Summary: For 1/2 inch thread milling in 6061 aluminum, a common starting point for feed and speed is around 150-350 SFM (Surface Feet per Minute) and 0.002-0.005 IPT (Inches Per Tooth). Always consult your thread mill manufacturer’s recommendations for precise settings and consider coolant for best results.

Indeed, mastering thread milling can seem daunting, especially when you’re just exploring the world of metal lathes, milling tools, and wood lathes. It’s a crucial skill for creating functional, precise parts, but the numbers – the feeds and speeds – can feel like a secret code. If you’ve ever stared at a print and wondered what settings to use for that important internal thread, you’re not alone. Many beginners find this part of machining a bit intimidating. The good news is, it doesn’t have to be! Today, we’re going to demystify thread milling for 1/2 inch threads in 6061 aluminum. We’ll break down exactly what you need to know to get those perfect threads, safely and efficiently. Get ready to gain the confidence to tackle this common machining task!

Unlocking the Secrets: Thread Milling 1/2 Inch Threads in 6061 Aluminum

Thread milling isn’t just about making threads; it’s about precision, efficiency, and creating parts that fit together perfectly. When you’re working with a material as versatile as 6061 aluminum and need to create a 1/2 inch internal thread, knowing the right feeds and speeds is key. Get it wrong, and you can end up with tool breakage, poor thread quality, or a frustratingly slow process. Get it right, and you’ll be producing accurate, reliable threads with ease.

This guide is designed with you in mind, the budding machinist, the DIY enthusiast, or anyone looking to expand their machining toolkit. We’ll cut through the jargon and focus on practical, actionable advice. We’ll explore why specific parameters matter, how to find reliable starting points, and the essential factors that influence your success.

What is Thread Milling? A Quick Overview

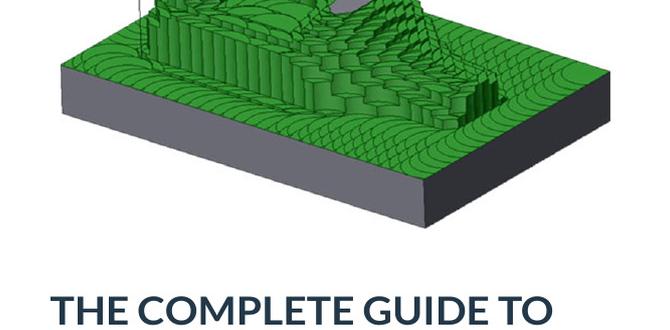

Before we dive into the numbers, let’s quickly recap what thread milling is. Unlike tapping, where a single tool cuts the entire thread in one pass, thread milling uses a special milling cutter that moves in a helical path to create the internal thread. This method offers several advantages:

Better Thread Quality: Often results in more accurate and cleaner threads.

Reduced Stress: Less stress on the machine spindle and the workpiece compared to rigid tapping.

Versatility: Can create threads in materials that are difficult to tap, such as hardened steels or very large diameters.

Tool Breakage: If the tool breaks, it’s usually just the cutter insert, not the entire tap, making it more economical.

Why Feeds and Speeds Matter for 1/2 Inch Threads in 6061 Aluminum

You’ve probably heard “feeds and speeds” mentioned countless times. But why are they so critical, especially for this specific application?

Surface Speed (SFM or SMM): This is how fast the cutting edge of the tool is moving across the surface of the material. Too slow, and you won’t cut efficiently; too fast, and you’ll overheat the tool, causing it to dull or break. For 6061 aluminum, which is a relatively soft and machinable material, you can generally use higher surface speeds.

Inches Per Tooth (IPT or IPM/tooth): This dictates how much material each cutting tooth removes with every rotation. Too high can overload the tool, leading to breakage or poor surface finish. Too low, and you’ll be rubbing rather than cutting, again leading to tool wear and inefficient machining.

Depth of Cut: While not directly a feed or speed, the radial and axial depth of cut influences how much load is put on the tool.

Material Properties: 6061 aluminum is known for its good machining characteristics, but variations in temper (like T6) can slightly affect how it behaves. Its tendency to form aluminum chips also needs consideration.

Getting these numbers right ensures:

Tool Longevity: Your thread mill will last longer.

Excellent Surface Finish: The threads will look and feel smooth.

Accurate Dimensions: The threads will measure correctly.

Efficient Machining: You’ll cut parts faster and more reliably.

Finding Your Starting Point: Manufacturer Data and General Guidelines

The absolute best place to start is always the thread mill manufacturer’s recommendation. They know their tools best and provide parameters tailored to specific materials. However, if you don’t have that data handy, or if you’re looking for a good general starting point for a common thread like 1/2 inch in 6061 aluminum, we can provide some reliable figures.

