Have you ever watched a metal lathe work? It’s amazing to see how it shapes metal into different forms. Now, imagine making that process easier and faster. This is where benchtop metal lathe automation comes in.

Many hobbyists and professionals are discovering the benefits of automating their metal lathes. They can save time and effort while creating high-quality parts. But how does this automation work? And why is it becoming so popular?

Picture this: You have a project due in a few hours. You want it to be perfect. Instead of manually adjusting your lathe, you can sit back and let automation do the hard work. Sounds great, right?

In this article, we will explore how benchtop metal lathe automation can change the way you work. From improving precision to increasing productivity, the advantages are hard to ignore. So, let’s dive in and discover how this technology can enhance your metalworking experience!

Benchtop Metal Lathe Automation: Advancements In Precision Machining

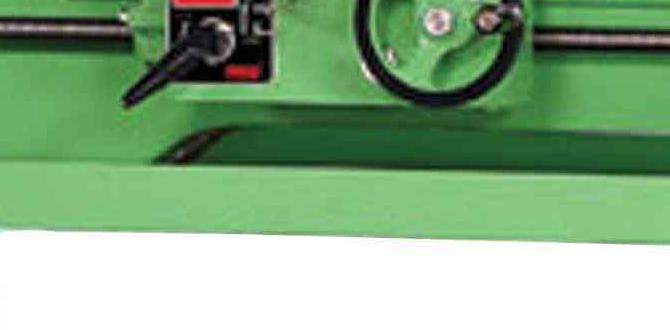

Benchtop Metal Lathe Automation

Discover the exciting world of benchtop metal lathe automation! This technology helps perform precise machining tasks more quickly and accurately. Users learn about enhanced efficiency, improved safety, and how these machines reduce human error. Imagine a tool that works tirelessly, producing consistent results every time. Plus, automation in metal lathes allows for more creative projects. With the right setup, even beginners can tap into professional-grade results. Isn’t it amazing what technology can do for crafting?Understanding Benchtop Metal Lathes

Definition and basic functions of benchtop metal lathes. Advantages of using benchtop lathes in smallscale machining.A benchtop metal lathe is a small but powerful tool used to shape metal. It spins the metal while a sharp tool cuts it in different shapes. Think of it as a spinning pizza wheel, only instead of dough, it’s slicing through metal! These lathes are great for small projects, fitting easily on tables. They save space and are perfect for hobbyists and small businesses. Plus, they are easier to use than their bigger cousins.

| Advantages of Benchtop Lathes | Details |

|---|---|

| Space-saving | They fit in small workspaces! |

| Cost-effective | Perfect for budget-friendly projects. |

| Easy operation | Simple to learn and use. |

With these tools, anyone can turn metal into art or functional pieces. Just don’t forget your safety goggles—metal shavings can be more dangerous than a cat in a room full of laser pointers!

Key Features of Automated Benchtop Metal Lathes

Essential components that enhance automation. Userfriendly interfaces and programming options.Automated benchtop metal lathes come with amazing features that make your life a tad easier. First, they have essential components like automatic tool changers, saving you time and effort—no more hunting for tools in a chaotic toolbox! They also offer user-friendly interfaces that even a cat could operate after a few tries. With simple programming options, you can set everything up quickly. So, if your lathes could talk, they’d probably say, “Let’s get to work without any drama!”

| Feature | Benefits |

|---|---|

| Automatic Tool Changer | Speeds up the process and reduces manual work. |

| User-Friendly Interface | Makes operation simple, even for beginners. |

| Simple Programming Options | Allows quick setup and adjustments. |

With these features, you can unleash your inner machining wizard!

Types of Automation Technologies for Benchtop Lathes

CNC (Computer Numerical Control) vs. manual operation. Potential advancements in robotics for lathe automation.Automation in benchtop lathes can be exciting! There are two main types to explore: CNC and manual operation. CNC stands for Computer Numerical Control. It allows machines to run with great precision. Many factories prefer CNC because it’s faster and can produce more parts without errors. On the other hand, manual operation needs skilled workers. They control machines by hand, which can be slower.

There’s potential to improve lathe automation even more with robotics. Robots can help lift heavy materials, sort parts, and even fix machines. This can allow workers to focus on more complex tasks.

What is CNC automation in lathes?

