Yes, a 3/16″ 8mm shank carbide end mill is ideal for achieving proven FR4 precision, especially long-reach versions that excel in tight tolerance PCB milling. This guide will show you how to use it effectively for accurate cuts.

Choosing the right cutting tool can make all the difference when you’re working with delicate materials like FR4. If you’ve ever struggled to get clean, precise cuts on your printed circuit boards (PCBs), you’re not alone. It can feel frustrating, especially when your projects demand accuracy. But don’t worry, there’s a fantastic tool for the job: the 3/16″ (or 8mm shank) carbide end mill. This guide will take you step-by-step through understanding and using this specialized tool for perfect FR4 milling. We’ll cover everything you need to know to get those tight tolerances you’ve been aiming for!

Understanding Your 3/16″ 8mm Shank Carbide End Mill for FR4

When we talk about milling PCBs, especially those made from FR4 (Flame Retardant 4), precision is key. FR4 is a common, yet somewhat unforgiving, material. It’s a composite epoxy glass fabric and is the backbone of most circuit boards. Its strength comes from fiberglass, but this also means it can chip or delaminate if cut improperly. This is where the carbide end mill shines.

Why Carbide?

Carbide, specifically tungsten carbide, is an incredibly hard and wear-resistant material, making it perfect for cutting through tough fiberglass composites like FR4. Unlike high-speed steel (HSS) tools, carbide cutters can maintain their sharpness and cutting edge at higher speeds and temperatures. This means:

- Durable Cuts: They can handle the abrasive nature of FR4 with less wear.

- Sharpness Retention: They stay sharp longer, ensuring consistent results.

- High-Speed Machining: They allow for faster cutting speeds, improving efficiency.

- Heat Resistance: They dissipate heat better, reducing the risk of burning the FR4.

Why 3/16″ (or 8mm Shank)?

The 3/16-inch diameter is a very common size for PCB milling. It offers a good balance between detail capability and material removal rate. The 8mm shank size is also prevalent, fitting many common CNC router and milling machine collets. For specialized applications requiring a longer reach into deeper pockets or to avoid clamps, you might look for “long reach” variants. This particular combination is chosen for its versatility and compatibility with many desktop CNC machines and hobbyist milling setups.

The “Proven FR4 Precision” Factor

The term “proven FR4 precision” means this type of end mill has a track record of delivering accurate and clean results on FR4 material. This is often due to specific design features:

- Flute Count: Often a 2-flute design is preferred for FR4. Two flutes provide good chip clearance, which is crucial for preventing heat buildup and material melting or clogging in the cut. More flutes can sometimes lead to clogging with composite materials.

- Edge Geometry: The cutting edges (or ‘teeth’) are precisely ground. For FR4, a sharp, well-defined edge at a specific rake angle helps to shear the material cleanly rather than tear it.

- Coating: Some high-end carbide end mills come with specialized coatings (like TiN, TiCN, or diamond-like carbon – DLC) that further reduce friction, increase wear resistance, and improve chip evacuation.

- Helix Angle: A moderate helix angle allows for efficient material removal while maintaining a smooth surface finish.

When you see “long reach” mentioned with these end mills, it specifically refers to the length of the cutting portion and the overall stick-out from the collet. This is vital for milling deeper features or when your workholding setup might interfere with a standard-length tool.

Key Features to Look for

When selecting your 3/16″ 8mm shank carbide end mill for FR4, consider these important features:

- Material: Always opt for solid carbide for FR4 due to its hardness and heat resistance.

- Number of Flutes: For FR4, 2 flutes are generally optimal for good chip evacuation.

- Shank Diameter: Ensure it’s 8mm to fit your collet.

- Cutting Diameter: This will be 3/16″ (approximately 4.76mm).

- Overall Length & Flute Length: Consider your project’s depth requirements. A “long reach” end mill will have extended flute and/or overall length.

- Coating (Optional but Recommended): For frequent or demanding FR4 work, coatings enhance performance and tool life.

- End Type: For PCB milling, a “square” or “flat” end is standard.

Essential Tools and Setup for Milling FR4

Before you even think about a cut, gather everything you need. Having the right setup ensures safety and the best results.

Your Milling Machine

This could be a desktop CNC router, a small vertical milling machine, or even a high-end hobbyist mill. Ensure it’s rigid and capable of precise movements. Regular maintenance, like checking for play in the axes and ensuring the spindle runs true, is vital.

The 3/16″ 8mm Shank Carbide End Mill

As discussed, this is your primary cutting tool. Make sure it’s clean, undamaged, and securely held in the collet.

