Quick Summary:

For efficient and clean aluminum cutting, a 3/16 inch carbide end mill with an 8mm shank is an excellent choice. These tools excel at dry cutting tough aluminum alloys like 7075, offering precision without excessive heat buildup, making them ideal for home workshops.

Aluminum can be tricky to machine. It’s soft, gummy, and can easily clog your cutting tools, leading to poor finishes and broken bits. But don’t let that discourage you! Cutting aluminum cleanly and efficiently is very achievable, especially when you have the right tool for the job. We’re going to focus on a specific hero for aluminum work: the 3/16 inch (or 8mm shank) carbide end mill.

Many machinists and makers trust this size and material for its balance of cutting power and manageability. It’s perfect for detailed work and handles common aluminum alloys like 7075 like a champ. This guide will walk you through everything you need to know to use your 3/16 inch carbide end mill effectively and safely for your aluminum projects. Let’s get your machines cutting smoothly!

Why a 3/16 Inch Carbide End Mill is Your Aluminum’s Best Friend

When you’re starting out with milling aluminum, choosing the right cutting tool can make all the difference. The 3/16 inch carbide end mill, especially those with an 8mm shank, stands out for several good reasons:

- Carbide is King for Aluminum: Unlike High-Speed Steel (HSS), carbide retains its hardness at higher temperatures. Aluminum cutting generates heat, and carbide’s resistance to this heat means it stays sharp longer and cuts more cleanly. It’s also significantly harder, resisting wear and tear better.

- 3/16 Inch Sweet Spot: This size is fantastic for a variety of tasks. It’s small enough for intricate details and shallow cuts, but robust enough for more substantial material removal. It’s a versatile size that finds its way into many project plans.

- 8mm Shank Advantage: An 8mm shank provides a good balance of rigidity and compatibility with many common collet systems and tool holders found in hobbyist and entry-level milling machines. It offers more rigidity than a standard 1/4-inch (6.35mm) shank without requiring oversized collets.

- Designed for Dry Cutting: Many carbide end mills, especially those made for aluminum, are designed to perform well without flood coolant. This is a huge advantage for home workshops and DIY setups where managing coolant can be messy and complex. Dry cutting with carbide often works by clearing chips effectively, preventing them from welding to the cutter.

- Excellent for 7075 Aluminum: This alloy is known for being tough and prone to gummy behavior. A sharp carbide end mill is often the best way to tackle it cleanly, preventing the chip welding that plagues softer steels and even less well-suited cutters.

Understanding the “Gummy” Nature of Aluminum

Aluminum, especially alloys like 6061 and 7075, has a tendency to be “gummy.” This means it can stick to the cutting edge of your tool. When chips stick like this, they don’t get cleared away properly. Instead, they get recut, leading to increased friction, heat, and a rough surface finish. In severe cases, the chips can build up so much that they break the end mill. This is why the geometry and material of the end mill are so critical.

Key Features of a Good Aluminum-Cutting Carbide End Mill

Not all carbide end mills are created equal, especially when it comes to aluminum. Here’s what to look for in a 3/16 inch tool:

- Number of Flutes: For aluminum, 2-flute or 3-flute end mills are generally preferred.

- 2-Flute: Offers excellent chip clearance, which is vital for preventing that gummy buildup. This is often the best choice for general aluminum milling and hogging.

- 3-Flute: Provides a smoother finish than a 2-flute and can handle slightly higher feed rates without sacrificing chip evacuation too much. It’s a good all-around choice, especially if you want a bit more finesse.

- 4-Flute: While common for steels, 4-flute mills can sometimes struggle with chip packing in aluminum. If you use a 4-flute, you’ll need to ensure adequate chip clearance (often by using a higher feed rate and shallower depth of cut).

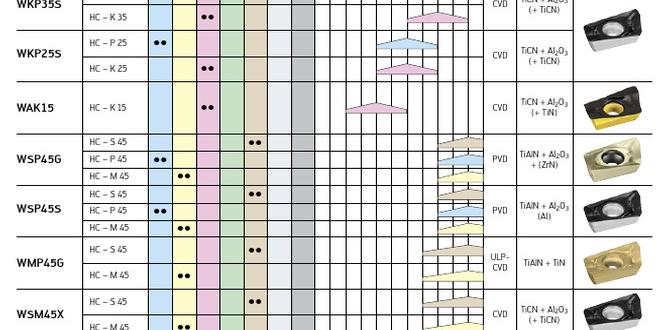

- Coating: While many aluminum-specific end mills perform well uncoated, some coatings can further improve performance and tool life.

- Uncoated: Often brightly polished, these are excellent for aluminum as they have a very low surface friction.

- ZrN (Zirconium Nitride): This biocompatible coating is thin and hard, reducing friction and helping prevent chip welding. It’s a good option for aluminum.

