Have you ever seen an antique wood lathe tool and wondered about its story? These tools, once used by skilled craftsmen, hold a charm that takes us back in time. Restoring an antique wood lathe tool can be a magical journey. It’s like bringing a piece of history back to life.

Imagine finding a dusty old lathe in your grandparent’s garage. At first glance, it may seem useless, a relic of the past. But with some love and care, it can shine again. The process of restoration can be exciting and rewarding. You might discover hidden beauty under layers of dirt and rust.

Did you know that wood lathe tools were essential for making furniture and toys in centuries gone by? Each tool has its own tale to tell. As you work on restoring one, you’ll not only revive the tool but also connect with the artisans who used it before you.

Join us as we explore the art of antique wood lathe tool restoration. Uncover tips, tricks, and the joy of crafting something old into something beautiful once again.

Antique Wood Lathe Tool Restoration: A Comprehensive Guide

Antique Wood Lathe Tool Restoration

Restoring antique wood lathe tools can be a rewarding hobby. First, gather the right supplies like sandpaper, wood oil, and polish. Next, inspect the tool for damage. Did you know that some tools date back hundreds of years? With careful cleaning and reconditioning, you can bring these gems back to life. This practice not only preserves history, but it also allows you to create beautiful woodwork. Embrace the charm of vintage craftsmanship today!

Understanding Antique Wood Lathes

Definition and history of antique wood lathes. Key features that distinguish antique lathes from modern models.

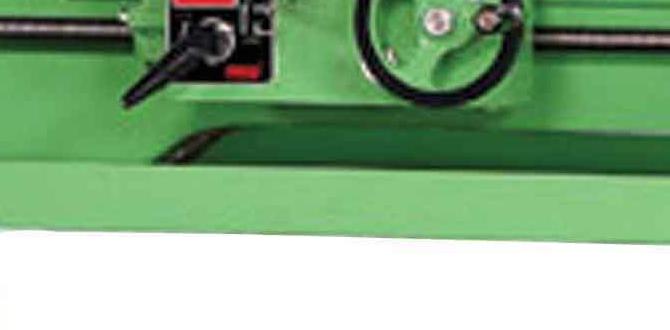

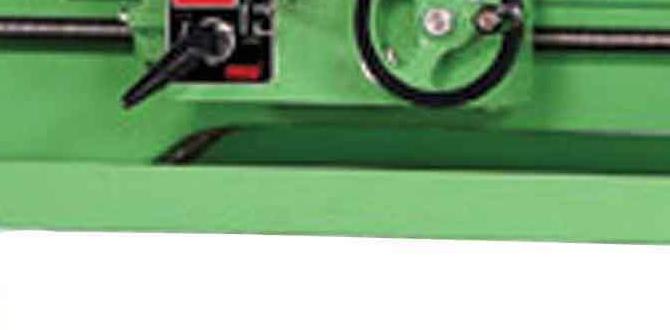

Antique wood lathes are fascinating tools used for shaping wood. They are much older than modern lathes and have a rich history. These machines started appearing around the 15th century and helped craft furniture and art. Antique lathes are different from today’s models in many ways:

- They are made of heavy wood and metal.

- They often have hand-powered mechanisms.

- Designs are simpler and less automated.

Knowing these features makes the restoration of these antique wood lathe tools even more exciting!

What Is the History of Wood Lathes?

Wood lathes date back over 5,000 years. They evolved from simple hand tools to complex machines used in workshops today.

Key Features of Antique Wood Lathes

- Manual operation

- Robust construction

- Unique designs, reflecting craftsmanship

Tools and Materials Needed for Restoration

Essential tools for disassembly and restoration. Recommended materials for repairs and refinishing.

Restoring antique wood lathe tools is exciting! To get started, you need some important items. Here are the essential tools and materials:

- Screwdrivers: Use these to remove screws safely.

- Pliers: Great for holding small parts snugly.

- Wood glue: Perfect for fixing cracks and joining pieces.

- Sandpaper: Helps to smooth surfaces before refinishing.

- Finish or stain: Make your restoration shine!

With these tools, you can restore your lathe tool like a pro!

What are the essential tools for disassembly?

The essential tools include screwdrivers, pliers, and wrenches. These help take apart the lathe tool safely.

Step-by-Step Restoration Process

Initial assessment and cleaning techniques. Detailed breakdown of disassembly and reassembly.

Start by looking closely at your lathe. Check for cracks and rust, like a detective solving a mystery. Clean it up with a gentle scrub to remove dirt. Use warm soapy water, and don’t forget an old toothbrush for those tricky spots! Next, it’s time to take it apart. Make sure to remember where every piece goes; a picture can help! Keep track of the parts in a table like this:

| Part | Condition |

|---|---|

| Body | Rusty |

| Chucks | Dirty |

| Bed | Cracked |

After cleaning and fixing pieces, it’s time to reassemble. Gently put everything back together, just like a puzzle. Make sure it’s snug but not too tight—no one likes a cranky lathe!

