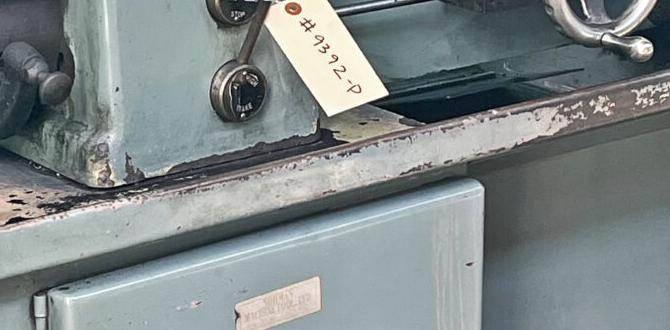

Have you ever wondered how metal parts are made? Metal lathes are fascinating machines that help shape metal into many items we use every day. If you’re a hobbyist or plan to start a project, understanding metal lathes is important. One vital feature of these machines is the threading dial. It’s a small yet mighty tool that helps cut precise threads in metal. But how do you choose the right metal lathe with a threading dial?

Imagine standing in a workshop filled with busy machines. Each one creates something new. You spot a metal lathe and picture making your custom parts. Now, think about how knowing which metal lathe to buy can make all the difference in your work. A good buying guide can help you make the best choice. With so many options, it can feel overwhelming. But don’t worry; we’re here to simplify it for you!

In this article, we’ll explore the essential features you should consider when buying a metal lathe with a threading dial. We’ll share tips to steer you in the right direction. Ready to dive in and uncover the secrets to finding the perfect metal lathe? Let’s get started!

Buying Guide: Metal Lathe Threading Dial Essentials

Buying Guide: Metal Lathe Threading Dial

Discover how a metal lathe threading dial can enhance your projects. This guide explains why this tool is essential for precise measurements and cuts. Learn about different types and features to consider, such as ease of use and compatibility with your lathe. Did you know a good threading dial can save you time and effort? Get ready to take your metalworking skills to the next level with the right threading dial that fits your needs!Understanding Metal Lathe Threading Dials

Definition and function of threading dials in metal lathes. Importance of accurate threading for machining projects.A threading dial is an important tool on a metal lathe. It helps the user create precise threads on metal pieces. This tool works by showing the exact position of the cutting tool as it moves. Accurate threading is essential for projects. It ensures parts fit together well and function properly. When you use a threading dial, you can avoid mistakes. This leads to better-sounding projects and less waste of materials.

Why is accurate threading important?

Accurate threading keeps parts in check.

- Fits snugly: Pieces align correctly.

- Better quality: Produces cleaner finishes.

- Less waste: Reduces material loss.

Key Features to Consider

Threading dial precision and accuracy measurement. Compatibility with different metal lathe models. Durability and material quality.Choosing a threading dial for your metal lathe is important. Here are key features to keep in mind:

- Precision and accuracy: A good threading dial helps you measure threads exactly. This is crucial for making precise cuts.

- Compatibility: Make sure the threading dial fits your lathe model. Different models need different types of dials.

- Durability: Look for a dial made from strong materials. This ensures it lasts a long time and withstands wear and tear.

What should I look for in a threading dial?

Look for precision, compatibility, and durability. These features make your work easier and more reliable.

Compatibility with Metal Lathes

Identifying lathe specifications for threading dials. How to determine if a threading dial fits your lathe.Every threading dial needs to match its metal lathe. It is important to find the right fit. Look at your lathe’s size and screw type. Check the specifications carefully. If you want the dial to work, it has to fit well. Here are some tips to help you:

- Know the lathe’s model number.

- Look for recommended threading dials.

- Measure the spindle thread size.

With a proper match, your threading dial will help you create precise threads.

How can you tell if the threading dial fits?

Check the lathe specifications and compare them with the threading dial. If the measurements match, it should fit nicely.

