A 1/8 inch carbide end mill can achieve a mirror finish on metals with the right technique. Proper speeds, feeds, coolant, and a sharp, high-quality tool are key to unlocking that glassy surface.

Getting a super smooth, shiny finish on metal can sometimes feel like chasing a ghost. You might be using a great tool, but if that mirror-like gleam isn’t showing up, frustration can set in. Don’t worry! Achieving a “mirror finish” with something as precise as a 1/8 inch carbide end mill is totally doable, even for beginners. It’s all about understanding a few key steps and paying attention to the details. This guide will walk you through exactly how to get that professional, showroom-quality look on your workpieces, making your projects shine. Ready to see your reflection in your metalwork? Let’s get started!

The Magic of the 1/8 Inch Carbide End Mill for Mirror Finishes

A 1/8 inch carbide end mill might seem small, but its precision is exactly what makes it ideal for achieving those sought-after mirror finishes. When we talk about a “mirror finish,” we mean a surface so smooth that it reflects light almost like a mirror. This isn’t just about looking good; it’s often crucial for part function, reducing friction, and improving durability.

Carbide is a fantastic material for milling because it’s incredibly hard and can withstand higher cutting speeds and temperatures than High-Speed Steel (HSS). This hardness allows it to cut cleanly and precisely, leaving behind a smoother surface with less effort. The 1/8 inch size is perfect for intricate details, small parts, or when you need fine control.

Why is a Mirror Finish Important?

Aesthetics: Let’s face it, shiny metal looks amazing. It elevates the look of any project.

Performance: In many applications, a smooth surface reduces friction. Think of moving parts, bearings, or molds. Less friction means less wear and better efficiency.

Corrosion Resistance: A smoother surface has fewer microscopic valleys where contaminants can hide, making it harder for rust and corrosion to take hold.

Form and Fit: For parts that need to mate with other components, a precise, smooth surface ensures a perfect fit.

Common Challenges and How We’ll Overcome Them

Sometimes, even with a carbide end mill, you end up with tool marks, chatter, or a dull finish. This usually comes down to:

Incorrect Speeds and Feeds: Too fast, too slow, or feeding too quickly can all ruin a finish.

Tool Condition: A dull or chipped end mill won’t cut cleanly.

Material Issues: The workpiece material itself can be tricky.

Machine Rigidity: Vibrations or flex in your machine can cause chatter.

Coolant/Lubrication: Not using enough, or the wrong type, can cause heat and poor finish.

Don’t let these challenges intimidate you. By following a structured approach, we can tackle each one and achieve that beautiful mirror surface.

What You’ll Need: Essential Tools and Materials

Before we dive into the milling process, let’s make sure you have everything ready. Having the right setup from the start saves time and prevents common mistakes.

The Star of the Show: Your 1/8 Inch Carbide End Mill

When choosing your end mill, look for these features for the best mirror finish results:

Material: Solid carbide is a must.

Flute Count: For mirror finishes, 2-flute end mills are often preferred. They provide better chip evacuation and can be run at higher speeds than 3 or 4-flute tools, which helps achieve a finer finish.

Coating: While not always necessary, coatings like TiN (Titanium Nitride) or AlTiN (Aluminum Titanium Nitride) can improve wear resistance and reduce friction, aiding in a smoother cut. For general purposes, an uncoated carbide mill is often sufficient if other parameters are dialed in.

Type: For general finishing, a square end or a ball end mill can work. A ball end mill is excellent for creating smooth, contoured surfaces, while a square end mill is better for flat surfaces and sharp internal corners. For this guide, we’ll focus on achieving a general mirror finish.

“Stub Length”: A stub length end mill is shorter and sturdier than a standard length. This increased rigidity helps reduce vibration and chatter, which are detrimental to a good finish. A 1/8 inch shank stub length end mill is a great choice for stability.

Your Milling Machine

Whether it’s a small benchtop CNC, a manual milling machine, or even a powerful drill press with a milling attachment, the principles remain the same. Ensure your machine is:

Rigid: Minimal flex in the spindle, table, and column.

Clean: Free from chips and debris.

Well-maintained: Bearings are tight, and movement is smooth.

Workholding: Secure Your Part

A firm grip is non-negotiable. You’ll need:

Vise: A good quality milling vise, securely mounted to your machine’s table.

Clamps: If you’re not using a vise, appropriate clamping methods that don’t interfere with the tool path.

Parallel Stock: To lift your workpiece slightly off the vise jaws, ensuring a flat gripping surface and preventing jaw damage.

Coolant and Lubrication

Flood Coolant System: Ideal for continuous milling.

Mist Coolant System: A good compromise for smaller machines.

Cutting Fluid/Oil: A high-quality soluble oil or a general-purpose cutting fluid. For aluminum, it’s critical. For steels, it’s highly recommended.

Spray Bottle: For manual application if other systems aren’t available.