For a standard 1/2 inch thread (e.g., 1/2-13 UNC or 1/2-20 UNF) in 6061 aluminum, here are some common starting ranges:

Surface Speed (SFM): 150 – 350 SFM is a good general range for 6061 aluminum.

Inches Per Tooth (IPT): 0.002 – 0.005 IPT is a common recommendation.

To convert these to your machine’s settings (RPM – Revolutions Per Minute), you’ll need to know the diameter of your thread mill. The formula is:

RPM = (Surface Speed 3.82) / Tool Diameter (inches)

Or, if you’re working in metric:

RPM = (Surface Speed (m/min) 1000) / (π Tool Diameter (mm))

And the feed rate in IPM (Inches Per Minute):

Feed Rate (IPM) = RPM Number of Inserts IPT

Let’s work through an example:

Suppose you have a 1/2 inch diameter, 2-flute thread mill and you choose a conservative starting point of 200 SFM and 0.003 IPT.

1. Calculate RPM:

RPM = (200 SFM 3.82) / 0.5 inches (tool diameter)

RPM = 764 / 0.5

RPM = 1528

2. Calculate Feed Rate (IPM):

Feed Rate = 1528 RPM 2 flutes 0.003 IPT

Feed Rate = 9.17 IPM

So, you’d set your machine to approximately 1528 RPM and a feed rate of around 9.2 IPM.

Factors Influencing Feeds and Speeds

While the numbers above are excellent starting points, several other factors can influence your ideal settings. Understanding these will help you fine-tune your process:

Thread Mill Design:

Number of Flutes: More flutes mean faster material removal but can also increase the load per tooth, requiring lower IPT.

Coating: TiALN, TiCN, or uncoated carbide tools will have different optimal speeds. uncoated carbide is common for aluminum.

Helix Angle: The angle of the cutting edge.

Insert Geometry: Sharpness and rake angles affect cutting efficiency.

Machine Rigidity and Power: A powerful, rigid machine can handle higher cutting forces than a smaller, less rigid one.

Coolant/Lubrication: Essential for machining aluminum. It cools the cutting edge, lubricates the interaction between chip and tool, and helps evacuate chips, preventing them from getting recut. A good quality flood coolant or a minimum quantity lubrication (MQL) system is highly recommended. You can see more about coolant systems from resources like the https://www.machinerylubricants.com/ [Machinery Lubricants website].

Chip Evacuation: Aluminum tends to produce long, stringy chips. Proper toolpath and effective coolant are crucial to prevent chip packing, which can lead to tool breakage and poor thread finish.

Depth of Thread: Deeper threads require stepping down the cut, which can affect your overall cycle time and tool load.

Desired Accuracy and Surface Finish: For critical applications, you might run slightly slower speeds and lower depths of cut to achieve a superior finish.

Step-by-Step: Thread Milling a 1/2 Inch Hole in 6061 Aluminum

Let’s walk through the process, assuming you’re using a CNC mill. The principles are similar if you’re doing it manually, but the precision and control are greater with CNC.

1. Preparation and Machine Setup

Tool Selection: Choose a thread mill designed for aluminum. For a 1/2 inch thread, you’ll typically use a 1/2 inch or slightly smaller diameter thread mill (depending on the thread type and your clearance). Ensure it’s the correct thread form (UNC, UNF, Metric, etc.) and has enough flutes (2 or 3 are common for this size).

Workholding: Securely clamp your workpiece. Inadequate workholding is a recipe for disaster, leading to inaccurate threads and potential tool crashes.

Machine Setup: Ensure your machine is clean and ready. Mount the thread mill in your spindle.

Tool Length Offset: Accurately measure and set the tool length offset.

2. Calculating Toolpath Parameters

This is where we plug in our feeds and speeds. Most CAM software will handle these calculations, but understanding them is vital:

Diameter: The nominal diameter of the thread mill (e.g., 0.500 inches for a 1/2 inch thread mill).

Number of Flutes: (e.g., 2).

Desired RPM: Calculated as shown above (let’s use 1500 RPM for this example).

Desired Feed Rate (IPM): Calculated as shown above (let’s use 9 IPM for this example).

Pitch Diameter: The diameter of the thread at the midpoint of the thread height. This is critical for the toolpath. For a 1/2-13 UNC thread, the pitch diameter is approximately 0.448 inches.

Minor Diameter: The diameter at the root of the internal thread. For a 1/2-13 UNC thread, this is approx. 0.427 inches.

Major Diameter (Hole Size): This is the diameter of the hole you are starting with. For a 1/2-13 UNC thread, you’d typically drill a hole slightly larger than the minor diameter, around 0.4375 inches (7/16 inch drill).

Pitch: The distance between the crests of adjacent threads (e.g., 13 threads per inch means a pitch of 1/13 = 0.0769 inches).

Your CAM software will use the pitch diameter to generate the correct helical path. The software will create a toolpath that spirals into the hole, interpolating the thread form.

