Quick Summary:

A 4-jaw chuck for lathes securely grips irregularly shaped workpieces. Its independent jaws offer superior versatility and precision, making it indispensable for custom jobs and challenging materials. This guide demystifies its use, helping beginners master this essential lathe accessory for accurate and repeatable results.

Welcome to Lathe Hub! If you’re diving into the world of metalworking or woodworking with a lathe, you’re likely to encounter chucks. While 3-jaw chucks are common, there’s a special kind called a 4-jaw chuck that unlocks a whole new level of possibilities. It might seem a bit intimidating at first, but understanding how to use a 4-jaw chuck can make tricky workholding tasks surprisingly simple. Think of it as your secret weapon for tackling those unique projects that don’t perfectly fit a standard grip. We’re here to break down exactly what it is, why you’d use it, and how to get started with confidence. Let’s get those projects holding steady and spinning true!

What is a 4-Jaw Chuck for Lathe?

At its core, a 4-jaw chuck is a workholding device that attaches to the spindle of a lathe. Unlike simpler chucks, it features four independent jaws that can be moved individually. This independence is its superpower! It allows you to grip workpieces that aren’t perfectly round, like square stock, irregular shapes, or even oddly shaped castings. Each jaw can be adjusted precisely to center your workpiece, giving you unmatched flexibility and accuracy for unique projects.

Why Choose a 4-Jaw Chuck? The Advantages

So, why would a beginner (or an experienced machinist!) choose a 4-jaw chuck over other options? It all comes down to its unique capabilities:

- Gripping Irregular Shapes: This is the main selling point. Need to hold a square bar, a hexagonal rod, or a piece with uneven surfaces? A 4-jaw chuck is your go-to solution.

- Independent Jaw Adjustment: Each jaw moves on its own, controlled by a separate screw. This allows for extremely precise centering and the ability to grip off-center.

- Versatility: It can grip both externally (like a typical chuck) and internally. This means you can hold a part from the inside diameter for certain operations.

- Superior Grip Strength: When properly adjusted, the four jaws distribute pressure more evenly, often providing a very secure grip, especially on larger or heavier workpieces.

- Centering Non-Round Stock: Getting a square or hexagonal bar perfectly centered in round jaws can be difficult. A 4-jaw chuck allows you to dial it in precisely.

- Holding Off-Center: Sometimes, you need to machine a feature that isn’t on the centerline. The independent jaws make this possible.

When to Use a 4-Jaw Chuck vs. Other Chucks

It’s helpful to understand where the 4-jaw chuck fits into the lathe accessory landscape. Here’s a quick comparison:

| Chuck Type | Key Features | Best For | Beginner Friendliness |

|---|---|---|---|

| 3-Jaw Scroll Chuck | Self-centering (all jaws move together), quick to operate, good for round or hexagonal stock. | Production runs, general-purpose turning of round stock, quick setup. | Very High – Easiest to learn and use. |

| 4-Jaw Independent Chuck | Each jaw moves independently, requires manual centering, excellent for irregular shapes. | Square, rectangular, irregular stock; off-center turning; large or inconsistent diameters. | Moderate – Requires more effort to center, but steps are clear. |

| Collet Chuck | Uses individual collets to grip specific diameters, very precise and repeatable. | Holding thin or relatively small diameter stock very precisely, bar feeding. | Moderate – Requires the correct collet for the job. |

As you can see, a 4-jaw chuck shines when versatility in shape is the priority. Think of it as the best tool for the job when a 3-jaw chuck just won’t cut it.

Understanding the Parts of a 4-Jaw Chuck

Before we get to using it, let’s quickly identify the key components:

- Body: The main housing of the chuck.

- Jaws: Usually hardened steel. Most 4-jaw chucks come with a set of “hard jaws” for gripping and sometimes reversible “soft jaws” that you can machine to fit a specific part.

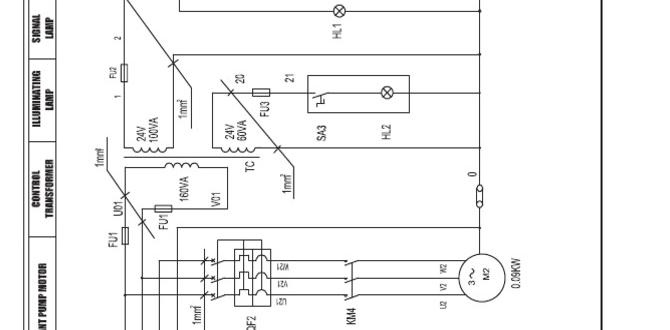

- Scroll Plate: A conical ring with spiral grooves that engage with the jaw T-slots. Turning the scroll pin causes the scroll plate to rotate, moving all jaws in or out.

- Scroll Pin: A lever inserted into the chuck body that meshes with the scroll plate’s teeth. This is what you turn to move the jaws.

