Lathes are essential tools used for centuries in woodworking and metalworking to shape and cut materials into various forms. Lathes are machines that rotate a workpiece on its axis, allowing the operator to perform a variety of cutting, sanding, and drilling operations. However, two main types of lathes are commonly used in these industries: wood lathes and metal lathes.

While both machines serve the same purpose, they have distinct design, functionality, and output differences. We will be delving into the debate of wood lathe vs metal lathe, examining their features, capabilities, and limitations to help you determine the best suited for your needs. So, let’s dive in and explore the world of lathes.

What Is A Wood Lathe?

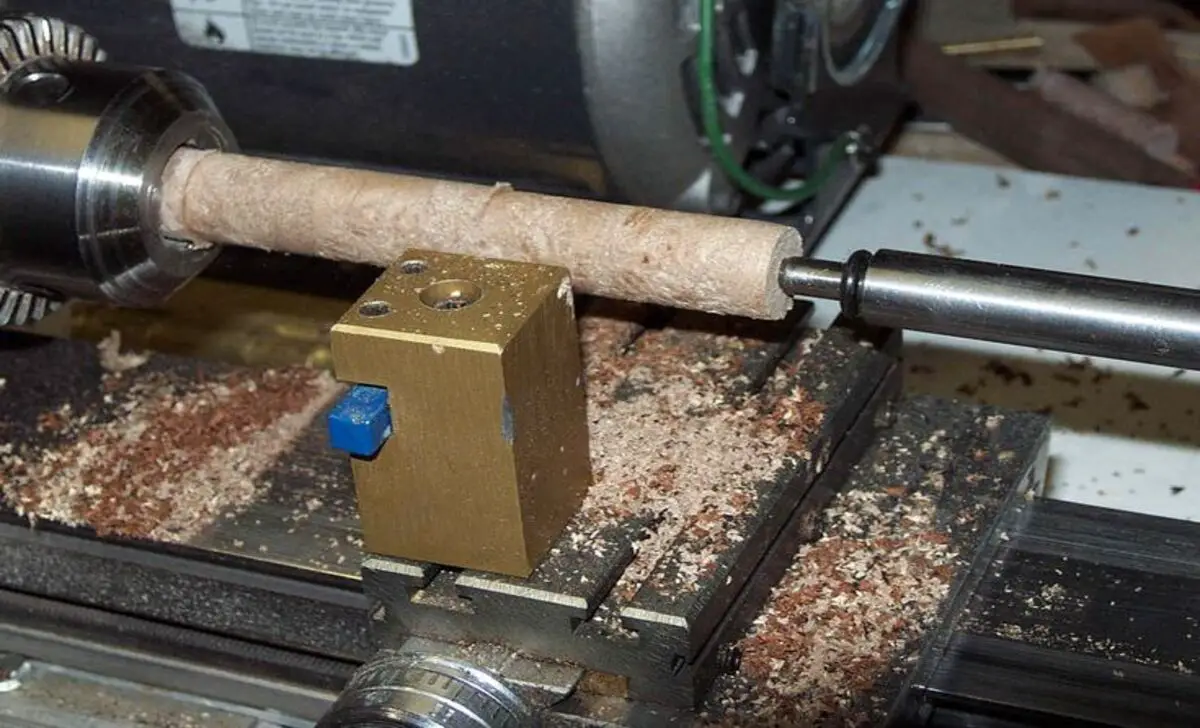

A wood lathe is a versatile tool used in woodworking. It consists of a motor that rotates a piece of wood on its axis, allowing the woodworker to shape it using various cutting tools. The lathe enables the creation of intricate designs, such as bowls, vases, and spindles. It is an essential tool for woodturning enthusiasts and professionals, offering endless possibilities for creativity and craftsmanship.

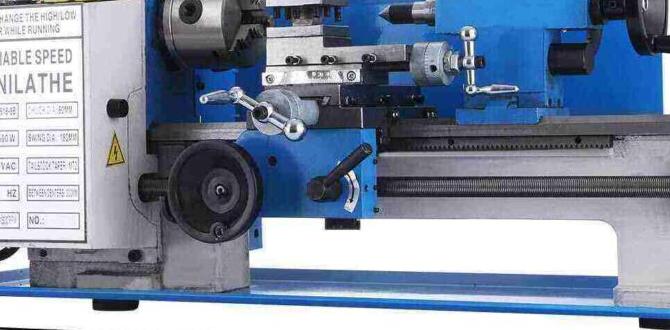

What Is A Metal Lathe?

