Have you ever wondered how metal lathes work so smoothly? These machines need a special liquid called coolant to keep them running well. When you use an automatic metal lathe, the coolant does more than cool down the metal. It helps keep the tools sharp and clean, too.

Imagine a race car speeding around a track. It needs oil to keep the engine cool and running fast. Similarly, an automatic metal lathe uses coolant to stay efficient. But what happens when there isn’t enough? The machine can overheat, and that can cause mistakes in the work.

Did you know that using the right coolant can make your metal parts last longer? You want your lathe to work perfectly every time. Choosing the right coolant is like picking the best fuel for your car. Let’s dive deeper into the world of automatic metal lathe coolant and discover why it’s so important.

Automatic Metal Lathe Coolant: Importance And Benefits

Understanding Automatic Metal Lathe Coolant

Automatic metal lathe coolant is essential for smooth machining. It keeps the tool and material cool, preventing damage. Imagine trying to cut a cake without a knife; it wouldn’t go well! Coolant helps remove metal chips, making your work cleaner and safer. Did you know that using coolant can extend the life of your tools? It’s true! By investing in a good coolant system, you save time and money in the long run.What is Automatic Metal Lathe Coolant?

Definition and purpose of coolant in metal lathes. Types of coolants used in automatic metal lathes.Coolant is like a superhero for metal lathes! It helps keep machines cool while they slice and dice metal. Think of it as the refreshing drink after a long run. Without it, things can get too hot, and nobody likes a cranky machine. There are different types of coolants out there, each with its own special powers, like water-soluble oils or synthetic coolants. Here’s a quick look:

| Type of Coolant | Description |

|---|---|

| Water-Soluble Oil | Mixes with water and cools well. |

| Synthetic Coolant | No oil, good for the environment and great cooling. |

| Straight Oil | Good for heavy materials, but can be sticky! |

These coolants not only cool the machine but also help improve the finish of the metal. In short, they’re the best sidekick a lathe could ask for!

Benefits of Using Coolant in Metal Lathes

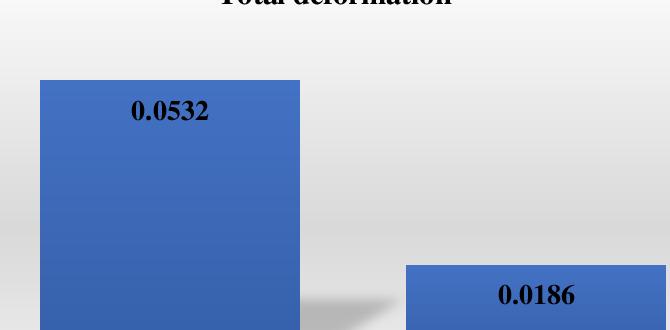

Reducing heat buildup during machining processes. Improving tool life and surface finish quality.Using coolant in metal lathes is very helpful. It reduces heat buildup during work. Less heat means less chance of mistakes. This keeps both the metal and the tools safe. Coolant also helps tools last longer. They can cut more without wearing out. It also gives a better finish to the metal. This looks nice and works better. Here are some benefits:

- Reduces heat during machining

- Improves tool life

- Enhances surface finish

Why is cutting fluid important in machining?

Cutting fluid cools the tool and reduces friction. It prevents overheating and increases efficiency. This helps create a smoother surface and extends the life of equipment.

Types of Coolants for Automatic Metal Lathes

Watersoluble vs. oilbased coolants. Synthetic and semisynthetic options.Coolants are vital for automatic metal lathes. They keep things cool and help metal pieces glide smoothly. There are two main types: water-soluble and oil-based. Water-soluble coolants mix easily with water, making them great for cooling but tricky to clean up. Oil-based coolants, on the other hand, are thick and clingy, offering great lubrication but can be messy. Then you have synthetic and semisynthetic options! Synthetic coolants are made from chemicals and are super effective, while semisynthetic ones mix oil and chemicals for a nice balance. Here’s a quick look at both:

| Type | Benefits | Drawbacks |

|---|---|---|

| Water-Soluble | Easy to use and great cooling! | Can be messy to clean. |

| Oil-Based | Stays on, great lubrication! | Can get slippery and messy. |

| Synthetic | Super effective! | May cost a bit more. |

| Semi-Synthetic | Good balance! | Not as powerful as full synthetic. |

Choosing the right coolant can feel like finding the right pizza topping—everyone has their favorite! Make sure you pick one that fits your needs best!

