A 1/8 inch carbide end mill can be tricky, but a simple trick with chip load and feed rate will dramatically reduce deflection, ensuring cleaner cuts and protecting your workpiece. Learn how to master this small but powerful tool.

Working with small diameter tools, especially at the 1/8 inch size, presents a unique set of challenges for any machinist, beginner or experienced. One of the most common frustrations you’ll face is deflection – that annoying tendency for the end mill to bend away from your intended cutting path. This can lead to inaccurate dimensions, rough finishes, and even broken tools. But don’t worry! With a little understanding and a smart adjustment to your cutting parameters, you can conquer this problem. We’re going to dive into a simple, but incredibly effective, tip that will help you get the most out of your 1/8 inch carbide end mill. Get ready to cut with confidence!

Understanding Deflection with Tiny End Mills

Imagine trying to push a long, thin stick through a piece of wood. It’s going to bend, right? That’s essentially what happens when your tiny 1/8 inch end mill tries to cut through metal. The forces of the cut, combined with the inherent flexibility of a small, slender tool, cause it to flex away from the cutting edge. This unwanted bending is called deflection.

Even the best carbide end mills, known for their hardness and rigidity, have their limits. When you’re working with a 1/8 inch diameter, the tool is simply less structurally sound than a larger one. This means it’s much more susceptible to bending under the pressure of the material you’re milling. For beginners, this can be incredibly disheartening, leading to scrap parts and a feeling of being overwhelmed.

The consequences of excessive deflection are:

- Inaccurate Cuts: Your part won’t match your design dimensions because the tool isn’t following the programmed path precisely.

- Poor Surface Finish: The wobbling action of the end mill can leave behind a rough, wavy surface.

- Increased Tool Wear: Uneven cutting forces can lead to premature wear on the cutting edges.

- Tool Breakage: In severe cases, the stress from deflection can snap your small end mill.

Fortunately, there’s a powerful, yet often overlooked, strategy that directly combats this issue. It’s not about buying a more expensive tool or a heavier machine; it’s about understanding and manipulating your chip load and feed rate.

What is Chip Load and Why It Matters for Small End Mills

Let’s break down two fundamental concepts: feed rate and chip load. Understanding how they work together is the key to solving deflection problems.

Feed Rate Defined

The feed rate is simply how fast the cutting tool moves through the material. It’s usually measured in inches per minute (IPM) or millimeters per minute (mm/min). A higher feed rate means the tool travels faster, and a lower feed rate means it travels slower.

Chip Load Explained

Chip load, on the other hand, is the thickness of the chip that each cutting edge of the end mill removes as it rotates. It’s often measured in inches per tooth (IPT) or millimeters per tooth (mm/tooth). Think of it as the ‘bite’ size of each flute of the end mill. A larger chip load means a thicker chip is being removed, while a smaller chip load means a thinner chip.

The relationship between feed rate and chip load is crucial:

Feed Rate = Chip Load x Number of Teeth x Spindle Speed (RPM)

This formula shows that you can achieve a certain feed rate by adjusting chip load, number of teeth, and spindle speed. When dealing with deflection, manipulating the chip load is where the magic happens.

The Genius Tip: Optimizing Chip Load for Minimal Deflection

Here’s the core of the solution: When working with a 1/8 inch carbide end mill, you need to prioritize a smaller chip load. Why? Because a smaller chip load means less force is exerted on the cutting edge at any given moment.

With a tiny 1/8 inch end mill, the cutting edges are inherently delicate and the tool shank is slender. Forcing it to take large, aggressive bites of material (high chip load) is a recipe for deflection. Instead, we want to persuade the end mill to take many small, gentle bites. This significantly reduces the sideways pressure that causes the tool to bend.

How to Achieve the Right Chip Load

You achieve your desired chip load by adjusting your feed rate and, to some extent, your spindle speed. For most 1/8 inch carbide end mills:

- Consult the Manufacturer’s Data: Always, always start by checking the manufacturer’s recommendations. They provide optimal chip load ranges for their specific tools, often varying based on the material being cut (e.g., aluminum, steel, plastic). Reputable manufacturers like Sandvik Coromant provide extensive tool data.

- Err on the Side of Caution: For a 1/8 inch end mill, using the lower end of the recommended chip load range is often the safest bet, especially if you’re new to the tool or the material. You might start with a chip load that’s 25-50% lower than the maximum recommended.

- Calculate Your Feed Rate: Once you have your target chip load (IPT), use the formula:

Feed Rate (IPM) = Chip Load (IPT) x Number of Flutes x Spindle Speed (RPM)

Example Calculation

Let’s say you have a standard 2-flute, 1/8 inch carbide end mill and are milling 6061 aluminum. The manufacturer’s recommended chip load range might be 0.0015″ – 0.0030″ IPT.

Scenario 1 (Higher Chip Load – Potential Deflection):

- Spindle Speed: 10,000 RPM

- Chip Load: 0.0025″ IPT

- Feed Rate = 0.0025 IPT x 2 Flutes x 10,000 RPM = 50 IPM

If you use this higher feed rate and chip load, you’re asking for a lot of force on that small end mill.

