1/8 Inch Face Mill Speeds for Cast Iron: Find Your Sweet Spot! Get the perfect cast iron face milling speeds with a 1/8 inch cutter. This guide simplifies finding the ideal settings for smoother cuts, longer tool life, and better finishes. Perfect for beginners!

Milling cast iron can feel a bit daunting, especially when you’re just starting out. You’ve got this shiny new 1/8 inch face mill, and you want to take a nice, clean cut across a piece of cast iron. But what are the right speeds? Too fast, and you risk damaging your cutter or leaving a terrible surface finish. Too slow, and it feels like you’re not getting anywhere. It’s a common puzzle for hobby machinists and beginners in the workshop. Don’t worry, finding those “genius” speeds for your 1/8 inch face mill on cast iron is simpler than you think. We’ll break it down step-by-step, making it easy to achieve great results and build your confidence. Let’s get your mill set up for success!

Understanding Your 1/8 Inch Face Mill and Cast Iron

Before we dive into speeds, let’s quickly chat about what we’re working with. A 1/8 inch face mill is a small but mighty tool. It’s great for taking light passes, surfacing, and getting into tighter spots on your workpiece. When we talk about “cast iron,” we’re referring to a whole family of iron alloys. They can vary in hardness and composition, which is why finding a universal setting can be tricky. However, for most common cast irons you’ll encounter in hobby machining, we can aim for a good starting point. Think of cast iron as being on the harder side for many common metals, requiring careful consideration of your cutting parameters.

Why Speeds and Feeds Matter for Cast Iron

Choosing the right “feeds and speeds” is like giving your cutting tool the perfect conditions to do its job. Too much speed (RPM) can cause the tool to overheat, dull quickly, or chatter, leading to a rough surface. Too little speed might not engage the material effectively, leading to poor chip formation and potentially burning the cutter or workpiece. Feed rate – how fast the cutter moves into the material – is equally important. A good feed rate helps the tool clear chips properly and ensures a smooth cutting action. For a 1/8 inch face mill on cast iron, getting this balance right is key to preventing premature wear and achieving that sought-after smooth finish.

The Core Concepts: RPM and Feed Rate

Let’s demystify these terms. They are the two main gears in our cutting speed machine.

Spindle Speed (RPM) Explained

Spindle speed, measured in revolutions per minute (RPM), is how fast your milling machine’s spindle spins. It’s a crucial factor in how a cutting tool interacts with the material. For a face mill, a higher RPM generally means the cutting edges hit the material more times per minute. However, for harder materials like cast iron, and especially with smaller tools like a 1/8 inch face mill, we usually need to be a bit more conservative with RPM to manage heat and tool pressure.

Feed Rate Explained

Feed rate refers to how quickly the cutter is advanced into or through the workpiece. It’s often measured in inches per minute (IPM) or millimeters per minute (mm/min). A higher feed rate means faster material removal, but it also increases the load on the cutting tool and machine. A lower feed rate can be more gentile, creating finer chips and reducing stress, which is often beneficial for finishing passes or when working with delicate setups. For face milling with a small cutter on cast iron, finding a feed rate that allows for good chip evacuation without overloading the tool is important.

Calculating Your “Genius” Speeds: A Practical Approach

While there are complex formulas, for beginners, we can use common sense and some reliable starting points. The goal is to find a combination that works well without needing a supercomputer!

Surface Speed (SFM) – The Magic Number

Professional machinists often work with “surface speed” (SFM – surface feet per minute). This is the speed at which the edge of the cutting tool is moving along the material. Different tool materials (like HSS or carbide) and different workpiece materials (like cast iron) have recommended SFM ranges. For a 1/8 inch face mill, especially if it’s carbide, you’ll often see recommendations around 200-400 SFM for cast iron, but it’s always best to check your tool manufacturer’s data.

From SFM to RPM: The Simple Formula

The formula to convert surface speed (SFM) into spindle speed (RPM) is straightforward:

RPM = (SFM 3.28) / Diameter_in_Inches

Let’s break this down:

- SFM: The recommended surface speed for your tool and material (e.g., 300 SFM for cast iron with carbide).

- 3.28: This is a conversion factor to change feet to meters, as tool manufacturers often provide SFM, but the diameter is in inches. (Diameter in feet PI) = Circumference in feet. SFM = RPM Circumference. RPM = SFM / Circumference. Since Circumference = (Diameter_Inches/12) PI, the formula becomes RPM = SFM / ( (Diameter_Inches/12) PI) which simplifies to RPM = (SFM 12) / (Diameter_Inches PI). When using metric SFM, you’d adjust this. For simplicity with imperial measurements, the 3.28 factor or a direct equivalent is often used in online calculators. Let’s stick to a more direct imperial version for clarity:

A simplified, commonly used imperial formula is:

RPM = (SFM 4) / Diameter_in_Inches

This is often derived from assuming a PI of approximately 3.14 and a factor to convert feet to inches. For precise calculations, use the first formula, but the second is a good quick estimate for many hobbyists.

