Carbide end mills are a game-changer for machining aluminum, especially with their design for efficient chip evacuation. This article explains why they’re brilliant for this material and how to use them effectively for cleaner cuts and better part finishes.

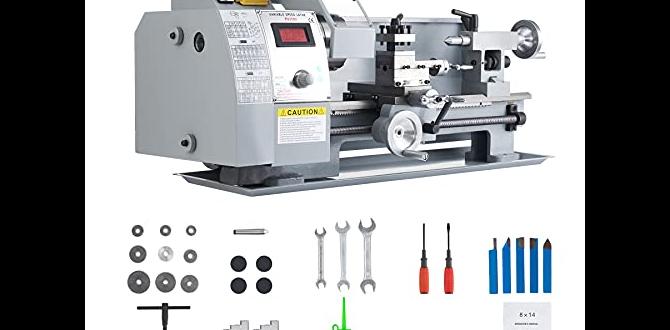

Working with aluminum on a milling machine can sometimes feel like a sticky situation, literally! Chips can cling to the cutting tool, leading to poor surface finishes, tool breakage, and a lot of frustration. But there’s a clever solution that makes a world of difference, and that’s using the right carbide end mill. We’re going to dive into why these specific tools are so fantastic for aluminum and how you can harness their power in your own workshop, making your machining experience smoother and much more successful.

Why Aluminum Loves Carbide End Mills (and Why You Will Too!)

Aluminum is a fantastic material for hobbyists and professionals alike. It’s relatively soft, easy to machine, and can produce some beautiful finished parts. However, its lower melting point and tendency to “gum up” present a unique challenge. When the chips generated during milling don’t clear away from the cutting edge properly, they can re-cut, build up heat, and cause all sorts of problems. This is where the genius of specific carbide end mill designs for aluminum truly shines.

Carbide, a super-hard material, offers incredible wear resistance, meaning it stays sharp and effective for longer than traditional high-speed steel (HSS) cutters. When designed with chip evacuation in mind, carbide end mills become the ultimate tool for tackling aluminum’s sticky nature. We’ll explore the features that make them so effective and guide you on how to select and use them.

Understanding Chip Evacuation: The Heart of the Matter

Before we get into the specifics of end mills, let’s quickly touch on what chip evacuation means and why it’s so critical, especially with aluminum.

- What are Chips? When your milling tool cuts into material, it shaves off small pieces. These are called chips.

- Why Evacuation is Key: For efficient machining, these chips need to be removed from the cut zone as quickly as possible. If they get stuck, they can:

- Cause a rougher surface finish.

- Increase friction and heat, potentially melting aluminum onto the cutter.

- Load up the flutes of the end mill, reducing its cutting ability.

- Lead to tool breakage if enough pressure builds up.

- Aluminum’s Challenge: Aluminum is known for its ductility. This means it tends to deform rather than chip cleanly. These softer, pliable chips can easily pack into the flutes of a poorly designed end mill.

The Design Secrets of Carbide End Mills for Aluminum

Not all end mills are created equal, and when it comes to machining aluminum, certain design features make a carbide end mill particularly brilliant. These features are all aimed at getting those sticky aluminum chips out of the way:

1. Flute Design: More Space for Chips!

This is perhaps the most critical factor. End mills have grooves called flutes that carry chips away from the cutting surface.

- High Helix Angle: End mills designed for aluminum often feature a higher helix angle (the angle of the flutes around the tool’s shaft). Think of it like a tighter screw thread. This higher angle helps to “screw” the chips up and out of the workpiece faster, promoting better evacuation. Speeds up chip removal.

- Polished Flutes: Look for end mills with highly polished flutes. A smooth, shiny surface reduces the friction between the aluminum chips and the flute walls. This is crucial because it prevents the chips from sticking in the first place, much like how a non-stick pan works.

- Variable/Formed Flutes: Some specialized end mills use a variable flute design or a flute form optimized for chip control. These are less common for general beginner use but are worth knowing about.

- Number of Flutes: For aluminum, end mills with fewer flutes (often 2 or 3 flutes) are generally preferred over 4-flute tools when using flood coolant or for high-speed machining. Fewer flutes mean larger flute openings, allowing more room for chips to pass through, especially in deeper cavities. A 2-flute end mill is often the go-to for aluminum.

2. Coating: The Invisible Armor

While many carbide end mills for aluminum are uncoated for maximum lubricity, some benefit from special coatings.

- Uncoated: For aluminum, uncoated carbide is often preferred. The polished carbide surface itself provides excellent lubricity, reducing friction and preventing chip welding.

- ZrN (Zirconium Nitride): This is a gold-colored coating that offers good lubricity and hardness. It’s a step up from uncoated and can be very effective for aluminum.

