Effortlessly cut titanium with a 1/8″ carbide end mill featuring a reduced neck. Learn how this design minimizes deflection for precise, controlled machining, preventing tool breakage and ensuring smooth finishes even on tough Grade 5 titanium.

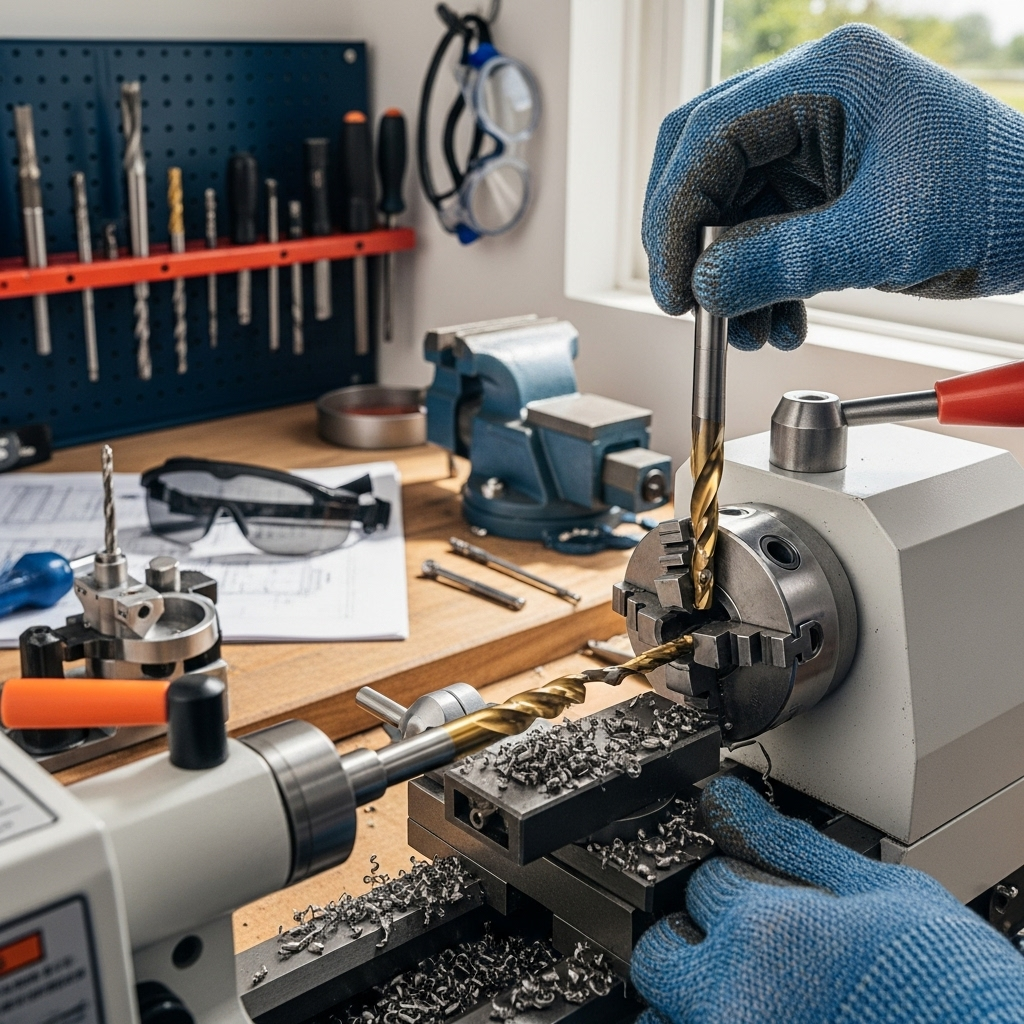

Hey everyone, Daniel Bates here from Lathe Hub! Today, we’re tackling a common frustration for anyone working with titanium: deflection. You know the feeling – you’re trying to make a precise cut with a small end mill, and it just seems to bend away from the material. This is especially true when using a 1/8″ end mill on tough materials like Titanium Grade 5. It’s annoying, wastes time, and can even break your delicate tool. But don’t worry, there’s a clever solution that makes this problem almost disappear. We’ll dive into how a specific type of end mill is designed to combat this, making your titanium machining much smoother and more successful.

Understanding the Challenge: Why Tiny End Mills Deflect in Titanium

Titanium, particularly Grade 5 (Ti-6Al-4V), is a Workhorse of the aerospace and medical industries for good reason. It’s incredibly strong, lightweight, and corrosion-resistant. However, these same qualities make it tough to machine. It has a low thermal conductivity, meaning heat generated during cutting tends to stay in the tool and the workpiece, leading to rapid tool wear and potential material damage. Furthermore, titanium’s high tensile strength and tendency to “string” or gall can create significant cutting forces.

