Have you ever wondered how machines make precise parts? The answer often lies in metal lathes. In 2025, new metal lathe controllers are set to change everything. They promise to be smarter and easier to use. Imagine creating complex designs with just a few clicks. This is now within reach thanks to advanced technology.

Think about it. What if you could program a machine to shape metal pieces exactly how you want? With the right controller, that dream can come true. In 2025, these tools will help hobbyists and professionals alike. They will make it simpler for anyone to turn ideas into reality.

Did you know that modern metal lathe controllers can learn from their past jobs? They can adjust their methods to improve future performance. This means more precision and less waste. It’s like having a personal assistant that gets better with time!

Join us as we dive into the exciting world of 2025 metal lathe controllers. Discover how they can help you craft amazing projects. It’s time to unleash your creativity!

Exploring The 2025 Metal Lathe Controller: Features And Benefits

2025 Metal Lathe Controller

The 2025 metal lathe controller represents a leap in technology for metalworking enthusiasts. Imagine creating precise parts with ease while simplifying complex tasks. This controller offers advanced features like real-time feedback and easy programming. Users can enjoy smoother operation, enhancing their projects. Fun fact: A well-tuned lathe can make parts that fit perfectly! With the right tools, anyone can turn a piece of metal into amazing creations. Will you be ready to try it?

Understanding Metal Lathe Controllers

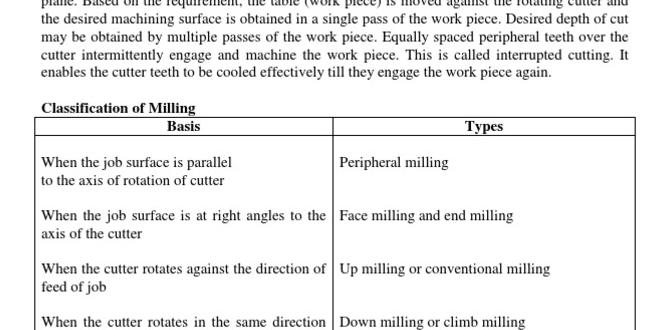

Definition and importance of a metal lathe controller. Key components and functionality.

A metal lathe controller is like the brain of a lathe machine. It tells the machine how to cut and shape metal. This process is super important because accurate cuts lead to better products. Key parts of a controller include the input interface, where you set your commands, and the drive motor, which powers the lathe. Without these components, you’d have a fancy paperweight instead of a working machine!

| Component | Function |

|---|---|

| Input Interface | Allows users to set commands and parameters |

| Drive Motor | Powers the lathe to cut material |

| Feedback Sensors | Provide real-time data for precision |

With the right controller, you can turn a block of metal into a masterpiece—or at least something that doesn’t resemble a lopsided birthday cake!

Features of the 2025 Metal Lathe Controller

Advanced technology and specifications. Userfriendly interface and controls.

The 2025 metal lathe controller comes with cutting-edge technology that puts other controllers to shame. It features advanced specifications like precision control and speedy adjustments. With user-friendly buttons and a bright screen, it feels like driving a luxury car instead of a machine. Controls are simple, even for beginners. Want to feel like a pro? You can think of it as your magic wand for metalworking!

| Feature | Description |

|---|---|

| Precision Control | Allows for accurate measurements and cuts. |

| User-Friendly Interface | Simple controls that everyone can understand. |

| Fast Adjustments | Quick settings for efficient workflow. |

Benefits of Upgrading to the 2025 Metal Lathe Controller

Improved precision and efficiency in machining. Enhanced programming and automation options.

Upgrading to a new controller brings many benefits. The 2025 metal lathe controller offers improved precision and higher efficiency in machining tasks. This means your projects will be done faster and more accurately. With its advanced programming and automation features, you can create complex designs easily. You can speed up your work while reducing mistakes.

- Better accuracy in cuts

- More control over the machining process

- Faster setups and adjustments

- More programming choices

What are the main advantages of the 2025 metal lathe controller?