- TiCN (Titanium Carbonitride): While harder, TiCN is less common for initial aluminum milling applications where chip evacuation and lubricity are paramount, as it can sometimes be more prone to welding with softer

materials if not applied perfectly.

3. Geometry: Fine-Tuning the Cut

Beyond the flutes, the overall shape of the end mill’s cutting edge also matters.

- Sharp Cutting Edges: This might seem obvious, but for aluminum, extra sharp cutting edges are paramount. Sharp edges shear the material cleanly with less force, producing smaller, more manageable chips.

- Center Cutting: Most end mills you’ll use for milling pockets or slots are “center cutting.” This means they have cutting edges on the very tip, allowing you to plunge straight down into the material.

- Stub Length: For many aluminum applications, especially where rigidity is key and chatter is a concern, stub-length end mills are beneficial. These have a shorter flute length relative to their diameter. This increased rigidity helps prevent vibration and improves accuracy.

Choosing the Right Carbide End Mill for Your Aluminum Project

Now that you know what makes these tools special, let’s talk about practical selection. For beginners tackling aluminum, focusing on a few key specifications will get you the best results.

Key Specifications to Look For:

- Material: Solid Carbide.

- Coating: Uncoated is often best, or Gold ZrN.

- Flutes: 2-flute is ideal for most aluminum applications. 3-flute can be used with good coolant and careful settings.

- Helix Angle: High helix (e.g., 45-60 degrees).

- Flute Finish: Highly polished.

- Length: Stub length for rigidity, or standard length if deeper reach is needed (but be mindful of deflection).

- Diameter: This will depend on your part’s geometry. Common sizes for hobbyists include 1/8 inch, 1/4 inch, 1/2 inch.

- Shank: Standard round shank, often Weldon style for set screw grip.

Example Search Terms: If you’re looking online, try terms like “2 flute carbide end mill aluminum,” “high helix carbide end mill,” or “polished flute end mill.” Specific sizes like “1/8 inch carbide end mill aluminum 6061” or “1/4 shank stub length aluminum” will narrow it down further.

A Note on Coolant/Lubrication

While a well-designed end mill for aluminum aims to evacuate chips effectively, using some form of lubrication can make a massive difference. For aluminum:

- Flood Coolant: If your mill has a flood coolant system, use it! It dramatically helps wash chips away and keeps the cutting edge cool.

- Mist Coolant: A mist coolant system is also very effective and uses less fluid.

- Cutting Fluid/Lube Sticks: For manual machining or where flood coolant isn’t an option, specialized cutting fluids or even a bit of wax-based cutting paste can be applied with a brush or stick periodically. This reduces friction and prevents chip welding. Avoid WD-40; it’s a penetrant, not a cutting lubricant.

- Tabco (Triple Action Broach Cutting Fluid) is a popular choice for aluminum.

For more on machining fluids and their importance, you can check out resources from organizations like the Society of Manufacturing Engineers (SME) which often has research and resources on best practices in machining.

Setting Up Your Mill for Success: Speed, Feed, and Depth of Cut

Choosing the right tool is only half the battle. How you use it – your machine’s settings – is equally important for that brilliant chip evacuation.

1. Spindle Speed (RPM)

Aluminum machines well at higher speeds. Carbide tools can handle it, but you need to manage the heat and chip load. A good starting point for carbide on aluminum is typically:

- General Range: 3,000 to 15,000+ RPM, depending on the end mill diameter and machine capability.

- Smaller Diameter = Higher RPM: A 1/8 inch end mill will run much faster than a 1/2 inch end mill.

- Rule of Thumb: A common starting point for uncoated carbide on aluminum is around 400-800 SFM (Surface Feet per Minute). To convert this to RPM multiply by 3.82 and divide by the diameter in inches (RPM = (SFM 3.82) / Diameter).

2. Feed Rate (IPM)

This is how fast the tool moves through the material. It’s directly linked to how much material each cutting edge “grabs” in one rotation – the chip load.

- Crucial for Chip Load: A proper feed rate ensures you’re taking a reasonable chip. If the feed rate is too low, you’ll rub the tool rather than cut, generating heat and poor finishes. Too high, and you risk tool breakage or overloading the spindle.

- Chip Load Formula: Chip Load (CL) = Feed Rate (IPM) / (RPM Number of Flutes). For aluminum, you want to maintain a good chip load.

- Starting Point: For a 1/4 inch 2-flute end mill in 6061 aluminum, a chip load might range from 0.001″ to 0.003″ per tooth. So, a feed rate could be around (0.002″ 2 flutes 6000 RPM) = 240 IPM. These are just starting points, and you’ll adjust based on sound and surface finish.

Finding reliable cutting parameters can be tricky. You can often find charts from end mill manufacturers or consult resources like the CNCCookbook, which offers extensive data and calculators for various materials and tool types.

