Quick Summary:

For machining cast iron, a 3/16 inch carbide end mill with an 8mm shank is an excellent choice. Its robust carbide construction and specific dimensions offer superior performance, durability, and precision, making it a proven solution for this challenging material.

Machining cast iron can feel like wrestling a stubborn beast. It’s dense, abrasive, and prone to chipping, which can quickly wear down standard tools. If you’ve ever struggled with getting a clean cut or enduring premature tool failure when working with cast iron, you’re not alone. Many beginners and even experienced makers find it a tricky material. But what if there was a tool specifically designed to handle cast iron’s toughness, providing smooth cuts and lasting performance? The answer lies in the right end mill. Today, we’re diving deep into the 3/16 inch carbide end mill with an 8mm shank – a real workhorse for cast iron projects. We’ll break down why this specific tool is so effective and guide you on how to use it like a pro.

The Carbide Advantage for Cast Iron

When you’re tackling cast iron, the material you choose for your end mill is crucial. While high-speed steel (HSS) has its place, carbide materials are often the champions for abrasive and hard metals like cast iron. Carbide, or tungsten carbide, is an incredibly hard, dense ceramic compound. This hardness means it can withstand the high friction and temperatures generated when milling cast iron without rapidly dulling or deforming.

Here’s why carbide stands out:

- Superior Hardness: Cast iron is tough. Carbide’s inherent hardness allows it to cut through it efficiently, maintaining its cutting edge far longer than HSS.

- High Thermal Resistance: Machining generates heat. Carbide can handle much higher temperatures before softening compared to HSS, which is vital for consistent cutting.

- Increased Rigidity: Because carbide is denser and harder, it offers better rigidity. This means less tool deflection, leading to more accurate cuts and a better surface finish, especially important when dealing with the nature of cast iron.

- Higher Cutting Speeds: With its superior properties, carbide allows for faster cutting speeds and feed rates, significantly reducing machining time, often referred to as Material Removal Rate (MRR). For cast iron machining, a high MRR means you get the job done faster and more efficiently.

For those looking to boost their machining efficiency, understanding concepts like Material Removal Rate (MRR) is key. MRR is a measure of how much material your tool can remove per unit of time. A higher MRR saves time and increases productivity. For a detailed understanding of MRR and its calculations, resources from organizations like the National Institute of Standards and Technology (NIST) offer valuable insights into machining parameters.

Why a 3/16 Inch Size Matters

The 3/16 inch diameter of the end mill is a very common and versatile size for hobbyists and small-scale professional shops. It’s large enough to remove material effectively for many general machining tasks, such as slotting, profiling, and creating pockets, but not so large that it requires excessive machine rigidity or power. This size is often ideal for working with smaller cast iron parts, intricate designs, or when you need to mill sharp internal corners where a larger tool wouldn’t fit.

The 3/16 inch dimension is roughly equivalent to 4.76mm. While you might find tools specified in both imperial and metric units, it’s important to know the exact size for your machine’s collets and for setting your machining parameters.

The 8mm Shank Advantage

The 8mm shank is a standard metric size that provides a good balance of strength and compatibility. For a 3/16 inch end mill, an 8mm shank (approximately 0.315 inches) offers ample support and rigidity. A properly sized shank prevents chatter and vibration, which are common enemies of precision machining, especially in materials like cast iron. This shank size is often found on end mills designed for smaller or intermediate milling machines, making it a practical choice for many home workshop setups.

The combination of a 3/16 inch cutting diameter and an 8mm shank is frequently chosen for its efficiency in smaller tool holders and collets, while still providing the necessary strength for the forces involved in cutting cast iron. This pairing ensures that the cutting forces are well-managed, leading to cleaner cuts and longer tool life.

Choosing the Right Carbide End Mill for Cast Iron

Not all carbide end mills are created equal, especially when it comes to cast iron. You’ll want to look for specific features that make a carbide end mill “cast iron friendly.”

Key Features to Look For:

- Number of Flutes: For cast iron, 2-flute or 4-flute carbide end mills are usually recommended.

- 2-Flute: Offers excellent chip evacuation, which is critical for abrasive materials like cast iron that produce fine, powdery chips. More chip clearance helps prevent clogging and tool breakage.

- 4-Flute: Provides a smoother finish and can handle higher feed rates due to more cutting edges. However, chip evacuation can be slightly more challenging, so proper coolant or air blast is often necessary. For general-purpose cast iron milling, a 4-flute uncoated or specialized cast iron coating is often the best bet.

- Geometry: Look for end mills with a high rake angle and a sharp cutting edge. This geometry helps to reduce cutting forces and heat generation. Some end mills have a specific “corner radius” which adds strength to the cutting edge, preventing chipping.

- Coating: While uncoated carbide is effective, certain coatings can further enhance performance on cast iron.

- Uncoated Carbine: Still a very capable choice, especially if it has a good geometry and is used with proper coolant.

- TiN (Titanium Nitride): A common, cost-effective coating that adds a bit of hardness and reduces friction, offering some improvement over uncoated carbine.

