Have you ever wondered how metal parts are made? It’s pretty neat! A benchtop metal lathe bench is a fantastic tool for crafting metal pieces. Imagine creating small gears, tools, or even art just from a chunk of metal!

Many people think lathes are big and complicated machines. But a benchtop metal lathe is compact and easy to use. You can set it up right on your workbench. This means anyone can start turning metal into something amazing. Isn’t that cool?

What if you could make that special project you’ve been dreaming about? With a benchtop metal lathe, you can turn your ideas into reality. Plus, it’s fun to see your creations come to life!

In this article, we’ll explore the world of benchtop metal lathes. We’ll look at how they work and what you can make with them. Get ready to dive into a world of creativity!

Benchtop Metal Lathe Bench: Your Essential Tool Guide

Discovering the Benchtop Metal Lathe Bench

Are you curious about creating precise metal projects at home? A benchtop metal lathe bench is your answer! This handy tool is small yet powerful, perfect for hobbyists and DIYers. It allows you to shape metal into desired forms with ease. Fun fact: many professionals started with a bench lathe in their basement! With the right techniques, you can transform raw metal into beautiful items. Get ready to unleash your creativity!Understanding Benchtop Metal Lathes

Definition and function of a benchtop metal lathe. Advantages of using a benchtop model over floorstanding lathes.A benchtop metal lathe is a small machine used for shaping metal. It spins a piece of metal while a tool cuts it into the desired shape. This makes it perfect for making screws, bolts, and other small parts.

Using a benchtop model has many benefits:

- It takes up less space than larger lathes.

- It’s usually more affordable.

- It’s easier to move around.

This compact design lets hobbyists and professionals create parts without needing a large workshop. With a benchtop lathe, you can work efficiently and comfortably.

What are the advantages of a benchtop metal lathe?

Benchtop metal lathes are compact, affordable, and portable. They fit in small spaces and can be moved easily, making them ideal for home workshops.

Key Features to Consider

Motor power and speed variations. Weight and stability factors for bench placement.Finding the right features can make a big difference. Motor power is important for how fast and strong the lathe can work. More power means it can handle tough materials easily. Next, think about how much the lathe weighs. A heavy lathe is stable and won’t move around while you work. This gives you better control and results.

What is the best motor power for a benchtop metal lathe?

A motor power of at least 1 HP is ideal for most tasks.Here are some points to remember:

- Choose a motor with adjustable speeds.

- Heavier lathes are harder to move but provide stability.

- Look for good weight distribution for balance.

Types of Benchtop Metal Lathes

Manual vs. CNC benchtop lathes. Specialty lathes for specific projects.There are two main types of benchtop metal lathes: manual and CNC. Manual lathes are great for hands-on work. They let users turn knobs and make adjustments directly. On the other hand, CNC lathes use a computer to control the machine. This means they can produce items quickly and accurately.

Specialty lathes focus on specific projects. These machines are designed for tasks like jewelry making or making parts for machines. They can handle unique shapes and materials. Choosing the right type of lathe makes a big difference in your project success.

What are the benefits of manual and CNC lathes?

Manual lathes offer hands-on control, while CNC lathes provide speed and precision.Quick Comparison:

- Manual Lathes: Affordable, good for learning, hands-on.

- CNC Lathes: Fast, precise, great for complex designs.

- Specialty Lathes: Tailored for specific tasks like jewelry or mechanical parts.

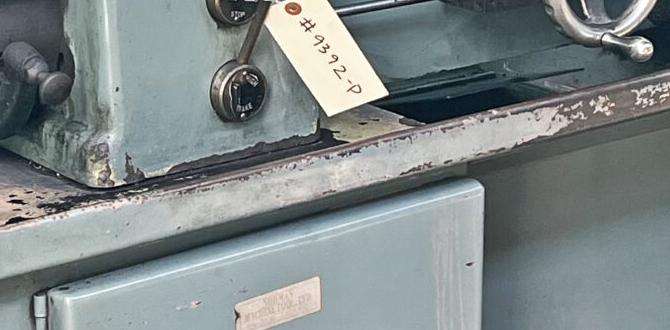

Top Brands and Models in the Market

Comparison of popular brands. Review of highlyrated models and their specifications.Choosing a benchtop metal lathe can feel like picking a favorite ice cream flavor. So many options! Some popular brands really shine. For example, Grizzly and Jet are top choices. They offer great quality and features. Let’s dive into a simple comparison of their best models:

| Brand | Model | Specifications | Rating |

|---|---|---|---|

| Grizzly | G8688 | 7×12 inches, 1 HP | 4.5/5 |

| Jet | JWL-1442 | 14×42 inches, 1 HP | 4.7/5 |

| Mini-Lathe | WEN 3420 | 10 inches, Variable speed | 4.3/5 |

These machines are not only reliable but also fun to use. Whether you want to make tiny parts or impressive projects, there’s a model for you! Remember, it’s like finding your perfect chair. Comfort matters!

