Have you ever watched a skilled craftsman create something amazing on a metal lathe? The precision they achieve is truly impressive. Many hobbyists and professionals use a benchtop metal lathe with a digital readout (DRO) to make their projects easier and more accurate.

Imagine turning a rough piece of metal into a sleek, shiny part. With a benchtop metal lathe DRO, this can be done with great ease. This tool shows exactly where the tool is on the metal. Wouldn’t it be cool to see all the measurements on a screen? It takes the guesswork out of metalworking!

Fun fact: Did you know that using a DRO can cut your working time in half? That’s right! By adding this technology to your lathe, you can make everything quicker and more precise.

In this article, we will explore why a benchtop metal lathe DRO is a game changer. Whether you are a beginner or an expert, this tool can improve your work. Are you ready to learn more and take your crafting skills to the next level?

Benchtop Metal Lathe Dro: Enhance Precision And Efficiency

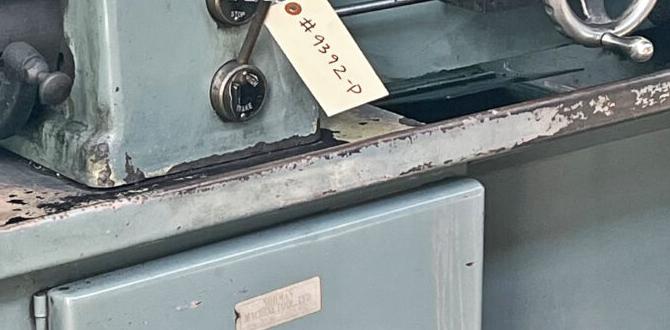

Benchtop Metal Lathe DRO

A benchtop metal lathe with a Digital Readout (DRO) makes precise machining easier. Imagine a tool that tells you exactly where your cutting tool is! With a DRO, you can see measurements clearly, preventing mistakes. This feature is perfect for hobbyists and professionals alike. Did you know that using a DRO can save time and material? As you explore this equipment, think about how it can enhance your projects and craft work effectively.What is a Benchtop Metal Lathe DRO?

Definition and components of Digital Readout (DRO). Importance of DRO in metalworking applications.A benchtop metal lathe DRO is a handy tool that helps machinists measure things accurately. It features a Digital Readout (DRO) which shows precise measurements on a screen. The main parts include sensors, a display, and a control box. This setup is super important in metalworking. It can save time and reduce mistakes, plus it makes you look like a professional! Who knew math could be this cool?

| Component | Function |

|---|---|

| Sensors | Track movement and distance |

| Display | Shows measurements |

| Control Box | Processes data from sensors |

With a DRO, you can work faster and smarter. It’s like having a calculator that doesn’t judge you for rounding up!

Benefits of Using a DRO on a Benchtop Metal Lathe

Enhanced precision and accuracy. Increased efficiency in machining tasks.Using a digital readout (DRO) on your benchtop metal lathe is like giving it a superpower! It improves precision and accuracy, making sure your measurements are spot on. No more guessing games! Everything lines up, and each cut is exactly what you need.

Plus, a DRO helps you work faster. It saves time by showing measurements quickly, boosting your efficiency in machining tasks. Imagine finishing your projects with extra time to enjoy a snack or play with your favorite toy! Now that’s a win-win!

| Benefit | Description |

|---|---|

| Precision | Every detail is measured accurately, leading to better cuts. |

| Efficiency | Work faster and smarter, leaving time for snacks! |

Key Features to Look for in a Benchtop Metal Lathe DRO

Display quality and size. Measurement range and resolution.Choosing the right benchtop metal lathe dro can make a big difference. First, look at the display quality and size. A bright and clear display helps you see measurements easily. Next, check the measurement range and resolution. A wider range lets you work on different projects. Higher resolution gives better accuracy. Here are key points to consider:

- Display quality: High-resolution screen is best.

- Display size: Larger screens are easier to read.

- Measurement range: Wider options are more flexible.

- Resolution: More precise numbers help reduce errors.

What to check before buying?

Before making a decision, check the display size and quality. **A larger, clearer screen is easier to use.** Also, look for precise measurement options. **Wider measurement ranges allow for more project choices.**

Installation Process for Benchtop Metal Lathe DRO

Stepbystep guide to installation. Common challenges and troubleshooting tips.Installing a benchtop metal lathe dro can be simple with the right steps. First, gather all tools and parts. Second, follow the manual carefully. If you hit a snag, here are some common challenges:

- Misalignment of parts.

- Incorrect wiring connections.

- Software not updating.

For troubleshooting, check your connections and ensure everything is secure. Test each function after installation. Stay patient, and you’ll get it right!

What should I do if the DRO is not working?

If the DRO is not functioning, check the power supply and connections. Make sure all wires are securely attached. Restart the machine and see if the problem persists.