A metal lathe is a machine tool for shaping and machining metal workpieces. It consists of a rotating spindle that holds the workpiece and various cutting tools to remove material and create the desired shape. The lathe allows for precise and accurate cutting operations, making it a crucial tool in metalworking industries such as manufacturing, machining, and fabrication. It is commonly used for turning, facing, drilling, and threading metal components.

The Main Differences Between Wood Lathe Vs Metal Lathe

Several key factors come into play when considering the main differences between a wood lathe and a metal lathe. Firstly, the construction materials of these two types of lathes differ significantly. Wood lathes are typically built with cast iron or steel frames, providing the stability and durability necessary for woodworking tasks. On the other hand, metal lathes are usually made with heavier-duty materials such as cast iron or steel, ensuring the strength and rigidity required for machining metal. In this discussion, we will compare wood lathes and metal lathes.

1. Construction Material

Both wood lathes and metal lathes serve different purposes in construction materials. Wood lathes are specifically designed for working with wood, allowing craftsmen to shape and carve intricate designs. On the other hand, metal turning lathes are built to handle the rigors of working with various metals, providing precision and strength for tasks like threading or facing.

While wood lathes produce wood dust as a byproduct, metal lathes generate metal shavings. Both types of lathes play essential roles in their respective domains, catering to the specific needs of woodworkers and metalworkers alike.

2. Design And Construction

There are notable differences in design and construction when comparing wood lathes to metal lathes. Wood lathes have various components and structures, including powerful motors and wood pieces. They primarily construct them using materials suitable for working with wood.

On the other hand, manufacturers design metal lathes with components and structures specifically tailored for working with soft metals. They are constructed using materials that can withstand metalworking demands, ensuring durability and precision in their operation.

3. Purpose And Applications

Wood lathes and metal lathes have distinct purposes and applications. Wood lathes are handy for shaping and creating intricate designs on wooden objects, such as bowls or spindle legs. They provide precision and control for woodworking projects. On the other hand, metal lathes have specific designs for working with various metals, including steel and aluminum.

They are commonly handy in machining processes to cut, shape, and finish metal parts, making them essential in automotive manufacturing and aerospace engineering. While both lathes share similarities in spinning workpieces, they serve different needs and industries.

4. Speed Settings

Regarding speed settings, there are notable differences between wood lathes and metal lathes. Wood lathes, commonly referred to as manual lathes, are designed specifically for working with wood. They usually have variable speed controls that allow woodworkers to adjust the rotation speed based on their project requirements.

Metalwork lathes, on the other hand, require higher speed settings to handle more robust materials and shape and cut through metal effectively. These lathes often have a wider range of speed options to accommodate the specific needs of metalworking tasks. So, while both types of lathes serve different purposes, their speed settings reflect the unique demands of their respective materials.

5. Size And Capacity

There are notable differences when comparing the size and capacity of a woodworking lathe to a modern lathe used for metalworking. Woodworking lathes are typically larger and designed to handle larger pieces of wood, allowing for the creation of bigger projects. On the other hand, modern lathes used for metalworking are more compact and precise, designed to work with smaller and more intricate metal pieces. These differences in size and capacity make each lathe suitable for their respective purposes in craftsmanship and manufacturing.

6. Precision And Accuracy

There is a clear distinction in precision and accuracy between wood lathes and metal lathes. Wood lathes are commonly handy for shaping and carving wooden objects, focusing more on artistic expression. On the other hand, metal lathes have specific designs that can handle tougher materials and perform intricate machining operations. With features like a metal lathe machine and bench lathes, metalworking enthusiasts can achieve remarkable precision and accuracy in their projects.

Working Principles

There are notable distinctions in working principles between wood lathes and metal lathes. Wood lathes rotate a piece of wood on an axis, allowing for shaping and carving. The turning process involves using various tools to shape the wood into desired forms. On the other hand, metal lathes operate differently, focusing on the machining process. These lathes use cutting tools to remove material from metal workpieces, allowing for precision and accuracy in creating intricate metal components.