CNC automation uses computer systems to control lathes. This method improves precision and speed, making it popular in many industries.

Benefits of CNC automation:

- High accuracy

- Less human error

- Faster production

- Consistency in output

Choosing the Right Benchtop Metal Lathe for Automation

Factors to consider: size, capabilities, and budget. Comparison of top models available in the market.Finding the right benchtop metal lathe for automation is key to smooth operations. Start by considering the following factors:

- Size: Make sure it fits your workspace.

- Capabilities: Choose one that meets your project needs.

- Budget: Find a model that won’t break the bank.

Here are some top models to look into:

- Model A: Great for small projects.

- Model B: Offers advanced features for serious users.

- Model C: Budget-friendly with reliable performance.

Always read customer reviews before deciding. It helps to know what others think!

What should I consider when choosing a benchtop metal lathe?

Look at size, capabilities, and your budget. Each of these factors will help you pick the best machine for your work.

Step-by-Step Guide to Automating Your Benchtop Lathe

Initial assessments and planning for automation. Installation and setup process for automation technologies.Before you dive into automation, check your tools. Look for wear and tear. Make a list of what you need. Planning is key, so you don’t end up with a lathe that only spins in circles!

Next, it’s time for installation. Follow the instructions for the automation gadgets like they’re a treasure map. Keep everything organized. A messy workspace can lead to losing vital screws or, worse, your sanity!

| Steps | Details |

|---|---|

| Assessment | Check tools and list needs. |

| Installation | Follow instructions closely. |

| Setup | Keep workspace tidy. |

Remember, automation can save time and effort, but it should never make you feel like a robot. Laugh at your mistakes; they might just be the best part of the process!

Common Challenges and Solutions in Lathe Automation

Technical issues that may arise during automation. Maintenance tips and support resources.Automation of benchtop metal lathes brings many benefits but can also pose challenges. Technical issues often arise, such as software glitches and mechanical faults. Regular maintenance can help. Here are some tips:

- Check connections often.

- Clean parts regularly.

- Update software as needed.

For support, reliable resources can be found online. Many forums share useful tips and advice. Connect with others facing similar issues to find practical solutions.

What support resources are available for lathe automation?

Many websites provide useful manuals and guides. Community forums are great for real-time help and suggestions.

Case Studies of Successful Benchtop Lathe Automation

Realworld examples of businesses leveraging automation. Results achieved and lessons learned from automation implementations.Many businesses have successfully automated their benchtop lathes. This has made their work faster and more accurate. For example, a small machine shop saw a 30% boost in productivity after automating their lathe operations. They learned that automation reduces errors and saves time. Another company reduced costs by using automation. Here are some key points from these cases:

- Increased Efficiency: Companies finished jobs quickly.

- Better Quality: Products were made with higher precision.

- Cost Savings: Less waste meant more profits.

What are the benefits of benchtop lathe automation?

The main benefits are faster production, lower costs, and better quality products. Automation helps companies work smarter and achieve more.

The Future of Benchtop Metal Lathes and Automation

Emerging trends in automation technologies. Predictions for the future of benchtop lathes in the industry.The world of benchtop metal lathes is gearing up for some exciting changes! New automation technologies are popping up everywhere. These advancements could make our lathes smarter and more efficient. Imagine a lathe that finishes your project while you grab a snack. Predicting the future, experts believe we might see lathes that not only work faster but also require less human help. This could mean fewer coffee breaks for operators and more time for fun! Here’s a glance at some trends:

| Trend | Description |

|---|---|

| AI Integration | Smart lathes that learn from past jobs. |

| Remote Monitoring | Check on your lathe from the couch! |

| Energy Efficiency | Save power, save money! |

So, buckle up! The future looks bright for benchtop metal lathes, with robots and smart tech taking the stage!

Conclusion

In summary, benchtop metal lathe automation can make your projects easier and more precise. It saves time and helps you create better parts. By understanding the basics of automation, you can improve your skills. Consider exploring tutorials or guides online to start automating your lathe today. With practice, you’ll see great results and enjoy your work even more!FAQs

Here Are Five Related Questions On The Topic Of Benchtop Metal Lathe Automation:Sure! A benchtop metal lathe is a machine that helps us shape metal into different parts. Automation means using machines or computers to do tasks without much help from people. By automating a lathe, we make it faster and easier to create parts. This means we can spend less time working and more time making cool things. It also helps us make lots of parts that are all the same.

