Quick Summary:

A 1/8 inch stub carbide end mill is perfect for dry cutting plastics like PMMA. Its short length minimizes chatter and deflection, ensuring clean cuts and a smooth finish, making it ideal for beginners and hobbyists working with these materials.

Hey there, fellow makers! Daniel Bates here from Lathe Hub. Ever looked at a tiny plastic project part and thought, “How am I going to cut this precisely without melting it or breaking my tiny tool?” A common headache for anyone dipping their toes into machining, especially with materials like PMMA (acrylic), is getting clean, accurate cuts without a mess. The good news? There’s a fantastic little tool that makes this job much easier: the 1/8 inch stub carbide end mill. It’s a game-changer, especially when you’re dry cutting. Let’s dive in and see why this specific end mill should be in your workshop toolbox.

Why a 1/8 Inch Stub Carbide End Mill for Dry Cutting PMMA?

When you’re working with plastics like PMMA, heat is your enemy. Traditional milling can generate enough friction to melt the plastic, causing a gummy mess, tool binding, and frankly, disappointing results. That’s where dry cutting comes in. It means cutting without a coolant, relying on efficient chip evacuation and the right tool geometry to manage heat. And for this type of work, a 1/8 inch stub carbide end mill is often the champion.

Let’s break down why:

- Carbide Material: Carbide is incredibly hard and heat-resistant. This means it can withstand the higher temperatures generated during dry machining better than high-speed steel (HSS). It stays sharp longer and cuts more efficiently, which is crucial for plastics that can gum up softer metals.

- 1/8 Inch Diameter: This small diameter is perfect for intricate details, small parts, and light-duty machining prevalent in hobbyist projects. It allows for precise cuts and maneuvers in tight spaces.

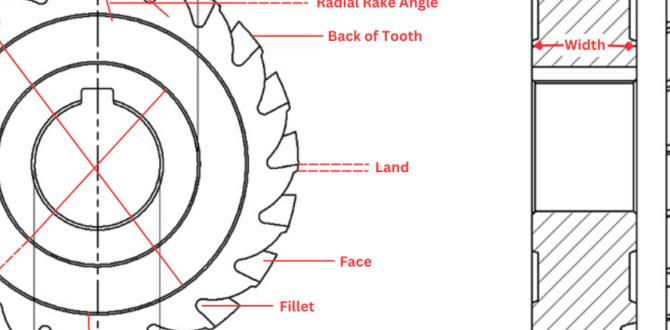

- Stub Length: This is a key feature. A “stub” end mill has a shorter flute length and a shorter overall length compared to standard end mills. Why is this a big deal for dry cutting PMMA on a CNC or manual mill? Shorter tools are inherently stiffer. This means less vibration (chatter) and less deflection, leading to cleaner cuts, better surface finish, and less stress on your machine, especially on smaller or lighter-duty CNC machines. For PMMA, which can be brittle, minimizing vibration is paramount to avoid chipping or fracturing.

- Dry Cutting Focus: While many end mills can be used for dry cutting, specific designs and flute geometries are optimized for it. For plastics, often a high number of flutes (like 3 or 4) is good for chip evacuation, and the flute polish can help prevent material buildup.

The “Stub Length” Advantage Explained

Imagine trying to hold a long, thin stick. It bends easily, right? Now imagine holding a short, thick stick – it’s much more rigid. That’s essentially the difference between a standard end mill and a stub end mill. The shorter flute length of a stub end mill reduces the leverage that can cause it to flex or vibrate. This is especially important when…

- Machining smaller parts or features.

- Working with softer materials like plastics or aluminum, which can cause tool deflection.

- Using smaller, lighter-duty milling machines or CNC routers.

- Achieving very tight tolerances and smooth surface finishes.

For PMMA, this rigidity translates directly into cleaner edges, fewer chips, and a more professional-looking result. It also means your tool is less likely to break on you, saving you money and frustration.

Essential Tools and Setup for Dry Cutting PMMA

Before you plunge that shiny new end mill into your project, let’s make sure you have the right setup. Safety and proper tools are your best friends in the workshop, especially when learning.

What You’ll Need:

- 1/8 Inch Stub Carbide End Mill: Specifically designed for your material and operation. Look for end mills with a geometry suited for plastics – sharp edges, good chip evacuation, and a polished flute are beneficial.

- Milling Machine or CNC Router: Ensure your machine is capable of holding a 1/8 inch shank tool securely.

- Collet Chuck or Collet: A good quality collet system is essential for accurately gripping the end mill shank. A runout of less than 0.001″ is ideal.

- Workholding: This is critical! Your PMMA workpiece needs to be held down firmly and securely. This could be double-sided tape (for lighter cuts), clamps, or a vacuum table. A workholding failure is a safety hazard and will ruin your workpiece.

