Discover The Best Milling Tools For Aluminum Projects

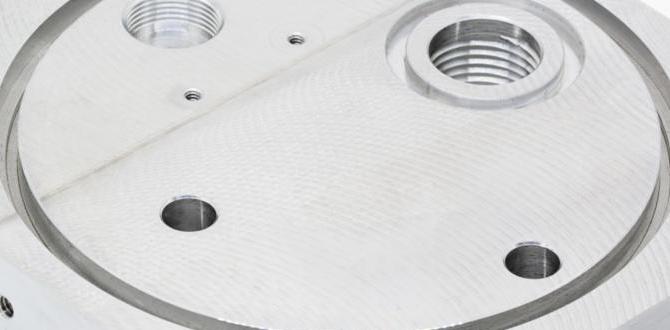

When milling aluminum, choosing the right tools is key for success. Special tools designed for aluminum, like high-speed steel end mills or carbide cutters, make a big difference. They can cut faster and provide smoother finishes. Did you know using the wrong tool can cause rough edges and damage? Finding the best milling tools helps achieve precision and saves time in your projects. Consider the material, cutting speed, and feed rate for optimal results!

Understanding Aluminum Milling

Explanation of aluminum properties and why milling is important.. Common applications of aluminum in various industries..

Aluminum is light and strong. This metal is easy to shape, which is why it’s perfect for milling. Milling helps make the aluminum smooth and ready for use in many products. You see aluminum in planes, cars, and even soda cans! It helps them be light yet tough. In fact, about 75% of all aluminum made is used in transportation! So, understanding aluminum milling is key to making great products.

| Industry | Common Applications |

|---|---|

| Aerospace | Aircraft components |

| Automotive | Lightweight car parts |

| Construction | Frames and windows |

| Consumer Goods | Kitchens and electronics |

Key Features to Look for in Milling Tools

Importance of tool material and coating for aluminum milling.. Cutting geometry and its impact on performance..

Choosing the right milling tools is key for working with aluminum. The tool’s material and coating matter a lot. Strong materials, like carbide, resist wear and tear. Coatings, such as titanium nitride, make cutting easier and last longer. Cutting geometry affects how well the tool cuts. Here are important aspects to consider:

- Material: Select durable options like carbide.

- Coating: Look for coatings that reduce friction.

- Geometry: A sharp angle helps in efficient cutting.

Why is tool material important?

The right tool material helps the tool last longer and work better.

Top Brands Offering Milling Tools for Aluminum

Brief description of leading manufacturers in the market.. Highlighting popular models and their unique features..

Many brands shine in the world of milling tools for aluminum. These companies make tools that stand out for quality and performance. Let’s check out a few stars in the game. First up is Haas Automation. They offer robust tools like the VM Series, great for precision work. Then there’s Sandvik Coromant, known for the CoroMill line, which is ideal for smooth finishes. Finally, Walter Tools features the versatile M4000, perfect for tough materials!

| Brand | Popular Model | Unique Feature |

|---|---|---|

| Haas Automation | VM Series | Precision milling |

| Sandvik Coromant | CoroMill | Smooth finishes |

| Walter Tools | M4000 | Versatile for tough materials |

Factors Influencing Tool Performance

Impact of cutting speed, feed rate, and depth of cut.. Discussion on tool wear and how to minimize it..

Several things affect how well milling tools work with aluminum. First, cutting speed matters. Fast speeds can make smoother cuts but can also cause overheating. Next, the feed rate is important—if it’s too high, you might break the tool, and if too low, it may drag. Then there’s depth of cut. A deeper cut can be efficient but may wear the tool out faster. Speaking of wear, keeping tools sharp is key! Regular maintenance can help you avoid scissors-hiding-in-your-children’s-drawers moments when you realize your tools are dull!

| Factor | Impact | Minimization Tips |

|---|---|---|

| Cutting Speed | Too high can cause wear | Monitor temperatures |

| Feed Rate | Too fast may break | Find the sweet spot |

| Depth of Cut | Deeper cuts mean more wear | Adjust based on material |

Best Practices for Milling Aluminum

Tips for effective machining of aluminum with the right tools.. Maintenance tips to prolong tool life and performance..