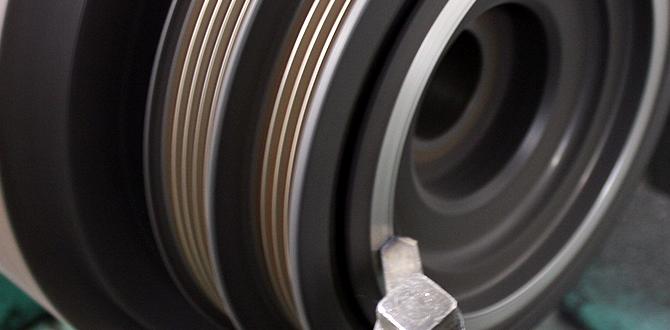

Collet & Spindle

An 8mm collet is necessary to properly grip the 8mm shank of the end mill. Ensure your spindle can accommodate this size. A well-functioning spindle free of runout is critical – wobble will lead to poor cut quality and tear-out.

Workholding

This is how you secure your FR4 material to the machine bed. For PCBs, this often involves:

- Double-sided tape: Strong industrial tape can work for very light milling tasks, but it’s not ideal for precision.

- Vacuum table: Excellent for holding flat sheets, but requires a vacuum pump.

- Fixturing: Dedicated clamps designed not to interfere with the cutting path. For most hobbyists, a combination of small clamps and potentially a sacrificial spoilboard beneath your FR4 is common.

Safety Note: Ensure your FR4 is held down extremely securely. Any movement during cutting will ruin your work and can be dangerous.

Dust Extraction

Milling FR4 produces fine dust that can be harmful to inhale and can quickly clog your machine. Use a dust collection system or a shop vac connected directly to your router/spindle setup. A well-designed dust collection system is highly recommended for health and environmental reasons.

Safety Gear

Never compromise on safety!

- Safety Glasses: Essential to protect your eyes from flying debris.

- Face Shield: Recommended for added protection, especially when starting out.

- Hearing Protection: Milling can be loud.

- Dust Mask/Respirator: Crucial for FR4 dust.

- Gloves: While not always worn during operation (to avoid entanglement), handy for handling materials and cleaning.

Measuring Tools

A digital caliper is indispensable for verifying dimensions and ensuring your tool’s accuracy.

Step-by-Step Guide: Milling FR4 with Your 3/16″ 8mm Shank End Mill

Let’s get your FR4 milled with precision. This guide assumes you have your design ready (e.g., in CAD/CAM software like Fusion 360, Easel, or similar) and your CNC machine is set up.

Step 1: Secure Your FR4 Material

Place your FR4 board onto a clean, flat surface (like a spoilboard). Use your chosen workholding method (clamps, tape, vacuum) to ensure the material cannot move during the milling process. Position it so the cutting area is well supported and away from any clamps that might be in the tool’s path. Double-check that it’s held down TIGHT.

Step 2: Install the End Mill

With the spindle off and stationary, insert the 8mm shank of your carbide end mill into the 8mm collet. Tighten the collet securely in the spindle. Ensure the end mill is seated properly and not sticking out excessively from the collet unless a long-reach application requires it. Too much stick-out can cause vibration and breakage.

Step 3: Define Your Zero Point (Origin)

This is arguably the most critical step for accuracy. You need to tell your machine where the “zero” point of your workpiece is. This is usually done by jogging your CNC machine’s X, Y, and Z axes to specific points on your FR4 material.

- X and Y Zero: Typically set at a corner of your FR4 piece or the intended origin of your PCB design. Use your CNC controller’s jogging functions to carefully bring the center of the spinning (or stationary, if you prefer) end mill to this desired corner. Then, set your X and Y zero.

- Z Zero: This is setting the height of the cutting surface. The safest method is to use a Z-probe or an electronic edge finder. If you don’t have one, you can carefully touch off the end mill to the surface of the FR4. Lower the Z-axis until the end mill just touches the surface. A common technique is to place a thin piece of paper between the end mill and the FR4; when you can just slide the paper with a slight drag, you’re at or very near zero Z. Set your Z zero.

Important: Always double-check your zero points after setting them.

Step 4: Load Your CAM/G-Code Program

Load the toolpath file (G-code) that you generated from your CAM software into your CNC controller. Review the tool settings within your CAM software, ensuring the correct end mill diameter (3/16″ or 4.76mm) was specified.

Step 5: Configure Cutting Parameters (Feeds and Speeds)

This is where the “proven precision” meets your machine. For FR4, optimal feeds and speeds are crucial. Too fast, and you risk burning or chipping. Too slow, and you can overheat the bit or get a poor finish.