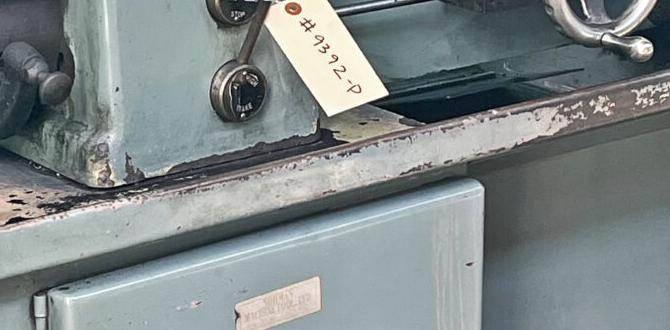

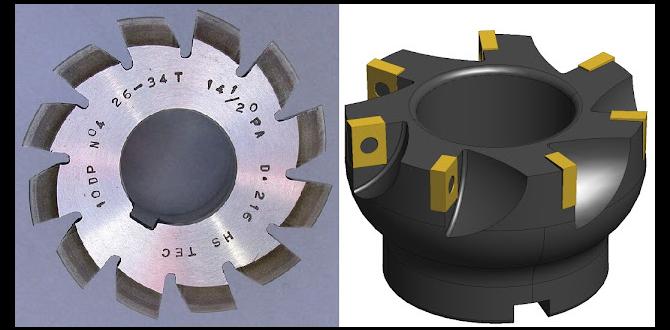

Essential Accessories and Tools

List of necessary tools for effective lathe operation. Recommended accessories for enhanced functionality.For smooth lathe operations, having the right tools is key. Essential tools make work easier and safer. Here are some necessary items for a benchtop metal lathe bench:

- Cutting Tools

- Measuring Tools

- Tool Holders

- Chucks

- Bed and Cross Slide Lubricants

To enhance your setup, consider these accessories:

- Digital Calipers

- Wrenches

- Face Shield

- Safety Gloves

With these tools and accessories, your lathe work will be more efficient and enjoyable!

What accessories improve lathe performance?

Digital calipers and safety gear are excellent accessories. They help measure accurately and keep you safe while working. Good accessories make every project easier!

Maintenance Tips for Longevity

Routine maintenance practices. Troubleshooting common issues.Keeping your lathe in top shape is easier than you think! Regularly check oil levels and clean the machine to avoid dust bunnies turning into pesky gremlins. If you hear strange noises, it might be time for some TLC or a quick peek under the hood. Below is a handy table to help you remember essential care tips:

| Task | Frequency | Notes |

|---|---|---|

| Clean the lathe | After each use | Goodbye, dust! |

| Check oil levels | Weekly | Lubricate for smooth sailing! |

| Tighten loose parts | Monthly | Keep things snug! |

Don’t worry about minor hiccups. If the lathe isn’t spinning right, simply double-check the power supply or settings. After all, even machines have them off days! Keeping it clean and tuned can make your benchtop metal lathe bench last for years. Like a good joke, it needs the right setup and timing!

Safety Precautions When Using a Benchtop Lathe

Importance of personal protective equipment (PPE). Best practices for safe operation.Using a benchtop lathe can be safe if you follow the right steps. Personal protective equipment (PPE) is essential. Always wear goggles, gloves, and ear protection to keep yourself safe. Here are some best practices:

- Always check the equipment before use.

- Keep your hands away from moving parts.

- Follow the machine’s instructions carefully.

- Never work alone. Have someone nearby for help.

Stay focused. Avoid distractions while working. This way, you can enjoy creating things safely!

What is personal protective equipment (PPE) for lathe use?

PPE includes safety goggles, gloves, and earplugs. These items protect against flying debris and loud noises while you work.

Projects You Can Undertake with a Benchtop Metal Lathe

Ideas for beginners to advanced users. Stepbystep guides for popular projects.A benchtop metal lathe opens doors to many fun and useful projects. Beginners can start with simple tasks like making spacers or knobs. Once you gain confidence, try creating custom tools or designing unique metal sculptures. Advanced users might enjoy making precision parts for machines or building tiny engines. Here are some fun ideas for your next project:

- Create a simple tool holder.

- Make intricate jewelry pieces.

- Design functional machine parts.

- Craft decorative items for your home.

Each project builds skills. They also let you enjoy working with your hands and sparks creativity!

What are beginner projects for a benchtop metal lathe?

Beginner projects include making basic shapes, like knobs or spacers. You can also create simple tools and small decorative pieces.

How do I start a project with a benchtop metal lathe?

Start by choosing a simple project. Next, gather materials and follow step-by-step guides for best results.

Cost Considerations and Budgeting

Average price ranges and what influences cost. Tips for finding the best deals and financing options.Buying a benchtop metal lathe bench can cost between $500 and $3,000. The price mostly depends on size and features. For lower rates, shop during sales or online. Consider used options to save money. Be wary of cheap deals; quality matters too. If you need help with costs, look into financing plans that can spread out payments over time.

