A 3/16-inch carbide end mill is perfect for machining PEEK with high Material Removal Rates (MRR) on your CNC machine. It offers the strength and heat resistance needed to efficiently cut this tough polymer, ensuring smooth finishes and fast work.

Hey there, fellow makers! Daniel Bates here from Lathe Hub. Ever stared at a piece of PEEK (Polyetheretherketone) and thought, “How on earth am I supposed to cut this without melting it?” You’re not alone. PEEK is a fantastic material, super strong and heat resistant, but it can be a real challenge to machine. We often hit a wall when trying to get a good Material Removal Rate (MRR), meaning we’re not cutting fast enough. This can lead to poor surface finishes, tool chatter, and frankly, a lot of frustration. But don’t worry! Today, we’re going to unlock the secret to efficiently cutting PEEK using a specific tool: the 3/16-inch carbide end mill. We’ll break down why this tool is so special and how to use it for maximum results. Stick around, and we’ll have you cutting PEEK like a pro in no time!

Why PEEK is Tricky (And Why a 3/16″ Carbide End Mill is Your Hero)

PEEK is one of those super-materials that engineers love because it can withstand extreme temperatures, harsh chemicals, and significant mechanical stress [Source: Plastics Technology]. Think of it as a high-performance plastic built for tough jobs in aerospace, automotive, and medical industries. But all those great properties that make it desirable also make it a pain to cut. It’s tough, it has a low thermal conductivity (meaning it doesn’t dissipate heat well), and it can get gummy if you’re not careful.

When you try to machine a material like PEEK with the wrong tools or settings, a few things usually go wrong:

- Melting: The friction from cutting generates heat. Because PEEK doesn’t conduct heat away easily, it can start to soften and melt, leading to smeared surfaces and a tool that gums up quickly.

- Poor Surface Finish: If the tool isn’t sharp or the cutting speed is off, you’ll get a rough, uneven surface that looks bad and might not be functional.

- Tool Wear: The abrasive nature of PEEK, combined with heat, can quickly wear down standard cutting tools, meaning you’ll be replacing them often.

- Low MRR: This is the big one for efficiency. If you have to cut super slowly to avoid melting or poor finishes, your Material Removal Rate (MRR) plummets. This means longer machining times and higher costs.

This is where our hero, the 3/16-inch carbide end mill, steps onto the stage! Why this specific size and material?

- Carbide: Made from tungsten carbide, this material is incredibly hard and can withstand higher cutting temperatures than high-speed steel (HSS). This is crucial for PEEK. Its hardness also means it stays sharp longer.

- 3/16-Inch Diameter: This size is fantastic for PEEK because it allows for precise cuts and good control. It’s small enough to get into detailed areas but offers enough cutting edges to achieve a decent MRR without taking excessively long passes. For PEEK, a smaller diameter can sometimes be advantageous for chip evacuation and heat management.

- End Mill Design: Specifically designed end mills for plastics often feature fewer flutes (like 2 or 3) to help with chip evacuation and prevent recutting chips, which generates more heat. They also often have polished flutes and specific edge preparations to reduce friction.

Using the right carbide end mill, especially a 3/16-inch one optimized for plastics, is key to achieving high MRR while maintaining excellent surface quality and tool life when working with PEEK.

Choosing the Right 3/16-Inch Carbide End Mill for PEEK

Not all 3/16-inch carbide end mills are created equal, especially when it comes to tackling a material like PEEK. To get that high MRR and a great finish, you need to look for specific features. Think of it like picking the right screwdriver for a screw – using the wrong one just won’t work well.

Key Features to Look For:

- Number of Flutes: For plastics like PEEK, fewer flutes are generally better.

- 2-Flute End Mills: These are often the top choice for plastics. They offer excellent chip clearance, which is vital for preventing heat buildup and material buildup on the flutes.

- 3-Flute End Mills: Can also work well, providing a good balance between chip thinning and smoother finishes.

- 4-Flute End Mills: Generally less ideal for softer plastics as they can lead to chip recutting and increased heat.

- Helix Angle: This is the angle of the cutting edge.

- Low Helix (0-15 degrees): Can sometimes be used for softer plastics, but they tend to give a rougher finish.

- Moderate Helix (20-30 degrees): A common and often good choice for many plastics, offering good chip evacuation.

- High Helix (45 degrees or more): Excellent for plastics. The steeper angle helps “slice” through the material with less friction and provides superior chip evacuation, leading to better cooling and higher MRR.

- Coating: While standard carbide is good, certain coatings can further improve performance.

- Uncoated: Can work, but may not be as efficient.

- ZrN (Zirconium Nitride): Offers good lubricity and heat resistance.

