Carbide end mills, especially the 3/16 inch size with an 8mm shank, are fantastic for woodworking. They offer superior durability and precision, leading to longer tool life and cleaner cuts in wood. This guide makes understanding and using them simple for any beginner.

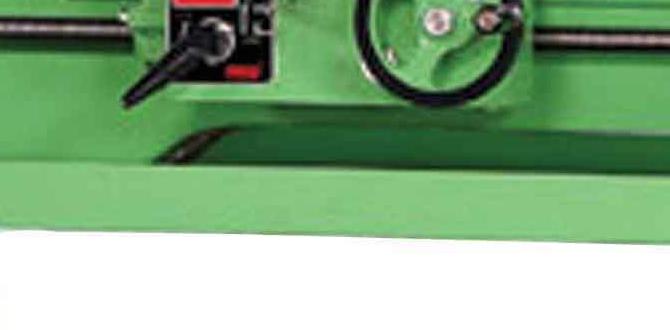

Hey folks, Daniel Bates here from Lathe Hub! Ever found yourself staring at a beautiful piece of wood, ready to carve intricate details, only for your tool to chatter, burn, or break? It’s a common frustration, right? Especially when you’re just starting out with CNC routers or other precision woodworking machines. But there’s good news! A tiny tool, the 3/16 inch carbide end mill, can be a game-changer. This little powerhouse is incredibly versatile and can make your woodworking projects smoother and more professional. Stick around, and I’ll walk you through exactly why this specific size is so essential and how to make the most of it.

Why the 3/16″ Carbide End Mill is a Wood Dream

When it comes to woodworking with precision machines like CNC routers, the right tool makes all the difference. You might be tempted by bigger bits or different materials, but for a wide range of tasks, the 3/16 inch carbide end mill shines. Let’s break down why this specific size and material combination is so popular and effective.

The Magic of Carbide

Carbide, or tungsten carbide, is a material known for its incredible hardness and durability. It’s much harder than high-speed steel (HSS), which is often used for cutting tools. What does this mean for your woodworking?

Longer Tool Life: Carbide bits resist wear much better than HSS. This means they stay sharp for greatly extended periods, saving you money and the hassle of frequent replacements, especially when cutting abrasive woods or composite materials. In fact, wear resistance dramatically increases the number of parts that can be produced before tool failure.

Higher Cutting Speeds: Because carbide is so hard, you can often run your machine at faster speeds without dulling the tool. This translates to quicker project completion times.

Better Performance on Tough Materials: While we’re focusing on wood, certain woods can be very dense or abrasive. Carbide handles these with ease, maintaining its edge where HSS might quickly dull.

The Sweet Spot: 3/16 Inch Diameter

The 3/16 inch (which is approximately 4.76mm) diameter is a fantastic sweet spot for many woodworking applications. It’s not too big to be unwieldy, and not too small to be fragile.

Detail Work: This size is perfect for creating fine details, intricate carvings, and crisp lettering. It allows for precise movements without taking away too much material at once.

Pocketing and Slotting: For creating cavities or channels in your wood projects, a 3/16 inch end mill offers a good balance between speed and control. It can remove material efficiently without being overly aggressive.

Versatility: From cutting out intricate inlays to creating dados for joinery, this size covers a surprisingly broad range of tasks.

The Benefit of a Reduced Neck (Commonly 8mm Shank)

Often, you’ll find 3/16 inch end mills with an 8mm shank. This might seem a bit unusual if you’re used to imperial measurements, but it makes sense! An 8mm shank (approximately 0.315 inches) is slightly larger than the 3/16 inch cutting diameter.

Increased Rigidity: A shank that’s larger than the cutting diameter provides more support. This means less vibration and deflection, leading to cleaner cuts and a reduced risk of tool breakage, especially during aggressive plunging or side milling operations.

Easier Collet Compatibility: Many CNC machines and routers use collets that are sized in metric. An 8mm shank will often fit perfectly into common 8mm collets, simplifying setup and ensuring a secure grip. You can learn more about CNC collets and chucks from resources like Haas Automation’s explanation of collets.

Understanding Carbide End Mill Types for Wood

Not all carbide end mills for wood are created equal. There are a few key features you’ll want to look for when choosing your 3/16 inch tool to ensure you get the best results and maximum tool life.

Helix Angle: The Key to Wood Cutting

The helix angle refers to the angle of the flutes (the spiral grooves) around the cutting tool. For woodworking, this is crucial!

High Helix (e.g., 30° – 45°): These are generally preferred for wood. A steeper helix angle provides a sharper cutting angle, which helps to “sheer” the wood fibers cleanly.

Pros: Produces a smoother finish, reduces tear-out, and can cut faster in many wood types. Excellent for detail work and finishing passes.

Cons: Can produce more sawdust (“chips”) and might require a more robust machine due to increased sideways forces.

Low Helix (e.g., 15° – 25°): Less common for general wood cutting, these are sometimes used for specific applications like very soft woods or roughing passes.