- Diameter_in_Inches: The diameter of your face mill, which is 1/8 inch or 0.125 inches.

Example: If your carbide 1/8 inch face mill recommends 300 SFM for cast iron:

RPM = (300 SFM 4) / 0.125 inches = 1200 / 0.125 = 9600 RPM.

Wait! 9600 RPM for a 1/8 inch face mill? This highlights a critical point for very small tools. The maximum RPM of your machine and the physical limitations of the cutting tool come into play. A 1/8 inch diameter tool spinning that fast might have excessive chip load per tooth, leading to poor performance or breakage. This is why for very small diameter tools, especially in harder materials, we often need to adjust our thinking downwards. Think of this calculation as an upper limit or a theoretical starting point before practical adjustments.

Chip Load per Tooth (CLPT) – The Micro-Level Detail

Chip load per tooth (CLPT) is the thickness of the chip that each cutting edge removes as it passes through the material. It’s measured in inches per tooth (IPT) or millimeters per tooth (mm/tooth). For cast iron with a small face mill, we typically want a very small chip load, and we need to ensure our feed rate keeps this consistent.

Calculating Feed Rate (IPM) from Chip Load

The formula is:

Feed Rate (IPM) = R PM × Number of Teeth (Z) × Chip Load per Tooth (IPT)

Number of Teeth (Z): This is the number of cutting inserts on your face mill. A 1/8 inch face mill might have 2, 4, or even more teeth, depending on its design. Always check your tool.

Chip Load per Tooth (IPT): For small carbide inserts on cast iron, you might be looking at very fine chip loads, perhaps in the range of 0.0003 to 0.0008 inches per tooth. This is where checking your tool’s datasheet is invaluable.

Let’s reconsider our example:

If your machine can safely spin at a high RPM (though often impractical for this size tool on cast iron) and your manufacturer suggests a chip load of 0.0005 IPT for a 4-tooth 1/8 inch face mill on cast iron, and you decide to run at a more manageable 2000 RPM:

Feed Rate = 2000 RPM × 4 teeth × 0.0005 IPT = 4 IPM.

This lower feed rate is much more realistic for a small diameter cutter. The key is to maintain that low chip load consistently. If your machine’s minimum feed rate is higher than this, you might need to increase RPM (carefully!) or accept a slightly higher chip load if the tool can handle it.

Recommended Settings for Your 1/8 Inch Face Mill on Cast Iron

Based on common practices for hobby machinists and typical small carbide tooling, here are some starting points. Remember, these are guidelines, and fine-tuning will be necessary!

General Recommendations for 1/8″ Carbide Face Mills on Cast Iron

These settings are designed to be safe, reliable, and produce good results for general-purpose milling of common cast irons like gray iron.

Target Material: Gray Cast Iron (e.g., Class 30)

Cutting Tool: 1/8″ diameter carbide face mill (2, 4, or 6 flute)

Depth of Cut (DOC): For finishing, aim for 0.005″ to 0.010″ (0.12 to 0.25 mm). For roughing, you might go up to 0.020″ (0.5 mm), but be mindful of tool load and machine rigidity.

| Parameter | Carbide (e.g., TiN coated) | High-Speed Steel (HSS) |

|---|---|---|

| Surface Speed (SFM) | 200 – 350 SFM | 60 – 100 SFM |

| Chip Load per Tooth (IPT) | 0.0003 – 0.0008 IPT | 0.0001 – 0.0003 IPT |

Calculating Practical RPM and Feed Rates

Let’s use a concrete example for a 4-flute carbide 1/8″ face mill.

Scenario: You have a 4-flute carbide 1/8″ face mill and your machine can comfortably run at 2500 RPM. Your goal is to achieve a Chip Load per Tooth (CLPT) of approximately 0.0005 IPT.

1. Calculate Target Feed Rate:

Feed Rate (IPM) = RPM × Number of Teeth (Z) × Chip Load per Tooth (IPT)

Feed Rate = 2500 RPM × 4 teeth × 0.0005 IPT = 5 IPM.

This is a very manageable feed rate. If your machine has a minimum feed rate higher than this, you might need to increase RPM (carefully, watching for chatter) or accept a slightly higher chip load if your tool can handle it.

