Have you ever wondered how machines make precise metal parts? Automatic metal lathe cutting tools are a big part of that mystery. These tools spin metal at high speeds to shape it into useful items. From small screws to large car parts, these tools do it all!

Imagine watching a metal lathe in action. The metal rotates as the cutting tool glides along its surface. It’s like watching a sculptor carve a statue, but much faster. This process can create parts that fit together perfectly.

Did you know that the first lathes appeared over 3,000 years ago? While they were simple, today’s automatic metal lathes use advanced technology. They can produce thousands of pieces in a single day. This speed and precision help industries save time and money.

In this article, we will explore how these cutting tools work and why they are essential. You’ll learn about different types and how they can help both big factories and small shops. Ready to dive into the fascinating world of automatic metal cutting tools?

Automatic Metal Lathe Cutting Tools: Enhance Your Machining Efficiency

Automatic Metal Lathe Cutting Tools

Automatic metal lathe cutting tools are essential for precision and efficiency in metalworking. These machines help create various parts by shaping metal quickly and accurately. Imagine how much easier it is to make intricate designs without manual labor! They use carbide tips that last longer and cut faster. Did you know these tools can produce hundreds of identical pieces in a fraction of the time? Learning about them opens doors to exciting possibilities in manufacturing and design!Understanding Automatic Metal Lathes

Definition and functionality of automatic metal lathes. Comparison with traditional manual lathes.Automatic metal lathes are machines that shape metal parts quickly and accurately. They use computer programs to control the cutting tools. This makes them more precise than manual lathes. In contrast, traditional manual lathes require a human to turn the handles and make adjustments. Here’s a quick comparison:

- Speed: Automatic lathes are faster.

- Precision: Automatic lathes provide better accuracy.

- Skill Level: Manual lathes need more training.

Automatic lathes save time and effort. They help factories produce parts more efficiently.

What are the benefits of automatic metal lathes?

Automatic metal lathes offer speed and accuracy. They reduce errors and waste. This means less time and money spent on repairs. Companies can produce more items in less time.

Key Features of Cutting Tools for Automatic Metal Lathes

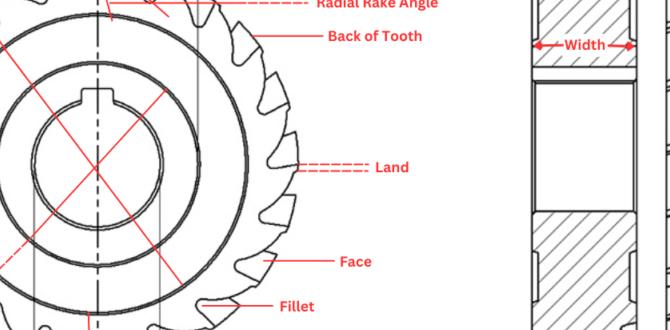

Importance of tool geometry and design. Role of coating materials in cutting tool performance.Cutting tools are like superheroes for automatic metal lathes. Their geometry and design influence how well they slice through metal. Good geometry ensures smooth cuts, kind of like a knife gliding through butter! Coatings are the secret sauce that protects tools from wear and tear. They improve performance and make tools last longer. Think of it as sunscreen for metal! Here’s a quick look at some key features:

| Feature | Description |

|---|---|

| Tool Geometry | Affects cutting efficiency. |

| Coating Materials | Enhances durability and performance. |

Choosing the Right Cutting Tool for Your Project

Factors to consider when selecting cutting tools for specific applications. Examples of suitable tools for various metals and materials.Choosing the right cutting tool is key for any project. Think about what you are cutting. Different materials need different tools. For example, soft metals like aluminum use fast-cutting tools. Hard metals like steel need strong tools. Here are some factors to consider:

- Material type: Different tools work better on hard or soft materials.

- Tool shape: The shape can affect how clean the cut is.

- Project size: Larger projects may need bigger tools.

To get the best results, pick the right tool for the job. It will make your work easier and faster!

What factors should I consider when choosing cutting tools?

Consider the material, tool shape, and size of your project.

Maintenance and Care for Cutting Tools

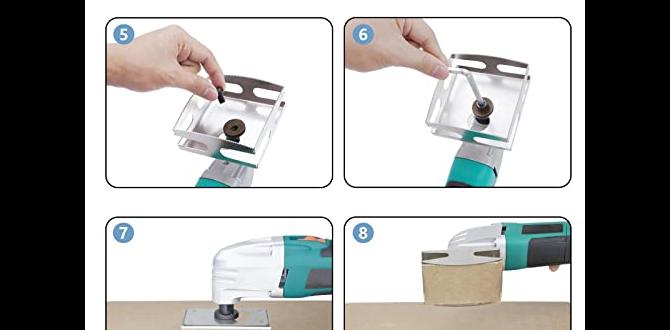

Best practices for maintaining tool sharpness and longevity. Techniques for cleaning and storing cutting tools.To keep your cutting tools sharp and long-lasting, remember these simple tips. Regularly sharpen your tools to maintain their edge. Proper cleaning is essential too. Clean tools right after use to avoid rust. Store tools in a dry place to protect them. Here are some best practices:

- Sharpen tools after every few uses.

