your workpiece is securely held by your faceplate or between centers. Loose work can wobble severely.

2. Incorrect Tool Rest Placement

The tool rest is crucial for supporting your turning tools. If it’s too far from the workpiece, your tools won’t have adequate support. This can lead to chattering and vibration as the tool digs in or bounces. The goal is to have the tool rest as close to the wood as possible without it interfering with the rotation.

How to Fix It:

- Proximity is Key: Adjust the tool rest so it’s just a hair’s breadth away from the wood – literally the thickness of a piece of paper. This offers maximum support for your cutting tool.

- Angle Matters: For most turning, the tool rest should be parallel to the bed of the lathe. When doing specific cuts like parting or scraping, you might angle it slightly, but for general turning, keep it straight.

- Proper Height: The top of the tool rest should generally be about the same height as the center line of your workpiece. For certain operations like hollowing or bevel scraping, you might lower it slightly, but for most cuts, keep it at center height.

3. Loose Headstock or Tailstock Components

The headstock (where the motor is) and the tailstock (the part on the other end that supports the wood) are critical for stability. If any of their components are loose – such as the tailstock quill, tool rest banjo, or even the entire tailstock locking mechanism – they can vibrate during operation. This is especially true if you’re applying significant pressure during a cut.

How to Fix It:

- Tailstock Lock: Always ensure the lever or handwheel that locks the tailstock to the lathe bed is tightened securely. Give it a good snug turn.

- Quill Tightness: The tailstock quill (the part that moves in and out) should also be locked down firmly when you’re cutting. Check the lock screw or lever for looseness.

- Banjo Lock: The tool rest banjo, which slides along the bed, has a locking mechanism. Make sure this is tightened before you start turning.

- Headstock Cover: While less common, ensure any covers or access panels on the headstock are securely fastened.

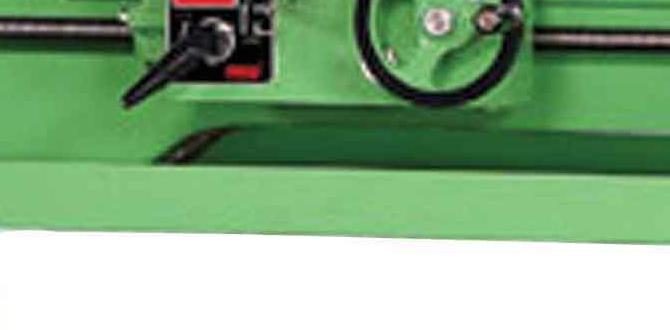

4. Machine Not Level or Secure

A lathe needs a stable, level foundation to operate without excessive vibration. If your lathe is placed on an uneven floor, or if the machine itself isn’t sitting flat and securely on its legs or stand, vibrations will quickly amplify. This is particularly important for larger, heavier lathes.

How to Fix It:

- Use a Level: Place a spirit level on the lathe bed and check if it’s level both side-to-side and front-to-back.

- Shims: If the floor is uneven, use shims (like thin pieces of hardwood or composite material) under the lathe’s legs or base to achieve a perfectly level and stable setup. Industrial-grade rubber anti-vibration mats can also be a great investment for reducing vibration transfer to the floor. You can find these from specialized industrial suppliers.

- Bolt Down (If Applicable): For some benchtop or smaller floor lathes, there might be mounting holes to bolt the machine to a workbench or a dedicated stand. If possible, using these can significantly increase stability.

5. Dull or Damaged Turning Tools

Your turning tools are your interface with the wood. If they’re dull, you have to force them, which leads to tearing, chattering, and increased vibration. Damaged tools, like those with nicks or bent tips, will also behave erratically and create vibration.

How to Fix It:

- Regular Sharpening: Make sharpening your tools a routine part of your workflow. A sharp tool cuts cleanly and requires less force. Regularly honing and sharpening your gouges, chisels, and scrapers will make a huge difference.

- Proper Grinding Angles: Ensure you’re maintaining the correct grinding angles for your tools. Refer to your tool manufacturer’s recommendations or trusted woodworking resources. For example, the Woodworker’s Journal offers excellent guides on tool sharpening.

- Inspect for Damage: Before you start turning, give your tools a quick visual inspection. Remove any burrs or chips from the edge.

