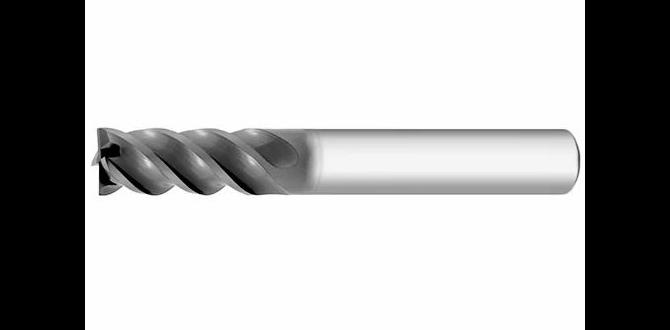

A 1/8 inch carbide end mill is absolutely essential for achieving a mirror finish on Aluminum 6061, especially when using a 10mm shank stub length. This versatile tool is perfect for detailed work, offering precision, durability, and a clean cut vital for this popular aluminum alloy.

Working with metals can sometimes feel like a puzzle, especially when you’re just starting out. Aluminum 6061 is a fantastic material, widely used for its good strength and ease of machining. But getting that perfectly smooth, almost shiny finish? That can be tricky! You might find common end mills leave behind undesirable marks, or the material gums up, causing frustration. Don’t worry, though! There’s a specific tool designed to make this job achievable and satisfying. We’re going to dive into why a 1/8 inch carbide end mill, particularly one with a 10mm shank stub length, is your secret weapon for tackling Aluminum 6061 and achieving that coveted mirror finish. Get ready to learn exactly what makes it so special and how to use it effectively!

Why a 1/8 Inch Carbide End Mill is Your Go-To for Aluminum 6061

Aluminum 6061 is a workhorse alloy, loved in workshops for its excellent combination of properties. It’s strong yet lightweight, corrosion-resistant thanks to its magnesium and silicon content, and it’s weldable. However, when you want to achieve a high-quality surface finish, especially a mirror polish, on this material, especially for intricate parts or precise mold making, you need the right cutting tool. This is where the 1/8 inch carbide end mill truly shines.

The Magic of Carbide

Carbide, also known as tungsten carbide, is a super-hard ceramic material. It’s significantly harder and more rigid than High-Speed Steel (HSS), which is what many standard end mills are made from. This hardness offers several key advantages when machining Aluminum 6061:

Heat Resistance: Machining generates heat. Carbide can withstand much higher temperatures than HSS without losing its hardness or dulling. This is crucial for aluminum, which can get gummy and generate significant heat during cutting.

Wear Resistance: The extreme hardness translates to superior wear resistance. This means a carbide end mill will maintain its sharp cutting edge for much longer, providing consistent results over many cuts. For detailed work, this edge retention is paramount.

Rigidity: Carbide is a very rigid material. This rigidity helps minimize tool deflection. When a tool deflects, it can lead to inaccurate dimensions and a poor surface finish. For small tools like 1/8 inch end mills, rigidity is vital.

Why 1/8 Inch? Precision in Small Packages

The 1/8 inch (approximately 3.175mm) diameter is where this tool becomes indispensable for specific tasks. This small size allows for:

Intricate Details: For milling small features, sharp internal corners, fine text, or delicate pockets, a smaller diameter tool is essential. A 1/8 inch end mill can get into tight spaces where larger tools simply cannot reach.

Reduced Cutting Forces: Smaller tools generally exert less force on the workpiece and the machine. This can be beneficial on lighter-duty milling machines or when working with thinner stock where excessive force could cause distortion.

Surface Finish Control: While larger end mills can produce good finishes, smaller diameters, when used correctly, are often easier to control for achieving extremely fine surface finishes, especially when taking light finishing passes.

The 10mm Shank Stub Length Advantage

You might see terms like “stub length” or “short flute” end mills. For a 1/8 inch end mill, especially when targeting Aluminum 6061 with a mirror finish, a stub length (often the same as a standard 1/8 inch end mill, but it’s worth noting the design principle) is beneficial. The term “10mm shank” refers to the diameter of the part of the tool that goes into the collet or tool holder. This implies you might be using a collet adapter or that the manufacturer offers this option. A shorter flute length generally means a more rigid tool.

