Have you ever thought about what it takes to enhance your metalworking skills? Upgrading your benchtop metal lathe might be the perfect start. These small machines can do wonders in a workshop.

Imagine transforming basic metal pieces into intricate designs. With a good upgrade, your crafts could shine like never before! It’s exciting to think about the possibilities.

Many folks don’t realize how a simple upgrade can change everything. A better lathe can make work faster and easier. Plus, it can help you achieve results that will amaze your friends.

In this article, we will explore the best ways to upgrade your benchtop metal lathe. Are you ready to take your metalworking to the next level? Let’s dive in and discover what’s possible!

Benchtop Metal Lathe Upgrade: Enhancing Your Workshop Performance

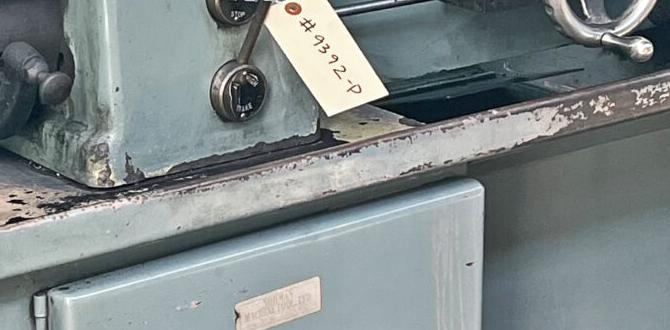

Benchtop Metal Lathe Upgrade

Upgrading your benchtop metal lathe can bring new life to your workshop. With better precision and more features, this upgrade makes metalworking easier and more enjoyable. Imagine cutting metal with smoothness you never thought possible! Even small upgrades, like new tooling and attachments, can significantly enhance your projects. Did you know a quality lathe can make parts with tolerances as tight as a hair? Embrace this exciting change in your crafting journey!Understanding Benchtop Metal Lathes

Definition and basic functionality of benchtop metal lathes. Common uses and applications in various industries.Metal lathes are clever machines that shape metal into useful items. A benchtop model is small, making it perfect for workshops. These lathes spin metal while tools grind, cut, and shape it. Think of them as magic wands for metalworkers!

Common uses include crafting parts for cars, planes, and even toys! They make everything from bolts to custom tools. With a benchtop lathe, creativity runs wild. Just remember: if it doesn’t work the first time, try not to throw a wrench at it!

| Use | Industry |

|---|---|

| Part production | Automotive |

| Custom tools | Aerospace |

| Toy making | Manufacturing |

In short, a benchtop metal lathe is a handy tool that opens up a world of possibilities. So, if you’re up for an upgrade, you’re in for a spin-tastic experience!

Benefits of Upgrading Your Benchtop Metal Lathe

Enhanced precision and accuracy in machining. Increased versatility with additional features.Upgrading your metal lathe can bring many benefits. First, you’ll notice improved precision and accuracy in your machining tasks. This means perfect cuts every time, almost like magic! Second, with added features, your lathe becomes more versatile. You can tackle various projects, from tiny screws to big parts. You’ll feel like a superhero in the workshop! Here’s a quick look at the perks:

| Benefit | Description |

|---|---|

| Enhanced Precision | Achieve exact measurements with upgraded tools. |

| Increased Versatility | Handle a wider range of tasks with new features. |

Key Components to Consider for Upgrades

Upgrading the motor for improved performance. Adding digital readouts and DRO systems for accuracy.Upgrading your metal lathe can be exciting, like giving your favorite toy a superpower! One critical upgrade is the motor; a stronger motor means faster turning and smoother work. Who doesn’t love speed? Adding digital readouts and DRO systems is another great idea. These nifty gadgets can make your measurements spot-on. Imagine crafting parts as precise as a wizard’s wand! Here’s a handy table to outline these upgrades:

| Component | Benefit |

|---|---|

| Motor Upgrade | Improved performance and speed |

| Digital Readouts & DRO | Enhanced accuracy and ease of use |

Popular Upgrades for Benchtop Metal Lathes

Tool post and chuck upgrades for better tool stability. Upgrading the carriage and crossslide mechanisms.Upgrading your benchtop metal lathe can make a world of difference! First, consider enhancing the tool post and chuck. This makes your tools more stable and reduces wobbles. No one wants a dance party when they’re trying to cut metal.

Next, let’s talk about the carriage and crossslide mechanisms. Upgrading these parts can help you achieve smoother operation and better precision. It’s like giving your lathe a nice, new set of roller skates!

| Upgrade Type | Benefit |

|---|---|

| Tool Post & Chuck | Better tool stability |

| Carriage & Crossslide | Smoother operation |

With these upgrades, you’ll cut like a pro and maybe even impress your neighbors. Who knew metalworking could be so fun?

