A 1/8 inch carbide end mill is essential for accurately and efficiently machining carbon steel, especially for detailed cuts and smaller workpieces. Its hardness and precision make it ideal for this tough material, ensuring clean results and prolonged tool life when used correctly.

Hey makers! Daniel Bates here from Lathe Hub. Ever stared at a piece of carbon steel and wondered how to get those super-clean, precise cuts without a fuss? It can seem a bit daunting, right? You’ve got your project planned, but the right tool is key. That’s where a tiny but mighty tool comes in: the 1/8 inch carbide end mill. It might seem small, but for working with stubborn carbon steel, it’s a game-changer for getting those intricate details just right. Don’t worry if you’re new to this. We’re going to walk through exactly why this little guy is so important and how to use it to make your projects shine.

Why a 1/8 Inch Carbide End Mill is Your Carbon Steel Secret Weapon

Carbon steel can be tough. It’s strong, durable, and great for many applications, but it can also be challenging to machine precisely, especially with standard tools. This is where the magic of carbide comes in. Carbide, or tungsten carbide, is an extremely hard material. When formed into an end mill, especially a smaller diameter one like 1/8 inch, it offers some serious advantages for working with carbon steel. Think of it as bringing a super-sharp, super-tough knife to battle a stubborn material – it just makes the job so much easier and cleaner.

Unpacking the Benefits for Carbon Steel Machining

So, what makes this specific tool so good for carbon steel? Let’s break it down.

- Superior Hardness: Carbide is significantly harder than high-speed steel (HSS). This means it can cut through tough materials like carbon steel with less effort and less wear. For a material as dense as carbon steel, this difference is huge.

- Heat Resistance: Machining creates friction and heat. Carbide can withstand much higher temperatures than HSS without losing its cutting edge. This is vital for carbon steel, which can generate a lot of heat during milling.

- Precision and Detail: The 1/8 inch diameter is perfect for smaller, more intricate work. Whether you’re engraving, creating small slots, or doing fine profiling on carbon steel, this size allows for incredible accuracy.

- Longer Tool Life: Because carbide is so hard and resistant to heat, a carbide end mill will last much longer when machining carbon steel compared to an HSS tool. This means fewer tool changes and more consistent results over time.

- Cleaner Cuts: The sharpness and rigidity of carbide end mills lead to cleaner, more precise cuts with less tearing or burring on the material surface. This is especially noticeable on materials like carbon steel that can chip if cut improperly.

When you’re aiming for those crisp edges and detailed features on carbon steel, a 1/8 inch carbide end mill isn’t just a good option; it’s often the best option.

Understanding the “Carbide End Mill 1/8 Inch 3/8 Shank Extra Long for Carbon Steel Dry Cutting”

You might see a full description like “carbide end mill 1/8 inch 3/8 shank extra long for carbon steel dry cutting.” Let’s break down what each part of that name tells us:

- Carbide End Mill: We’ve covered this – it’s made of tungsten carbide.

- 1/8 Inch: This is the cutting diameter. It tells you how wide the cutting end of the tool is. This is crucial for the size of the grooves or features you can create.

- 3/8 Shank: This is the diameter of the non-cutting part of the tool that fits into your milling machine’s collet or tool holder. A 3/8 inch shank is a common size for many milling machines, offering good rigidity.

- Extra Long: This refers to the overall length of the end mill, particularly the length of the cutting flutes and the reach from the shank. An extra-long end mill allows you to machine deeper cavities or reach tougher spots without needing extensions.

- For Carbon Steel: This indicates the tool is specifically designed or recommended for machining carbon steel. This often means the flute geometry (the shape of the cutting edges) and the carbide grade are optimized for this material.

- Dry Cutting: This suggests the end mill is designed to perform well without the need for cutting fluid or coolant. While coolant is often recommended for harder materials, some carbide end mills have coatings or geometries that allow for dry machining, which can simplify setups.

Knowing these details helps you select the right tool for your specific job. For beginners, starting with basic specifications is important, and then you can explore variations like “extra long” or “dry cutting” as your projects become more complex.

Choosing the Right 1/8 Inch Carbide End Mill

Not all 1/8 inch carbide end mills are created equal, especially when it comes to carbon steel. Here are a few key factors to consider to ensure you pick a tool that will perform reliably and safely.

Key Features to Look For

- Number of Flutes: For machining steel, you’ll typically want an end mill with 2 or 4 flutes.

- 2-Flute: Generally better for slotting and leaving a good chip load, which helps with chip evacuation in materials like steel.

- 4-Flute: Offers smoother finishes and can handle higher feed rates, often good for profiling and general machining where surface finish is important. For harder steels, 2 flutes might be preferred to help clear chips more easily.

- Coating: End mills can come with various coatings (like TiAlN, TiN, or ZrN). For carbon steel, a black or dark coating like TiAlN (Titanium Aluminum Nitride) is often beneficial. These coatings improve heat resistance, reduce friction, and extend tool life significantly.