- AlTiN (Aluminum Titanium Nitride): Provides excellent thermal protection, making it a good choice for high-temperature materials like PEEK.

- DLC (Diamond-Like Carbon): Offers supreme lubricity and hardness, but can be more expensive.

For PEEK, an uncoated, bright finish tool optimized for plastics or one with a ZrN or AlTiN coating is usually a safe bet.

- Polish: Look for end mills with highly polished flutes. This reduces friction and prevents plastic from sticking to the tool, leading to cleaner cuts and better chip flow.

- Material: Ensure it’s solid carbide. Avoid carbide-tipped for small diameters like this, as they are less precise and can be prone to chipping.

- “O-Flute” or “Plastic” Specific: Some manufacturers make end mills specifically designed for plastics, often labeled as “O-flute” (meaning zero flutes, which is usually a single-point cutting tool, or more commonly, a single-flute end mill for plastics) or “plastic router bits.” These often have a sharp, pointed geometry. For more robust machining, a 2-flute design with polished flutes and steep helix is preferred.

When shopping, search for terms like “carbide end mill for plastic,” “2-flute plastic end mill,” or “high helix plastic end mill.” A 3/16-inch (or often 4.75mm, close to 8mm shank is common for this size of end mill) carbide end mill with these characteristics is your best friend for machining PEEK efficiently.

Setting Up Your Machine for Success (The Smart Way!)

Getting the right tool is only half the battle. How you set up your machine and your cutting parameters is incredibly important when machining PEEK with a 3/16-inch carbide end mill. We want to maximize that MRR without making the tool or the material unhappy!

Essential Machine Preparations:

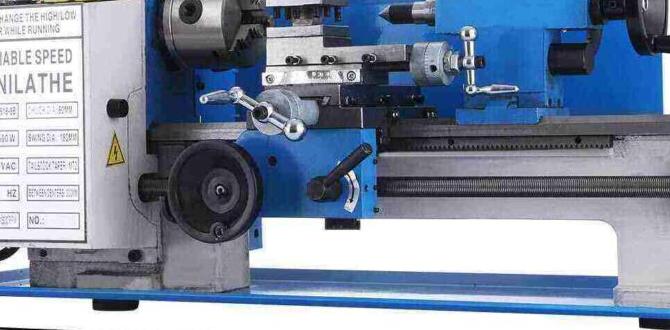

- Rigidity is Key: Ensure your CNC machine is rigid. Any flex in the spindle, tool holder, or machine frame will lead to chatter, poor finishes, and reduced tool life, especially with a small tool like a 3/16-inch end mill.

- Secure Workholding: PEEK can be slippery. Make sure your workpiece is held down very securely. Double-sided tape can work for some light-duty jobs, but for anything requiring precision or higher forces, vices, clamps, or specialized fixtures are a must. A loose part is a recipe for disaster!

- Coolant/Lubrication: This is a big one for PEEK. Because it generates heat and doesn’t dissipate it well, you need a way to keep things cool.

- Air Blast: A strong blast of compressed air directly at the cutting zone is often the most effective for plastics. It blows chips away and provides cooling.

- Mist Coolant: A fine mist of coolant can also be very effective. It lubricates and cools without flooding the machine or creating a mess.

- Flood Coolant: Sometimes used, but it can wash chips into areas where you don’t want them and might not provide the same focused cooling as air or mist for plastics.

Avoid using oil-based coolants if possible, as they can react with some plastics and make a mess. Water-based or synthetic coolants are better.

- Chip Evacuation: Ensure your machine’s vacuum system (if applicable) is running and that there are clear paths for chips to exit the cutting area. Clogged chips = heat buildup.

Understanding Material Removal Rate (MRR)

MRR is a measure of how much material you’re removing per unit of time. For machining, it’s often calculated as:

MRR (in³/min) = Chip Load (in) × Feed Rate (in/min) × Depth of Cut (in)

Or, expressed in terms of spindle speed:

MRR (in³/min) = Chip Load (in) × Number of Flutes × Spindle Speed (RPM) × Depth of Cut (in)

Our goal is to increase this number, which means increasing feed rates and/or depth of cut without negatively impacting the cut. A 3/16-inch carbide end mill is excellent for this because it allows us to take reasonable depths of cut and push the feed rate higher than a smaller diameter tool might allow, especially in PEEK.

Putting it All Together: Cutting Strategies for PEEK

Now for the fun part – actually cutting! Here’s how to approach machining PEEK with your 3/16-inch carbide end mill to get that great MRR.

Step-by-Step Cutting Process:

- Safety First!

- Always wear safety glasses. PEEK chips can be sharp.

- Wear hearing protection.

- Ensure your machine’s emergency stop button is accessible.