- TiCN (Titanium Carbonitride): Harder than ZrN, but can sometimes increase friction slightly. Generally better for harder materials, but can be used on aluminum if needed.

- AlTiN (Aluminum Titanium Nitride): Best for high-temperature applications and harder materials. Generally overkill and not ideal for aluminum machining.

For aluminum, an uncoated, highly polished mill is often the simplest and most effective starting point.

- Helix Angle: A higher helix angle (30-45 degrees) is generally better for aluminum. This steeper angle helps lift chips out of the flutes more effectively, improving chip evacuation and reducing the risk of recutting.

- End Cut Type:

- Square End: The most common type, good for pockets, profiles, and general milling.

- Ball End: Creates rounded corners and is used for 3D contouring and creating fillets.

- Corner Radius: A square end with a small radius on the corners. This adds strength to the tool and helps prevent chipping, while still allowing for sharp internal corners in some cases. For aluminum, a slight corner radius can be beneficial.

- Material: As mentioned, solid carbide is the standard for performance. Ensure it’s good quality carbide.

Essential Setup for Cutting Aluminum with Your 3/16 Inch Carbide End Mill

Before you even think about turning on the machine, proper setup is crucial. This ensures accuracy, safety, and a good finish.

1. Secure Workpiece Holding

Aluminum needs to be held firmly to prevent chatter and movement during cutting.

- Vise: A good quality milling vise with hardened jaws is the most common method. Ensure the jaws are clean and the vise is tight.

- Clamps: For larger or irregularly shaped parts, clamp them directly to the milling table. Use a combination of strap clamps and toe clamps. Always ensure clamps are not in the tool’s path and aren’t hindering chip evacuation.

- Fixtures: For production runs or highly precise parts, custom fixtures are ideal.

Tip: Placing a thin sheet of aluminum or brass shim stock between your workpiece and the vise jaws can protect the part from marring and provide a more even clamping surface.

2. Tool Holder and Collet

Your 3/16 inch end mill needs to be held securely. Since we’re focusing on an 8mm shank, you’ll need an 8mm collet that fits your milling machine’s collet chuck.

- Collets: Use a quality set of ER collets or similar. Ensure the collet you choose is the correct size for the shank (8mm in this case) and that it’s clean.

- Collet Chuck: Make sure the collet chuck is clean and properly installed in your spindle.

- Tool Rigidity: The shorter the tool is extended from the collet, the more rigid the setup. Minimize overhang whenever possible.

3. Machine Setup – Spindle Speed and Feed Rate

This is where things get specific to aluminum. The goal is to cut without melting or clogging.

Spindle Speed (RPM):

Carbide generally likes to spin faster than HSS. For aluminum, typical surface speeds are in the range of 300-600 surface feet per minute (SFM). You’ll need to convert this to RPM based on your tool’s diameter.

The formula is:

$$ RPM = frac{SFM times 12}{D times pi} $$

Where:

- SFM = Surface Feet per Minute

- D = Diameter of the end mill in inches

- $pi$ (pi) ≈ 3.14159

For a 3/16 inch (0.1875 inch) end mill and a target SFM of 400:

$$ RPM = frac{400 times 12}{0.1875 times 3.14159} approx 8150 text{ RPM} $$

This is a starting point. You might find better results slightly higher or lower depending on your material and machine rigidity. Many smaller desktop CNC machines and some Bridgeport-style mills can easily achieve these speeds.

Feed Rate (IPM):

The feed rate is how fast the cutter moves through the material. For aluminum, you want a feed rate high enough to create distinct chips, rather than rubbing or “plowing.”

A common starting point for a 3/16 inch, 2-flute carbide end mill in aluminum is around 0.001 to 0.002 inches per tooth (IPT).

The formula for Inches Per Minute (IPM) is:

$$ IPM = IPT times text{Number of Flutes} times RPM $$

Using our example RPM and an IPT of 0.0015 for a 2-flute mill:

$$ IPM = 0.0015 times 2 times 8150 approx 24 text{ IPM} $$

Chipload Calculation Table (Approximation for 3/16″ Carbide in Aluminum)

This table gives you a rough idea, but always listen to your machine!

| End Mill Type | Target Chipload (IPT) | Example RPM (400 SFM) | Example Feed Rate (IPM, 2-Flute) | Example Feed Rate (IPM, 3-Flute) |

|---|---|---|---|---|

| 3/16″ Carbide, 2-Flute | 0.001″ – 0.0025″ | ~8150 RPM | 16 – 41 IPM | – |

| 3/16″ Carbide, 3-Flute | 0.0008″ – 0.002″ | – | 19 – 49 IPM |

Note: IPT = Inches Per Tooth. This is a guideline; always adjust based on your specific material and machining sound.