Restoring the Lathe Bed and Components

Techniques for repairing and refinishing the lathe bed. Caring for other components: tailstock, headstock, and bed rails.

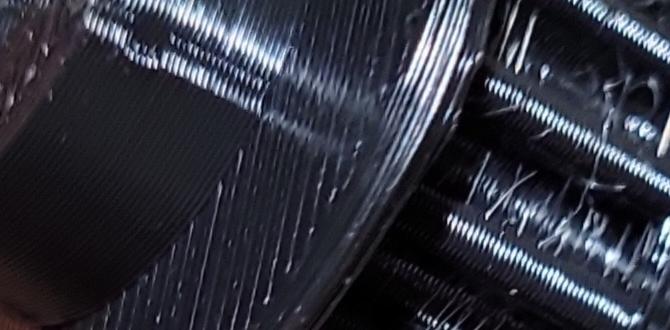

Repairing the lathe bed is the first step in restoration. Start by removing rust with a wire brush. Use sandpaper to smooth rough areas. After cleaning, apply a protective finish to keep it safe from moisture.

Caring for the tailstock, headstock, and bed rails is important too. Keep them clean and lubricated regularly. Tighten any loose parts to prevent wobbling. These steps ensure your lathe works well and lasts long.

How can you clean and maintain other components?

Regular cleaning and lubrication help extend the life of your lathe components. Check for tightness and smooth operation frequently. Here’s a quick checklist:

- Wipe down each component after use.

- Use a light oil to lubricate moving parts.

- Inspect for damage or wear.

Preserving Original Features and Patina

Importance of authenticity in restoration. Methods to maintain vintage character while ensuring functionality.

Keeping the unique features and patina of an antique wood lathe is key in restoration. Authenticity adds charm and tells a story. To maintain its vintage look, use gentle cleaning methods and avoid harsh chemicals. Upgrading parts can keep it functional without ruining its character. For instance, consider replacing worn-out pieces and leaving scratches as is. Remember, “Old things are like fine wine; they get better with age!”

| Restoration Method | Purpose |

|---|---|

| Gentle Cleaning | Preserves original finish |

| Part Replacement | Enhances functionality |

| Leave Scratches | Maintains vintage charm |

Common Challenges in Restoration

Identifying and fixing common issues found in antique lathes. Tips for troubleshooting unexpected problems during restoration.

Restoring an antique lathe can be like solving a mystery. You may encounter rust, broken parts, or confusing mechanisms. The first step is identifying issues, like squeaky wheels or wobbly tables. Don’t fret; even the bravest woodworkers face these puzzles! Here are some tips:

| Common Issues | How to Fix |

|---|---|

| Rusty parts | Use vinegar and elbow grease. |

| Worn bearings | Replace or recondition them. |

| Loose belts | Tighten them or get new ones. |

Keep an eye out for unexpected surprises. Even the best plans can go awry! Remember, a bit of humor helps. Think of each challenge as a quirky puzzle in the grand adventure of restoration!

Finishing Touches and Enhancements

Suggested finishes for protection and aesthetics. Upgrades that can enhance performance without compromising originality.

After bringing your antique wood lathe back to life, it’s time for the finishing touches! A good finish not only protects the tool but also makes it shine. Popular options like polyurethane or natural oils can keep your lathe looking brand new while safeguarding it from dust and moisture. Consider sprucing up performance too! Upgrades like a new drive belt or precision bearings can enhance functionality without messing with that original charm. Remember, we’re not trying to turn it into a spaceship, just helping it run smoother!

| Finish Type | Benefits |

|---|---|

| Polyurethane | Durable and water-resistant |

| Natural Oils | Eco-friendly and enhances wood grain |

Maintaining Your Restored Antique Lathe

Best practices for regular maintenance and care. Tips for storing your antique lathe to prevent future damage.

To keep your antique lathe in top shape, regular maintenance is key. Here are some simple practices: clean the lathe often to remove dust and oil, and check for any loose parts. Store your lathe properly to prevent future damage. Make sure it’s in a dry place, away from moisture. Cover it with a cloth to keep dust off. These steps help your lathe last longer and work better.

How can I maintain my antique lathe?

Regular upkeep helps your lathe stay in great condition. Wipe it down regularly and check for loose parts. Follow these tips for storage:

Tips for Storage:

- Keep it in a dry area.

- Use a cover to protect from dust.

- Avoid extreme temperatures.