Choosing the Right Coolant for Your Operations

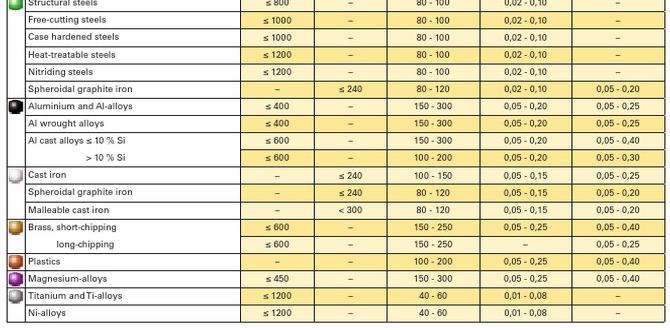

Factors to consider when selecting coolant. Compatibility with materials and machining processes.Choosing the right coolant is important for smooth machining. There are a few things to think about before you make your choice. First, check if the coolant will work well with the materials you use. Different metals need different care. Second, consider how the coolant fits with your machining process. Some coolants are better for turning, while others work great for drilling.

- Compatibility with metals

- Effectiveness in specific processes

- Cooling and lubrication abilities

How do you select the right coolant?

Look for coolants that match your materials and processes. Always test small samples first. This helps ensure you make the best choice for your work. A good coolant can improve performance.

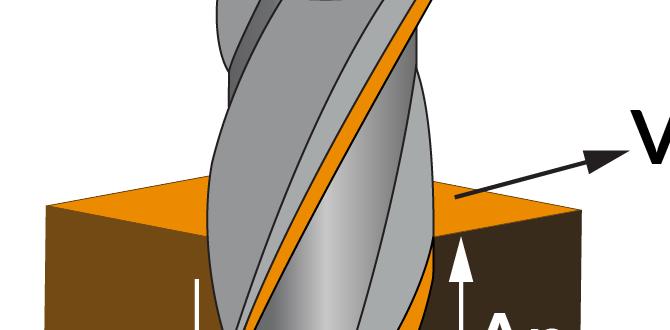

Coolant Delivery Systems in Automatic Metal Lathes

Types of coolant delivery systems. Importance of coolant flow and application.Coolant delivery systems are like the lifeline of automatic metal lathes. They help keep the tools cool and happy. There are a few types to choose from, including flood coolant, mist coolant, and even through-tool coolant. Each type has its perks. Flood coolant pours a refreshing stream over the cut, while mist sprinkles a fine drizzle—like giving the lathe a spa day! Proper coolant flow is essential. It prevents overheating, boosts tool life, and makes for smoother cuts. No one likes a hot tool, unless it’s in a dance-off!

| Type of Coolant | Description |

|---|---|

| Flood Coolant | Continuous flow that cools large areas. |

| Mist Coolant | Fine spray that reduces excess liquid. |

| Through-Tool Coolant | Delivers coolant directly to the cutting edge. |

Maintenance of Coolant Systems

Regular checks and maintenance practices. Common issues and troubleshooting tips.Keeping coolant systems in good shape is important for automatic metal lathes. Regular checks help prevent problems. Clean the coolant tank and check for leaks often. Common issues include low coolant levels and contamination. If the coolant looks dirty or smells bad, change it. To fix these issues:

- Inspect hoses for cracks.

- Check the pump for clogs.

- Ensure filters are clean.

What should you regularly check in coolant systems?

Regular checks include inspecting coolant levels, cleaning the tank, and replacing filters.

Why is coolant maintenance important?

Coolant maintenance prevents overheating and extends the life of the machine.

Regulations and Safety Considerations

Environmental regulations surrounding coolant use. Safety measures for handling and disposing of coolants.Coolants are important in many machines, but they can harm the environment if not used properly. Different laws help keep our air and water safe. Always check local rules on coolant use and disposal. Safety is key too. Here are a few important safety measures:

- Store coolants in labeled containers.

- Wear protective gear when handling coolants.

- Dispose of used coolants according to local guidelines.

Following these rules helps protect us and our planet.

What are the regulations for coolant use?

Regulations vary by region but generally include guidelines for proper use and disposal to protect the environment.

Future Trends in Coolant Technology

Innovations and advancements in coolant formulations. The impact of technology on coolant efficiency and sustainability.Coolant technology is changing fast. New inventions make coolants work better. Companies are creating special mixtures that are safer for the earth. Less harmful ingredients mean greater sustainability. Smart machines now monitor coolant levels, improving efficiency. This helps save money and time in factories. Exciting trends suggest that future coolants will be even more friendly to the environment and will not harm workers. The future looks bright for this important industry!

What are the latest innovations in coolant formulations?

Innovations focus on safer, eco-friendly ingredients. Companies are exploring bio-based coolants that create less waste. This means better health for workers and the planet!

Key Points

- New blends for better cooling

- Less toxic materials

- Smart coolant systems

How does technology impact coolant efficiency?