- Carbide Grade: Carbide itself comes in different grades, affecting its toughness and hardness. For general-purpose machining of carbon steel, a fine-grain carbide is usually a good balance of strength and wear resistance.

- Helix Angle: This refers to the angle of the cutting edges. A standard helix angle (around 30 degrees) is good for general use. Higher helix angles can offer a sharper cutting action but may be less rigid.

- End Type: Most 1/8 inch end mills will be “square” or “ball” end.

- Square End: Creates sharp 90-degree corners. Ideal for pockets, slots, and general contouring.

- Ball End: Has a rounded tip, creating a rounded profile. Useful for 3D contouring and creating fillets.

When to Consider an “Extra Long” Shank

The “extra long” designation on an end mill means it has an extended reach. This is incredibly useful for several reasons:

- Deeper Machining: If your design requires pockets or slots that are deeper than the standard flute length of an end mill, an extra-long one is essential.

- Reaching Difficult Areas: Sometimes, you might need to machine inside a part where access is limited. The longer reach can help with this.

- Reduced Tool Deflection: While a longer tool can be more prone to deflection (bending), if used correctly with appropriate speeds and feeds, it can sometimes allow for a more direct cut, avoiding the need for multiple setups or tool changes.

For beginners, starting with a standard length end mill is usually a good idea. As you gain experience and tackle more complex projects, you’ll appreciate the utility of extra-long options.

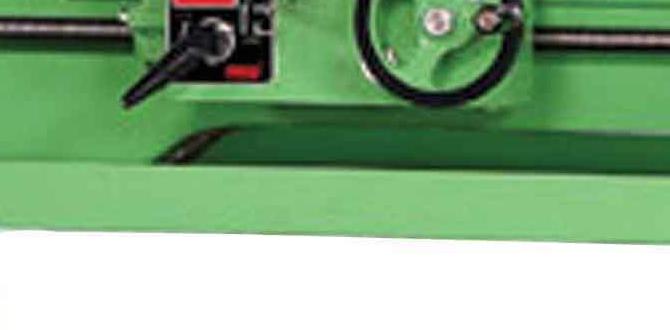

Setting Up Your Milling Machine for Carbon Steel

Getting your machine ready is as important as choosing the right tool. For carbon steel, a bit more care in setup can prevent headaches and broken tools.

Essential Machine Checks

- Rigidity: Ensure your milling machine is stable and all components (spindle, table, vise) are firmly locked. Any play or vibration will be amplified and can lead to poor cuts or tool breakage.

- Collet/Tool Holder: Use a high-quality collet or tool holder for your 1/8 inch end mill. A worn or improperly seated collet can cause runout (wobble), leading to chatter and inaccurate cuts.

- Workholding: Secure your carbon steel workpiece firmly in a vise or appropriate fixturing. It should not move at all during the machining process. Double-check that your vise jaws are clean and tight.

Speed and Feed Considerations (Beginner’s Guide)

This is where things can get technical, but let’s keep it simple. Speeds and feeds determine how fast the tool spins (speed) and how fast it’s pushed through the material (feed). For 1/8 inch carbide end mills on carbon steel, a good starting point is often lower speeds and conservative feeds.

A general rule of thumb for carbide on steel:

- Spindle Speed (RPM): Start relatively low. For very hard steels, you might be in the range of 1,000 – 5,000 RPM. This is much lower than you might use for aluminum or plastics.

- Feed Rate (IPM – Inches Per Minute): This depends heavily on the depth of cut and the machine’s rigidity. For a 1/8 inch end mill in carbon steel, you’ll want a feed rate that allows the tool to cut effectively without overworking it. This might be anywhere from 2 to 15 IPM, depending on the specific steel and cut.

Why these settings matter:

- Too Fast RPM / Too Slow Feed: Will cause the tool to rub rather than cut, leading to rapid wear and tool breakage.

- Too Slow RPM / Too Fast Feed: Can overload the flutes, also resulting in tool breakage or poor surface finish.

- Depth of Cut: For a 1/8 inch end mill, especially in a hard material like carbon steel, take light passes. A radial depth of cut (how much of the tool’s diameter is engaged sideways) of around 0.010″ to 0.030″ and an axial depth of cut (how deep you’re cutting down) of around 0.005″ to 0.015″ is a safe starting point.

Always check the manufacturer’s recommendations for your specific end mill, as they often provide starting speed and feed charts. You can also consult resources like the Machinery’s Handbook for more detailed tables, though for beginners, finding manufacturer data is often easier and more direct.

Pro Tip: Listen to your machine! A well-set-up cut will sound like a consistent, light “shaving” sound. Any high-pitched squealing, loud chattering, or grinding indicates something is wrong and you should stop immediately.

