Have you ever wondered how tools can adapt to complete different tasks? Imagine a tool that changes based on what you need. That’s exactly what adaptive milling tools do. They can cut and shape materials in smart ways. This makes work faster and easier.

Think of a chef. A chef needs the right knife for different foods. If they only have one knife, cooking becomes hard and slow. Just like that, adaptive milling tools help workers in factories and workshops. They save time and improve results.

Did you know that using adaptive milling tools can cut production costs by up to 30%? This amazing fact shows their importance. In this article, we will explore how using an adaptive milling tools strategy can change the game. We’ll dive into how these tools work and why they are becoming popular. Get ready to discover a smarter way to work!

Adaptive Milling Tools Strategy: Optimizing Efficiency And Precision

Adaptive Milling Tools Strategy

Adaptive milling tools strategy allows manufacturers to adjust tools based on the material being cut. This can improve efficiency and reduce costs. Imagine trying to use a single knife to chop all kinds of food; it simply doesn’t work! With adaptive tools, machines can precisely adapt, offering a tailored approach. This flexibility not only enhances production speed but also improves the final product’s quality. Ultimately, embracing this strategy can lead to smarter manufacturing and better results.Understanding Adaptive Milling Tools

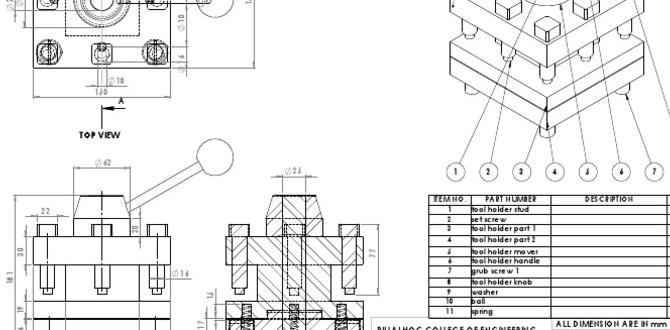

Definition and characteristics of adaptive milling tools. Types of adaptive milling tools and their applications.Adaptive milling tools are smart cutting tools that change their shape to fit the job. Imagine if a pencil could turn into a crayon when you needed it! These tools make the process smoother and faster. There are several types of adaptive milling tools, like cutter heads and drilling bits. Each has its own special job, whether it’s carving wood or cutting metal. They are like superheroes of the machining world!

| Type | Application |

|---|---|

| Cutter Heads | Woodworking |

| Drilling Bits | Metal Cutting |

| End Mills | Plastic Shaping |

Using the right tool can save time and energy. It’s like picking the right shoes for a marathon. No one wants to run in sandals, right?

The Importance of Adaptive Milling in Manufacturing

Benefits of using adaptive milling tools in production. Comparison with traditional milling techniques.Adaptive milling tools make manufacturing faster and smarter. They adjust to different materials, saving time and energy. These tools help create precise shapes, which can lead to fewer mistakes.

- Efficiency: Adaptive tools work quickly, improving production speed.

- Flexibility: They adapt to various tasks without changing tools.

- Cost-saving: Decreased waste means lower costs.

In contrast, traditional milling techniques can be slow and less efficient. They often require more time to set up and may produce more errors. Overall, adaptive milling tools offer clear advantages. Using them can transform how businesses make products.

What are the benefits of adaptive milling tools?

Adaptive milling tools boost efficiency and reduce waste, making them ideal for modern manufacturing.

Key Components of an Adaptive Milling Tools Strategy

Identifying the right tools for specific applications. Integration of technology and automation in adaptive milling.Choosing the right tools is key for adaptive milling. Different jobs need different tools. For example, a softer material uses one type of drill, while harder materials need another. Technology plays a big role too. Tools can now work smarter with automation. They help by making the milling process quicker and more accurate. This means fewer mistakes and better results.

How do you choose the right tools for adaptive milling?

Look for tools that fit the material and task. Consider the hardness and thickness of the material. Check if the technology can adjust cutting speeds automatically. These choices make a big difference in how well the tools work.

Key Factors in Tool Selection:

- Material type

- Job requirements

- Ability to use automation

Designing an Effective Adaptive Milling Process

Steps to develop an adaptive milling workflow. Factors to consider when designing an adaptive milling strategy.Creating a cool adaptive milling process is like building a fancy Lego set. First, you need to identify your materials, like wood or metal. Next, establish goals. What do you want to achieve? More efficiency? Less waste? Fun fact: A good adaptive milling strategy can cut costs by up to 30%! Now, consider your tools and machinery. They should fit your materials and goals.

| Steps | Factors |

|---|---|

| Identify materials | Tool compatibility |

| Set clear goals | Machine capabilities |

| Choose the right tools | Safety measures |

| Test and tweak | Budget constraints |

Keep asking questions and adjusting to feedback. It’s like baking a cake; sometimes you need a pinch more of this or a sprinkle less of that!