Milling aluminum is a fun task that can feel like a breeze with the right tools! First, choose sharp tools to avoid dull moments… literally! Using high-speed steel or carbide tools makes a big difference. Don’t forget to keep your workspace tidy. It’s like giving your tools a spa day! Regular maintenance is key—clean them often and check for wear. A little love goes a long way in making them last.

| Tip | Description |

|---|---|

| Use Sharp Tools | Sharp tools cut better and last longer. |

| Keep It Clean | A clean workspace helps tools work efficiently. |

| Regular Checks | Check tools for wear and replace as needed. |

Customer Reviews and Testimonials

Sharing user experiences and feedback on various milling tools.. Analyzing how customer satisfaction influences buying decisions..

Buying the right milling tool for aluminum can be tricky. Luckily, customer reviews can shine a bright light on this process. Users rave about tools that make their jobs easier and quicker. Some say, “This tool is like magic!” Others stress the importance of durability and precision. Happy customers often share tips, helping others make smart choices. One user even joked, “If only my lunch could be as smooth as my cuts!” Check out this quick table summarizing user feedback:

| Tool Name | Customer Rating | Highlights |

|---|---|---|

| AluminiMax | ⭐⭐⭐⭐⭐ | Fast cuts, lightweight |

| CutMaster Pro | ⭐⭐⭐⭐ | Sturdy, affordable |

| EdgeSharp Elite | ⭐⭐⭐⭐⭐ | Durable, super smooth |

Positive experiences not only boost excitement but also guide new customers. Remember, a happy tool user can be the best salesperson!

Conclusion

In conclusion, the best milling tools for aluminum include end mills, face mills, and drills. These tools help you create smooth and precise cuts. When choosing tools, consider factors like material and design. Always maintain your tools for best performance. Now, you can explore more about these tools to enhance your projects. Happy milling!

FAQs

What Are The Most Effective Types Of End Mills For Machining Aluminum?

The best end mills for cutting aluminum are usually made from high-speed steel or carbide. You want end mills with sharp, wide flutes. These help remove metal chips easily. It’s also good to pick end mills with a special coating to reduce heat. This way, your cutting will be smooth and fast!

How Does The Geometry Of Milling Tools Impact Their Performance When Cutting Aluminum?

The shape of milling tools matters a lot when cutting aluminum. Different shapes can help them slice better and stay sharp longer. If a tool has sharp edges, it cuts through aluminum easily. If the tool is designed well, it won’t get stuck or break. This makes your work faster and smoother!

What Coatings Are Recommended For Milling Tools Used On Aluminum To Enhance Tool Life And Finish Quality?

To make milling tools last longer and work better on aluminum, we can use special coatings. Some good options are titanium nitride (TiN) and aluminum titanium nitride (AlTiN). These coatings help reduce wear and make cutting smoother. When we use these coatings, our tools can create cleaner cuts and last longer. So, using the right coating is important for better results!

Are There Specific Brands Or Models Of Milling Tools That Are Particularly Well-Regarded For Aluminum Machining?

Yes, there are some good brands for milling tools that work well with aluminum. Brands like HSS (High-Speed Steel) tools, Kyocera, and Helicoidal are popular choices. They make tools that cut aluminum smoothly and quickly. When you choose a tool, look for ones made just for aluminum. This helps you do a better job!

What Is The Ideal Cutting Speed And Feed Rate For Milling Aluminum With Different Tool Types?

When milling aluminum, the cutting speed and feed rate depend on the tool type. For a high-speed steel tool, use a cutting speed of 100 to 200 feet per minute. For carbide tools, you can go faster, around 300 to 600 feet per minute. The feed rate should be about 0.005 to 0.015 inches per tooth, depending on the tool. Always remember to check the tool’s instructions for the best results!