Pros: More rigid, can handle aggressive material removal.

Cons: Can lead to a rougher surface finish and more burning if not used carefully.

Number of Flutes: Balancing Chip Clearance and Finish

The number of flutes (the cutting edges) on an end mill impacts its performance.

2-Flute:

Pros: Excellent chip clearance. This is very important in woodworking, as it prevents sawdust from packing up in the flutes, which can lead to overheating, burning, and tool breakage. Great for plunging operations and materials that produce long, stringy chips. Generally produces a cleaner cut.

Cons: Can produce more vibration than a multi-flute tool.

3-Flute:

Pros: A good balance between chip clearance and smooth cutting. Can often run slightly faster than a 2-flute due to more cutting edges engaging the material.

Cons: Chip clearance is reduced compared to a 2-flute, making it more prone to clogging in gummy woods or when taking deep cuts.

4-Flute and Up:

Pros: Can achieve very smooth finishes and higher feed rates in materials that don’t produce excessive chips. Very rigid.

Cons: Poor chip clearance. Generally NOT recommended for most woodworking applications, especially for pocketing, as they tend to clog and burn easily.

For 3/16 inch carbide end mills for wood, a 2-flute high-helix end mill is often the top recommendation for versatility and performance.

Coatings: An Extra Layer of Performance

While less common for basic wood cutting than for metal, some specialized carbide end mills might have coatings. For wood, a standard, uncoated carbide is usually sufficient. However, if you plan on cutting very abrasive materials like MDF or plastics, or if you’re pushing your tools very hard, a TiN (Titanium Nitride) coating might offer marginal benefits, but it’s typically overkill for most wood. The primary advantage of carbide itself is already significant.

Essential Specifications for Your 3/16″ Carbide End Mill

When you’re shopping for this tool, you’ll see spec sheets. Don’t let them scare you! Here’s what to focus on for your 3/16 inch tool:

Key Specifications Table

| Specification | Typical Range / Value for 3/16″ Wood End Mill | Description |

| :——————– | :——————————————— | :—————————————————————————————————————————————– |

| Diameter | 3/16″ (approx. 4.76mm) | The cutting width of the end mill. Crucial for the detail and slot size. |

| Shank Diameter | 8mm (approx. 0.315″) or 1/4″ (0.25″) | The diameter of the non-cutting part that is held in the collet. 8mm is common for rigidity and collet fit. 1/4″ is also very common. |

| Overall Length | Varies (e.g., 2″ to 4″) | Total length of the tool from tip to end of shank. Affects reach into workpieces. |

| Cutting Length | Varies (e.g., 1/2″ to 1.5″) | The length of the fluted cutting portion. Important for plunge depth and cutting depth. |

| Number of Flutes | 2 or 3 (2 is often preferred for wood) | The number of cutting edges. More flutes mean smoother finish at the cost of chip clearance; fewer flutes mean better chip clearance. |

| Helix Angle | 30° to 45° (Higher is often better for wood) | The angle of the spiral flutes. Steeper angles provide a shearing action for cleaner cuts. |

| Material | Solid Carbide | Extremely hard and wear-resistant material. |

| Coating | Uncoated (common) | Some may have coatings for specific abrasive materials, but standard uncoated carbide is excellent for most woods. |

| End Type | Flat | For general milling, pocketing, and profiling. Ball nose or other types are for specific 3D carving. |

What about “8mm Shank Reduced Neck”?

This phrasing often describes a tool where the shank diameter (e.g., 8mm) is larger than the cutting diameter (3/16″). This design strategy reinforces the tool, making it stronger and less prone to bending or breaking, especially when used with a compatible 8mm collet for a very secure fit.

Practical Applications for Your 3/16″ Carbide End Mill

So, what can you actually do with this versatile tool in your workshop? Loads! Here are some common and rewarding applications.

Cutting Out Parts (Profile Cutting)

This is perhaps the most common use. You design a shape (like a sign, a puzzle piece, or a cabinet component), and the CNC router uses the 3/16″ end mill to cut it out from a larger sheet of material.

Step 1: Secure Your Material: Make sure your wood is firmly clamped or held down by a vacuum table to prevent any movement during the cut.

Step 2: Set Your Zero: Accurately set your machine’s X, Y, and Z zero points according to your CAM software and workpiece.

Step 3: The Cut: The end mill will follow the vector path programmed in your CAM software, leaving you with a precisely cut part.

Pocketing and Recessing

Creating cavities for inlays, battery compartments, or to recess hardware.

Step 1: Define the Pocket: In your design software, create a shape for the area you want to cut out.

Step 2: Set Depth: Specify how deep you want the pocket to be.

Step 3: Machine Parameters: Program the machine to use the 3/16″ end mill to clear out the material within the defined shape to the desired depth. The 2-flute design is excellent here for efficient chip removal.

Creating Engravings and Lettering

For signs, labels, or decorative elements, this end mill is perfect for fine text and small graphics.