- Keep hands and loose clothing away from the moving machine.

- Set Up Your Tool:

- Install your 3/16-inch carbide end mill securely in a clean collet or tool holder. A precision-balanced tool holder is best for high RPMs.

- Ensure the tool is at the correct height (Z-zero relative to your workpiece).

- Initial Speeds and Feeds (Starting Point):This is where the magic happens. For PEEK, we want relatively high spindle speeds and feed rates, but we need to balance this with chip load to avoid overheating and melting. A good starting point for a 2-flute carbide end mill on PEEK might be:

- Spindle Speed (RPM): 15,000 – 25,000 RPM (This depends heavily on your machine’s capabilities and the specific cutter. Higher RPMs are generally better if your machine can handle it and maintain torque).

- Chip Load: 0.001″ – 0.003″ per flute. For a 3/16″ end mill, this is a very small chip, so precision is key.

- Feed Rate (IPM): Calculated using the above. For example, at 20,000 RPM with a 0.002″ chip load and 2 flutes: Feed Rate = 20,000 RPM 2 flutes 0.002″ = 80 IPM.

- Depth of Cut (DOC): For roughing, start with about 0.100″ – 0.150. For finishing, 0.010″ – 0.020″ is usually sufficient.

- Stepover: For profiling or pocketing, a stepover of 40-75% of the tool diameter is common. For finishing, 20-30% can yield smoother results.

Important Note: These are general starting points. The exact optimal settings will depend on your specific machine, the PEEK grade, the exact geometry of your end mill, and your coolant setup. Referencing manufacturer recommendations is always a good idea. Many tool manufacturers offer cutting data charts [Source: Kennametal Cutting Data].

- Implement Cooling:Turn on your air blast or mist coolant BEFORE the tool engages the material. Keep it running throughout the entire cutting operation.

- Perform a Test Cut:Before cutting your final part, find a scrap piece of PEEK and perform a simple test cut (e.g., a pocket or a profile). Watch and listen carefully.

- Listen: Is it a smooth cutting sound, or is there a screaming/chattering noise? Chatter indicates rigidity or speed/feed issues.

- Look: Are the chips coming off cleanly, or are they melting and sticking to the tool or workpiece? Are you getting smoke?

- Feel: (Carefully, after the cut!) Is the part excessively hot? Is the tool gummed up?

- Adjust as Needed:

- Chips are Melting/Gummy: Increase air blast/coolant. If that doesn’t help, you might need to slightly increase chip load (if possible) or decrease spindle speed.

- Chattering/Poor Finish: Check machine rigidity, tool runout, and potentially adjust feed rate or depth of cut. Try a slightly smaller stepover.

- Tool is Getting Hot (Visibly): Reduce depth of cut or feed rate, or increase coolant.

- If you’re getting good chips, a smooth sound, and the tool isn’t exhibiting excessive heat or buildup, you’re likely in a good range for high MRR.

- Roughing and Finishing Passes:For best results, consider a two-stage approach:

- Roughing: Use a more aggressive depth of cut and stepover to rapidly remove material. Focus on getting to your final shape quickly.

- Finishing: Use a lighter depth of cut and a finer stepover, often with a slightly different cutting strategy (like a cleaner profile pass), to achieve a smooth surface finish. The polished flutes on your end mill will really shine here.

- Tool Life:Even with carbide, PEEK can be abrasive. Keep an eye on the cutting edge. If you start seeing fuzziness on the edges of your cuts or the sound changes, it might be time to replace the tool. Good machining practices prolong tool life significantly.

Troubleshooting Common Issues with PEEK Machining

Even with the best tools and setup, PEEK can present some unique challenges. Here are a few common issues and how to tackle them:

Issue 1: Melting and Gummy Buildup on the Tool

- Cause: Insufficient chip evacuation, low surface speed, or inadequate cooling.

- Solutions:

- Increase the power of your air blast or mist coolant. Ensure it’s directed right at the cutting zone.

- Reduce the depth of cut or the width of cut (stepover) to create smaller, easier-to-manage chips.

- Increase spindle speed slightly, IF your machine can maintain torque and you have good chip evacuation. Higher RPMs with proper chip load can sometimes generate chips that clear heat better.

- Ensure you are using a polished flute end mill designed for plastics.

Issue 2: Poor Surface Finish (Fuzzy or Smeary)

- Cause: Tool dullness, incorrect feeds/speeds, too much heat, or tool deflection.

- Solutions:

- Double-check your chip load. If it’s too small, you’re rubbing instead of cutting.

- Ensure your spindle runout is minimal. A wobbling tool creates a poor finish.

- Use a smaller depth of cut and stepover for a finishing pass.

- Try increasing spindle speed and feed rate proportionally (main