Measuring Tools

Calipers: For measuring your workpiece.

Dial Indicator/Test Indicator: To ensure your vise is square and your workpiece is properly indicated.

Safety Gear: Always First!

Safety Glasses: Non-negotiable. Always.

Face Shield: Recommended for added protection.

Gloves: Cut-resistant gloves for handling sharp parts and tools.

Ear Protection: For noisy machines.

Closed-toe Shoes: To protect your feet.

Understanding the Variables: Speeds, Feeds, and Depth of Cut

This is where the magic happens, and it’s crucial for any finish, especially a mirror finish. Getting these dialed in can feel like an art, but it’s based on science and experience.

Spindle Speed (RPM)

This is how fast the end mill spins. For soft metals like aluminum, you can often run your spindle faster than for harder steels. High RPMs mean more cuts per second, which can lead to a smoother finish but also generates more heat.

Rule of Thumb for Carbide:

Aluminum: 600-1200+ SFM (Surface Feet per Minute)

Steel (e.g., 1018, 4140): 200-500 SFM

To convert SFM to RPM, use the formula:

RPM = (SFM × 12) / (π × Diameter)

For a 1/8 inch (0.125 inch) end mill:

RPM = (SFM × 12) / (3.14159 × 0.125)

RPM ≈ SFM × 305.6

If SFM for aluminum is 800: RPM ≈ 800 × 305.6 ≈ 24,448 RPM

If SFM for steel is 300: RPM ≈ 300 × 305.6 ≈ 91,680 RPM

Important Note: These are starting points! Many hobbyist machines may not reach these RMP ranges, especially for steel. You’ll need to adjust based on your machine’s capabilities and the actual results. Higher RPMs are generally better for mirror finishes if your machine can handle them and you manage heat properly.

Feed Rate (IPM or Inches Per Minute)

This is how fast the cutting tool moves through the material. A higher feed rate means the tool takes bigger bites. For a mirror finish, you want small, clean chips, not chips that are gouging the surface.

Chip Load: This is a more precise way to think about feed rate. It’s the thickness of the chip being removed by each cutting edge of the end mill. For finishing passes, you want a very light chip load.

Chip Load = Feed Rate / (RPM × Number of Flutes)

Rule of Thumb for Carbide:

Finishing Pass: Aim for a chip load between .0005″ and .002″ per flute. This is very light!

Roughing Pass (if needed): You can use a heavier chip load, but we’re aiming for finish here.

To calculate Feed Rate (IPM):

Feed Rate = Chip Load × RPM × Number of Flutes

Let’s use our 1/8 inch, 2-flute end mill.

For a chip load of .001″ targeting aluminum at 10,000 RPM: Feed Rate = .001″ × 10,000 RPM × 2 flutes = 20 IPM.

For a chip load of .0005″ targeting steel at 5,000 RPM: Feed Rate = .0005″ × 5,000 RPM × 2 flutes = 5 IPM.

Key Takeaway: For a mirror finish, you’re generally looking for high RPM and a moderate-to-low feed rate, resulting in a light chip load. This produces small, fluffy chips and a smooth surface.

Depth of Cut (DOC)

This is how deep the end mill cuts into the material on each pass.

Full Depth of Cut: This is the maximum depth the end mill can cut. It’s usually a fraction of the end mill’s diameter for carbide. For a 1/8 inch end mill, a full radial depth of cut might be around 0.06″ to 0.12. Axial (depth into Z) cut is usually a percentage of the diameter.

Stepover: This is the distance the end mill moves sideways (radially) between passes when doing contour milling or surface finishing. A small stepover is critical for a smooth, artifact-free surface.

For Mirror Finishing:

Axial Depth of Cut (Z-axis): For a finishing pass, you want this to be very shallow. Aim for 0.005″ to 0.020″.

Radial Depth of Cut (X/Y-axis – Stepover): This is extremely important. For a mirror finish, you want a very small stepover. Aim for 5-20% of the end mill diameter. That’s 0.006″ to 0.025″ for a 1/8″ end mill. A smaller stepover creates less visible “stair-stepping” between passes.

A Note on “Trickness” and High SFM:

It’s worth noting that achieving incredibly high SFM (like 1,000+ SFM for aluminum) often requires machines capable of 40,000 RPM or more, which are common in high-speed machining (HSM) but rare in standard hobby setups. However, even with lower RPM machines, a good finish is achievable by carefully managing feed rate, depth of cut, and especially stepover. The fundamental principle of taking light, clean cuts remains.