The main advantages include higher accuracy, speed, and more options for programming. This allows for better and faster work on any project. The new controller helps you make fewer errors.

Compatibility with Different Metal Lathes

Brands and models that work with the 2025 controller. Integration process and requirements.

Many metal lathe brands work well with the 2025 controller. Popular brands include Grizzly, Jet, and Haas. Each brand has specific models that are compatible, so check your metal lathe’s details. The integration process usually requires basic tools and knowledge. Follow the provided instructions carefully for a smooth setup.

- Grizzly: G4003, G0602

- Jet: JWL-1442

- Haas: TL-1, TL-2

What are some integration requirements for the 2025 controller?

Users need basic tools, compatible wiring, and a clear manual for smooth setup.

Installation Process of the 2025 Metal Lathe Controller

Stepbystep installation guide. Common challenges and troubleshooting tips.

Installing the 2025 metal lathe controller can be like piecing together a jigsaw puzzle—fun but sometimes tricky! Start by gathering all your tools and parts. Next, carefully follow these steps:

| Step | Description |

|---|---|

| 1 | Read the manual. It’s like treasure maps for your lathe! |

| 2 | Mount the controller securely. Nobody likes a wobbly contraption. |

| 3 | Connect the wires. Match colors like a fashion contest. |

| 4 | Power it up and check if it works. Fingers crossed! |

Common challenges include confusion over wires and funky error messages. If things go haywire, check connections first. If you see “Error: Not Responding!”, it’s probably a wire issue. Just remember, every problem has a solution—even if it’s just a snack break!

Maintenance Tips for the 2025 Metal Lathe Controller

Regular maintenance routines to ensure longevity. Signs of wear and necessary repairs.

Keeping your 2025 metal lathe controller in tip-top shape is easier than you think! First, regularly check the oil levels and clean the parts. Dust bunnies may love hiding in there, but you don’t! Watch for signs of wear, like strange noises or loose parts. If it sounds like a cat trying to sing, it’s time to investigate! Here’s a quick reminder list:

| Maintenance Task | Frequency |

|---|---|

| Oil Levels | Weekly |

| Lubrication | Monthly |

| Visual Inspection | Every Use |

Regular check-ups will help avoid costly repairs. Remember, a healthy controller keeps your projects running smoothly!

Comparing the 2025 Metal Lathe Controller with Competitors

Key differentiators and advantages over other models. User reviews and testimonials.

When looking at the 2025 metal lathe controller, it stands out from the crowd. Key features like precision control and user-friendly design make machining easier. Users rave about its smooth performance and reliability. One happy customer said, “It’s like having a magic wand for metal!”

| Features | 2025 Metal Lathe Controller | Competitor Model A | Competitor Model B |

|---|---|---|---|

| Precision | High | Medium | Low |

| User-Friendly | Yes | Somewhat | No |

| Durability | Strong | Weak | Medium |

Many users believe the 2025 offers the best bang for their buck. With happy reviews, it’s clear this controller gets the job done right!

Future Innovations in Metal Lathe Controller Technology

Upcoming trends and advancements. Predictions for the next generation of controllers.

Exciting changes are coming for metal lathe controller technology. Future controllers will use smart features and new materials. They will be easier to use and more precise. Some trends to watch include:

- Improved sensors for better accuracy.

- Advanced software for easy programming.

- Eco-friendly designs that save energy.

Experts predict that the next generation of controllers will make work faster and safer. Imagine a device that works with voice commands or connects to the internet for updates. These innovations will change how machines work in a big way!

What are the future trends in metal lathe controllers?

Future trends include smart technology, improved sensors, and eco-friendly designs. Controllers will become quicker and more user-friendly, making tasks easier for everyone.