- TiCN (Titanium Carbonitride): Offers even greater hardness and abrasion resistance than TiN, making it better suited for tougher materials like cast iron.

- ZrN (Zirconium Nitride): A great option for cast iron, known for its excellent lubricity and resistance to built-up edge (BUE), which can be a problem with cast iron.

- Advanced Coatings (e.g., AlTiN, SiAlON): These are typically for high-performance machining and may be overkill or unnecessarily expensive for a beginner’s 3/16 inch end mill for cast iron.

- Material Grade: General-purpose carbide grades are usually fine, but some manufacturers will specify grades optimized for cast iron. Typically, these are micro-grain carbides that offer a good balance of hardness and toughness.

For a 3/16 inch end mill with an 8mm shank specifically advertised for cast iron, you’re likely looking at a tool that incorporates many of these features as a standard offering. The emphasis is usually on durability and chip handling.

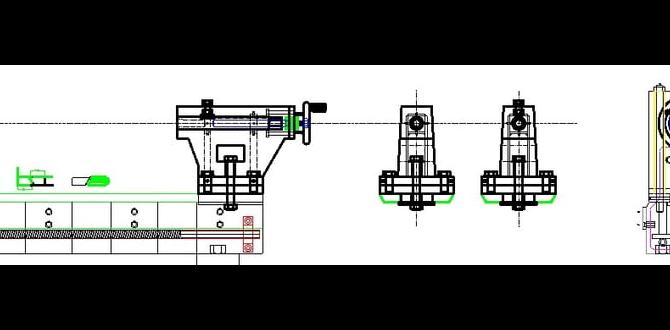

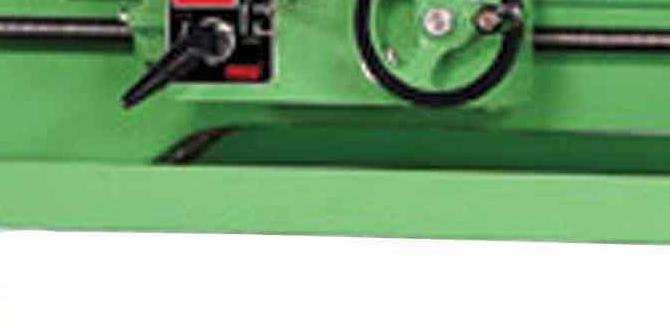

Setting Up Your CNC or Milling Machine

Getting the most out of your 3/16 inch carbide end mill for cast iron involves careful setup. This is where precision and attention to detail pay off, leading to better results and preventing tool damage.

Essential Setup Checks:

- Collet and Holder: Ensure you are using a clean, high-quality collet that precisely matches the 8mm shank. A worn or slightly oversized collet can lead to runout, vibration, and ultimately, tool breakage. For carbide, ER collets are a common and reliable choice.

- Machine Rigidity: Cast iron machining generates significant forces. Ensure your milling machine is rigid, with no excessive play in the ways or spindle.

- Workholding: Secure your cast iron workpiece with robust workholding. Use vises, clamps, or fixtures that can withstand the cutting forces without shifting. A loose part is a recipe for disaster.

Speeds and Feeds: The Heart of the Matter

This is often the most critical aspect. Getting speeds and feeds right will make or break your cast iron machining experience. For a 3/16 inch carbide end mill, high MRR is achievable with good parameters. These are general guidelines; always consult the end mill manufacturer’s recommendations if available.

Here’s a starting point for a 3/16 inch (4.76mm) 4-flute carbide end mill in cast iron:

| Parameter | Typical Range for Cast Iron | Notes | |

|---|---|---|---|

| Spindle Speed (RPM) | 4000 – 7000 RPM | Higher RPMs are generally better for carbide in cast iron, assuming machine capability. | |

| Feed Rate (IPM) | 10 – 30 IPM | Start on the lower end and increase as confidence grows. This is for manual machining. For CNC, IPM is directly related to chip load. (See Chip Load below) | |

| Chip Load (Per Flute) | 0.001″ – 0.003″ | This is the thickness of material removed by each flute per revolution. Crucial for CNC programming. | |

| Depth of Cut (Axial DOC) | 0.050″ – 0.150″ | For roughing. Can be shallower for finishing. | |

| Width of Cut (Radial DOC – Stepover) | 0.050″ – 0.150″ (for slotting or full width) | 0.020″ – 0.080″ (for profiling or pocketing) | Smaller stepovers are used for finishing passes or when full width is required. |

CNC Programming Note: For CNC machining, you’ll typically set the spindle speed and then calculate the feed rate based on the desired chip load, number of flutes, and spindle RPM (Feed Rate = Chip Load × Number of Flutes × Spindle RPM). For example, with a chip load of 0.002″, 4 flutes, and 5000 RPM: Feed Rate = 0.002″ × 4 × 5000 = 40 IPM. Always check the manufacturer’s specific recommendations for your end mill.

Adjusting Parameters:

- If you hear squealing: Increase feed rate or decrease spindle speed.

- If you see chip welding (material sticking to the tool): Decrease feed rate, increase spindle speed, or improve chip evacuation/coolant.