When you introduce a small diameter tool, like a 1/8″ carbide end mill, into this equation, the forces can become even more problematic. The rigidity of a cutting tool is directly related to its diameter. A smaller diameter naturally has less inherent stiffness. As the cutting edges of the end mill engage with the titanium, sideways forces are generated. With a standard 1/8″ end mill, these forces can easily overcome the tool’s strength, causing it to bend or deflect away from the intended path. This deflection leads to:

Loss of Accuracy: The cut won’t be where you intended it to be, ruining precision.

Poor Surface Finish: Chatter marks and uneven surfaces are common.

Increased Tool Wear: The cutting edges are subjected to uneven forces, accelerating wear.

Tool Breakage: In severe cases, the deflection can be enough to snap the end mill, leading to further damage to the workpiece and machine.

This is where specialized tool design enters the picture.

The Solution: The Reduced Neck Carbide End Mill

The key to minimizing deflection with small diameter end mills in tough materials like titanium lies in a clever design feature: the reduced neck or “neck relief”. This isn’t just a cosmetic change; it’s a functional modification engineered to a specific purpose.

What Exactly is a Reduced Neck?

A reduced neck carbide end mill looks like a standard end mill, but with a crucial difference: the shank diameter is significantly smaller than the cutting diameter. Imagine a standard end mill where the cutting flutes extend almost all the way down to the collet. Now, picture an end mill where, just above the cutting flutes, there’s a section where the diameter is intentionally reduced. This reduced section is the “neck.”

Here’s a breakdown of the typical design:

Cutting Diameter: This is the diameter of the flutes that actually cut the material (e.g., 1/8″).

Neck Diameter: This is the smaller diameter of the shank above the cutting flutes. This diameter is intentionally smaller than the cutting diameter.

Shank Diameter: This is the main diameter of the tool where it’s held in the collet or tool holder. It’s typically the same as the neck diameter for this type of tool.

For a “carbide end mill 1/8 inch 1/4 shank reduced neck for titanium grade 5,” you’ll commonly see:

A cutting diameter of 1/8″ (0.125 inches).

A shank diameter of 1/4″ (0.250 inches) or sometimes even smaller for maximum relief.

The crucial feature: a portion of the tool just above the cutting flutes is necked down to a diameter smaller than 1/8″, often to match the shank diameter.

How the Reduced Neck Works to Minimize Deflection

The magic of the reduced neck lies in how it handles the cutting forces. When a standard end mill cuts, the entire cutting flute is in contact with the material. As the tool rotates and advances, forces are applied along the entire length of the flute.

With a reduced neck end mill, the design aims to reduce the effective length of the cutting edge that’s experiencing the full radial cutting force. Here’s how it achieves this:

1. Controlled Chip Evacuation: As the flutes cut, they generate chips. In tough materials like titanium, these chips can be sticky and contribute to cutting forces. The reduced neck allows for more clearance behind the cutting edges. This improved chip evacuation means less material re-cutting and reduced drag.

2. Flexibility in the Neck: The crucial part is the intentionally weakened neck. When sideways forces are applied during cutting, the thinner neck section is designed to flex slightly. This controlled flex absorbs some of the shock and bending force that would otherwise be transmitted directly to the tool tip.

3. Reduced Engagement Length: While the cutting diameter is 1/8″, the region of the tool responsible for resisting radial forces is effectively reduced by the neck. This means the tool is less likely to bend because the leverage created by the cutting forces acting on the entire flute length is mitigated.

4. Preventing Tool Binding: In some cutting scenarios, especially with smaller tools, the workpiece material can try to “climb” the flutes. The reduced flute length above the effective cutting edge in a necked mill can help break this tendency and reduce the chance of the tool being pulled into the cut or binding.

It’s a bit like bending a thin twig versus bending a thick branch. The twig will flex significantly before breaking, while the branch is much more rigid. The reduced neck acts like the twig, absorbing some of the stress before it causes the entire tool to deflect excessively or snap.

Key Features of a 1/8″ Carbide End Mill for Titanium Deflection Control

When you’re looking for the right tool to conquer titanium’s stubborn nature, a few specific features are non-negotiable for minimizing deflection:

High-Quality Carbide Material

Why it matters: Titanium is abrasive and generates significant heat during machining. Standard tool steels would quickly dull or melt. Carbide, especially with high-quality binders (like Cobalt), offers excellent hardness and hot hardness – the ability to retain its hardness at high temperatures. For titanium, grades of carbide with a higher percentage of binder (e.g., 6% or 10% cobalt) are often preferred for their increased toughness, which helps resist chipping and fracture, though this can slightly reduce hardness.