Resources and Community for Antique Lathe Enthusiasts

Recommended books, online forums, and workshops. Connecting with local woodworking clubs and antique tool shows.

Finding help in the antique lathe community is easy. Many resources exist to boost your skills. Recommended books can teach you tricks and history. Online forums allow you to share ideas with others. Check out local woodworking clubs for hands-on support. Antique tool shows are great places to learn and meet people. Here are some helpful resources:

- Books on antique restoration

- Woodworking forums online

- Local clubs for woodworking

- Antique tool shows and fairs

Where can I find antique lathe resources?

Books, online forums, and local clubs are the best places to connect with other antique lathe lovers.

Conclusion

In conclusion, restoring antique wood lathe tools is a rewarding hobby. You can bring old tools back to life with some patience and care. Start by cleaning and repairing the tools, then explore how to use them safely. For more tips, look for books or online resources. Enjoy the journey of preserving history through craftsmanship!

FAQs

What Are The Essential Steps Involved In Restoring An Antique Wood Lathe Tool To Ensure It Functions Properly?

To restore an antique wood lathe tool, you should follow these steps. First, clean the tool to remove dirt and old grease. Next, check for any broken parts and fix or replace them. Then, sharpen the tool’s cutting edges so it can work well. Finally, oil the moving parts to help them glide smoothly.

What Types Of Materials And Finishes Should Be Used For Preserving The Integrity Of Antique Wood Lathe Tools?

To keep antique wood lathe tools safe, we should use some good materials. First, clean them gently with a soft cloth. Next, we can apply a light oil, like mineral oil, to keep the wood smooth. Finally, store them in a dry place to avoid rust or damage. This way, your tools can last a long time!

How Can You Identify The Age And Origin Of An Antique Wood Lathe Tool Before Starting The Restoration Process?

You can find out how old and where a wood lathe tool came from by checking its design. Look for special marks or stamps on the tool. These can show who made it and when. You can also compare it to pictures in old tool books or online. Talking to experts or visiting antique shops can help you learn more, too.

What Safety Precautions Should Be Taken When Restoring Antique Wood Lathe Tools, Especially Those With Rust Or Damage?

When restoring antique wood lathe tools, always wear safety goggles to protect your eyes. Use gloves to keep your hands safe from rust and sharp edges. Work in a well-lit area so you can see clearly. Make sure to use tools carefully and keep your workspace clean. If you’re using any chemicals, read the labels and follow the instructions.

What Are The Common Issues Found In Antique Wood Lathe Tools, And How Can They Be Effectively Repaired During Restoration?

Antique wood lathe tools often have rust, broken parts, or dull edges. You can remove rust using sandpaper or a wire brush. If parts are broken, you might need to replace them or use glue. For dull edges, sharpening with a whetstone can help. Always clean the tools well to make them work better.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Steps Involved In Restoring An Antique Wood Lathe Tool To Ensure It Functions Properly? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To restore an antique wood lathe tool, you should follow these steps. First, clean the tool to remove dirt and old grease. Next, check for any broken parts and fix or replace them. Then, sharpen the tool’s cutting edges so it can work well. Finally, oil the moving parts to help them glide smoothly.”}},{“@type”: “Question”,”name”: “What Types Of Materials And Finishes Should Be Used For Preserving The Integrity Of Antique Wood Lathe Tools? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep antique wood lathe tools safe, we should use some good materials. First, clean them gently with a soft cloth. Next, we can apply a light oil, like mineral oil, to keep the wood smooth. Finally, store them in a dry place to avoid rust or damage. This way, your tools can last a long time!”}},{“@type”: “Question”,”name”: “How Can You Identify The Age And Origin Of An Antique Wood Lathe Tool Before Starting The Restoration Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find out how old and where a wood lathe tool came from by checking its design. Look for special marks or stamps on the tool. These can show who made it and when. You can also compare it to pictures in old tool books or online. Talking to experts or visiting antique shops can help you learn more, too.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Restoring Antique Wood Lathe Tools, Especially Those With Rust Or Damage? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When restoring antique wood lathe tools, always wear safety goggles to protect your eyes. Use gloves to keep your hands safe from rust and sharp edges. Work in a well-lit area so you can see clearly. Make sure to use tools carefully and keep your workspace clean. If you’re using any chemicals, read the labels and follow the instructions.”}},{“@type”: “Question”,”name”: “What Are The Common Issues Found In Antique Wood Lathe Tools, And How Can They Be Effectively Repaired During Restoration? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Antique wood lathe tools often have rust, broken parts, or dull edges. You can remove rust using sandpaper or a wire brush. If parts are broken, you might need to replace them or use glue. For dull edges, sharpening with a whetstone can help. Always clean the tools well to make them work better.”}}]}