Summary: For machining tough tool steels, a carbide end mill is the superior choice. Its hardness and heat resistance allow it to cut effectively where high-speed steel (HSS) struggles, preventing tool damage and ensuring better results.

Hey makers! Daniel Bates here from Lathe Hub. Ever tried cutting into tough stuff like tool steel and felt like your mill bit was just… giving up? It’s a common frustration. Standard bits can overheat, dull instantly, or even break. But what if there’s a tool designed precisely for this challenge? There is, and it’s a bit of a workshop superhero: the carbide end mill. In this guide, we’ll explore why carbide is your best buddy for tool steel and how to use it like a pro. Get ready to tackle those hard metals with confidence!

Why Tool Steel is Such a Tough Nut to Crack

Tool steels are amazing materials. They’re built to be hard, strong, and wear-resistant. This makes them perfect for making things like punches, dies, molds, and, well, other cutting tools! But this incredible toughness is exactly what makes them so difficult to machine.

When you try to cut tool steel with less robust materials, a few things happen:

- Friction and Heat: Machining creates a lot of friction. This friction generates intense heat, especially at the cutting edge of your tool.

- Dulling: Standard bits, like those made from High-Speed Steel (HSS), are much softer than tool steel. The heat and abrasive nature of tool steel quickly dulls an HSS bit. A dull bit not only cuts poorly but also creates even more heat.

- Chipping and Breaking: When a tool dulls or encounters excessive force (due to the material’s hardness), it can chip or snap. This can damage your workpiece, your machine, and even be dangerous.

- Slow Machining Speeds: To try and compensate, you might slow down your machining speeds. However, even at slower speeds, HSS often struggles against the hardness of tool steel.

It’s like trying to carve granite with a butter knife – it’s just the wrong tool for the job! You end up frustrated, wasting time, and potentially damaging expensive materials and tools.

Enter the Carbide End Mill: The Hero of Hard Materials

This is where carbide end mills shine. Carbide, specifically Tungsten Carbide, is an extremely hard and dense material. It’s significantly harder than High-Speed Steel and can withstand much higher temperatures.

Here’s why carbide is the genius solution for tool steel:

- Superior Hardness: Carbide’s hardness means it can cut through tough materials like tool steel without readily dulling or deforming. Think of it as using a diamond-tipped saw for a very hard rock.

- High-Temperature Resistance: Machining generates heat. Carbide can maintain its hardness at temperatures that would turn HSS soft and useless. This allows for more aggressive cutting parameters and faster material removal.

- Edge Retention: Because it stays sharp for longer, a carbide end mill provides consistent cutting performance over its lifespan, leading to better surface finishes and more predictable results.

- Wear Resistance: Its dense structure makes it highly resistant to abrasive wear, which is crucial when working with abrasive materials like many tool steels.

Carbide end mills come in many shapes and sizes, designed for specific tasks and materials. For tool steel, you’ll often see them with specific flute designs and coatings optimized for heat dissipation and chip evacuation. For instance, a “carbide end mill 3/16 inch 8mm shank reduced neck for tool steel D2 MQL friendly” is a very specific tool designed for precision work on demanding materials.

Understanding Carbide End Mill Types for Tool Steel

Not all carbide end mills are created equal, especially when it comes to tool steel. The type of carbide, the number of flutes, the geometry, and any coatings all play a big role.

Carbide Grades

Tungsten carbide powder is mixed with a binder material, usually cobalt, and then sintered (heated under pressure). The ratio of tungsten carbide to cobalt affects the properties:

- Higher Cobalt Content (e.g., 10-15%): This makes the carbide tougher and more resistant to chipping, which can be good for interrupted cuts or less rigid setups. However, it’s slightly less hard.

- Lower Cobalt Content (e.g., 6-10%): This results in a harder, more wear-resistant grade, ideal for finishing operations or when dealing with very abrasive materials where edge retention is key.

For tool steel, a good balance is often sought, or a harder grade for finishing. Manufacturers usually specify recommended grades for different material types.

Number of Flutes

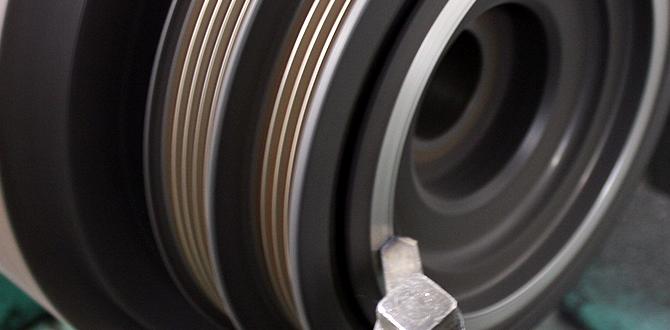

Flutes are the spiral grooves that run along the cutting edge of the end mill. They help to evacuate chips and cool the cutting zone.

