Imagine a workshop where creativity meets precision. A benchtop metal lathe tailstock plays a key role in this setting. Have you ever wondered how craftsmen create beautiful metal projects? The tailstock of a lathe is vital for keeping workpieces steady while cutting. Wouldn’t it be exciting to learn how this simple piece of equipment can produce amazing results?

Many people picture large machines when they think of lathes. But, a benchtop model is compact yet powerful. It fits snugly in most workshops. You can easily work on small or intricate designs with this handy tool. In fact, it often surprises beginners how much they can achieve! Did you know that a well-adjusted tailstock can make a big difference in accuracy? It’s true!

In this article, we’ll explore the world of benchtop metal lathe tailstocks. We’ll explain how they work and why they’re so important. Whether you’re a beginner or more experienced, you’ll find useful tips to improve your skills. Let’s dive in!

Benchtop Metal Lathe Tailstock: Key Features And Uses

Understanding the Benchtop Metal Lathe Tailstock

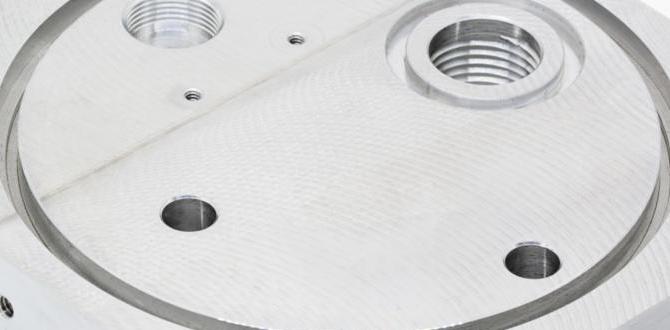

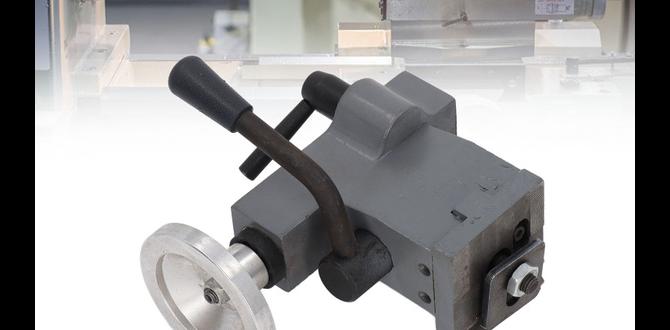

The tailstock of a benchtop metal lathe is key for precision work. It supports the end of the workpiece and holds tools like drills or live centers. This amazing feature helps create smooth and accurate cuts. Did you know that a sturdy tailstock can improve your project’s quality? Imagine finishing a beautiful metal piece without errors! Learning about this tool opens doors to better craftsmanship and greater creativity in metalworking.What is a Benchtop Metal Lathe Tailstock?

Definition and function. Importance in metalworking processes.A benchtop metal lathe tailstock is a key part of a lathe. It holds tools and helps shape metal. Think of it as the sidekick to the main tool. This little buddy plays a big role in keeping everything steady. It helps you make precise cuts, just like a pro chef slices vegetables. Without this tailstock, your projects could end up looking a bit crooked. So, it’s important for smooth metalworking. In fact, using a tailstock can improve accuracy by up to 40%!