Scenario 2 (Lower Chip Load – Minimizing Deflection – The Genius Tip!):

- Spindle Speed: 10,000 RPM

- Chip Load: 0.0015″ IPT (lower end of range)

- Feed Rate = 0.0015 IPT x 2 Flutes x 10,000 RPM = 30 IPM

By reducing your chip load and consequently your feed rate, you spread the cutting force over more, smaller “bites,” drastically reducing the sideways pressure on the end mill. You’re still removing material efficiently, but much more gently.

Choosing the Right 1/8 Inch Carbide End Mill

Not all 1/8 inch end mills are created equal. When you’re focused on minimizing deflection, selecting the right tool is also important. For general-purpose milling, especially when dealing with materials like aluminum and mild steels, a standard length end mill is common.

Key Features to Consider:

- Material: Carbide is essential for working with metals. It’s much harder and more heat-resistant than High-Speed Steel (HSS).

- Number of Flutes: For general milling of softer metals like aluminum, 2-flute end mills are often preferred. They offer good chip clearance. For harder materials or finishing passes, 3-flute or 4-flute can be used, but they require more power and potentially a higher RPM for acceptable chip load. Given our focus on minimizing deflection with a 1/8 inch tool, 2 flutes are generally a good starting point.

- Coating: While not always necessary for hobbyists, coatings like TiN (Titanium Nitride) can improve tool life and performance, especially for harder materials.

- Shank Type: A standard round shank is most common. Ensure it fits securely in your collet or tool holder. Some higher-end tools might have Weldon flats for better holding, but this is less common on very small end mills.

- Length: For most common milling tasks where deflection is a concern, a standard length end mill is perfectly suitable. Extended length tools increase the lever arm, making them even more prone to deflection. Stick to standard lengths unless your machining operation absolutely requires it.

When searching for your tool, you might look for terms like “1/8 inch carbide end mill 1/4 shank standard length for carbon steel” or “1/8 inch 2 flute end mill aluminum.” Remember that a 1/4 inch shank on a 1/8 inch cutter provides a bit more rigidity to the tool holder connection, which can indirectly help.

Optimizing Your Milling Process for Small End Mills

Beyond just chip load, several other factors contribute to successful milling with small carbide end mills and minimizing deflection.

Feeds and Speeds for Different Materials

The ideal chip load and spindle speed depend heavily on the material you’re cutting. Always research the specific material you’re using.

Here’s a simplified overview. Remember, these are starting points, and actual values may vary based on the specific tool, machine rigidity, and coolant.

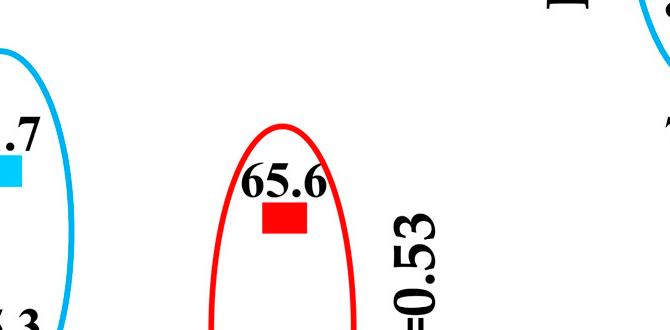

| Material Type | Approx. Chip Load (IPT) | Typical RPM for 1/8″ 2-Flute | Calculated Feed Rate (IPM) |

|---|---|---|---|

| 6061 Aluminum | 0.001″ – 0.002″ | 8,000 – 15,000 | 16 – 601 |

| Mild Steel (e.g., 1018) | 0.0005″ – 0.001″ | 5,000 – 10,000 | 5 – 202 |

| Acetal (Delrin) | 0.002″ – 0.004″ | 10,000 – 20,000 | 40 – 1603 |

1Example: 0.0015 IPT x 2 Flutes x 10,000 RPM = 30 IPM

2Example: 0.0008 IPT x 2 Flutes x 10,000 RPM = 16 IPM

3Example: 0.003 IPT x 2 Flutes x 10,000 RPM = 60 IPM

Climb Milling vs. Conventional Milling

For small diameter end mills, especially when deflection is a concern, climb milling is often the preferred method. In climb milling, the cutter rotates in the same direction the workpiece is feeding into it. This tends to “pull” the chip out cleanly and reduces the tendency for the tool to dig in and deflect than conventional milling where the cutter rotates against the feed direction.

Important Note on Climb Milling: For climb milling to work effectively and safely, your machine needs to have minimal “backlash” in its feed mechanisms. If you have significant backlash (play in the lead screws), climb milling can be problematic and potentially dangerous. Always understand your machine’s characteristics. For many hobbyist machines, especially older ones, adjusting to conventional milling might be safer due to backlash, but be prepared for increased tool pressure and potential deflection.

Depth of Cut (DOC) and Width of Cut (WOC)

Just as important as chip load is how much material you’re trying to remove at once. For 1/8 inch end mills:

- Depth of Cut (DOC): Keep your depth of cut very conservative. A good rule of thumb for general milling with a 1/8 inch end mill is to set the DOC to no more than 25-50% of the tool’s diameter. For example, if your DOC is 0.030″ to 0.060″ for a 1/8″ (0.125″) end mill. Taking cuts deeper than this dramatically increases cutting forces and deflection.

- Width of Cut (WOC): When slotting or pocketing, the width of cut also matters. A full slot (WOC = 100% of tool diameter) puts a lot of stress on the tool. If possible, use a series of shallower passes offset from each other to create the slot, keeping the WOC around 50% of the tool diameter for each pass. This is sometimes called “