- Use a soft brush for cleaning.

- Store in a protective case.

- Check regularly for wear and tear.

Following these steps will help you enjoy your tools for years.

How do you maintain cutting tools?

To maintain cutting tools: keep them clean, sharp, and store them safely. Regular care reduces damage and keeps tools working well.

Common Problems and Solutions in Cutting Tool Usage

Identification of frequent issues encountered with cutting tools. Practical solutions and troubleshooting tips.Cutting tools can sometimes be tricky, which can make you feel like you’re trying to tame a wild beast! Common problems include dull edges, incorrect speeds, and vibrations that feel more like a disco party than focused work.

To tackle these issues, check your tool sharpness frequently and adjust your speeds based on the material. If vibrations arise, make sure everything is tight, like your favorite pair of jeans after Thanksgiving dinner!

| Problem | Solution |

|---|---|

| Dull cutting tool | Sharpen or replace it |

| Incorrect speed | Adjust the RPM |

| Vibrations | Tighten all screws |

With these tips, you’ll keep your tools in shape and your cutting smooth—no less than a hot knife through butter!

Innovations in Cutting Tool Technology

Recent advancements and trends in cutting tool development. Future prospects for automatic metal lathe cutting tools.Cutting tools are changing fast! New materials and designs are making tools last longer and work better. These innovations help workers save time and effort. For automatic metal lathe cutting tools, high-speed steel and carbide are popular choices now. In the future, we may see tools that use smart technology. This could lead to more precise cuts and less waste. How exciting is that?

What are the latest trends in cutting tool technology?

Recent trends include the use of advanced materials and smart features. These tools maximize efficiency and precision while reducing costs.

Key developments:

- Stronger materials for better durability

- Smart chips for improved performance

- Recycling tools to help the environment

Case Studies: Successful Implementations of Automatic Metal Lathes

Examples of industries effectively utilizing automatic metal lathes. Impact on productivity and quality using specific cutting tools.Many companies benefit from automatic metal lathes. These machines help improve their work. For example, the automotive industry uses them to make precise car parts. The results are faster production times and better quality. Another example is the aerospace sector. They rely on these tools to create strong and safe components. Using cutting tools like these leads to less waste and higher efficiency.

- Automotive Industry: Faster production and precision.

- Aerospace Sector: Stronger, safer components.

- Manufacturing: Reduced waste and higher efficiency.

How do automatic metal lathes improve productivity?

Automatic metal lathes increase speed and accuracy. They allow companies to produce more items quickly with fewer mistakes. This saves time and materials, making businesses more profitable.

Conclusion

In conclusion, automatic metal lathe cutting tools make machining easier and more precise. They save time and improve your projects’ quality. By using these tools, you can create complex shapes with less effort. If you’re interested in trying them, research different models or ask for advice. Explore more about how these tools can help you in your work!FAQs

What Are The Different Types Of Cutting Tools Commonly Used In Automatic Metal Lathes, And How Do They Differ In Application?In automatic metal lathes, there are different cutting tools you can use. Some common ones are flat tools, round tools, and parting tools. Flat tools shape the metal flat, round tools make curves, and parting tools cut pieces off. Each tool helps in creating different shapes and sizes in the metal. So, you choose a tool based on what you want to make!

How Do Tooling Materials, Such As High-Speed Steel And Carbide, Affect The Performance And Longevity Of Cutting Tools In Automatic Metal Lathes?Tooling materials like high-speed steel and carbide help cutting tools last longer and work better. High-speed steel is tough and can handle heat, but it wears out faster. Carbide is even harder and stays sharp longer, making it great for cutting metal. When you use the right material, your tools cut smoother and don’t need to be replaced as often. This means you save time and money while working!

What Factors Should Be Considered When Selecting Cutting Tools For Specific Materials Being Turned On An Automatic Metal Lathe?When choosing cutting tools for turning metal, we need to think about a few important things. First, we consider the type of metal we are working with because different metals need different tools. Next, we check the speed and strength of the tool. Some tools can handle tougher jobs. Lastly, we make sure the tool lasts a long time, so we don’t have to replace it often. These choices help us work better and make nice parts.

How Does Cutting Tool Geometry, Including Rake Angle And Clearance Angle, Influence The Cutting Process In Automatic Metal Lathes?The shape of cutting tools is important for how they work. The rake angle helps the tool slice better and need less force. A good angle makes cutting smoother and helps the tool last longer. The clearance angle stops the tool from rubbing against the metal, which can cause problems. Together, these angles help us cut metal more easily and safely.

What Are The Best Practices For Maintaining And Sharpening Cutting Tools Used In Automatic Metal Lathes To Ensure Optimal Performance?To keep your cutting tools in good shape, you should clean them after each use. Use a soft cloth to remove chips and dirt. Sharpen them regularly with the right tool to cut smoothly. Check them often for any damage. Lastly, store them safely to avoid accidents and keep them from getting dull.