| Function | Importance |

|---|---|

| Holds tools | Enhances accuracy |

| Supports metal pieces | Ensures steady cutting |

Key Features of a Benchtop Metal Lathe Tailstock

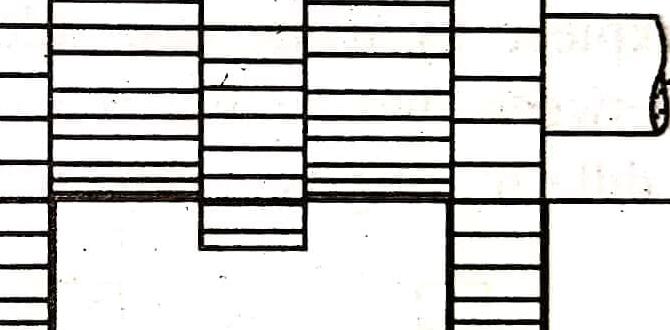

Material and construction quality. Types of tailstocks and their mechanisms.A tailstock is a key part of a benchtop metal lathe. It helps hold the workpiece steady. Good quality materials make for strong tailstocks. Common materials include cast iron and steel. Both are tough and can handle heavy work. There are different types of tailstocks, such as fixed and sliding. A fixed tailstock stays in one place, while a sliding tailstock can move. Each type has its own mechanism for adjusting and locking. This makes working with different sizes of materials easy.

What should I look for in a benchtop metal lathe tailstock?

Look for the build quality and the type of tailstock you need. A good tailstock should be durable, easy to adjust, and stable during use.

How to Use a Benchtop Metal Lathe Tailstock Effectively

Stepbystep usage guide. Common techniques for precision work.Using a benchtop metal lathe tailstock can be easy and fun. Follow these simple steps for best results:

- First, adjust the tailstock to fit your workpiece.

- Next, lock it in place securely.

- Then, align the tailstock with the lathe center.

- Finally, apply steady pressure while turning the lathe.

For precision work, keep the following tips in mind:

- Always check for tightness.

- Use the right tools for measuring.

- Take your time for better results.

With practice, you’ll master the art of using a tailstock efficiently.

How do you set up a tailstock on a metal lathe?

To set up a tailstock, slide it along the bed to the desired spot, then lock it in place using the handwheel.

What is the purpose of the tailstock in a lathe?

The tailstock supports the far end of a workpiece. It helps provide stability for better cutting.

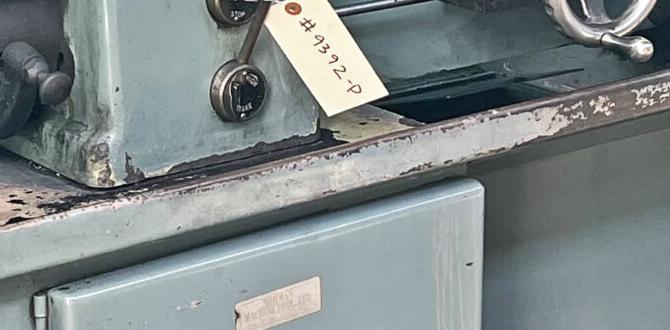

Maintaining Your Benchtop Metal Lathe Tailstock

Routine maintenance practices. Troubleshooting common issues.Taking care of your benchtop metal lathe tailstock is like giving your car a tune-up. Routine checks can keep it running smoothly! First, always clean the tailstock to remove dust and metal shavings. A soft cloth or brush works wonders. If it starts to feel loose, check the alignment. Remember, a crooked tailstock is as helpful as a screen door on a submarine! Common issues include sticky movement or leveling problems. If things get tricky, don’t fret; adjust the gib screws or re-lubricate. A little love goes a long way in keeping your lathe in top shape!

| Common Issues | Fixes |

|---|---|

| Sticky movement | Lubricate and clean |

| Misalignment | Adjust gib screws |

Choosing the Right Tailstock for Your Benchtop Metal Lathe

Factors to consider when selecting a tailstock. Comparison of popular tailstocks in the market.Picking the best tailstock for your benchtop metal lathe is important. Consider these factors:

- Size: Make sure it fits your lathe well.

- Material: Choose durable materials for long-lasting use.

- Features: Look for adjustable centers and smooth operation.

Popular tailstocks often feature different designs. Here are some options:

- MT2 Tailstock: Great for small lathes, easy to adjust.

- MT3 Tailstock: More robust, ideal for larger projects.

- Quick-release Tailstock: Saves time with easy adjustments.

What should I consider when choosing a tailstock?