The sound of the cut is your best indicator. If it’s screaming, screeching, or you hear a “chattering” rhythmic banging, your feed rate or spindle speed is likely off. A nice, smooth “hissing” or “swishing” sound is what you’re aiming for.

4. Depth of Cut (DOC) and Stepover

These parameters dictate how much material you remove per pass.

- Depth of Cut (DOC): For roughing cuts, you can often take a DOC equal to about 50-100% of the end mill’s diameter. For finishing, you want a much shallower DOC, often just 0.005″ to 0.010″, to achieve a good surface finish. With a 3/16″ end mill, this means a roughing DOC of around 0.09″ to 0.18″, and a finishing DOC of 0.005″ to 0.010″. However, for beginners and less rigid machines, starting with shallower DOCs (e.g., 0.060″ for roughing) is wiser.

- Stepover: This is the distance the tool moves sideways between passes. For roughing, a stepover of 30-70% of the tool diameter is common. For finishing, a much smaller stepover (e.g., 10-20%) is used to create a smooth surface.

Step-by-Step Guide: Cutting Aluminum with Your 3/16 Inch Carbide End Mill

Let’s walk through a typical milling operation.

Step 1: Prepare Your Machine and Workspace

- Ensure your milling machine is clean and free of debris.

- Check that all belts and gears are properly tensioned and lubricated.

- Clear any obstructions from the work area.

- Wear safety glasses, enclosed-toe shoes, and appropriate clothing (no loose sleeves or jewelry).

Step 2: Secure Your Workpiece

- Using your chosen method (vise, clamps, etc.), firmly secure the aluminum block or sheet to your milling table. Ensure it is perfectly parallel to the milling axis if needed for flatness.

- Double-check that the workpiece is stable and won’t shift during machining.

Step 3: Load Your End Mill

- Select the correct 8mm collet for your end mill.

- Ensure both the collet and the end mill shank are clean and free of oil, chips, or debris.

- Insert the 3/16 inch carbide end mill into the collet, ensuring it’s seated all the way.

- Tighten the collet securely in the collet chuck according to your machine’s procedure.

- Install the collet chuck into the milling machine spindle.

Step 4: Set Your Zero Point (Work Coordinate System)

- This is critical for accuracy. You’ll typically set your X, Y, and Z zero points based on your workpiece.

- For X and Y, you might use an edge finder or a dial indicator to find the corner or center of your workpiece.

- For Z zero, it’s common to touch off on the top surface of the workpiece with your end mill. You can do this manually by carefully lowering the spindle until the rotating end mill just kisses the surface (use a piece of paper to detect contact) or by using an electronic Z-probe or touch-off plate.

Step 5: Program or Manually Operate the Mill

- For CNC: Load your G-code program. Double-check your program for any obvious errors, especially in the toolpath, speeds, and feeds. It’s always wise to run a “dry run” in air first, or a “simulation” mode if your machine supports it, to watch the tool path.

- For Manual Mill: You will be controlling the X, Y, and Z axes manually using handwheels. Understand your machine’s DRO (Digital Readout) or machine dials to track your position.

Step 6: Perform the First Cut (Test Cut)

- Start Slow: It’s always best to start with conservative speeds and roughly halved depths of cut for your very first operation on a new material or with a new tool.

- Engage Spindle: Turn on the spindle to the calculated RPM. Ensure it runs smoothly.

- Plunge or Engage:

- Plunge (for pockets): If you’re plunging into the material, do so slowly and carefully at your programmed feed rate. Some plunges can be done at 50% of your regular feed rate.

- Engage (for profiling/contouring): Approach the edge of the material and engage the cut smoothly.

- Observe: Listen to the sound of the cut. Watch for chip formation. Are they small and dusty, or are they long, stringy, and packing up? Are you getting excessive vibration or chatter?

Step 7: Adjust as Needed

- Too much chatter or noise? Try reducing the feed rate slightly, or increasing the spindle speed slightly, or take a shallower depth of cut. Check for loose workholding or tool runout.

- Chips packing up? Increase the feed rate slightly to create larger chips. Ensure your spindle speed isn’t too low. A higher helix angle end mill can also help here. For desktop machines, sometimes increasing the spindle RPM is the only option.

- Poor surface finish (orange peel or rough)? Clean up your feed rate and DOC. A finishing pass with a very shallow DOC (e.g., 0.005″) and a small stepover (e.g., 10-15%) can dramatically improve the finish.

Step 8: Roughing and Finishing Passes

- Roughing: Perform the bulk of the material removal using your calculated roughing speeds, feeds, and depths of cut. Aim to leave a small amount of material (e.g., 0.010″ – 0.020″) for a finishing pass.

- Finishing: With your roughing geometry complete, perform a final pass or