What to look for: Reputable manufacturers will specify the grade or composition of their carbide. Look for terms like “submicron carbide” or specific cobalt percentages if available.

Specific Geometry for Titanium

Helix Angle: Titanium tends to create long, stringy chips. A higher helix angle (often 30-45 degrees) helps to “lift” and evacuate these chips more effectively from the cutting zone. This reduces chip recutting and galling.

Number of Flutes: For titanium, you’ll typically find end mills with 2 or 3 flutes.

2-flute: Offers the best chip clearance and is generally preferred for plunging and roughing in gummy materials like titanium.

3-flute: Can offer a slightly better surface finish and can handle slightly higher feed rates in some applications, but chip evacuation can be more constrained. For minimizing deflection and dealing with sticky titanium, 2-flute is often the safer bet.

Coating: A specialized coating can dramatically improve performance.

AlTiN (Aluminum Titanium Nitride): This is a very common and effective coating for machining titanium. It forms a protective aluminum oxide layer at high temperatures, providing excellent thermal resistance and reducing friction.

TiCN (Titanium Carbonitride): Can also be used, offering good wear resistance.

ZrN (Zirconium Nitride): Sometimes used for its lubricity.

DLC (Diamond-Like Carbon): For very advanced applications, DLC coatings offer extreme hardness and low friction but are typically more expensive.

The Critical Reduced Neck Design

The Neck Relief: As discussed, this is the defining feature. The neck diameter should be noticeably smaller than the cutting diameter, often matching the shank diameter. A common setup for a 1/8″ end mill for titanium would be a 1/8″ cutting diameter with a reduced neck down to 1/4″ or even 3/16″ shank below the flutes. This provides excellent clearance and reduces the leverage of cutting forces.

Reinforced Core: While the neck is reduced, the rest of the tool’s core strength is still important. Look for tools with a robust internal structure.

Special Considerations for 1/8″ Tools

Working with a 1/8″ (0.125″) tool is inherently challenging due to its small size.

Rigidity at the Shank: While the neck is reduced, ensure the shank diameter where you grip it (e.g., 1/4″) is robust enough to be held securely in a quality collet or holder. A loose grip will amplify any deflection issues.

Tool Length: Shorter tools are always more rigid. If possible, use the shortest tool that can reach your target features. An extended neck relief is less effective if the overall tool stick-out is excessive.

When is a Reduced Neck End Mill Essential?

While a reduced neck end mill offers significant advantages, it’s not always necessary for every cutting task. However, for specific scenarios, it becomes indispensable:

Machining Titanium Grade 5: This is the prime candidate. Its strength, toughness, and tendency to gall make it notoriously difficult.

Small Diameter Tools (1/8″ or smaller): The smaller the tool, the greater the inherent risk of deflection. A reduced neck is highly beneficial for 1/8″ and even 1/4″ tools in tougher materials.

High-Precision Features: When tight tolerances are required, any deflection can lead to scrap parts.

Slotting or Pocketing: These operations often involve higher radial loads compared to profiling, increasing the likelihood of deflection.

Deep Cuts: Deeper cuts mean longer tool engagement and increased forces, making deflection a bigger problem.

Minimizing Tool Breakage: If you find yourself breaking small end mills frequently in specific materials, a reduced neck design is a smart investment to improve tool life.

How to Use Your 1/8″ Reduced Neck End Mill Effectively

Simply having the right tool isn’t enough; you need to use it correctly. Here’s how to get the most out of your 1/8″ reduced neck carbide end mill when working with titanium:

1. Secure Workholding is Paramount

Before you even power up the spindle, ensure your workpiece is clamped down securely. Any movement of the workpiece under cutting forces will exacerbate deflection and lead to inaccurate machining. Use sturdy clamps, vises, or fixturing appropriate for the job.

2. Use a High-Quality Collet or Tool Holder

The tool needs to be held as rigidly as possible. A high-quality, precision collet or a tool holder (like a hydraulic or shrink-fit holder for more demanding applications) will minimize runout and ensure the tool is centered. A worn collet or loose holder is a recipe for disaster with small tools.

3. Optimize Your Speeds and Feeds (SFM & IPR)

This is arguably the most critical factor after tool selection. Titanium requires specific cutting parameters, and running too fast or too slow can lead to problems.