Look for size, material, and features that match your lathe and projects.Upgrading Your Benchtop Metal Lathe Tailstock

Benefits of upgrading. Recommended upgrades for enhanced performance.Upgrading your benchtop metal lathe tailstock can bring many benefits. For example, it improves accuracy and stability. A better tailstock helps produce cleaner cuts and reduces time spent fixing mistakes. Recommended upgrades include:

- Stronger materials for durability

- Precision alignments for better performance

- Quick-release handles for easy adjustments

These upgrades enhance your lathe’s performance, making your projects easier and more enjoyable.

What are the benefits of upgrading a tailstock?

Upgrading a tailstock improves the quality of your work, boosts accuracy, and saves time. Better parts lead to fewer errors and smoother operation. This can make a big difference in your projects.

Common Mistakes to Avoid with Benchtop Metal Lathe Tailstocks

Typical errors novice users make. How to prevent these mistakes for better results.Using a benchtop metal lathe tailstock can be tricky for beginners. One common mistake is not tightening the tailstock firmly. If it’s loose, your work piece might wobble. No one likes a wobbly project! Another blunder is misaligning the tailstock. Always check that it’s in line with the lathe for precise cuts.

To avoid these mishaps, take your time. Always double-check settings and measurements. A little patience can save a lot of rework. Remember, it’s all about making great pieces, not just spinning metal!

| Error | How to Prevent |

|---|---|

| Loose tailstock | Tighten securely |

| Misaligned tailstock | Check alignment |

Real-Life Applications of Benchtop Metal Lathe Tailstocks

Examples of projects using tailstocks. Impact on overall project quality and efficiency.Benchtop metal lathe tailstocks are handy for many projects. They help hold long pieces of metal securely. Imagine trying to turn a pencil with one hand! You’ll end up with sharp bits flying everywhere. But with a tailstock, you can ensure your workpiece stays in place.

Common uses include making parts for machines, jewelry, and even toys. This tool can improve quality by ensuring smooth cuts and saving time. Less time fixing mistakes means more time for cake breaks, right? Here’s a table showing some fun projects:

| Project | Benefits |

|---|---|

| Machine Parts | High precision and durability |

| Jewelry Making | Creative designs with clean finishes |

| Toy Creation | Safe parts for all ages |

Using a tailstock can make your work easier and boost project quality. So next time you’re crafting, give your tailstock a big thumbs-up! It deserves all the credit.

Expert Tips for Mastering Your Benchtop Metal Lathe Tailstock

Insights from professional machinists. Advanced techniques for experienced users.Using a benchtop metal lathe tailstock can seem tricky, but fear not! Here are some wise tips from expert machinists that might tickle your fancy. Firstly, always ensure your tailstock is aligned correctly. Misalignment can make your project go haywire faster than a cat at a dog show! Secondly, leverage the tailstock for support when finishing long workpieces. This stability is the secret sauce for smooth results. With practice, you’ll master it like a pro – and soon, even your best friend will consider you a lathe genius!

| Tip | Details |

|---|---|

| Alignment | Make sure your tailstock is aligned for precision. |

| Support | Use the tailstock to support long materials. |

Conclusion

In summary, the benchtop metal lathe tailstock is crucial for accuracy and stability in metalworking projects. It helps you hold and position materials precisely. Understanding its function will improve your skills in using a lathe. We encourage you to explore more about lathes and practice your techniques. Happy machining, and keep learning about this exciting craft!FAQs

Sure! Here Are Five Related Questions About A Benchtop Metal Lathe Tailstock:Sure! A benchtop metal lathe tailstock is a part of a machine that helps hold and support the piece of metal you’re working on. It can slide along the lathe to help you make different shapes. You can also use it to drill holes in the metal. It’s important because it keeps everything steady while you work. Finally, cleaning it regularly helps make sure it works well!

Sure! Please provide the question you need me to answer.