Machining Techniques with Your 1/8 Inch Carbide End Mill

Now that you’re set up, let’s talk about how to actually use that 1/8 inch carbide end mill on carbon steel.

Roughing vs. Finishing Passes

For precision work, especially on a tough material like carbon steel, it’s often best to use multiple passes:

- Roughing Pass: This pass removes the bulk of the material. You can use a slightly more aggressive depth of cut (while still being conservative for a 1/8 inch tool) and potentially a slightly faster feed rate than your final finishing pass. The goal is to get close to your final dimensions.

- Finishing Pass: This is the final light pass that cleans up the surface and brings the part to its exact final dimensions. For this pass, you’ll use a much lighter depth of cut (e.g., 0.005″ to 0.010″) and a slower, more delicate feed rate. This ensures a smooth, accurate finish.

Climb Milling vs. Conventional Milling

These terms refer to the direction the cutting tool engages the workpiece relative to the direction the spindle is rotating.

- Conventional Milling: The cutter rotates against the feed direction. This is generally safer for beginners as it tends to push the workpiece away from the cutter, reducing the risk of the tool grabbing.

- Climb Milling: The cutter rotates in the same direction as the feed. This results in a cleaner surface finish and reduces tool wear because the chip is being thinned as it’s cut. However, it requires a machine with minimal backlash (play in the lead screws) and a very rigid setup, or the cutter can “climb” the material leading to breakage.

For 1/8 inch carbide end mills on carbon steel, many machinists prefer climb milling if their machine allows for it, especially for finishing passes. However, if you’re unsure about your machine’s rigidity or backlash, conventional milling is a safer bet.

Dry Cutting Considerations

As mentioned earlier, some end mills are designed for “dry cutting.” This means they can operate efficiently without coolant. This is often thanks to advanced coatings and geometries designed to manage heat and chip evacuation.

Pros of Dry Cutting:

- Simpler setup – no need for coolant systems.

- Cleaner workspace.

- Reduced risk of coolant contamination on machined parts.

Cons of Dry Cutting:

- Tool life might be slightly shorter than with optimal coolant application.

- Chip evacuation becomes even more critical, as chips can trap heat. Ensure your machine has good air blast or vacuum to remove chips.

- Not suitable for all materials or all machining operations.

If your end mill is rated for dry cutting, it implies it’s designed to handle the heat generated by working with materials like carbon steel without significant degradation.

Safety First! Working with Milling Tools

Machining, especially with rotating tools like end mills, demands respect for safety. A few fundamental practices will keep you safe and your projects on track.

Essential Safety Gear

- Safety Glasses: Always wear ANSI-approved safety glasses or a full face shield. Metal chips are sharp and can fly at high speeds.

- No Loose Clothing or Jewelry: Anything that can get caught in rotating machinery must be removed.

- Gloves (When Appropriate): Wear gloves when handling sharp metal or setting up, but never while the machine is running, as they can get caught.

- Hearing Protection: Milling can be noisy.

Safe Machining Practices with End Mills

- Secure Workpiece: As mentioned, ensure the workpiece is absolutely locked down.

- Secure Tool: Ensure the end mill is properly seated in the collet and the collet is tightened securely in the spindle.

- Start Slow: Begin with conservative speeds and feeds. It’s always better to be too cautious initially.

- Clear Chips Regularly: Use a brush or an air hose (with caution – wear eye protection and be aware of flying chips) to remove chips from the workpiece and the flutes. Don’t let chips build up.

- Listen and Observe: Pay attention to the sounds and vibrations your machine makes. Any unusual noise is a warning sign.

- Know Your E-Stop: Familiarize yourself with the emergency stop button on your machine.

- Never Reach Over a Running Tool: Always stop the spindle before attempting to clear chips, measure your work, or make any adjustments.

For more in-depth workplace safety guidelines, especially those related to metalworking machinery, the Occupational Safety and Health Administration (OSHA) provides valuable resources for safe operation.

Troubleshooting Common Issues

Even with the best preparation, you might encounter a few bumps in the road. Here’s how to tackle them:

Chatter / Vibration

Cause: Not rigid enough setup (machine, workpiece, or tool), incorrect speeds/feeds, worn tool, dull tool.

Solution: Increase rigidity, take lighter cuts, adjust speeds/feeds (often slightly higher RPM with lighter feed can help), check and potentially replace the tool.

Poor Surface Finish

Cause: Tool is dull, incorrect speeds/feeds, insufficient depth of cut, chip recutting.

Solution: Use a sharp tool, optimize speeds and feeds, ensure you’re taking a light finishing pass, make sure chips are evacuating cleanly.

Tool Breakage

Cause: Too aggressive feed rate, too deep of a cut, improper tool engagement (e.g., plunging too fast), machine backlash, weak setup, dull tool.

Solution: Reduce feed rate, take lighter axial and radial depths of cut,