What affects the cost of a benchtop metal lathe bench?

Size, brand, and features play a big role in the cost. Higher quality tools usually cost more. Research different options to find what fits your needs best.

Tips for Finding the Best Deals:

- Check online marketplaces.

- Look for seasonal sales.

- Consider refurbished units.

Community and Resources for Benchtop Lathe Enthusiasts

Online forums and support groups. Recommended books and tutorials for further learning.Find a world of help in online forums and support groups. These spaces offer advice and share tips about using a benchtop metal lathe. Many enthusiasts gather here to chat and exchange ideas. You can ask questions and find answers with just a few clicks.

Books and tutorials are great for learning more. They can give you new skills and techniques. Check out these recommendations:

- “Lathe Work: A Home Workshop Guide” – Great for beginners.

- “The Metal Lathe” – A detailed guide written for all levels.

- Online video tutorials – Perfect for visual learners.

What are some good online resources for lathe enthusiasts?

Visit forums like Reddit or specific machining sites for helpful tips and support.Connecting with a community makes learning easy and fun. These resources will not only improve your skills but also inspire you to create amazing projects.

Conclusion

In conclusion, a benchtop metal lathe is a great tool for metalworking. It’s compact, affordable, and perfect for small projects. You can create precise parts easily. If you’re interested, start by researching different brands and features. Consider your space and needs before buying. Get ready to explore the fascinating world of metalworking! Enjoy your next project!FAQs

What Are The Essential Features To Look For When Purchasing A Benchtop Metal Lathe For Home Use?When buying a benchtop metal lathe, look for a strong motor. A good motor helps you spin metal easily. Check the size, too. You want it to fit in your workspace. Also, make sure it has easy controls. This helps you use it safely and correctly.

How Does A Benchtop Metal Lathe Differ From A Larger Industrial Lathe In Terms Of Capabilities And Applications?A benchtop metal lathe is smaller and good for simple projects. You can use it for hobby work, like making parts for models. A larger industrial lathe can handle big jobs and works on heavy materials. It’s used in factories for making many parts quickly. So, the smaller lathe is for home use, while the bigger one is for big businesses.

What Types Of Materials Are Best Suited For Machining With A Benchtop Metal Lathe?For a benchtop metal lathe, you should use materials like aluminum, brass, and mild steel. These metals are easy to shape and cut. They also hold their form well. Avoid hard materials like stainless steel or very hard metals, as they can be tough to work with.

What Safety Precautions Should Be Taken When Operating A Benchtop Metal Lathe?When using a benchtop metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothing to avoid accidents. Never reach into the machine while it’s running. Make sure the lathe is on a stable surface and check that all tools are in good condition. Always pay close attention to what you are doing and ask for help if you’re unsure.

How Can You Effectively Maintain And Clean A Benchtop Metal Lathe To Ensure Its Longevity And Performance?To keep your metal lathe working well, start by cleaning it regularly. Use a soft cloth to wipe off dust and metal shavings. Check the oil levels and add oil to the moving parts to keep everything running smoothly. Tighten any loose screws or parts to avoid problems. Finally, cover your lathe when you’re not using it to protect it from dirt and damage.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Features To Look For When Purchasing A Benchtop Metal Lathe For Home Use? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When buying a benchtop metal lathe, look for a strong motor. A good motor helps you spin metal easily. Check the size, too. You want it to fit in your workspace. Also, make sure it has easy controls. This helps you use it safely and correctly.”}},{“@type”: “Question”,”name”: “How Does A Benchtop Metal Lathe Differ From A Larger Industrial Lathe In Terms Of Capabilities And Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A benchtop metal lathe is smaller and good for simple projects. You can use it for hobby work, like making parts for models. A larger industrial lathe can handle big jobs and works on heavy materials. It’s used in factories for making many parts quickly. So, the smaller lathe is for home use, while the bigger one is for big businesses.”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Best Suited For Machining With A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a benchtop metal lathe, you should use materials like aluminum, brass, and mild steel. These metals are easy to shape and cut. They also hold their form well. Avoid hard materials like stainless steel or very hard metals, as they can be tough to work with.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a benchtop metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothing to avoid accidents. Never reach into the machine while it’s running. Make sure the lathe is on a stable surface and check that all tools are in good condition. Always pay close attention to what you are doing and ask for help if you’re unsure.”}},{“@type”: “Question”,”name”: “How Can You Effectively Maintain And Clean A Benchtop Metal Lathe To Ensure Its Longevity And Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe working well, start by cleaning it regularly. Use a soft cloth to wipe off dust and metal shavings. Check the oil levels and add oil to the moving parts to keep everything running smoothly. Tighten any loose screws or parts to avoid problems. Finally, cover your lathe when you’re not using it to protect it from dirt and damage.”}}]}