Increased Rigidity: With less flute length sticking out, the tool is less prone to vibration and deflection. This is a significant advantage when taking light, finishing cuts for a mirror finish.

Better Chip Evacuation (Sometimes): In some designs, shorter flutes can aid in directing chips away from the cutting zone, though for aluminum, chip evacuation is always something to manage carefully.

Suitability for Die/Mold Work: This design is often preferred in die and mold making where precise, detailed cuts are required, and tool rigidity is paramount.

Mirror Finish on Aluminum 6061: A Brief Overview

Achieving a mirror finish on Aluminum 6061 involves more than just the right tool. It’s a combination of:

Tool Geometry: The flute design and edge preparation of the end mill play a crucial role.

Cutting Parameters: Speed (RPM), feed rate, depth of cut, and stepover all significantly impact the surface quality.

Coolant/Lubrication: Proper lubrication and cooling are vital for aluminum to prevent chip welding and maintain a clean cut.

Machine Rigidity: A stable machine without backlash will contribute to a smoother finish.

The 1/8 inch carbide end mill is the cornerstone of this process, providing the cutting edge required to meet these demands.

Understanding CNC Milling Terminology for Beginners

Before we dive into the specifics of using your end mill, let’s demystify a few terms you’ll encounter. Understanding these will make following instructions and selecting the right tools much easier.

End Mill: A type of milling cutter, shaped like a drill bit but with cutting edges on the sides as well as the tip. Used for cutting slots, profiles, contours, and pockets.

Carbide: A very hard and brittle compound, often tungsten carbide, favored for its wear resistance when cutting hard materials or maintaining sharp edges.

Aluminum 6061: A common, medium-strength aluminum alloy known for its good corrosion resistance and machinability.

1/8 Inch: Refers to the diameter of the cutting flutes of the end mill. This is a small diameter, suitable for fine details.

Shank: The non-cutting part of the end mill that is held by the tool holder or collet.

10mm Shank: The diameter of the shank. This means the tool holder or collet you use must be able to accept a 10mm shank. Many machines use inch-based collets, so you might need an adapter or a metric collet system. For a 1/8 inch end mill, a 10mm shank is quite substantial, often indicating a specialized or robust tool shank compared to the cutting diameter.

Stub Length: Describes an end mill with shorter flutes relative to its diameter and shank. This generally makes the tool more rigid and less prone to deflection.

RPM (Revolutions Per Minute): How fast the spindle of your milling machine is rotating.

Feed Rate: How fast the cutting tool moves through the material, usually measured in inches per minute (IPM) or millimeters per minute (MPM).

Depth of Cut (DOC): How deep the end mill cuts into the material in a single pass.

Stepover: The amount of overlap between successive passes of the end mill, particularly when milling a wider area. A smaller stepover is used for finishing passes to achieve a smoother surface.

Coolant/Lubricant: A fluid used to reduce heat and friction, flush chips away, and improve the surface finish during machining. For aluminum, a suitable cutting fluid is essential.

Collet: A sleeve used in a milling machine spindle to hold a tool. It can be compressed to grip the tool shank.

Tool Holder: A device that holds the end mill and is attached to the milling machine spindle.

Choosing Your 1/8 Inch Carbide End Mill: Key Features

Not all 1/8 inch carbide end mills are created equal, especially when you’re aiming for that perfect mirror finish on Aluminum 6061. Here are the key features to look for:

1. Number of Flutes

2 Flutes: Generally preferred for softer materials like aluminum. They offer wider chip gullets (the space between the flutes) for better chip evacuation, which is critical for sticky materials like aluminum. This helps prevent the aluminum from gumming up the flutes.

3 or 4 Flutes: More common for harder materials or when a smoother finish is desired on materials that don’t chip easily. While they can offer a smoother finish due to more cutting edges engaging, they can also clog more easily with aluminum if not managed with flooded coolant and appropriate feed rates.