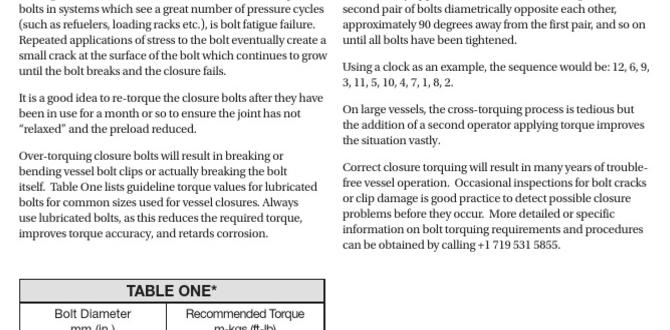

Here’s a table to help summarize starting points for a 1/8 inch, 2-flute carbide end mill:

| Operation | Material | SFM (Approx.) | RPM (for 1/8″ tool) | Chip Load (per flute) | Feed Rate (IPM) | Axial DOC (in) | Radial Stepover (in) | Notes |

| :————– | :———— | :———— | :—————— | :——————– | :————– | :————- | :——————- | :————————————– |

| Shoulder/Face | Aluminum 6061 | 600 | ~23,000 | 0.001″ – 0.002″ | ~46 – 92 | 0.005″ – 0.010″ | 0.006″ – 0.025″ | High RPM, low radial stepover crucial. |

| Shoulder/Face | Steel 1018 | 250 | ~9,500 | 0.0005″ – 0.001″ | ~10 – 19 | 0.005″ – 0.010″ | 0.008″ – 0.030″ | Use plenty of coolant, lower RPM. |

| Pocketing | Aluminum 6061 | 600 | ~23,000 | 0.001″ – 0.002″ | ~46 – 92 | 0.010″ – 0.020″ | 0.020″ – 0.050″ | Higher DOC is possible, still keep stepover light for finish. |

| Pocketing | Steel 1018 | 250 | ~9,500 | 0.0005″ – 0.001″ | ~10 – 19 | 0.010″ – 0.020″ | 0.025″ – 0.060″ | Ensure robust cooling for steel. |

These are starting points. Always listen to your machine and observe the chips produced.

Step-by-Step Guide: Achieving That Mirror Finish

Let’s get down to business. Follow these steps to mill your way to a perfect shine.

Step 1: Prepare Your Machine and Workpiece

1. Clean Your Machine: Ensure the table, vise, and spindle are free of any debris. A clean environment prevents contamination and inaccurate cuts.

2. Mount Your Vise: Securely bolt your milling vise to the machine table. Use a dial indicator to ensure it’s perfectly square to the machine’s axes. This is crucial for precise cuts.

3. Prepare the Workpiece: Clean your stock material thoroughly. Any dirt, oil, or scale can affect the cut and your finish.

4. Secure the Workpiece: Place your workpiece in the vise, using parallels if necessary to get a good grip on a flat surface. Tighten the vise firmly. Ensure the workpiece is very stable – no movement is allowed!

5. Indicate the Workpiece (Optional but Recommended): For critical parts, use a dial indicator to ensure the surface you’re milling is perfectly flat and parallel to the table.

Step 2: Install the 1/8 Inch Carbide End Mill

1. Clean the Collet and End Mill: Make sure both are spotless.

2. Insert into Collet: Place the end mill into the correct size collet. If using a 1/8″ end mill, use a 1/8″ collet.

3. Secure in Spindle: Insert the collet assembly into the milling machine’s spindle. Tighten it securely according to your machine’s procedure. Ensure the end mill is seated properly and not sticking out excessively, as this can increase vibration.

Step 3: Set Up Coolant and Lubrication

If using a flood or mist system, turn it on.

If manually applying, have your spray bottle of cutting fluid ready. For materials like aluminum, a good quality soluble oil mixed with water is excellent and helps carry chips away. For steels, a specific cutting oil might be better.

Step 4: Determine Your Starting Speeds and Feeds

Use the table provided in the previous section as a starting point.

For aluminum, aim for higher RPMs (if your machine can achieve them) and moderate feeds.

For steel, you’ll likely be using lower RPMs and slower feeds.

It’s often best to start at the lower end of the recommended range and slowly increase speed or feed until you achieve the desired chip formation and surface finish.

Step 5: Program or Manually Set Your Toolpath and Parameters

This is where you tell the machine what to do:

1. Zero the Z-Axis: Carefully bring the end mill down to the surface of your workpiece (or a reference point) and set your Z-axis zero.

2. Set Zero for X and Y Axes: Position the tool at your desired starting point for the cut and set your X and Y zeros.

3. Program Your Passes:

Axial Depth of Cut (DOC): Set this to a shallow value, like 0.005″ to 0.020″ for finishing.

Radial Depth of Cut (Stepover): This is CRITICAL for a mirror finish. Set this to a small percentage of the tool diameter, such as 10-20% (0.012″ – 0.025″ for a 1/8″ end mill). Too large a stepover will leave visible lines.

Feed Rate: Enter your calculated finishing feed rate.

* Spindle Speed: Set your target RPM.

CNC Users: Input these parameters into your CAM software or directly into the machine controller. Use a 2D contour toolpath for the exterior or a pocketing toolpath for internal