Sure! Please provide the question you would like me to answer.

What Are The Key Benefits Of Automating A Benchtop Metal Lathe Compared To Manual Operation?Automating a benchtop metal lathe helps us work faster and more accurately. It does the hard part for us, so we don’t get tired. We can also make the same parts over and over without making mistakes. Plus, it’s safer because machines can help keep our hands away from sharp tools. Overall, it’s just easier and more fun!

What Types Of Sensors And Software Are Commonly Used In The Automation Of Benchtop Metal Lathes?In automated benchtop metal lathes, we use sensors to help machines work better. We often use temperature sensors to check how hot things get. But we also have position sensors that tell the machine where the tools are. The software helps control the machine and keep everything running smoothly. This way, machines can make parts accurately without us watching all the time.

How Can Cnc (Computer Numerical Control) Technology Be Integrated Into A Benchtop Metal Lathe For Improved Automation?You can add CNC technology to a small metal lathe to make it work automatically. First, you need a computer that sends commands to the lathe. Then, you can use special software to create designs. Finally, the lathe will follow these designs, cutting metal perfectly. This makes it faster and helps you make pieces just right!

What Safety Considerations Should Be Taken Into Account When Automating A Benchtop Metal Lathe?When automating a benchtop metal lathe, we need to think about safety first. Make sure to wear eye protection to keep your eyes safe from flying pieces. You should also keep your hands away from the moving parts to avoid getting hurt. It’s important to have emergency stop buttons that you can reach easily. Lastly, make sure the area is clean so that there are no tripping hazards.

What Are The Cost Implications And Return On Investment (Roi) For Automating A Benchtop Metal Lathe In A Small Workshop Setting?If you automate a benchtop metal lathe, you might spend money on the machine and software first. However, automation can save you time and help you make more parts faster. This means you can earn more money because you’re working smarter. Over time, the money you save and earn back can be more than what you spent. This is called return on investment or ROI.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Benchtop Metal Lathe Automation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A benchtop metal lathe is a machine that helps us shape metal into different parts. Automation means using machines or computers to do tasks without much help from people. By automating a lathe, we make it faster and easier to create parts. This means we can spend less time working and more time making cool things. It also helps us make lots of parts that are all the same.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Benefits Of Automating A Benchtop Metal Lathe Compared To Manual Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automating a benchtop metal lathe helps us work faster and more accurately. It does the hard part for us, so we don’t get tired. We can also make the same parts over and over without making mistakes. Plus, it’s safer because machines can help keep our hands away from sharp tools. Overall, it’s just easier and more fun!”}},{“@type”: “Question”,”name”: “What Types Of Sensors And Software Are Commonly Used In The Automation Of Benchtop Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In automated benchtop metal lathes, we use sensors to help machines work better. We often use temperature sensors to check how hot things get. But we also have position sensors that tell the machine where the tools are. The software helps control the machine and keep everything running smoothly. This way, machines can make parts accurately without us watching all the time.”}},{“@type”: “Question”,”name”: “How Can Cnc (Computer Numerical Control) Technology Be Integrated Into A Benchtop Metal Lathe For Improved Automation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can add CNC technology to a small metal lathe to make it work automatically. First, you need a computer that sends commands to the lathe. Then, you can use special software to create designs. Finally, the lathe will follow these designs, cutting metal perfectly. This makes it faster and helps you make pieces just right!”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Be Taken Into Account When Automating A Benchtop Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When automating a benchtop metal lathe, we need to think about safety first. Make sure to wear eye protection to keep your eyes safe from flying pieces. You should also keep your hands away from the moving parts to avoid getting hurt. It’s important to have emergency stop buttons that you can reach easily. Lastly, make sure the area is clean so that there are no tripping hazards.”}},{“@type”: “Question”,”name”: “What Are The Cost Implications And Return On Investment (Roi) For Automating A Benchtop Metal Lathe In A Small Workshop Setting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you automate a benchtop metal lathe, you might spend money on the machine and software first. However, automation can save you time and help you make more parts faster. This means you can earn more money because you’re working smarter. Over time, the money you save and earn back can be more than what you spent. This is called return on investment or ROI.”}}]}