Pros And Cons Of Wood Lathe

A wood lathe is a necessary tool for woodworking, as it greatly improves the accuracy and efficiency of shaping wooden objects. However, like any tool, using a wood lathe has pros and cons. While wood lathes offer numerous advantages, such as precision, versatility, and time-saving capabilities, weighing these benefits against the drawbacks is essential.

Pros Of Wood Lathe:

- Versatile for a wide range of woodworking projects

- It helps develop precision and hand-eye coordination

- Efficient use of materials

- Allows for creative expression

Cons Of The Wood Lathe:

- Expensive equipment

- Steep learning curve

Limitations Of Wood Lathe

Wood lathe, despite its versatility and usefulness, does have its limitations. One major constraint is the size of the lathe itself, as it can only accommodate materials of a certain length and diameter. The wood lathe is also primarily designed for woodworking projects, so it may not be suitable for other materials like metal or plastic.

Moreover, due to its limited precision and control, intricate or complex designs may be challenging to achieve on a wood lathe. However, despite these limitations, the wood lathe remains an invaluable tool for many woodworkers, offering endless possibilities for creativity and craftsmanship.

Pros And Cons Of Metal Lathe

When considering the pros and cons of metal lathe machines, evaluating their benefits and drawbacks is important to make an informed decision. One of the significant advantages of metal lathes is their versatility. These machines can be handy for various metalworking operations, such as turning, facing, drilling, and threading. This versatility increases efficiency and productivity, as the machine can perform multiple operations.

Pros:

- Versatility: Metal lathes are capable

- Precision: Metal lathes are popular

- Efficiency: advanced features and capabilities

- Durability: Metal lathes are built

Cons:

- Cost: Metal lathes can be quite expensive

- Learning Curve: Operating a metal lathe requires skill

Limitations Of Metal Lathe

The metal lathe, while a versatile and essential tool in machining, does have its limitations. One such limitation is the maximum size of the workpiece that can be accommodated, as the lathe bed and spindle have a finite length. Additionally, the lathe may not be suitable for certain materials that require specialized cutting tools or processes.

Furthermore, complex shapes and intricate details may be challenging to achieve accurately on a metal lathe. Nonetheless, with proper skill and technique, the metal lathe remains a valuable asset in countless machining applications.

Factors To Consider When Choosing Between A Wood Lathe And A Metal Lathe

You must consider several factors when deciding between a wood lathe and a metal lathe. Firstly, think about your project requirements and what type of material you will be working with. Secondly, consider your budget and how much you are willing to invest in a lathe.

Additionally, think about your skill level and whether you have experience with either wood or metal turning. Lastly, consider your future needs and whether you require a versatile lathe to handle wood and metal projects. Taking all these factors into account will help you make an informed decision.

- Project requirements

- Budget

- Skill level

- Future needs and versatility

Conclusion

While both wood lathe and metal lathe have their unique benefits and uses, it is important for professionals to carefully consider their specific needs and intended projects before making a decision. Wood lathes are better suited for creating intricate designs and decorative pieces, while metal lathes are more commonly handy for functional and industrial objects.

Both machines require proper training and safety precautions, and with the right skills and knowledge, they can produce high-quality results. Choosing between a wood lathe and a metal lathe will ultimately depend on the individual’s expertise and project requirements. Still, either option can be valuable in a professional’s workshop.

FAQ

1.How Many Rpm Is A Metal Lathe?

A metal lathe’s rpm (revolutions per minute) can vary depending on its size, design, and purpose. Smaller benchtop lathes typically range from 500 to 3000 rpm, while larger industrial lathes can have a wider range of 100 to 5000 rpm or more.

2.What Is A Wood Lathe Good For?

A wood lathe is a versatile tool for shaping and turning wood into symmetrical forms such as bowls, spindles, and furniture legs. It allows for precise and smooth cutting, carving, and sanding of wood, making it ideal for woodworkers and craftsmen.

3.How Fast Is A Wood Lathe?

The speed of a wood lathe can vary depending on the model and settings, but generally, they can rotate at speeds ranging from a few hundred to a few thousand revolutions per minute (RPM).

4.How Powerful Is A Metal Lathe?

A metal lathe is a powerful tool capable of shaping and cutting various metal materials. The power of a metal lathe can vary depending on its size, motor capacity, and other specifications.

5.Why Buy A Metal Lathe?

A metal lathe is a valuable tool for any workshop or hobbyist. It allows you to shape and cut metal precisely, creating custom parts or repairing existing ones.