Recommendation for Aluminum 6061 with a mirror finish: Start with a 2-flute end mill. If you have excellent coolant delivery and are taking very light finishing passes, a 3-flute might be considered, but 2-flutes usually offer a better balance for aluminum.

2. Helix Angle

The helix angle refers to the slant of the cutting flutes.

Standard Helix (30-45 degrees): Good all-around performance.

High Helix (60 degrees or more): Can provide a smoother finish and better chip evacuation, as the cutting edge has a more shearing action. However, they can also induce more vibration.

Zero Helix (Square End Mills): Have flutes that are essentially straight up and down. These are good for plunge cuts but less ideal for side milling aluminum.

Specialized for Aluminum: Some end mills are designed with specific helix angles, coatings, or geometries optimized for aluminum. Look for tools marketed for aluminum machining.

Recommendation for Aluminum 6061: Consider a high-helix (around 45-60 degrees) end mill with polished flutes if available. This combination often helps in shearing the aluminum cleanly and evacuating chips effectively.

3. Coatings

Uncoated: Often sufficient for aluminum, especially if you’re using a high-quality carbide grade and good lubrication. The natural surface texture of polished carbide can work well.

ZrN (Zirconium Nitride): A good general-purpose coating that offers moderate heat resistance and lubricity.

TiAlN (Titanium Aluminum Nitride) / AlTiN (Aluminum Titanium Nitride): Excellent for high-temperature applications, but generally better suited for steels and exotic alloys where heat is a major factor. Can be overkill for aluminum and might even increase friction.

Specialty Aluminum Coatings: Some manufacturers offer specific coatings designed for aluminum that reduce friction and prevent material buildup.

Recommendation for Aluminum 6061: An uncoated, polished carbide end mill is often the best choice. If you want a coating, look for something that specifically targets aluminum and reduces friction, such as those with a low coefficient of friction.

4. End Mill Type

Square End Mill: The most common type. The tip is flat, allowing for square internal corners (though a small radius is often left by the tool tip).

Ball End Mill: The tip is shaped like a ball. Used for creating rounded profiles, fillets, and 3D milling.

Corner Radius End Mill: A square end mill with a small radius on the cutting corners. This helps reduce stress concentration and can improve tool life and surface finish.

Recommendation for Mirror Finish: For general milling to achieve a mirror finish, a square end mill is often used for the bulk of the material removal. For the final “cleanup” passes or when specific radii are needed, you’d use the appropriate type. If you need a truly sharp 90-degree internal corner, you’d need to pocket with a smaller diameter tool. For a mirror finish on surfaces, a square end mill with a very small corner radius (e.g., 0.005″ or 0.127mm, which is often close to zero for a 1/8″ tool) is suitable.

5. Shank Diameter and Length (10mm Shank Stub Length)

As mentioned, a 10mm shank on a 1/8 inch end mill is a somewhat unusual but robust combination. It implies a stout tool.

Stub Length: Shorter flute length means more rigidity. This is excellent for precise finishing passes. When the depth of cut is not excessive, a stub length end mill will deflect less, contributing to a better surface.

Key Takeaway: For Aluminum 6061 and a mirror finish, prioritize a 2-flute, polished carbide end mill. A stout shank like 10mm for a 1/8 inch cutter suggests good rigidity, which is a plus.

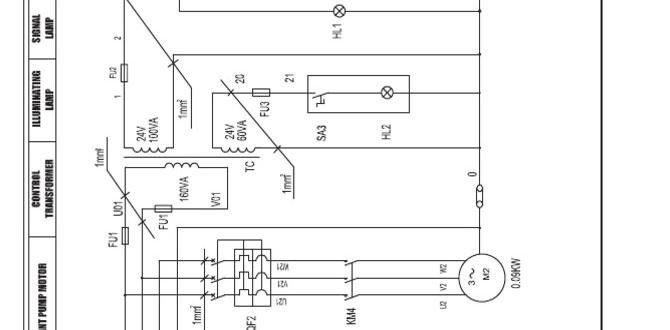

Setting Up Your Machine and Workpiece

Getting your setup right is half the battle when aiming for a quality finish.