Spindle Speed (RPM):

This depends on the tool’s diameter, the material, and the recommended Surface Feet per Minute (SFM) from the tool manufacturer.

Formula: RPM = (SFM 3.82) / Diameter (in inches)

For a 1/8″ (0.125″) end mill in Titanium Grade 5, typical SFM recommendations can range from 50 to 250 SFM, depending on the tool coating, number of flutes, and machining operation. Always consult the tool manufacturer’s recommendations first. A good starting point for a coated 2-flute carbide end mill might be around 100-150 SFM.

Example: For 100 SFM on a 1/8″ tool: RPM = (100 3.82) / 0.125 = 3056 RPM. You’d likely round this to 3000 RPM.

Feed Rate (IPM – Inches Per Minute):

This depends on the chip load (Inter-tooth Feed, IPR) and the RPM.

Formula: IPM = IPR Number of Flutes RPM

Chip Load (IPR): This is the thickness of the material removed by each cutting edge per revolution. For a 1/8″ tool in titanium, chip loads are very small, often in the range of 0.0005″ to 0.0015″ IPR. A good starting point might be 0.0008″ IPR for a 2-flute tool.

Example: Using 0.0008″ IPR, 2 flutes, and 3000 RPM: IPM = 0.0008 2 3000 = 4.8 IPM. You might start around 5 IPM and adjust.

Table 1: Starting Speed & Feed Recommendations for 1/8″ 2-Flute Carbide End Mill in Titanium Grade 5 (Coated)

| Parameter | Typical Range (Titanium Grade 5) | Example Value | Notes |

| :————- | :——————————– | :—————- | :————————————————————————– |

| SFM | 50 – 250 | 100 SFM | Consult manufacturer. Lower SFM for less rigid setups. |

| Chip Load | 0.0005″ – 0.0015″ IPR | 0.0008″ IPR | Crucial for controlling forces and chip formation. |

| RPM | 2,500 – 7,500 (for 1/8″) | ~3,000 RPM | Calculated from SFM. Higher RPMs require better machine rigidity. |

| IPM | 2 – 10 | ~5 IPM | Calculated from Chip Load and RPM. Very slow feeds are common. |

| Depth of Cut (Axial) | 0.010″ – 0.040″ | 0.020″ | Keep axial depth shallow to reduce forces. |

| Width of Cut (Radial) | 0.010″ – 0.060″ (typically <50% Dia) | 0.005″ – 0.015″ | For slotting/pocketing, use high stepover to avoid heavy radial forces. |

Note: These are starting points. Always listen to your machine, feel for chatter, and observe chip formation. Adjustments will be necessary based on your specific machine, tool, and setup.

4. Employ High-Quality Coolant/Lubrication

Machining titanium generates a lot of heat. To prevent tool welding and ensure proper chip evacuation, a good coolant or specialized cutting fluid is essential.

Flood Coolant: A powerful through-spindle coolant system is ideal. It flushes chips away, cools the cutting edge, and lubricates the cut.

MQL (Minimum Quantity Lubrication): Mist coolant systems can be effective if flood coolant isn’t available, but they might not provide enough cooling for heavy cuts in titanium.

Cutting Fluids: For best results in titanium, a specialized high-EP (Extreme Pressure) cutting fluid designed for difficult-to-machine alloys is recommended. These fluids are formulated to handle the high forces and temperatures involved.

5. Use Advanced Machining Strategies (When Appropriate)

For even better results and to further reduce deflection, consider these strategies:

High-Efficiency Machining (HEM) / Trochoidal Milling: Instead of taking a large radial stepover, HEM uses a small radial stepover (e.g., 10-20% of tool diameter) combined with a high feed rate and a circular or helical path. This keeps the tool in constant engagement with a small amount of material, generating consistent chip loads and shallower cutting forces.

This is extremely effective in reducing deflection because the tool is always moving, and the cutting forces are spread out. Many modern CAM software packages have specific HEM strategies.

Step-Over Management: When pocketing or slotting, avoid taking large radial cuts. A step-over of 10-20% of the tool diameter is often best for titanium to manage radial forces and prevent deflection.

Plunge Milling: If plunging is necessary, do it at a slow, controlled rate and consider using a specialized plunge end mill if available, or ensure your chosen end mill is designed for it. A reduced neck can help here too, but always plunge slowly.

6. Monitor Tool Wear and Adjust

Even with the best tools and techniques, wear will occur.

Listen: Pay attention to any changes in cutting sound. A sudden increase in noise often indicates the tool is dulling or chipping.

* Observe Chips: Look at