- Safety Glasses: Always, always wear safety glasses. PMMA chips can be sharp.

- Dust Collection (Recommended): While dry cutting, fine plastic dust is generated. A dust collection system will keep your workspace cleaner and healthier.

- Measurement Tools: Calipers and a ruler for measuring and setting up your part.

- Machine Controls: Whether manual handwheels or a CNC controller, you need a way to move the tool accurately.

Setting Up Your Workpiece:

Securing your PMMA is one of the most vital steps. If your workpiece shifts during machining, you’ll get inaccurate cuts, double-cut grooves, or even catastrophic tool failure and damage to your machine. For small projects or prototyping, strong double-sided tape designed for machining can work well. For larger or more demanding jobs, consider using clamps that don’t interfere with the cutting path, or invest in a vacuum table if your CNC setup allows. Ensure the material is flat and not warped before you start.

Choosing the Right Machine Settings (Speeds and Feeds)

This is where many beginners get a bit intimidated. But don’t worry, we’ll keep it simple. Speeds and feeds determine how fast the tool spins (speed) and how fast it moves through the material (feed rate). Getting these right for PMMA with a 1/8 inch stub end mill is key to a successful dry cut.

Surface Speed (SFM) and Spindle Speed (RPM)

Surface speed is the linear speed of the cutting edge of the tool. Different materials and tool types have recommended SFM ranges. For PMMA with carbide, a common range is often between 300-700 SFM. However, for plastics, it’s often better to err on the lower side to avoid melting.

The relationship between SFM and your machine’s spindle speed (RPM) is:

RPM = (SFM 3.82) / Diameter (inches)

Let’s do an example for a 1/8 inch (0.125 inch) diameter end mill:

- If we aim for 400 SFM: RPM = (400 3.82) / 0.125 = 12,224 RPM.

- If we aim for 600 SFM: RPM = (600 3.82) / 0.125 = 18,336 RPM.

Most hobbyist CNC machines or manual mills might not reach these exact RPMs. This is where we use the “stub” advantage. A shorter tool will cut more cleanly at lower RPMs than a longer one because it vibrates less. The key is to find a speed that cuts effectively without melting. It’s often better to be a little slower on RPM and faster on feed rate.

Feed Rate (IPM)

Feed rate is measured in inches per minute (IPM) for CNC or inches per revolution (IPR) for manual mills. This is how fast the material is being removed.

A good starting point for feed rate depends on the chipload. Chipload is the thickness of the material removed by each cutting tooth of the end mill. A typical chipload for a 1/8 inch carbide end mill in plastic might be around 0.001″ to 0.002″.

The relationship is:

Feed Rate (IPM) = Chipload (inches/tooth) Number of Flutes RPM

Let’s use our previous RPM example and assume a 3-flute end mill and a chipload of 0.0015″:

- At 12,224 RPM: Feed Rate = 0.0015 3 12,224 = 733 IPM.

- At 18,336 RPM: Feed Rate = 0.0015 3 18,336 = 1,100 IPM.

These are very high feed rates, common in industrial high-speed machining. For hobbyist machines, we often need to adjust these based on the machine’s capabilities and rigidity. The goal is to hear and feel a consistent, clean cutting sound. If it sounds like it’s rubbing or hear loud squealing/screeching, you might be too slow on feed rate or too fast on RPM, or the chips aren’t evacuating.

Recommended Starting Speeds and Feeds for 1/8 Inch Stub Carbide End Mill in PMMA (Dry Cut):

These are just starting points. Always do a test cut on scrap material!

| Parameter | Typical Range for PMMA (Dry Cut) | Notes |

|---|---|---|

| Spindle Speed (RPM) | 12,000 – 18,000+ RPM | Higher RPM can help, but listen for melting/rubbing. Stub length helps stability. |

| Chipload (IPR) | 0.001″ – 0.002″ | Crucial for chip formation. Too small = rubbing, too big = breakage. |

| Feed Rate (IPM) | (Chipload Flutes * RPM) – Adjust for machine capability | Aim for a consistent cutting sound. Start slower and increase if comfortable. |

| Depth of Cut (DOC) | 0.050″ – 0.125″ (or 1/2 of tool diameter) with full engagement | For full slotting, shallower is better for rigidity. For profiling, step-overs matter more. |

| Width of Cut (WOC) | 0.020″ – 0.060″ (for profiling) | Smaller step-overs create less stress and better surface finish. |

Important Note on Manual Mills: On a manual mill, you control the feed rate with handwheels. Aim for a steady, consistent feed. If you have an DRO (Digital Readout), you can track your movement. The goal is a smooth, even cut without hesitating, which can cause glazing on plastics.