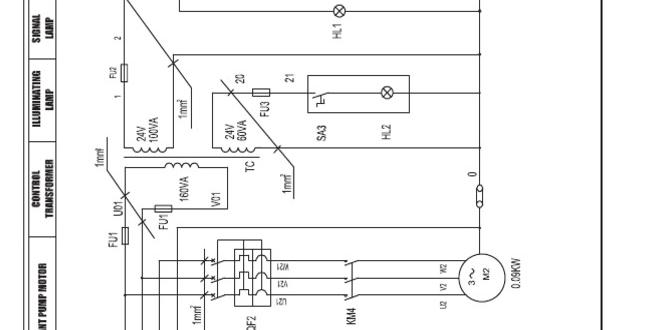

6. Worn or Damaged Lathe Bearings

The bearings in your lathe’s headstock and tailstock allow the spindle to rotate smoothly. If these bearings become worn, damaged, or are not properly lubricated, they can be a source of noise and vibration. This is often accompanied by a grinding or rumbling sound.

How to Fix It:

This is a more involved fix that might require professional attention or a good mechanical aptitude:

- Listen Carefully: Try to pinpoint the source of the vibration. Does it seem to come from the motor itself, or the rotating spindle?

- Lubrication: Check your lathe’s manual for recommended lubrication points and types. Ensure all bearings are adequately greased or oiled.

- Bearing Check: Gently rotate the spindle by hand (with the power off!). Do you feel any roughness, clicking, or hear grinding sounds?

- Replacement or Service: If you suspect worn bearings, it’s best to consult your lathe’s manual for bearing numbers and consider replacement. For many users, this might be a job for a repair shop or an experienced machinist friend. The Old Woodworking Machines Forum is a great place to find advice on older machine maintenance.

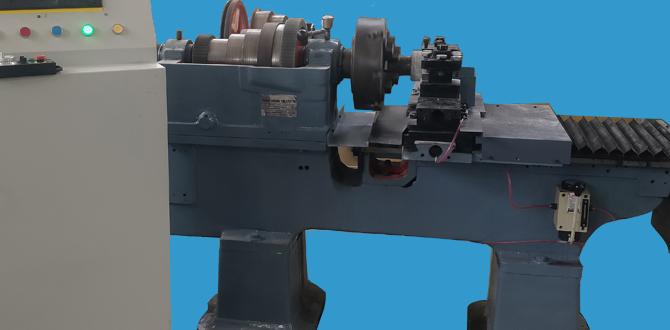

7. Drive Belt Issues

Most wood lathes use a belt drive system to connect the motor to the spindle. If the belt is worn, damaged, has a splice that’s out of balance, or is not tensioned correctly, it can cause vibration. A belt that is too loose can slip and cause inconsistent speeds, while a belt that is too tight can put undue stress on the motor and spindle bearings.

How to Fix It:

- Inspect the Belt: Look for any signs of fraying, cracking, or damage on the belt.

- Check Belt Tension: The belt should have a slight give but not be excessively loose. Consult your lathe’s manual for specific tensioning instructions. Most lathes have an adjustment mechanism for belt tension.

- Belt Splice: If your belt has a spliced joint, check if it’s smooth. A poorly made splice can create a significant imbalance.

- Pulley Alignment: While you’re at it, ensure the pulleys on the motor and spindle are aligned correctly.

8. Motor Mounting Issues

The motor driving your lathe needs to be securely mounted. If the motor bolts are loose, or if the motor itself has internal issues, it can introduce vibration into the entire machine. This is less common than workpiece imbalance but can be a persistent problem if overlooked.

How to Fix It:

- Motor Mount Bolts: With the lathe unplugged, check that all bolts securing the motor to its mounting plate are tight.

- Motor Condition: Listen to the motor when it’s running. If the vibration seems to be coming directly from the motor itself (even when disconnected from the belt), it might indicate an internal motor problem.

- Fan Balance: Some motors have fans for cooling. If a fan blade is bent or damaged, it can cause vibration.

Troubleshooting Vibration: A Step-by-Step Approach

When your lathe starts acting up, it’s easy to get frustrated. But with a systematic approach, you can usually find the root cause. Here’s a method to follow:

- Start with the Wood: Is the vibration present with any piece of wood, or just the current one? Turn off the lathe, remove the current workpiece, and then spin the spindle by hand. Does it feel smooth? If the vibration only occurs with a specific piece, the wood itself or its mounting is the likely culprit. Try a known good, round blank to see if the vibration disappears.