- If the tool is vibrating or chattering: Reduce depth of cut, reduce feed rate, check workholding, or ensure your spindle/collet runout is minimal.

Coolant and Lubrication: Your Cast Iron Allies

Machining cast iron generates significant heat, and inadequate cooling can lead to rapid tool wear and poor surface finish. While some cast iron can be machined dry with specific tooling or vacuum dust collection, using a coolant is highly recommended for optimal performance and tool life.

- Flood Coolant: A steady stream of coolant delivered directly to the cutting zone is ideal. This flushes chips away, dissipates heat, and lubricates the cutting edge.

- Mist Coolant/Air Blast: For machines not equipped for flood coolant, a mist coolant system or a directed air blast can help manage heat and chip evacuation. This is especially useful when dealing with the fine dust of cast iron, creating a less hazardous environment.

- Cutting Fluid: Even a small amount of cutting fluid applied directly can make a difference if flood or mist systems are unavailable.

Safety Note: Cast iron dust can be harmful if inhaled. Always use appropriate respiratory protection (e.g., a dust mask or respirator) and consider dust collection systems when machining cast iron. Many automotive shops and foundries use specialized ventilation systems. For more on industrial safety practices, the Occupational Safety and Health Administration (OSHA) provides comprehensive guidelines on workplace safety, including controlling dust and fumes.

Step-by-Step Machining Process with Your 3/16″ Carbide End Mill

Let’s walk through a typical machining operation. For this example, we’ll assume you’re creating a slot in a block of cast iron using your 3/16 inch carbide end mill with an 8mm shank on a manual milling machine.

Preparation:

- Secure the Workpiece: Clamp your cast iron block firmly in the milling machine vise. Ensure it’s seated squarely.

- Install the End Mill: Insert the 3/16 inch carbide end mill into a clean 8mm collet. Tighten the collet securely in the milling machine spindle.

- Set Z-Zero: Carefully bring the tip of the end mill down to the top surface of your workpiece using the Z-axis handwheel. This is your Z-zero reference point.

- Set X/Y-Zero: Jog the machine to the starting point of your slot in the X and Y directions and set your X and Y zero references.

Machining the Slot:

- Engage Spindle: Turn on your milling machine spindle to the calculated RPM (e.g., 5000 RPM). Ensure coolant is flowing or the air blast is on.

- Initiate Plunge (if applicable): If you need to plunge the end mill into the material to start the slot, do so slowly and at an appropriate feed rate (often slower than a milling feed). For a 3/16″ end mill, a 2-flute end mill is often preferred for plunging due to better chip evacuation. If using a 4-flute, shallow plunges or “helical interpolation” (ramping into the material in a circle) are safer.

- Begin Milling: Once at the desired depth (e.g., 0.100″ axial DOC), engage the feed rate (e.g., 15 IPM for manual milling). Move the workpiece or the machine head/table in the X or Y direction to create the slot.

- Maintain Consistency: Feed smoothly and avoid sudden stops or reversals. Listen to the sound of the cut. A consistent, crisp cutting sound is good; bogging down or chattering is a warning sign.

- Take Multiple Passes: For deeper slots or tougher cast iron, it’s often better to take multiple passes at a shallower depth of cut rather than one deep cut. For example, if you need a 0.200″ deep slot, take two passes of 0.100″ each. You might even consider a roughing pass and a finishing pass.

- Finishing Pass: For a precise dimension or smooth surface finish, retract the tool to your starting point and make a final pass at a shallower depth of cut and possibly a slightly adjusted feed rate.

- Retract and Stop: Once the slot is complete, carefully retract the end mill out of the workpiece and then turn off the spindle and coolant.

Post-Machining:

- Clean Up: Remove the workpiece from the machine. Clean the workpiece and the machine tool to remove chips and coolant residue.

- Inspect: Check your slot for dimensions, surface finish, and any signs of excessive tool wear.

Long Reach End Mills vs. Standard

When faced with cast iron, the concept of “long reach” can come into play. A standard end mill has a cutting length that is roughly proportionate to its diameter. A long reach end mill, as the name suggests, has an extended flute length relative to its shank diameter.

For a 3/16 inch diameter end mill, a “long reach” version would typically have a cutting length significantly longer than the standard, perhaps 1 inch or more. The 8mm shank still provides rigidity, but the extended reach comes with considerations:

- Increased Potential for Chatter: The longer the tool extends from the holder, the more prone it is to vibration and chatter. This is why maintaining sharp cutting edges, using appropriate speeds and feeds, and ensuring good rigidity are even more critical with long reach tools.

- Flexibility for Deep Pockets: Long reach is essential when you need to machine deep pockets or features that are recessed far down from the top surface of the workpiece. Without it, the shank would collide with the workpiece before the cutting flutes could reach the desired area.

- Higher MRR Challenges: Achieving high MRR with a long reach end mill requires careful parameter selection to counterbalance the increased flexibility. You might need to reduce depths of cut or stepovers compared to a standard length tool.

If your cast iron project involves reaching into deep cavities, a long reach 3/16 inch carbide end mill with an 8mm shank is your solution. However, be prepared for slightly more delicate setup and parameter