External Resource: For more general information on calculating speeds and feeds, the Engineering Shock Speeds and Feeds Calculator can be a helpful tool, though always adapt values for specific materials and tool geometries.

Step-by-Step Guide: Machining PMMA with a 1/8 Inch Stub End Mill

Let’s walk through the process of using your 1/8 inch stub carbide end mill to cut PMMA. Remember, patience and precision are key.

-

Prepare Your Machine:

Ensure your milling machine or CNC router is clean and in good working order. Install a clean collet that perfectly matches the 1/8 inch shank of your end mill into your spindle. Mount the end mill securely in the collet. Check for any runout – if the tool visibly wobbles, tighten the collet or try a different one. Minimum runout is critical for a clean cut.

-

Secure Your Workpiece:

Firmly attach your PMMA sheet to the machine bed using your chosen method (double-sided tape, clamps, etc.). Double-check that it’s stable and won’t move during the machining process. If using clamps, ensure they are positioned so the end mill won’t collide with them. For precise work, referencing off a machined datum on your workpiece or machine bed is ideal.

-

Set Up Your Zero Point:

For CNC users, this involves “probing” or manually setting your X, Y, and Z zero points relative to your workpiece. For manual milling, you’ll use edge finders or indicators to locate edges and set your zero points on your DRO. The Z-zero is particularly important – it’s the surface of your material, or slightly below it depending on your cutting strategy (e.g., to ensure a clean cut through the entire thickness).

-

Load Your Program/Set Manual Controls:

If using CNC, load your CAM-generated G-code program. If operating manually, set up your handwheels and be ready to control the feed and spindle speed. Start with conservative speeds and feeds as discussed earlier. Remember, it’s easier to increase speed than to fix a broken tool or melted plastic.

-

Perform a Dry Run (Optional but Recommended):

On a CNC, you can perform an “air cut” or dry run with the spindle OFF to watch the tool path and ensure there are no collisions with clamps or unexpected movements. On a manual mill, jog the tool to the start position and manually simulate the first few moves with the spindle off.

-

Start Cutting – First Pass:

Turn on your spindle to the set RPM. For CNC, start the program from the beginning. For manual operation, begin feeding the tool into the material with a steady, consistent motion. Listen to the sound of the cut. A clean, crisp sound is good. A high-pitched squeal or a dull, rubbing sound might indicate issues with your speeds or feeds. If you’re experiencing melting, your feed rate might be too low, or your RPM too high for the feed rate. Conversely, if the tool is chattering, the feed rate might be too high or depth of cut too large for the rigidity.

-

Chip Evacuation is Key:

Monitor chip evacuation. If chips are building up and not being cleared from the flutes, they can recut material, generate excessive heat, and lead to tool breakage or poor surface finish. This is where the stub length and sharpness of the end mill really help. You want to see nice, delicate chips, not dust or melted strands.

-

Making Multiple Passes (If Necessary):

For thicker PMMA, you’ll likely need to make multiple passes. Use a conservative depth of cut for each pass (e.g., 0.050″ to 0.125″ depending on rigidity and machine power). Always ensure each pass starts at the same Z-depth and progresses incrementally. The final pass should be set to cut through the entire thickness of the material.

-

Profiling and Slotting:

For cutting out a shape (profiling), you’ll typically move the end mill around the perimeter. Ensure your cutting strategy keeps the tool engaged with the material in a way that minimizes sideward force and allows for good chip evacuation. For cutting a slot, you’ll be engaging the tool on both sides, so a shallower depth of cut and moderate feed rate are important.

-

Finishing Up:

Once the cutting is complete, retract the tool from the workpiece. Turn off the spindle. Carefully remove the finished part from your machine. Clean your machine and your end mill. Inspect the end mill for any signs of excessive wear or buildup. A damp cloth (not wet!) can help clean PMMA dust off the end mill if needed. While dry cutting is the focus, if you find slight melting, a tiny bit of isopropyl alcohol can help clean residue from the end mill’s flutes.

Pros and Cons of Using a 1/8 Inch Stub Carbide End Mill for PMMA

Like any tool, there are advantages and disadvantages to consider. Understanding these will help you decide if it’s the right tool for your specific task.

Advantages:

- Superior Rigidity: The stub length significantly reduces flex and vibration, leading to much cleaner cuts and less risk of tool breakage compared to standard length end mills.

- Excellent for Detail: The 1/8 inch diameter allows for intricate designs and small features.

- Heat Resistance: Carbide handles the heat of dry machining PMMA better than HSS.

- Sharpness Retention: carbide stays sharper for longer, providing consistent cut quality.

- Reduced Chatter: Less vibration means a smoother surface finish on the