- Operating Screws (or Pinion Shafts): Each jaw has a screw that engages with the scroll plate. These are what you turn with the chuck key to move individual jaws.

- Chuck Key: The tool used to turn the operating screws.

How to Mount a 4-Jaw Chuck on Your Lathe

Mounting a chuck sounds daunting, but it’s a straightforward process. Safety is paramount here, as chucks can be heavy.

Step 1: Identify Your Lathe Spindle Mount Type

Chucks attach to the lathe’s spindle nose in specific ways. The most common for smaller to medium lathes are:

- Threaded Nose: The spindle has threads, and the chuck has corresponding internal threads.

- Cam Lock (D1-x Taper/Camlock): A tapered spindle nose with holes for cam locks.

- Threaded Adapter: Less common for direct mounting, but sometimes chuch adaptors are threaded onto the spindle nose.

Consult your lathe’s manual to be sure. This guide will focus on the threaded nose mount as it’s very common for beginners.

Step 2: Prepare the Spindle and Chuck

Ensure both the lathe spindle threads and the inside threads of your chuck are clean and free of debris. A light coating of grease on the spindle threads will help prevent galling and make future removal easier.

Step 3: Mount the Chuck

Safety First: A 4-jaw chuck can be heavy. Use a helper or an engine hoist if it’s too heavy to manage safely. Some lathes have a lift bar attachment. Never stand directly in the path of a falling chuck.

- Approach the lathe spindle with the chuck, aligning the chuck’s internal threads with the spindle’s external threads.

- Start threading the chuck onto the spindle by hand. It should thread on smoothly. If it feels tight or cross-threaded, back it off and try again.

- Continue threading until the chuck is snug against the spindle shoulder.

Step 4: Secure the Chuck

This is where different mount types vary significantly.

For Threaded Nose Mounts:

- Once snug, you need to “time” the chuck so that the scroll pin hole (where you insert the key to turn the jaws) is in a convenient position, usually at the top or side.

- You’ll need a soft hammer or a block of wood and a hammer to tap the chuck body.

- With the chuck key still in a scroll pin hole, gently tap the chuck body with the soft hammer/wood block. This will rotate the chuck slightly.

- Continue tapping and checking the position until the scroll pin hole is where you want it.

- The friction of the threads and thread angle typically holds these chucks sufficiently for most operations without needing additional locks, but check your lathe’s manual for any specific recommendations.

For Cam Lock Mounts:

- The chuck will have threaded holes on its face that correspond to threaded sections on the spindle nose.

- Align the chuck’s tapered face with the spindle’s tapered nose.

- Insert cam lock bolts through the holes in the chuck body and thread them into the corresponding threaded holes on the spindle nose.

- Tighten these bolts evenly.

- Then, insert the cam lock levers into the designated holes and rotate them to lock against the spindle flange, securing the chuck tightly.

Always refer to your lathe’s manual for the most accurate and safe mounting procedure for your specific machine.

How to Use a 4-Jaw Chuck: Step-by-Step

Now for the fun part! Using a 4-jaw chuck primarily involves two main scenarios: chucking up standard round stock and chucking up irregular shapes. The process for aligning is similar, but the outcomes are different.

Scenario 1: Centering Round or Hexagonal Stock

This is a common use case where you need better grip or want to ensure perfect centering on an off-size piece that a 3-jaw might struggle with.

Step 1: Loosen All Jaws

Insert your chuck key into one of the jaw operating screws. Turn it counter-clockwise to retract the jaw. Repeat for all four jaws, retracting them significantly so your stock can easily fit inside or be gripped.

Step 2: Place Your Stock

Place your round or hexagonal stock roughly into the chuck jaws. Ensure it’s seated well.

Step 3: Initial Grip

Insert your chuck key into one operating screw and turn it clockwise to advance the jaw, making contact with the stock. Repeat for all four jaws, moving them in sequence (jaw 1, then 2, then 3, then 4) to apply pressure evenly. Don’t tighten them forcefully yet; just get them to hold the stock firmly.

Step 4: Rough Centering (The Dial Indicator Method)

This is where the precision comes in. You’ll want a dial indicator. Mount the dial indicator securely on the lathe tool post or a magnetic base if you have one. Set it up so the indicator’s probe touches the surface of your workpiece.

- Chuck Rotation: Slowly rotate the chuck by hand. Watch the dial indicator. It will move up and down as the workpiece is not perfectly centered. The total indicator runout (TIR) is the difference between the highest and lowest reading.

- Adjusting Jaws: Identify the jaw that is “leading” the runout (where the indicator is highest as it approaches the jaw). You want to move the jaws to reduce the runout.

- The Technique:

- Slightly loosen (counter-clockwise) the operating screw of the jaw that is leading.

- Now, tighten (clockwise) the operating screw of the jaw opposite it.

- And, if necessary, slightly adjust the two adjacent jaws to help bring it into alignment.