- 2-Flute: Excellent for plunging, slotting, and general-purpose cutting. They have more space for chip evacuation, which is vital in deep cuts.

- 3-Flute: A good compromise between chip evacuation and surface finish. They can often be run slightly faster than 2-flute mills.

- 4-Flute: Best for finishing operations and general milling when chip evacuation is less of a concern. They provide a better surface finish and can handle higher feed rates for lighter passes.

For tool steel, especially in deeper cuts or when dealing with gummy materials, 2 or 3-flute mills are often preferred to maximize chip clearance and reduce the risk of chip recutting, which generates intense heat. A “reduced neck” on an end mill is a design feature where the shank diameter is smaller than the cutting diameter. This is crucial for reaching into deep or narrow pockets without the shank rubbing against the workpiece, which would cause damage and generate heat.

Coatings

Coatings add an extra layer of performance to carbide end mills:

- TiN (Titanium Nitride): A general-purpose coating, offers good hardness and reduces friction.

- TiCN (Titanium Carbonitride): Harder than TiN, good for abrasive materials and higher cutting speeds.

- AlTiN (Aluminum Titanium Nitride): Excellent for high-temperature applications and machining hard materials like tool steels. It forms a protective oxide layer, preventing heat buildup. This is often a go-to coating for tool steels.

- DLC (Diamond-Like Carbon): Extremely hard, excellent for gummy materials like aluminum, but can also be beneficial for some tool steels for wear resistance.

For your “carbide end mill 3/16 inch 8mm shank reduced neck for tool steel D2 MQL friendly,” an AlTiN coating would be a very smart choice for machining D2 tool steel.

MQL (Minimum Quantity Lubrication) Friendly

MQL is a lubrication system that delivers a very small amount of oil mist directly to the cutting zone. This is incredibly effective for cooling and lubricating without flooding the workpiece. Many end mills designed for tough materials are “MQL friendly,” meaning their flute geometry and coatings are optimized to work with this system. This is critical for tool steel, as effective cooling and lubrication are paramount to prevent catastrophic tool failure.

You can learn more about Machining Fundamentals from institutions like the National Institute of Standards and Technology (NIST), which often discusses advanced manufacturing techniques and materials.

Choosing the Right Carbide End Mill for Your Tool Steel Project

When you’re staring at a shelf full of end mills, how do you pick the right one for tool steel? Here’s a breakdown to help you select the best carbide end mill:

Key Considerations:

- Material Hardness: What is the specific Rockwell hardness (HRC) of your tool steel? Softer tool steels (under 45 HRC) might be manageable with more general-purpose carbide mills, while hardened tool steels (over 50 HRC) absolutely require specialized carbide end mills.

- Operation Type: Are you slotting, profiling, facing, or drilling? Different operations benefit from different flute counts and geometries. For slotting, a 2-flute is great. For profiling on hardened steel, a 4-flute might offer a better finish with lighter passes.

- Machine Rigidity: A more rigid machine can handle faster cutting speeds and heavier depths of cut, allowing you to take full advantage of a high-performance carbide end mill.

- Cooling Strategy: Will you use flood coolant, air blast, or MQL? Ensure your end mill is compatible with your chosen coolant delivery method.

Specific Features for Tool Steel

Look for end mills with these characteristics when machining tool steel:

- Material: Solid Tungsten Carbide is the standard.

- Flute Count: Often 2 or 4 flutes. 2 flutes for deep slots and high chip load, 4 flutes for finishing and lighter cuts where a good surface finish is critical.

- Geometry:

- Corner Radius: A small corner radius can add strength to the cutting edge and help prevent chipping, especially in harder materials.

- Strong, Sharp Edges: Look for end mills designed with positively raked cutting edges for easier cutting.

- Helical Cutters: Highly specialized end mills with complex geometries are often used for profile milling very hard materials.

- Coatings: AlTiN (Aluminum Titanium Nitride) or TiCN (Titanium Carbonitride) are excellent choices for their heat resistance and hardness.

- Helix Angle: A higher helix angle (e.g., 30° or 45°) can provide smoother cuts and better chip evacuation.

- Shank Design: Cylindrical shanks are common. For reaching into tight spaces, a “reduced neck” (shank smaller than cutter diameter) or a “long reach” end mill might be necessary, as seen in the “carbide end mill 3/16 inch 8mm shank reduced neck for tool steel D2 MQL friendly” example.

Example Scenario: Machining D2 Tool Steel

D2 tool steel is a popular workhorse, known for its high toughness, wear resistance, and moderate machinability (for a tool steel, that is!). It’s typically heat-treated to around 58-60 HRC before final machining, making it very hard.

For machining hardened D2, you’d want:

- A solid tungsten carbide end mill.

- Likely a 4-flute design for better surface finish and shallower depths of cut.

- An AlTiN coating to combat the high heat.