3. Depth of Cut (DOC) and Stepover

These settings determine how much material you remove in a single pass.

Depth of Cut (DOC)

- Radial Depth of Cut (Stepover): This is how far the end mill moves sideways in a pocket. For aluminum, a lighter stepover (e.g., 40-60% of the tool diameter) is often preferred for better chip control and surface finish. Using a smaller stepover ensures the chips have plenty of room to escape.

- Axial Depth of Cut: This is how deep the end mill cuts downwards. For roughing, you might take a larger axial DOC. For finishing, a light axial DOC is critical for achieving a smooth surface.

Using a “High-Efficiency Machining” (HEM) strategy, often involving a small stepover and a moderate depth of cut, can be very effective for aluminum. This strategy keeps the tool engaged in a consistent cutting path, optimizing chip load and heat management.

Practical Application: Machining Aluminum with a Carbide End Mill

Let’s walk through a simplified scenario. Imagine you need to mill out a pocket in a piece of 6061 aluminum using a 1/4 inch diameter, 2-flute, high-helix, polished carbide end mill.

Step 1: Material Preparation

- Securely clamp your 6061 aluminum workpiece to the milling machine table. Use dogs, vises, or stops to ensure it doesn’t move.

- Make sure the workpiece is clean and free of debris.

Step 2: Tool Setup

- Insert the 1/4 inch carbide end mill into your milling machine’s collet or tool holder. Ensure it’s seated properly and tightened securely.

- If using coolant, ensure the system is ready to operate.

Step 3: Setting Machine Parameters (Example for 6061 Aluminum)

- RPM: For a 1/4 inch end mill, try around 8,000 RPM as a starting point.

- Feed Rate: Aim for a chip load of approximately 0.002 inches per tooth. This gives a feed rate of roughly (0.002 2 8000) = 320 IPM.

- Axial Depth of Cut: For roughing, start with 0.100″ to 0.200″. For finishing, a very light pass of 0.005″ to 0.010″ is ideal.

- Radial Depth of Cut (Stepover): Start with 40% of the tool diameter, so 0.100 inches.

Step 4: Machining the Pocket

- Set your Z-zero point on the top surface of the workpiece.

- Initiate the milling operation. If your CAM software is generating toolpaths, ensure it’s set up for efficient pocketing (e.g., using a conventional or climb milling strategy optimized for chip evacuation).

- Listen and Watch: Pay close attention to the sound and chip formation. A healthy cut will produce clean, wispy chips that are flung away from the tool. If the chips are building up, smearing, or if there’s screaming or rubbing, adjust your feed rate or depth of cut.

- Coolant: If using coolant, ensure a steady stream is directed at the cutting zone.

Step 5: Finishing Pass

- After roughing (if done), perform a final finishing pass using a very light axial depth of cut (e.g., 0.005″). This pass uses the clean edges of the end mill to create a smooth surface finish. A slightly wider stepover can sometimes be used for finishing, but experiment to see what works best.

Step 6: Inspection

- Once the machining is complete, carefully inspect the part. The pocket should have a clean, smooth surface with minimal evidence of chip buildup on the tool.

Troubleshooting Common Issues

Even with the best tools, you might encounter some bumps. Here’s how to handle them:

Issue: Chips Clogging the Flutes

- Cause: Feed rate too low, depth of cut too high, insufficient coolant, or using an end mill not optimized for aluminum.

- Solution: Increase feed rate slightly, reduce DOC, ensure adequate coolant flow, or switch to a 2-flute, high-helix, polished carbide end mill.

Issue: Rough Surface Finish

- Cause: Feed rate too low (rubbing), dull tool, excessive runout, incorrect cutting speeds, or a finishing pass that is too aggressive.

- Solution: Increase feed rate, use a new sharp tool, check for spindle runout, adjust RPM, and ensure a very light finishing pass.

Issue: Tool Breakage

- Cause: Feed rate too high, DOC too aggressive for the tool’s rigidity, workpiece not clamped securely, chatter, or hitting a hard spot.

- Solution: Reduce feed rate and DOC, ensure workpiece is solid, use a shorter/stub length end mill if needed, and check for machine rigidity.

Issue: Aluminum Welded to the End Mill (Chip Welding)

- Cause: Insufficient lubrication, feed rubbing instead of cutting, excessive heat buildup, or using the wrong tool.

- Solution: Use appropriate cutting fluid or coolant, increase feed rate (to achieve proper chip load), reduce cutting speed if heat is extreme, and ensure you’re using an aluminum-specific end mill.

Tools and Accessories to Enhance Chip Evacuation

Beyond the end mill itself, several other shop aids can dramatically improve your aluminum machining experience by aiding chip evacuation:

- High-Pressure Coolant Systems: These systems deliver coolant at significant pressure, helping to blast chips out of deep pockets and small features.

- Air Blast Systems: A directed