- Check Tool Rest and Tool: With the power off, ensure the tool rest is positioned correctly (close and at center height for general turning). Feel your turning tools. Are they sharp and free of damage? Dull tools are a very common cause of poor finish and vibration.

- Verify Machine Stability: Gently try to rock the lathe. Does it move? Is it sitting level? Tighten any locking levers for the headstock, tailstock, and tool rest banjo.

- Inspect the Drive Train: If the above steps don’t help, it’s time to look at the belt and pulleys. With the power off, remove the belt guard (if accessible) and check the belt’s condition and tension. Inspect the pulleys for damage or debris.

- Listen to Mechanical Sounds: Turn the lathe on at a low speed (if it’s safe to do so) and listen very carefully. Can you isolate the sound of vibration to the motor, the headstock, or the tailstock? Grinding or rumbling sounds often indicate bearing issues.

- Consult Your Manual: Always your best friend! Your lathe’s manual will have specific information about troubleshooting, maintenance, and component checks.

Maintaining Your Lathe for Optimal Performance

Regular maintenance is the best defense against vibration and other performance issues. Think of it like taking care of any precision tool – routine care keeps it running smoothly and reliably.

Key Maintenance Tasks:

- Lubrication: Follow your manual’s guide for periodic lubrication of headstock bearings, tailstock ways, and any other moving parts. Proper lubrication reduces friction and wear, which in turn minimizes vibration.

- Cleaning: Keep your lathe clean, especially around the ways and moving parts. Dust, chips, and debris can interfere with smooth operation.

- Belt Inspection: Periodically check the drive belt for wear, cracks, or damage. Replace it if it looks compromised.

- Bolt Checks: Occasionally go over all accessible bolts and fasteners on your lathe. Ensure things like the motor mount, legs, and tailstock assembly are snug.

- Tool Sharpening Station: Ensure your grinding wheel or sharpening system is also in good condition. A well-maintained sharpening setup means well-maintained turning tools.

A well-maintained lathe is a safe lathe and a productive lathe. This proactive approach can save you a lot of headaches down the road.

Vibration Causes and Fixes at a Glance

Here’s a quick reference table to help you diagnose issues:

| Symptom | Likely Cause(s) | Primary Fix(es) |

|---|---|---|

| Shaking during turning, especially at higher speeds | Unbalanced Workpiece, Loose Tailstock/Tool Rest | Balance workpiece, secure tailstock/tool rest tightly |

| Chattering or choppy cuts | Dull Tools, Tool Rest Too Far Away | Sharpen tools, move tool rest closer |

| Rattling from the machine base | Lathe Not Level, Loose Mounts | Level machine, tighten mounting bolts/legs |

| Grinding or rumbling noise during operation | Worn Bearings, Motor Issues | Lubricate, inspect/replace bearings or motor |

| Inconsistent speed or stuttering | Drive Belt Issues (Loose, Damaged), Motor Problem | Check belt tension/condition, inspect motor |

When to Seek Professional Help

While many wood lathe vibration issues are straightforward fixes, some indicate more serious internal problems. If you’ve checked the common causes and your lathe is still aggressively vibrating, or if you hear loud grinding noises, it might be time to call in an expert. Issues with motor windings, internal headstock or tailstock bearing failures, or complex drive mechanism problems often require specialized knowledge and tools to repair safely. Don’t hesitate to contact the manufacturer of your lathe or a qualified machinery repair technician if you’re unsure or uncomfortable with a repair. For instance, if you have a very old or specialized lathe, resources like VintageMachinery.org can sometimes point you towards people with expertise in those specific models.

FAQ: Wood Lathe Vibration

Q1: My new piece of wood vibrates a lot. What’s wrong?

A: This is usually because the wood blank is not perfectly round or its weight distribution is uneven until you start shaping it. Start turning at a lower speed, focus on getting the blank as round as possible, and gradually increase your speed as the piece becomes more balanced.

Q2: Can a loose banjo or tool rest cause significant vibration?

A: Absolutely! The tool rest banjo locks the tool rest to the lathe bed. If it’s not tight, it will vibrate. Always ensure it’s locked down firmly. A tool rest that’s too far from the wood also acts like a lever, amplifying vibrations.

Q3: I hear a buzzing sound. Is that vibration?

A: A buzzing sound can be vibration, but it can also indicate a motor issue or loose component. Check if the sound changes with speed. If it’s constant and seems to come from the motor housing, it might need closer inspection. Ensure all motor mount bolts are tight.