Price Range and Value Assessment

Average pricing for various threading dials on the market. Evaluating features vs. cost for a worthwhile investment.Finding the right price for a threading dial can feel like a treasure hunt. Most models cost between $30 and $200. Remember, the more you pay, the more features you may get. Some dials include smooth adjustments, better accuracy, or sturdier materials. Always check if these perks are worth it for your needs. After all, a fancy dial is nice, but it shouldn’t cost more than your lathe! Here’s a quick price overview:

| Threading Dial Features | Average Price |

|---|---|

| Basic Dial | $30 – $70 |

| Intermediate Dial | $70 – $120 |

| Advanced Dial | $120 – $200 |

Deciding which one to buy depends on your needs and budget. A good deal is like finding a $20 bill in your winter jacket. Always shop smart!

Common Brands and Their Offerings

Review of reputable brands in the threading dial market. Comparison of product offerings and customer satisfaction.In the world of threading dials, a few brands stand tall. Brands like Jet and Grizzly are known for their strong and steady products. They both offer reliable dials that make threading easy for all users. Customer reviews show that buyers love their smooth actions and durability. On the other hand, Shop Fox stands out with its budget-friendly options. They may lack some fancy features, but they’re perfect for beginners who want to get started without breaking the bank!

| Brand | Key Features | Customer Satisfaction |

|---|---|---|

| Jet | Durability, Smooth Operation | High |

| Grizzly | Reliable, Easy to Use | Very High |

| Shop Fox | Budget-friendly, Simple | Good |

Choosing the right brand can make your metal lathe adventure smoother and a lot more fun. Remember, happy lathing leads to happy grooves!

Installation and Maintenance Tips

Stepbystep guide to installing a threading dial on your lathe. Maintenance practices to prolong threading dial lifespan.To install a threading dial on your lathe, follow these easy steps:

- Gather your tools, like screws and a wrench.

- Align the dial with the spindle.

- Attach it using your screws and tighten well.

- Double-check the alignment for accuracy.

For keeping your threading dial in great shape, do these:

- Clean it regularly to avoid dust buildup.

- Lubricate the moving parts to ensure smooth operation.

- Store your lathe in a dry area to prevent rust.

How do I maintain my threading dial?

Regular cleaning and lubrication are key. This helps it work better and last longer. Check the manual for specific care tips.

User Reviews and Recommendations

Insights from experienced users about their preferred threading dials. Common problems encountered and solutions suggested by users.Users love sharing their experiences with threading dials for metal lathes. Many recommend dials that are easy to read and adjust. Common issues include inaccurate readings or wear over time. Experienced users suggest keeping the dials clean and checking calibrations regularly.

- Choose a dial with clear markings.

- Regular maintenance helps prevent issues.

- Consider user-friendly models for beginners.

These tips can enhance your work and save time in the long run.

What do users think about threading dials?

Users appreciate accuracy and ease of use in their threading dials. They often share insights about which models perform best and how to solve typical problems.

Frequently Asked Questions (FAQs)

Addressing common queries regarding threading dials. Troubleshooting common issues with threading dials.Many people have questions about threading dials. Here are some common ones:

What should I do if my threading dial is not aligning?

If the threading dial won’t align, check these:

- Ensure the lathe is properly leveled.

- Inspect the dial for any damage.

- Make sure the gears are working smoothly.

How can I clean my threading dial?

For cleaning, use a soft cloth and a mild cleaner. Avoid harsh chemicals as they can damage the dial.

Why is my threading dial skipping numbers?

This often happens due to worn gears. Replace any damaged parts for better performance.

Understanding how to deal with these issues can improve your lathe experience!

Conclusion

In summary, a metal lathe threading dial makes your work easier and more precise. It helps you measure distances accurately. When buying, consider features like ease of use and durability. Make sure to read reviews and compare options. Now that you know what to look for, you can start exploring different lathes. Happy crafting and keep learning!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Buying A Metal Lathe Threading Dial:Sure! When you want to buy a metal lathe threading dial, think about what you need it for. Look for one that fits your machine well. Check the quality and see if it’s easy to use. You might also want to read reviews from other people. This helps you make a smart choice!

Sure! Just let me know the question you want me to answer.