Carbide end mills can generally run faster than HSS, but FR4’s fiberglass content is abrasive. A good starting point for a 3/16″ 2-flute carbide end mill on FR4 might look something like this. Always consult the end mill manufacturer’s recommendations if available, and be prepared to adjust. These are general guidelines.

| Parameter | Typical Value for 3/16″ 8mm Carbide End Mill on FR4 | Notes |

|---|---|---|

| Spindle Speed (RPM) | 18,000 – 24,000 RPM | Higher speeds can work with good chip evacuation. |

| Feed Rate (IPM or mm/min) | 20 – 50 IPM (approx. 500 – 1270 mm/min) | Start conservatively. Adjust based on cut quality. |

| Plunge Rate (IPM or mm/min) | 10 – 25 IPM (approx. 250 – 635 mm/min) | Slower than feed rate to reduce stress on entry. |

| Depth of Cut (DOC) | 0.005″ – 0.020″ (0.127mm – 0.508mm) per pass | Crucial for FR4. Small passes prevent glazing and chipping. |

| Stepover (Width of Cut) | 20% – 50% of tool diameter (0.037″ to 0.093″) | Smaller stepover for finishing passes, larger for clearing. |

Feeds and Speeds Calculator: For more precise calculations tailored to your specific machine and tooling, consider using an online feeds and speeds calculator, like those provided by major tool manufacturers. Remember that machine rigidity, spindle runout, and the exact FR4 grade will influence these numbers.

Material Specifics: A common guideline for FR4 milling, especially on desktop machines, is to keep the Depth of Cut very shallow, often within the range of 0.005″ to 0.020″ (0.127mm to 0.508mm). This prevents the tool from binding, reduces heat, and minimizes the risk of delamination.

Step 6: Perform a Test Cut (Highly Recommended)

Before milling your actual PCB, it’s a wise idea to perform a test cut on a scrap piece of FR4, or even a piece of MDF or plastic if you want to test tool movements without risking material. This allows you to:

- Hear if the sound of the cut is correct.

- Observe chip formation.

- Verify that your zero point was set correctly.

- Check if your feeds and speeds are producing a clean surface finish without burning.

Step 7: Start the Milling Job

Once you’re confident with your setup and settings:

- Turn on your dust collection system.

- Start your spindle to the programmed speed.

- Initiate the G-code program.

- Watch the first few passes carefully. Listen for any unusual sounds (chattering, grinding). Look for excessive smoke or signs of melting.

- Be ready to hit the emergency stop button if anything seems wrong!

Step 8: Monitor the Job

Most desktop CNC jobs can be monitored visually. For longer jobs, you might step away but keep an ear on the machine and your dust collector. Ensure the dust extraction is working effectively and not clogging.

Step 9: Clean Up and Inspect

After the milling is complete:

- Allow the spindle to stop completely.

- Turn off the spindle and dust collection.

- Carefully remove the milled FR4 from your workholding.

- Inspect the cuts. Look for clean lines, no burrs, no chipping, and no signs of burning. Use your calipers to check critical dimensions against your design.

- Clean your machine, including the spindle and collet, removing any dust and debris.

Troubleshooting Common Issues

Even with the best tools, you might run into some snags. Here are common problems and how to fix them:

Issue: Burning or Melting of FR4

- Cause: Feed rate too slow, spindle speed too high, depth of cut too large, dull tool, poor chip evacuation.

- Solution:

- Increase feed rate slightly.

- Decrease spindle speed slightly.

- Decrease depth of cut per pass.

- Ensure your end mill is sharp and clean.

- Improve dust collection and chip clearing.

- Ensure two flutes are used for better chip clearance.

Issue: Chipping or Delamination

- Cause: Feed rate too fast, depth of cut too large, dull tool, machine rigidity issues, improper material support.

- Solution:

- Slow down feed rate.

- Reduce depth of cut significantly. Small, shallow passes are key.

- Use a sharp, high-quality carbide end mill.

- Ensure FR4 is perfectly flat and well-supported from underneath.

- Check for any play or vibration in your machine’s axes or spindle.

Issue: Rough Surface Finish

- Cause: Dull tool, incorrect feeds/speeds, machine vibration, inconsistent depth of cut.

- Solution:

- Use a new, sharp end mill.

- Optimize feeds and speeds. A slightly smaller stepover for finishing passes can help.

- Ensure your machine is rigid with no backlash or play.

- Verify consistent Z-height during the cut.

Issue: Tool Breakage

- Cause: Depth of cut too aggressive, feed