1. Securing the Workpiece (Workholding)

Vise: A sturdy milling vise is the most common method. Ensure the vise jaws are clean and that the workpiece is seated squarely. Use soft jaws if you’re concerned about marring the surface, especially if this is a final finishing operation.

Clamping: For larger parts, edge clamps or toe clamps can be used directly on a machine table. Use as many clamping points as possible to ensure rigidity and prevent movement.

Fixturing: For repetitive parts or complex shapes, a custom fixture might be necessary.

Crucial for Mirror Finish: The workpiece absolutely must be held rigidly. Any vibration or movement during the cut will ruin a mirror finish and can lead to tool breakage.

2. Tool Holder and Collet

Collet Chuck: The best option for holding small end mills. They provide excellent runout accuracy (ensuring the tool spins perfectly true).

10mm Collet: You will need a collet that accepts a 10mm shank. If your machine typically uses inch-sized collets, you might need a set of metric collets or a specific adapter. Ensure the collet is clean and free of debris.

Runout: Aim for the lowest possible runout. Even a small amount of wobble can cause surface finish issues and premature tool wear.

3. Spindle Speed (RPM) and Feed Rate Setup (Initial Guidelines)

This cannot be stressed enough: Always consult the end mill manufacturer’s recommendations or use established machining formulas as a starting point. Aluminum 6061 machines differently depending on its temper and the specific cutting tool.

Here are some general starting points for a 1/8 inch 2-flute carbide end mill in Aluminum 6061. These are for roughing passes, and finishing passes will use different, typically lighter, parameters.

Surface Speed (SFM): For carbide in aluminum, this can range widely, but a common starting point might be around 300-700 SFM.

Calculate RPM:

RPM = (Surface Speed in SFM 12) / Pi (3.14159) / Diameter in inches

For 1/8″ (0.125″) diameter:

At 400 SFM: RPM = (400 12) / 3.14159 / 0.125 = ~12,193 RPM

At 600 SFM: RPM = (600 12) / 3.14159 / 0.125 = ~18,290 RPM

chip load (per tooth): For aluminum, a chip load of 0.0005″ to 0.0015″ per tooth is often a good starting point.

Calculate Feed Rate (IPM):

Feed Rate (IPM) = RPM Chip Load per Tooth Number of Flutes

Using 15,000 RPM, 0.001″ chip load, and 2 flutes:

Feed Rate = 15,000 0.001 2 = 30 IPM

For Finishing Passes:

Plunge/Feed Rate: You’ll typically use a much slower feed rate for finishing passes to maintain control and get a smooth surface. This might be 10-20 IPM or even slower, depending on the machine.

Depth of Cut: Very shallow, often 0.001″ to 0.005″.

Stepover: For a smooth surface, a fine stepover is crucial. For a 1/8 inch end mill, a stepover of 10-25% of the tool diameter is common for finishing. That’s 0.012″ to 0.030″. For a mirror finish, you might even push this finer if your machine can handle it without vibration.

Remember: These are just starting points. Always listen to your machine and adjust if you hear chattering, see excessive vibration, or notice chips welding to the tool.

4. Coolant/Lubrication System

Flood Coolant: The most effective method for aluminum. A continuous flow of coolant lubricates the cutting zone, cools the tool and workpiece, and flushes away chips effectively. This is almost essential for achieving a mirror finish on aluminum without welding.

Mist Coolant: A thinner spray of coolant and air. Can be effective if flood isn’t an option, but requires careful setup.

Cutting Fluid: Use a fluid specifically designed for aluminum. Many general-purpose cutting fluids can work, but some are better than others at preventing buildup. Avoid oils that are too viscous.

Air Blast: For very light finishing passes or certain machines, a strong air blast can help, but it’s generally not sufficient on its own for aluminum.

Importance for Mirror Finish: Proper cooling and lubrication prevent chip welding, which is a primary cause of