Technological Advancements in Adaptive Milling

Latest innovations in adaptive milling tools. The role of AI and machine learning in enhancing milling strategies.New tools are changing how we cut and shape materials. Innovations in adaptive milling tools make processes faster and easier. With the help of technology, the milling industry is transforming.

- Smart sensors improve precision.

- Robots save time and reduce mistakes.

- AI analyzes data to make better decisions.

Machine learning helps tools learn from past experiences. This means they get better over time. More companies are adopting these smart strategies to stay ahead. Technology is indeed reshaping the future of milling!

How does AI improve adaptive milling tools?

AI enhances precision and efficiency. It analyzes patterns and adapts processes to increase productivity.

Case Studies: Successful Implementation of Adaptive Milling Strategies

Examples from various industries. Lessons learned and best practices.Many industries have tried adaptive milling strategies with great success. For example, one automotive company improved production speed by 30% after adjusting their tools for better efficiency. Another case involves a kitchen appliance maker who reduced waste by 50%. Lessons from these experiences show that flexibility and teamwork are key. Companies that share best practices often thrive. As they say, “Two heads are better than one!” Below is a summary of these cases:

| Industry | Strategy Used | Outcome |

|---|---|---|

| Automotive | Tool Adjustment | 30% Production Speed Increase |

| Kitchen Appliances | Waste Reduction | 50% Less Waste |

Challenges and Solutions in Adaptive Milling Strategies

Common obstacles faced during implementation. Strategies to overcome challenges and enhance adaptability.Many face challenges with adaptive milling strategies. Common issues include lack of knowledge, technology limits, and high costs. These problems can slow down progress.

To overcome these challenges, here are some effective solutions:

- Training programs for workers to enhance skills.

- Investing in advanced technology to improve efficiency.

- Budget management to make projects more affordable.

Implementing these strategies can make adaptive milling easier and more successful. Remember, tackling obstacles leads to better results!

What are common challenges in adaptive milling strategies?

Common challenges include technology limitations, cost issues, and lack of knowledge among staff.How can we improve adaptability in milling?

Enhancing adaptability can be achieved through worker training, better technology, and careful budgeting.Future Trends in Adaptive Milling Tools

Predictions for the next generation of adaptive milling technology. Impact of evolving industry standards and practices on milling strategies.The next wave of adaptive milling tools promises exciting advancements. Imagine machines that learn and adjust while working, like a chef knowing how to perfect a recipe! As industry standards improve, these tools will provide better accuracy and efficiency. For instance, smarter sensors will help detect problems before they occur, saving both time and money. It’s like having a personal assistant who always prepares your favorite snacks just in time!

| Future Trends | Impact |

|---|---|

| Smart Sensors | Prevent issues and improve performance |

| Data Analytics | Enhance decision making for better output |

| Automation | Reduce human error and increase speed |

These changes are not only cool but also needed for our fast-paced world. Adapting to these trends will help stay ahead in the milling game. Get ready for a future where machines are not just tools; they might just become our new best friends!

Conclusion

In conclusion, an adaptive milling tools strategy helps improve efficiency and quality in manufacturing. You can adjust tools based on the material and project needs. This flexibility boosts productivity and reduces waste. To stay up-to-date, consider researching the latest tools and techniques. We can all benefit from smart strategies that enhance our work. Keep exploring and learning more!FAQs

What Are The Key Advantages Of Using Adaptive Milling Tools In Modern Manufacturing Processes?Adaptive milling tools are special tools that help us make things better. They can change to fit different shapes, which saves time and materials. You can use them with different types of machines easily. This means we can make more products and waste less stuff. Overall, they help us work faster and smarter!

How Does Real-Time Data Feedback Influence The Performance And Effectiveness Of Adaptive Milling Strategies?Real-time data feedback helps us make quick decisions when milling. It shows us what is happening right now, like if the machine needs to adjust or if the material is changing. With this information, we can make our milling strategies smarter. This means we can work faster and better, using tools more efficiently. Overall, it makes the whole process smoother and more effective!

What Materials Are Best Suited For Adaptive Milling Techniques, And How Do They Affect Tool Selection?Adaptive milling techniques work best with materials like aluminum, plastics, and wood. These materials are soft and easy to cut. When we choose tools, we pick sharper blades or special bits that fit these materials. This helps make the cutting faster and smoother. So, the right material affects which tools we use for the job.

How Can Machine Learning Algorithms Be Integrated Into Adaptive Milling Tools To Optimize Cutting Conditions?We can use machine learning to help milling tools cut better. First, we gather data about how the tool cuts. Then, the machine learning algorithms look for patterns in this data. The tools can learn which cutting conditions work best and adjust automatically. This way, we can make cutting faster and more efficient!

What Are The Potential Challenges And Limitations Associated With Implementing Adaptive Milling Tools In Existing Production Lines?When you add adaptive milling tools to current machines, you might face some problems. First, it can be costly to buy new equipment or upgrade what you have. Also, workers may need extra training to use the new tools properly. Sometimes, the tools might not fit well with older machines, making it hard to work smoothly. Finally, if the new tools break, it can slow down production and cause delays.