The key is that jaws work in pairs (or can be thought of as opposing). When one jaw moves, you often need to adjust its opposite to compensate and achieve true centering.

- Repeat: After making an adjustment, rotate the chuck and observe the dial indicator again. You’ll likely see less runout. Repeat the adjustment process, making smaller and smaller corrections.

- Final Tightening: Once you’re happy with the centering (aim for TIR of 0.001″ to 0.003″ for many projects, depending on precision needed), you need to secure the jaws firmly. Do this by tightening each jaw screw in sequence (1, 2, 3, 4) a little at a time. After tightening each, give them a final snug. Retest with the dial indicator; tightening can sometimes introduce a small amount of runout.

Step 5: Verify Grip

Give the workpiece a firm push and pull with your hand to ensure it’s not going to shift. The jaws should be holding it securely without deforming it.

Scenario 2: Holding Irregularly Shaped Workpieces

This is where the 4-jaw chuck really shines!

Step 1: Place and Rough Grip

Place your irregularly shaped piece into the jaws. It might be a casting, a block with a machined pocket, or something even more unique. Bring the jaws in just enough to lightly hold the piece in place. You might not be able to make all jaws contact evenly with irregular shapes.

Step 2: Adjust Jaws for Fit

This is where manual adjustment is key. You’ll be moving jaws independently to create a stable grip. The goal is to have each jaw contacting the workpiece at a solid, stable point.

- Work around the chuck, tightening and loosening each jaw screw as needed.

- Try to distribute the gripping force as evenly as possible across the available contact points.

- For very irregular shapes, it might be impossible to get perfect centering. The aim is a secure grip.

Step 3: Check for Stability and Movement

Once you think you have a good grip:

- Gently try to rotate or wiggle the workpiece by hand. Is it securely held?

- If it moves, identify the loose jaw(s) and adjust by tightening them.

- You may need to loosen one jaw to allow another to seat better.

Step 4: Reinforce Grip (If Necessary)

If the workpiece is still feeling a bit loose after initial adjustments, you can use the jaws to “cam” against features. For example, if you have a protrusion, you might use two jaws to grip its sides and the other two to push against a flat surface.

Step 5: Consider Soft Jaws for Complex or Delicate Parts

If gripping a delicate or complex shape, standard hard jaws might mar or crush it. In such cases, soft jaws (which are usually blank aluminum or steel jaws that you machine specifically for your part) are invaluable. You can mill pockets or contours into soft jaws to perfectly match your workpiece, providing a cushioned and secure grip.

Holding Internally (Gripping from the Inside)

A 4-jaw chuck can also grip a workpiece from the inside, which is useful for parts with flanges or lips. This requires specialized jaw inserts or jaws designed for internal gripping.

- Mount the workpiece so the chuck is inside it.

- Attach the appropriate internal gripping jaw inserts or jaws.

- Advance the jaws outwards to grip the inner diameter of the workpiece.

- Center using the dial indicator method as described before.

Tips for Using Your 4-Jaw Chuck Confidently

Here are a few pointers to make your 4-jaw chuck experience smoother:

- Always Use a Dial Indicator: For any critical turning or when precision matters, a dial indicator is your best friend for achieving true concentricity.

- Feel is Important: Develop a feel for how much force the jaws are applying. You don’t want to overtighten and distort your workpiece or crack a casting, but it needs to be secure.

- Tighten Jaws in Sequence: When gripping, always tighten jaws in a criss-cross or opposing pattern (1, 3, 2, 4 or 1, 2, 3, 4). This helps ensure even pressure.

- Cleanliness Matters: Keep the chuck, jaws, and scroll mechanism clean. Dirt can affect performance and accuracy. A good chuck cleaner or compressed air works well.

- Lubrication: Occasionally, a bit of light machine oil on the jaw slides and scroll threads can help them move smoothly.

- Consider Soft Jaws: For repeated jobs on specific odd shapes, or for delicate work, investing in or making a set of soft jaws can save a lot of frustration.

- Practice, Practice, Practice: The more you use your 4-jaw chuck, the quicker you’ll become at centering.

- Watch for Jaw Retraction Limits: Be aware that the jaws have a finite amount of travel. Make sure you can get a secure grip within their range.

Maintaining Your 4-Jaw Chuck

To ensure your chuck lasts and performs reliably, a little maintenance goes a long way:

- Cleaning: After use, especially with metal chips, clean the chuck thoroughly. Compressed air is excellent for blowing out debris from the scroll and jawways. A stiff brush can also help.

- Lubrication: Periodically, apply a light machine oil or grease to the jaw slides and the scroll mechanism. This prevents wear and corrosion. Don’t over-lubricate, as too much can attract dirt.

- Inspect Jaws: Check your jaws for wear or damage. Damaged jaws won’t grip well and can affect accuracy.

- Check for Tightness: Ensure the chuck itself