2. Check Surface Speed:

Let’s see what SFM this works out to:

SFM = (RPM × Diameter in Inches × PI) / 12

SFM = (2500 RPM × 0.125 inches × 3.14159) / 12 ≈ 65.45 SFM.

This is significantly lower than our earlier theoretical calculation (which was based on a higher number). This demonstrates how the practical limitations of your machine (max RPM) and desired chip load often dictate the actual achievable SFM. For carbide on cast iron, you ideally* want to be higher, but if your machine can’t achieve it, starting with a conservative lower SFM like this is better than not cutting at all or damaging the tool.

3. What if your machine can do more RPM?

Let’s say your machine can do 5000 RPM. Using the same 0.0005 IPT and 4 flutes:

Feed Rate = 5000 RPM × 4 teeth × 0.0005 IPT = 10 IPM.

SFM = (5000 RPM × 0.125 inches × 3.14159) / 12 ≈ 130.9 SFM.

This is closer to the lower end of the recommended SFM range for carbide, and a more aggressive feed rate. This scenario would likely result in faster material removal and a better surface finish if your machine is rigid enough and the tool can handle it.

Using High-Speed Steel (HSS) Tools

While carbide is generally preferred for efficiency, you might be using an HSS end mill or shell mill with inserts. HSS tools require significantly lower SFM and chip loads due to their lower heat resistance.

Scenario: You have a 4-flute HSS 1/8″ face mill and your machine runs at a maximum of 1500 RPM.

Target Chip Load per Tooth (IPT): 0.0002 IPT (very fine for HSS on cast iron).

1. Calculate Target Feed Rate:

Feed Rate = 1500 RPM × 4 teeth × 0.0002 IPT = 1.2 IPM.

This is a very slow feed rate, typical for HSS on hard materials. If your machine can’t achieve this low feed rate, you may need to consider using your slowest “geared” speed setting or very light spindle speeds.

2. Check Surface Speed:

SFM = (1500 RPM × 0.125 inches × 3.14159) / 12 ≈ 39.27 SFM.

This falls within the lower end of the HSS range, which is appropriate for cast iron.

Key Factors Influencing Your Settings

No two milling jobs are exactly alike. You’ll need to consider these points:

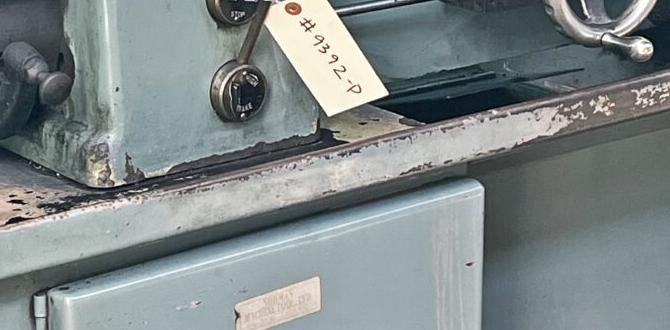

- Machine Rigidity: A more rigid machine can handle higher cutting forces and faster speeds. A less rigid machine (like a small benchtop mill) will require slower speeds and lighter cuts. Always err on the side of caution with less rigid machines.

- Coolant/Lubrication: Using a cutting fluid or coolant can significantly improve tool life and surface finish by cooling the cutting edge and flushing chips away. For dry milling cast iron, you must be extra careful about heat buildup.

- Tool Condition: Blunt or damaged tools will perform poorly, regardless of your settings. Ensure your inserts are sharp and free of built-up edge.

- Type of Cast Iron: Different types (gray, ductile, malleable) have different hardness. Softer irons can tolerate slightly higher speeds.

- Desired Finish: For a mirror-like finish, you’ll use very light depths of cut and potentially a slightly higher spindle speed with a controlled, matching feed rate.

Practical Tips for Face Milling Cast Iron with a 1/8 Inch Mill

Beyond just numbers, how you approach the cut makes a big difference.

Setting Up Your Tool

Ensure the face mill is securely mounted to your spindle. If it’s a shell mill, make sure the arbor is clean and properly seated. For smaller mills, a simple end mill holder with a good quality 1/8 inch end mill might be used as a makeshift face mill, but a true face mill will give a better finish and handle load better.

Depth of Cut (DOC) Strategy

For cast iron, especially with a small 1/8 inch cutter, it’s wise to take light depths of cut. This minimizes the load on the tool and machine, reduces heat, and helps achieve a good surface finish. Aim for:

- Finishing Pass: 0.005″ – 0.010″ (0.12 – 0.25 mm)

- Light Roughing: 0.010″ – 0.020″ (0.25 – 0.50 mm)