Conclusion

In 2025, metal lathe controllers will offer exciting advancements for metalworking. These tools will provide better precision and efficiency. You’ll find user-friendly interfaces, making it easier to operate. To get started, consider exploring different models and features. We encourage you to read more about updates and innovations in this field. Your next project could benefit from these powerful controllers!

FAQs

What Advancements In Technology Are Expected To Be Integrated Into Metal Lathe Controllers By 2025?

By 2025, metal lathe controllers will get some cool upgrades. We can expect better computer systems to help them work faster. They may also use smart sensors that tell us if something is wrong. More machines might connect to the internet, so we can control them from anywhere. This means you could check on your work from home!

How Will The Implementation Of Ai And Machine Learning Improve The Performance Of Metal Lathe Controllers?

AI and machine learning can help metal lathe controllers work better by making smart decisions. They can learn from past jobs, so they know the best way to cut metal. This makes the machines faster and more precise. You’ll get better-quality parts, and we’ll waste less material. Overall, it helps everyone do their job more easily!

What Are The Anticipated Changes In User Interface Design For Metal Lathe Controllers By 2025?

By 2025, metal lathe controllers will have easier screens that show colorful pictures and simple buttons. You will be able to touch the screen instead of using lots of knobs. These controllers might also talk to you and give clear instructions. We will see more help features to guide us through tasks. Overall, using a metal lathe will be more fun and less confusing!

How Will Connectivity Options, Such As Iot Capabilities, Evolve In Metal Lathe Controllers By 2025?

By 2025, metal lathe controllers will connect to the Internet of Things (IoT) more easily. You will be able to control machines from your tablet or phone. Machines will share data about their work. This means we can fix problems faster and make better parts. We will see safer and smarter factories that work together!

What Impact Will The 20Metal Lathe Controllers Have On The Efficiency And Precision Of Machining Processes In Various Industries?

The 20 metal lathe controllers will help machines work better and faster. They make sure each piece is cut exactly right. This means less waste and fewer mistakes. We can make more products in less time. Overall, it will help many industries work smarter and save money.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Advancements In Technology Are Expected To Be Integrated Into Metal Lathe Controllers By 2025?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “By 2025, metal lathe controllers will get some cool upgrades. We can expect better computer systems to help them work faster. They may also use smart sensors that tell us if something is wrong. More machines might connect to the internet, so we can control them from anywhere. This means you could check on your work from home!”}},{“@type”: “Question”,”name”: “How Will The Implementation Of Ai And Machine Learning Improve The Performance Of Metal Lathe Controllers?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “AI and machine learning can help metal lathe controllers work better by making smart decisions. They can learn from past jobs, so they know the best way to cut metal. This makes the machines faster and more precise. You’ll get better-quality parts, and we’ll waste less material. Overall, it helps everyone do their job more easily!”}},{“@type”: “Question”,”name”: “What Are The Anticipated Changes In User Interface Design For Metal Lathe Controllers By 2025?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “By 2025, metal lathe controllers will have easier screens that show colorful pictures and simple buttons. You will be able to touch the screen instead of using lots of knobs. These controllers might also talk to you and give clear instructions. We will see more help features to guide us through tasks. Overall, using a metal lathe will be more fun and less confusing!”}},{“@type”: “Question”,”name”: “How Will Connectivity Options, Such As Iot Capabilities, Evolve In Metal Lathe Controllers By 2025?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “By 2025, metal lathe controllers will connect to the Internet of Things (IoT) more easily. You will be able to control machines from your tablet or phone. Machines will share data about their work. This means we can fix problems faster and make better parts. We will see safer and smarter factories that work together!”}},{“@type”: “Question”,”name”: “What Impact Will The 20Metal Lathe Controllers Have On The Efficiency And Precision Of Machining Processes In Various Industries?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The 20 metal lathe controllers will help machines work better and faster. They make sure each piece is cut exactly right. This means less waste and fewer mistakes. We can make more products in less time. Overall, it will help many industries work smarter and save money.”}}]}