Calibration and Maintenance of DRO

Importance of regular calibration. Maintenance tips to prolong the DRO lifespan.Keeping your DRO accurate is as important as keeping your lunch away from a hungry friend. Regular calibration ensures your measurements are spot on, which means fewer surprises when you hit that “go” button. Here are some maintenance tips:

| Tip | Description |

|---|---|

| Clean Regularly | Dust and dirt can mess with precision. A gentle wipe keeps things smooth. |

| Check Connections | Loose wires can cause chaos. Make sure everything is snug as a bug! |

| Store Properly | Keep your DRO out of the rain and heavy machinery zones, unless you like surprises! |

By paying attention to these details, you’ll help your DRO live long and prosper, just like a wise old Yoda.

Top Benchtop Metal Lathe DRO Models on the Market

Review of leading models and brands. Pros and cons of each model.Many models of benchtop metal lathe DRO are popular today. Here are some top ones:

- Model A: Great for beginners. It is easy to use but less accurate.

- Model B: Offers advanced features. It is precise but can be expensive.

- Model C: Lightweight and portable. It is simple but lacks some advanced options.

Choosing the right model depends on your needs. Some focus on ease of use, while others offer more accuracy. Consider what you want before buying.

What should I consider when choosing a benchtop metal lathe DRO?

Think about your budget, skill level, and features needed. This helps you find the best model for your tasks.

Cost Considerations for Benchtop Metal Lathe DROs

Budgeting for purchase and installation. Assessing longterm value vs initial investment.Buying a benchtop metal lathe DRO can feel like diving into a piggy bank without knowing how deep it goes. First, set a budget for purchase and installation. Keep in mind that sometimes the shiny tools cost a little extra but can save you dough later on. Think of it as investing in a really cool robot that helps you work faster! Long-term value is key; some machines may be cheaper at first but turn out to be more trouble than your little brother. Below is a table to help you weigh your options:

| Cost Factor | Short-Term | Long-Term |

|---|---|---|

| Purchase Price | Low upfront cost | Potential for repair costs |

| Installation | Quick setup | More time needed for complicated models |

| Durability | May break easily | Lasts longer and saves money |

So, remember: Wise spending today means more fun with your tools tomorrow!

Case Studies and User Experiences

Reallife examples of DRO impact on machining work. Testimonials from experienced lathe users.Many lathe users have shared their positive experiences with a DRO. They found that it makes their work easier and more accurate. Here are some real-life examples:

- One user increased their work speed by 30%, thanks to the precise measurements.

- Another shared how they reduced mistakes by 50%, leading to less wasted material.

- A beginner felt more confident using a lathe after installing a DRO.

These stories show how effective a benchtop metal lathe DRO can be. It truly helps machinists improve their skills and results.

What do users say about DROs?

Many users agree that the DRO helps in getting better results. It simplifies the measuring process. Users also feel it makes their work more fun!

Conclusion

In conclusion, a benchtop metal lathe DRO enhances accuracy and efficiency in machining. It helps you measure and cut precisely. Understanding its features empowers you to choose the right one for your projects. We encourage you to explore different models and read reviews to find the perfect fit for your needs. Start improving your metalworking skills today!FAQs

Sure! Here Are Five Questions Related To Benchtop Metal Lathe Digital Readouts (Dro):Digital readouts, or DROs, help you see measurements on a metal lathe. They show how far you move the tools. This makes it easier to make exact cuts. You can read the numbers quickly without guessing. Using a DRO can help you make your projects better.

Sure! Please ask your question, and I’ll be happy to help you with a short answer.

What Are The Key Features To Look For When Selecting A Digital Readout System For A Benchtop Metal Lathe?When choosing a digital readout system for a benchtop metal lathe, look for a clear display. You want to see numbers easily. Check if it has easy-to-use buttons. It’s helpful if the system can store measurements too. Finally, make sure it fits your lathe properly.

How Does Installing A Dro On A Benchtop Lathe Improve Precision And Efficiency In Metalworking?Installing a Digital Readout (DRO) on a benchtop lathe helps you measure more accurately. You can see exact numbers on the screen, so you make better cuts. This means your metal parts fit together perfectly. It also saves time because you don’t have to measure again and again. With a DRO, we work faster and smarter!

What Are The Pros And Cons Of Different Types Of Digital Readout Systems Available For Benchtop Lathes?Digital readout systems help you see measurements clearly on benchtop lathes. One type is glass scale systems. They are very accurate, but can be pricey. Another type is encoders, which are often cheaper, but may not be as precise. You should pick one based on your needs and budget!

Can A Digital Readout Be Retrofitted To Older Models Of Benchtop Lathes, And What Considerations Should Be Taken Into Account?Yes, you can add a digital readout to older benchtop lathes. First, check if your lathe has space for the new parts. You also need to figure out how to attach the sensors safely. Lastly, make sure it works well with your machine to avoid any problems.

How Do You Calibrate And Maintain A Digital Readout For Optimal Performance On A Benchtop Metal Lathe?To calibrate your digital readout, first, check that it’s securely attached to the lathe. Then, move the tool to a known measurement and see if the readout shows the same number. If it doesn’t, you can adjust it until it matches. For maintenance, keep the display clean and check the connections regularly. Make sure you replace batteries if your readout uses them.