How to Choose the Right Upgrades

Assessing your specific machining needs and goals. Comparing aftermarket options versus OEM upgrades.Choosing the right upgrades can feel like picking the best candy in a big jar—hard but fun! First, think about what you need. Are you aiming for speed, precision, or both? An upgrade should match your specific machining needs and goals. Next, consider whether to go with aftermarket options or stick with Original Equipment Manufacturer (OEM) upgrades. Sometimes, OEM parts fit just right, but aftermarket can be cheaper and offer cool features.

| Upgrade Type | Pros | Cons |

|---|---|---|

| OEM | Reliable, perfect fit | Usually more expensive |

| Aftermarket | Often cheaper, unique features | May not always fit perfectly |

In the end, think about what makes sense for your project. A wise choice today can save you headaches tomorrow. Remember, upgrades are like your favorite video game power-ups but for your lathe!

Step-by-Step Guide to Upgrading Your Lathe

Detailed instructions for popular upgrade installations. Safety precautions to follow during the upgrade process.Upgrading your lathe can feel like preparing for a math test—tricky but totally rewarding! Start by picking the right upgrades, like a better motor or improved tooling. Grab some safety goggles; they’ll keep you from looking like a raccoon after a late-night working spree. Always unplug the lathe before installing new parts—no one wants an unexpected dance with a spinning tool.Your fingers will thank you!

| Upgrade | Installation Steps | Safety Precautions |

|---|---|---|

| New Motor | 1. Disconnect power 2. Remove old motor 3. Install the new motor |

Wear safety gloves and goggles |

| Tooling | 1. Identify required tools 2. Replace tooling head 3. Calibrate settings |

Keep hair tied back and clear workspace |

With these steps and precautions, you’ll have your lathe upgraded in no time—who knows, it might even help you become the next big metalworking wizard!

Maintenance Tips Post-Upgrade

Routine checks to ensure optimal performance of upgrades. Best practices for keeping your lathe in top condition.After upgrading your benchtop metal lathe, it’s important to keep it running well. Regular maintenance checks can make a big difference. Ensure to

- Inspect belts for wear

- Check for loose screws

- Clean the machine after use

- Lubricate moving parts

By following these simple practices, your lathe stays in top shape. It can help avoid future problems. Always remember, prevention is better than repair!

How often should I maintain my lathe?

Regular maintenance should be done at least every month for best results. This keeps your lathe safe and functioning smoothly.

Common Mistakes to Avoid During the Upgrade Process

Overlooking compatibility of parts with existing lathe. Ignoring manufacturer guidelines and specifications.Upgrading your benchtop metal lathe can be exciting, but don’t trip over common mistakes! First, always check if parts are compatible with your existing lathe. Buying a flashy piece that doesn’t fit is like wearing shoes two sizes too big—awkward and silly! Next, stick to the manufacturer’s guidelines. Ignoring these can turn your upgrade into an expensive puzzle with missing pieces. Remember, a smooth upgrade means less stress and more time to create cool projects!

| Common Mistakes | Why Avoid |

|---|---|

| Overlooking compatibility of parts | Can lead to wasted money and frustration |

| Ignoring manufacturer guidelines | Risk of damage and poor performance |

Real-Life Case Studies of Successful Upgrades

Examples of users who have successfully upgraded their benchtop lathes. Impact of upgrades on their machining capabilities and productivity.Many users have taken their benchtop lathes to the next level and seen amazing results. For instance, one hobbyist upgraded their tool with a powerful stepper motor. This change boosted their speed and precision. They reported making parts 50% faster! Another user added a digital readout system. Now, they can measure with the accuracy of a hawk. Their productivity soared and mistakes dropped significantly. Check out this table for more fun upgrades:

| User | Upgrade | Impact |

|---|---|---|

| Hobbyist A | Stepper Motor | 50% speed increase |

| Maker B | Digital Readout | Fewer mistakes |

| Craftsman C | Upgraded Tool Rest | Smoother cuts |

These stories show that with the right upgrades, you can turn a simple benchtop lathe into a productivity powerhouse. It’s like adding rocket fuel to your everyday work!

Future Trends in Benchtop Lathe Technology

Emerging technologies shaping the future of benchtop lathes. Predictions on advancements and upgrades in the industry.New tech is buzzing in the world of benchtop lathes! Smart sensors and advanced materials are set to change how we craft metal. These machines are getting more precise, faster, and easier to use. Imagine a lathe that could even tell you when it needs maintenance! Industry experts predict we’ll see upgrades that enhance safety and boost productivity. It’s like giving your old lathe a shiny new cape! Future makers, take note!

| Emerging Technology | Impact |

|---|---|

| Smart Sensors | Increase precision and track performance |

| Advanced Materials | Enhance durability and reduce wear |

| AI Integration | Predictive maintenance and efficiency |

Conclusion

In conclusion, upgrading your benchtop metal lathe can improve your projects significantly. You gain better accuracy, speed, and efficiency. Consider your needs and budget when choosing upgrades. Don’t forget to research various options and read user reviews for more insights. Ready to enhance your skills? Start exploring upgrade possibilities today and take your machining projects to the next level!FAQs

Sure! Here Are Five Related Questions On The Topic Of Benchtop Metal Lathe Upgrades:Sure! Upgrading your benchtop metal lathe can help you work better. You might want to add a new motor for more power. Changing the tool rest can help you make smoother cuts. Adding a better tailstock will make measuring easier. Lastly, improving the lighting will help you see your work clearly.