Step 1: Design Your Text/Graphic: Use vector-based software to create the text or image. Ensure letters are thick enough not to break.

Step 2: Set Toolpath: In your CAM software, assign the 3/16″ end mill to trace the vectors. You can choose to cut on the line, inside the line, or outside the line, depending on whether you want to engrave the line itself or create a channel. For lettering, cutting on the center line is common.

Step 3: Control Depth: Set a shallow depth for clean engraving.

Making Joinery (Dados, Rabbets)

The 3/16 inch size can be great for precise dados (slots) or rabbets (grooves on the edge) for simple joinery, especially in thinner sheet goods or for decorative effects.

Step 1: Measure and Design: Determine the exact width and depth of your dado or rabbet.

Step 2: Program the Cut: Set up toolpaths in your CAM software to mill out the material. For dados, you might need multiple passes if the dado is wider than the end mill, or program a series of parallel cuts. A good resource for understanding joinery techniques is the Woodbin’s explanation of dado and rabbet joints.

Safe Operation of Your 3/16″ Carbide End Mill

Safety is paramount in any workshop, and using CNC machinery and cutting tools is no exception. Here are some essential safety practices when working with your 3/16 inch carbide end mill.

Before You Start: Machine and Tool Check

Inspect the End Mill: Before every use, check the end mill for any signs of damage, chipping, or excessive wear. A damaged tool is a safety hazard and will produce poor results.

Secure the Collet: Ensure the end mill is seated correctly and firmly in the collet and that the collet nut is tightened to the manufacturer’s specifications. A loose tool can fly out of the spindle.

Check Machine Stability: Ensure your CNC machine is on a stable surface and that all its components are functioning correctly.

During Operation: The DOs and DON’Ts

DO Wear Safety Glasses: Always wear full safety glasses or a face shield. Sawdust and small chips can be ejected at high speeds.

DO Keep Clear: Maintain a safe distance from the machine while it’s operating. Never reach into the cutting area.

DO Secure Workpiece: Double-check that your workpiece is firmly secured. The forces involved in cutting can dislodge poorly held materials.

DON’T Rush Chip Evacuation: For wood, extra sawdust is the enemy. Ensure your dust collection system is running effectively. If you see excessive buildup, stop the machine and clear it.

DON’T Plunge Too Deeply: Avoid plunging the end mill too deeply into the material in a single pass, especially for 2-flute bits. This can lead to overheating or breakage. Use a stepped plunging strategy if your CAM software allows.

DON’T Exceed Tool Limits: Understand the recommended cutting parameters (feed rate, spindle speed) for your specific end mill and wood type. Pushing the tool too hard reduces its life and increases risk. Consulting tool manufacturer recommendations or reliable machining guides is crucial. For example, resources like the Mythics blog on feeds and speeds can provide general insights.

After Use: Maintenance and Storage

Clean the End Mill: After use, gently clean the end mill to remove any sawdust or resin buildup. A soft brush and some isopropyl alcohol can work well.

Proper Storage: Store your end mills in a protective case or holder to prevent them from getting chipped or damaged. Keep them organized so you can easily find the one you need.

Troubleshooting Common Issues with 3/16″ Carbide End Mills in Wood

Even with the best tools, you might encounter some hiccups. Here’s how to tackle common problems:

Problem: Burning or Scorching

Cause: Feed rate too slow, spindle speed too high, insufficient chip clearance (too many flutes, dull tool), or cutting too deep.

Solution: Increase feed rate, decrease spindle speed, ensure adequate chip evacuation (use a 2-flute bit if necessary), reduce cutting depth per pass. Make sure your dust collection isn’t pulling air over the cutting edge too aggressively, which can sometimes cool it too much leading to friction.

Problem: Tear-Out or Rough Surface Finish

Cause: Dull tool, wrong helix angle, incorrect feed/speed, or cutting against the grain in a way that lifts fibers.

Solution: Use a sharp, high-helix (30-45°) end mill. Optimize feed and speed. Consider a climb cut (if your machine supports it and you are comfortable) which can sometimes result in a smoother finish when cutting wood grain. Ensure your CAM strategy supports optimal cutting direction.

Problem: Tool Breakage

Cause: Plunging too fast or too deep, inadequate support for the tool (e.g., using a small shank in a large collet, or a weak collet), vibrations, or hitting a knot unexpectedly.

Solution: Use slower plunge rates, ensure secure tool holding (using the proper collet size), support the workpiece firmly, and consider a slightly more robust tool (like one with a larger shank if possible for the application) if you’re consistently breaking tools in specific workflows.

Problem: Excessive Vibration (Chatter)

Cause: Loose tool in collet, worn spindle bearings, workpiece not secured, too aggressive a cut, or incorrect feed/speed.

Solution: Check tool holding, secure workpiece, reduce cutting depth or feed rate, experiment with spindle speed.

Choosing Your Next 3/16″ Carbide End Mill

When you’re ready to buy, consider these factors:

Reputable Brands: Stick with well-