What Are The Primary Functions Of A Tailstock In A Benchtop Metal Lathe?A tailstock is a part of a benchtop metal lathe. It helps hold tools or parts in place. You can use it to drill holes in metal. The tailstock also supports long pieces of metal, keeping them steady while you work. This makes your job easier and more accurate.

How Do You Properly Adjust The Tailstock For Different Workpiece Lengths On A Lathe?To adjust the tailstock on a lathe, first, loosen the tailstock clamp by turning the handle. Then, slide the tailstock along the lathe bed to match your workpiece’s length. Make sure it lines up with the center of your piece. Finally, tighten the clamp again to hold it in place. Now you’re ready to start working!

What Are The Advantages Of Using A Sliding Tailstock Versus A Fixed Tailstock In Metalworking Applications?A sliding tailstock can move back and forth. This helps you adjust it easily for different jobs. It also holds parts more securely when you work on them. With a sliding tailstock, you can work faster and make better stuff. It’s more flexible than a fixed tailstock, which stays in one place.

How Can You Ensure Precision Alignment Of The Tailstock With The Headstock On A Benchtop Lathe?To align the tailstock with the headstock on your lathe, start by checking both points. You can use a long straight rod or a piece of wood. Place it in the headstock and slide it to the tailstock. Look for gaps between the rod and the tailstock. If there are gaps, adjust the tailstock until it’s lined up perfectly. Always double-check before you start working.

What Accessories Can Enhance The Functionality Of A Tailstock In A Benchtop Metal Lathe Setup?You can add a few accessories to improve the tailstock on a benchtop metal lathe. A drill chuck helps you hold different drill bits securely. A live center spins and supports long pieces of metal while you work. Tool holders let you keep different tools handy for quick changes. These accessories make your lathe more useful and fun to work with!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About A Benchtop Metal Lathe Tailstock:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A benchtop metal lathe tailstock is a part of a machine that helps hold and support the piece of metal you’re working on. It can slide along the lathe to help you make different shapes. You can also use it to drill holes in the metal. It’s important because it keeps everything steady while you work. Finally, cleaning it regularly helps make sure it works well!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you need me to answer.”}},{“@type”: “Question”,”name”: “What Are The Primary Functions Of A Tailstock In A Benchtop Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A tailstock is a part of a benchtop metal lathe. It helps hold tools or parts in place. You can use it to drill holes in metal. The tailstock also supports long pieces of metal, keeping them steady while you work. This makes your job easier and more accurate.”}},{“@type”: “Question”,”name”: “How Do You Properly Adjust The Tailstock For Different Workpiece Lengths On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the tailstock on a lathe, first, loosen the tailstock clamp by turning the handle. Then, slide the tailstock along the lathe bed to match your workpiece’s length. Make sure it lines up with the center of your piece. Finally, tighten the clamp again to hold it in place. Now you’re ready to start working!”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Sliding Tailstock Versus A Fixed Tailstock In Metalworking Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A sliding tailstock can move back and forth. This helps you adjust it easily for different jobs. It also holds parts more securely when you work on them. With a sliding tailstock, you can work faster and make better stuff. It’s more flexible than a fixed tailstock, which stays in one place.”}},{“@type”: “Question”,”name”: “How Can You Ensure Precision Alignment Of The Tailstock With The Headstock On A Benchtop Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock with the headstock on your lathe, start by checking both points. You can use a long straight rod or a piece of wood. Place it in the headstock and slide it to the tailstock. Look for gaps between the rod and the tailstock. If there are gaps, adjust the tailstock until it’s lined up perfectly. Always double-check before you start working.”}},{“@type”: “Question”,”name”: “What Accessories Can Enhance The Functionality Of A Tailstock In A Benchtop Metal Lathe Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can add a few accessories to improve the tailstock on a benchtop metal lathe. A drill chuck helps you hold different drill bits securely. A live center spins and supports long pieces of metal while you work. Tool holders let you keep different tools handy for quick changes. These accessories make your lathe more useful and fun to work with!”}}]}