Sure! Please provide the question you would like me to answer.

What Are The Most Common Upgrades To Enhance The Precision And Accuracy Of A Benchtop Metal Lathe?To make a benchtop metal lathe more precise and accurate, you can add a digital readout. This shows exact measurements. You can also upgrade the tailstock for better support and less wobbling. High-quality cutting tools can improve how smooth the cuts are. Lastly, a better tool holder can help keep everything steady while you work.

How Can Upgrading The Motor Or Drive System Improve The Performance Of A Benchtop Metal Lathe?Upgrading the motor or drive system of a benchtop metal lathe makes it work better. A stronger motor can cut metal faster and more smoothly. It also helps the lathe run quietly and with less shaking. This means your projects can be done quicker and look nicer. Overall, it makes using the lathe easier and more fun!

What Accessories Or Add-Ons Should I Consider For Increasing The Versatility Of My Benchtop Metal Lathe?To make your benchtop metal lathe more useful, you can add a few accessories. A chuck helps hold different shaped materials tightly. Tool holders let you change tools quickly and easily. A steady rest keeps long pieces steady while you work on them. Lastly, a cleanup kit helps you keep everything tidy and safe.

How Can I Determine If My Benchtop Metal Lathe Requires An Upgrade Or If It Meets My Current Machining Needs?To see if your metal lathe needs an upgrade, think about what you make. If it often struggles or takes too long, you might need a better machine. Check if it can handle the materials you’re using. If you find it hard to do new projects, an upgrade could help. Listen to your heart; if you’re not happy with it, it might be time to look for a new one.

What Safety Features Or Enhancements Should I Include When Upgrading My Benchtop Metal Lathe?When upgrading your benchtop metal lathe, you should add a good safety guard. This helps to keep your hands safe from moving parts. You can also include an emergency stop button. This button lets you quickly stop the machine if something goes wrong. Finally, use proper eye protection, like goggles, to keep your eyes safe from flying chips.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Benchtop Metal Lathe Upgrades:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Upgrading your benchtop metal lathe can help you work better. You might want to add a new motor for more power. Changing the tool rest can help you make smoother cuts. Adding a better tailstock will make measuring easier. Lastly, improving the lighting will help you see your work clearly.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Common Upgrades To Enhance The Precision And Accuracy Of A Benchtop Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a benchtop metal lathe more precise and accurate, you can add a digital readout. This shows exact measurements. You can also upgrade the tailstock for better support and less wobbling. High-quality cutting tools can improve how smooth the cuts are. Lastly, a better tool holder can help keep everything steady while you work.”}},{“@type”: “Question”,”name”: “How Can Upgrading The Motor Or Drive System Improve The Performance Of A Benchtop Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgrading the motor or drive system of a benchtop metal lathe makes it work better. A stronger motor can cut metal faster and more smoothly. It also helps the lathe run quietly and with less shaking. This means your projects can be done quicker and look nicer. Overall, it makes using the lathe easier and more fun!”}},{“@type”: “Question”,”name”: “What Accessories Or Add-Ons Should I Consider For Increasing The Versatility Of My Benchtop Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your benchtop metal lathe more useful, you can add a few accessories. A chuck helps hold different shaped materials tightly. Tool holders let you change tools quickly and easily. A steady rest keeps long pieces steady while you work on them. Lastly, a cleanup kit helps you keep everything tidy and safe.”}},{“@type”: “Question”,”name”: “How Can I Determine If My Benchtop Metal Lathe Requires An Upgrade Or If It Meets My Current Machining Needs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To see if your metal lathe needs an upgrade, think about what you make. If it often struggles or takes too long, you might need a better machine. Check if it can handle the materials you’re using. If you find it hard to do new projects, an upgrade could help. Listen to your heart; if you’re not happy with it, it might be time to look for a new one.”}},{“@type”: “Question”,”name”: “What Safety Features Or Enhancements Should I Include When Upgrading My Benchtop Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When upgrading your benchtop metal lathe, you should add a good safety guard. This helps to keep your hands safe from moving parts. You can also include an emergency stop button. This button lets you quickly stop the machine if something goes wrong. Finally, use proper eye protection, like goggles, to keep your eyes safe from flying chips.”}}]}