- A good chip evacuation design.

- Consider a tool with a positive rake geometry.

A specific tool like a “carbide end mill 3/16 inch 8mm shank reduced neck for tool steel D2 MQL friendly” would be ideal if you need to machine into a narrow area or a deep slot, and you plan to use an MQL system for cooling and lubrication. The 3/16 inch size is small, suggesting precision work, and the 8mm shank is the diameter of the tool holder connection often used in smaller milling machines or CNC routers.

Essential Setup: What You Need

Before you start carving into tool steel, make sure you have the right equipment and knowledge. This isn’t like milling aluminum; it requires a more deliberate approach.

Your Milling Machine

A small hobby mill or a full-sized CNC machine can work, but rigidity is key. The more stable your machine, the better you can cut tough materials without chatter and tool deflection.

Collets and Holders

Ensure you have good quality collets or tool holders that provide true concentricity (the tool runs dead center). A runout of even a few thousandths of an inch can cause uneven cutting, leading to tool breakage. An 8mm shank requires an 8mm collet or holder.

Coolant/Lubrication System

You absolutely need effective cooling and lubrication. This could be:

- Flood Coolant: Traditional system that bathes the cutting area.

- Through-Spindle Coolant: Coolant delivered through the tool holder and end mill.

- MQL (Minimum Quantity Lubrication): As mentioned, a mist of oil and air. This is excellent for tool steel as it provides lubrication and cooling while keeping the chip area relatively clear. Many specialized carbide end mills are designed for MQL.

- Air Blast: A strong jet of compressed air can help, but it’s often insufficient for aggressive tool steel machining.

For a “carbide end mill 3/16 inch 8mm shank reduced neck for tool steel D2 MQL friendly,” an MQL system or through-spindle coolant delivery would be highly recommended.

Workholding

Your workpiece must be held securely. Use clamps, vices, or fixturing that can withstand the forces involved. Any movement of the workpiece during cutting can lead to tool breakage.

Measuring Tools

Calipers and a dial indicator are essential for setting up your workpiece accurately and checking dimensions.

Safety Gear!

Never forget your safety glasses or face shield, ear protection, and sturdy work gloves (when handling tools and workpieces, disconnect power first!).

Step-by-Step: How to Mill Tool Steel with a Carbide End Mill

Use this guide to get started. Remember to always start with the most conservative settings and gradually increase if your machine and setup allow.

Step 1: Prepare Your Machine and Workspace

Clean your milling machine. Ensure the table and work area are free of debris. Set up your MQL system or coolant delivery, directing it straight at the cutting zone.

Step 2: Secure Your Workpiece

Use a vise or clamps to firmly secure your tool steel workpiece. Use parallels or shim stock if needed to get it level and positioned correctly. Indicate the workpiece to ensure it’s aligned with your machine’s axes.

Step 3: Install the Carbide End Mill

Choose the correct carbide end mill for your job (e.g., a 3/16 inch, 8mm shank, reduced neck, O-flute carbide end mill for aluminum but this is for D2 steel). Insert it into the appropriate 8mm collet and tighten it securely in your spindle. Ensure it’s seated properly.

Step 4: Set Your Cutting Parameters

This is crucial. Machining parameters depend heavily on the specific tool steel, its hardness, the end mill’s diameter, flute count, and your machine’s power and rigidity.

A good starting point for many hardened tool steels (around 55-60 HRC) using a general-purpose carbide end mill (like a 4-flute, AlTiN coated) might be:

- Surface Speed (SFM): 150-300 SFM (this is a broad range, consult tool manufacturer data).

- Feed per Tooth (IPT): 0.001″ – 0.003″ (this is for softer tool steels, for hardened tool steels, you might need even less, closer to 0.0005″ – 0.001″). This is why a .001″ -.002″ feed per tooth for a ½” diameter end mill is a starting point. For smaller tools like a 3/16” (0.1875”) end mill, you will need to significantly reduce your feed rate. A good starting point for a 3/16” carbide end mill on hardened tool steel would be around 0.0005” to 0.001” per tooth.

- Depth of Cut (DOC): 0.010″ – 0.050″ (for shallower cuts). For roughing, you might try up to 0.1″ with a larger diameter mill. Always use a shallow DOC and a conservative radial depth of cut (stepover) of 20-50% of the tool diameter.

- Spindle Speed (RPM): Calculate this using the Surface Speed formula:RPM = (SFM 3.82) / Diameter (inches)

For a 3/16″ (0.1875″) end mill at 200 SFM:

RPM = (200 3.82) / 0.1875 = 4075 RPM.

- Feed Rate (IPM): Calculate this using the Feed per Tooth formula:IPM = RPM Number of Flutes Feed per Tooth

Using the calculated RPM (4075) with a 4-flute mill and 0.0008″ feed per tooth:

IPM = 4075 4 0.0008 = 1