3. Setting Up the Program or G-Code

Tool Compensation: Ensure you’re using cutter radius compensation (G41/G42 in G-code) or that your CAM software correctly accounts for the tool radius.

Helical Interpolation: This is the core of thread milling. Most CNC controllers have specific G-codes (like G02/G03 with a Z-axis move and I/J or R offsets for the arc) or you’ll use specialized cycles from your CAM software.

Number of Passes: For deeper threads, it’s often wise to take multiple passes. This reduces the cutting load per pass, extending tool life and improving finish. You might take 2 or 3 passes.

Coolant: Make sure the coolant is turned on (M08).

A simplified G- G-code example for a 1/2-13 UNC thread might look something like this (this is highly simplified and for illustrative purposes):

“`gcode

N100 M06 T10 (Tool 10: 1/2″ Thread Mill)

N110 G54

N120 G00 X0 Y0 (Rapid to start Z)

N130 G43 H10 Z5.0 (Apply tool length offset, move to clearance plane)

N140 M03 S1500 (Spindle on, 1500 RPM)

N150 M08 (Coolant on)

N160 G01 Z-0.1 (Plunge to start depth)

N170 G02 I-0.202 J0 Z-0.0769 X0.448 Y0 R0.XXX (Helical interpolation – assuming pitch diameter is 0.448 and step is 0.0769)

(This G02 line would be repeated many times for the full thread depth, often with incremental Z moves)

N… G00 Z5.0 (Retract to clearance plane)

N… M09 (Coolant off)

N… M05 (Spindle off)

N… G00 X0 Y0 (Rapid home)

“`

Note: Modern CNC controls often use specific thread milling cycles (like a `G71` or `G76` variant, or manufacturer-specific `M` codes) that simplify this significantly by allowing you to input thread data directly. Always consult your machine’s manual.

4. Executing the Program

Dry Run (Air Cut): Always perform a dry run with the tool not touching the workpiece. Watch the toolpath carefully to ensure it’s moving correctly and not going to crash.

First Piece Inspection: After the first part is machined, meticulously inspect the threads. Check for:

Dimensional Accuracy: Use a thread gauge or a micrometer to check the pitch diameter.

Surface Finish: Look for any chatter marks or rough areas.

Chip Adhesion: Ensure chips aren’t welding to the tool.

Tool Wear: Inspect the thread mill for early signs of excessive wear.

5. Adjusting Feeds and Speeds

Based on your inspection, you might need to make adjustments:

If threads are rough or tool is chipping:

Reduce IPT slightly (e.g., from 0.003 to 0.0025).

Reduce SFM (RPM) slightly.

Ensure adequate coolant.

If the tool is rubbing or not cutting effectively:

Increase IPT slightly (e.g., from 0.003 to 0.0035).

Increase SFM (RPM) slightly.

Check for dullness or damage on the tool.

If chip evacuation is a problem:

Consider a slightly higher SFM to produce smaller chips (if the tool can handle it).

Optimize your coolant flow.

If using CAM, a trochoidal milling strategy for the initial hole prep can help with chip control.

Thread Mill Feeds and Speeds Chart for 1/2 Inch Threads in 6061 Aluminum

To make things even clearer, here’s a consolidated chart with common starting points. Remember, these are starting points. Always verify with your tool manufacturer’s recommendations.

| Thread Type | Thread Mill Diameter | Material | Surface Speed (SFM) | Inches Per Tooth (IPT) | Calculated RPM (for 0.5″ tool) | Calculated Feed Rate (IPM for 2-flute) | Notes |

| :—————— | :——————- | :———– | :—————— | :——————— | :—————————– | :————————————- | :—————————————————————– |

| 1/2-13 UNC | 0.500″ | 6061-T6 Alum | 150 – 350 | 0.002 – 0.005 | 936 – 2184 | 3.7 – 21.8 | Standard coarse thread. Good general purpose. |

| 1/2-20 UNF | 0.500″ | 6061-T6 Alum | 150 – 350 | 0.002 – 0.005 | 936 – 2184 | 3.7 – 21.8 | Fine thread. Requires more engagements per inch. |

| 1/2-13 UNC (Stub) | 0.4375″ | 6061-T6 Alum | 150 – 350 | 0.002 – 0.004 | 1080 – 2520 | 4.3 – 20.1 | Stub thread mills are shorter and can be more rigid. |

| 1/2″ Special Pitch | Varies | 6061-T6 Alum | 150 – 350 | 0.002 – 0.005 | Varies | Varies | Always check manufacturer data for custom threads. |

Calculations for RPM are based on a 0.500″ diameter thread mill. Adjust if your tool diameter is different.

Calculations for Feed Rate are based on a 2-flute thread mill. Multiply by the number of flutes.

Common Pitfalls to Avoid

* Relying Solely on “Generic” Speeds and Feeds: Always view them as