What Features Should I Look For In A Metal Lathe Threading Dial To Ensure Precision And Accuracy In My Threading Projects?When choosing a metal lathe threading dial, look for a clear, easy-to-read scale. A good dial shows exact numbers so you can measure accurately. You should also check if the dial turns smoothly without any sticking. A sturdy build helps it last longer and stay precise. Lastly, see if it fits your lathe well, so you can use it easily.

How Do The Different Types Of Threading Dials (E.G., Quick-Change, Manual, And Automatic) Affect The Usability Of A Metal Lathe?Different types of threading dials make using a metal lathe easier or harder. A quick-change dial lets you switch settings fast, which saves time. A manual dial needs you to adjust things by hand, which can be tricky and slow. An automatic dial does the work for you, making it simple and quick. So, the type of dial you choose really affects how smoothly you can work with the lathe.

What Are The Common Brands Or Models Of Threading Dials Recommended For Beginner Metal Lathe Users?For beginners using a metal lathe, good brands of threading dials are Grizzly, South Bend, and Jet. These brands make it easy to learn threading. Each model is simple and works well for new users. You can find these at stores that sell tools for metalworking. They will help you make smooth and accurate threads.

How Important Is The Material And Construction Quality Of A Threading Dial When Considering Durability And Long-Term Performance?The material and construction quality of a threading dial really matter. If it’s made from good materials, it will last longer. Strong parts help the dial work better over time. We want it to be reliable, so it’s worth choosing a well-made one. A good threading dial makes our work easier and more fun!

What Price Range Should I Expect For A Quality Metal Lathe Threading Dial, And How Can I Assess If I’M Getting Good Value For My Money?A good metal lathe threading dial usually costs between $50 and $150. To see if it’s a good deal, check if it’s made well. Look for strong materials and good reviews from other buyers. You can also compare prices from different shops. This way, you’ll know you’re spending your money wisely!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Buying A Metal Lathe Threading Dial:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you want to buy a metal lathe threading dial, think about what you need it for. Look for one that fits your machine well. Check the quality and see if it’s easy to use. You might also want to read reviews from other people. This helps you make a smart choice!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Features Should I Look For In A Metal Lathe Threading Dial To Ensure Precision And Accuracy In My Threading Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe threading dial, look for a clear, easy-to-read scale. A good dial shows exact numbers so you can measure accurately. You should also check if the dial turns smoothly without any sticking. A sturdy build helps it last longer and stay precise. Lastly, see if it fits your lathe well, so you can use it easily.”}},{“@type”: “Question”,”name”: “How Do The Different Types Of Threading Dials (E.G., Quick-Change, Manual, And Automatic) Affect The Usability Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different types of threading dials make using a metal lathe easier or harder. A quick-change dial lets you switch settings fast, which saves time. A manual dial needs you to adjust things by hand, which can be tricky and slow. An automatic dial does the work for you, making it simple and quick. So, the type of dial you choose really affects how smoothly you can work with the lathe.”}},{“@type”: “Question”,”name”: “What Are The Common Brands Or Models Of Threading Dials Recommended For Beginner Metal Lathe Users?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For beginners using a metal lathe, good brands of threading dials are Grizzly, South Bend, and Jet. These brands make it easy to learn threading. Each model is simple and works well for new users. You can find these at stores that sell tools for metalworking. They will help you make smooth and accurate threads.”}},{“@type”: “Question”,”name”: “How Important Is The Material And Construction Quality Of A Threading Dial When Considering Durability And Long-Term Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The material and construction quality of a threading dial really matter. If it’s made from good materials, it will last longer. Strong parts help the dial work better over time. We want it to be reliable, so it’s worth choosing a well-made one. A good threading dial makes our work easier and more fun!”}},{“@type”: “Question”,”name”: “What Price Range Should I Expect For A Quality Metal Lathe Threading Dial, And How Can I Assess If I’M Getting Good Value For My Money?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A good metal lathe threading dial usually costs between $50 and $150. To see if it’s a good deal, check if it’s made well. Look for strong materials and good reviews from other buyers. You can also compare prices from different shops. This way, you’ll know you’re spending your money wisely!”}}]}