Technology allows precise tracking of coolant use. Smart systems can adjust amounts, saving resources and ensuring maximum performance!

Conclusion

In summary, automatic metal lathe coolant is essential for efficient machining. It cools and lubricates tools, extending their life and improving cut quality. You should choose the right type for your lathe and keep it clean. To learn more, explore guides on coolant maintenance or talk to experts. Taking these steps will enhance your metalworking experience.FAQs

Sure! Here Are Five Related Questions On The Topic Of Automatic Metal Lathe Coolant:Automatic metal lathe coolant helps keep machines cool while they work. It also helps make sure the metal gets cut smoothly. When you use coolant, it reduces heat and helps avoid rust. It’s important for keeping tools and machines in good shape. Using the right amount makes your metalworking safer and easier.

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help!

What Are The Primary Functions Of Coolant In An Automatic Metal Lathe Operation?Coolant helps keep the metal lathe cool while it works. It also washes away tiny metal shavings and dirt. This makes the machine run better and helps our tools last longer. Plus, coolant makes sure the metal pieces stay clean and smooth.

How Does The Choice Of Coolant Affect The Overall Machining Process, Including Tool Life And Workpiece Quality?Choosing the right coolant is important for good machining. Coolants help keep tools cool and reduce heat. When tools stay cool, they last longer. This means we can make more parts without changing tools. Also, coolants help make the finished parts smooth and nice to look at.

What Are The Common Types Of Coolant Systems Used In Automatic Metal Lathes, And How Do They Differ In Terms Of Application And Efficiency?Automatic metal lathes often use two common types of coolant systems: flood coolant and mist coolant. Flood coolant covers the area with a steady flow of liquid. This helps keep the metal cool and clean. Mist coolant sprays tiny droplets of liquid, which is good for smaller parts. Flood systems usually work better for big jobs, while mist systems save space and use less liquid.

How Can The Proper Maintenance Of Coolant Systems Contribute To The Longevity Of An Automatic Metal Lathe?Taking care of the coolant system keeps the metal lathe running smoothly. Coolant helps cool down the lathe while it works. If we keep it clean and full, the machine won’t overheat. This helps the lathe last longer and work better. Regular checks make sure everything is in good shape!

What Factors Should Be Considered When Selecting A Coolant For A Specific Machining Application, Such As Material Type And Cutting Speed?When choosing a coolant for machining, we need to think about a few important things. First, check the type of material you’re cutting, like metal or plastic, because different materials need different coolants. Next, consider the cutting speed; faster speeds may require better cooling to prevent burning. Also, think about how safe the coolant is and if it’s easy to clean up. Lastly, cost is important too, so we want a coolant that works well without being too expensive.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Automatic Metal Lathe Coolant:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automatic metal lathe coolant helps keep machines cool while they work. It also helps make sure the metal gets cut smoothly. When you use coolant, it reduces heat and helps avoid rust. It’s important for keeping tools and machines in good shape. Using the right amount makes your metalworking safer and easier.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Primary Functions Of Coolant In An Automatic Metal Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Coolant helps keep the metal lathe cool while it works. It also washes away tiny metal shavings and dirt. This makes the machine run better and helps our tools last longer. Plus, coolant makes sure the metal pieces stay clean and smooth.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Coolant Affect The Overall Machining Process, Including Tool Life And Workpiece Quality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right coolant is important for good machining. Coolants help keep tools cool and reduce heat. When tools stay cool, they last longer. This means we can make more parts without changing tools. Also, coolants help make the finished parts smooth and nice to look at.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Coolant Systems Used In Automatic Metal Lathes, And How Do They Differ In Terms Of Application And Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automatic metal lathes often use two common types of coolant systems: flood coolant and mist coolant. Flood coolant covers the area with a steady flow of liquid. This helps keep the metal cool and clean. Mist coolant sprays tiny droplets of liquid, which is good for smaller parts. Flood systems usually work better for big jobs, while mist systems save space and use less liquid.”}},{“@type”: “Question”,”name”: “How Can The Proper Maintenance Of Coolant Systems Contribute To The Longevity Of An Automatic Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Taking care of the coolant system keeps the metal lathe running smoothly. Coolant helps cool down the lathe while it works. If we keep it clean and full, the machine won’t overheat. This helps the lathe last longer and work better. Regular checks make sure everything is in good shape!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Coolant For A Specific Machining Application, Such As Material Type And Cutting Speed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a coolant for machining, we need to think about a few important things. First, check the type of material you’re cutting, like metal or plastic, because different materials need different coolants. Next, consider the cutting speed; faster speeds may require better cooling to prevent burning. Also, think about how safe the coolant is and if it’s easy to clean up. Lastly, cost is important too, so we want a coolant that works well without being too expensive.”}}]}