Quick Summary: Control carbide end mill deflection in carbon steel by choosing the right tool, proper setup, balanced speeds/feeds, and smart cutting strategies. This guide ensures accuracy and tool life for beginners.

Hey there, fellow makers! Daniel Bates here from Lathe Hub. Ever tried milling carbon steel and ended up with a wobbly cut, a broken tool, or a workpiece that’s just… not quite right? You’re not alone. It’s a common frustration when our precise plans meet the reality of metal. The culprit is often something called “deflection” – that annoying bending of the end mill under the cutting forces. It’s like trying to push a noodle through a block of wood! But don’t worry, mastering deflection control with carbide end mills, especially when tackling tough carbon steel, is totally achievable. We’re going to walk through this step-by-step, so you can get those clean, accurate cuts you’re aiming for. Ready to turn that frustration into precision?

Understanding Carbide End Mills and Carbon Steel

Before we dive into controlling deflection, let’s get a handle on what we’re working with. Carbide end mills are fantastic tools. They’re made from tungsten carbide, which is super hard and can cut through tough materials like carbon steel much faster than older high-speed steel (HSS) tools. This hardness, however, also makes them a bit more brittle. Think of them like a really strong, thin glass rod – they can take a lot of pressure, but a sudden shock can snap them.

Carbon steel, while versatile, is known for its strength and hardness. This means it’s going to put up a fight when you try to cut it. Those cutting forces are what cause our end mill to bend, or deflect. If the deflection is too much, the tool won’t cut accurately, it can chatter (vibrate and make a rough surface), and eventually, it can break. Our goal is to work with the material and the tool, not against them.

Why Deflection Happens (It’s Not Magic, It’s Physics!)

Deflection is essentially the bending of the end mill under the forces that occur during cutting. Imagine you’re pushing on a ruler with your finger. The harder you push, the more it bends. The same thing happens with an end mill in a milling operation.

Here are the main reasons deflection is a bigger issue with carbon steel and carbide end mills:

- Cutting Forces: Carbon steel is tough, requiring significant force to shear the material. This force directly pushes against the cutting edge and shank of the end mill.

- Tool Stick-out: The further the end mill extends from the collet or holder, the longer and more flexible it becomes. More stick-out means more leverage for the cutting forces to bend it.

- Tool Diameter: Smaller diameter tools are inherently less stiff than larger ones. A tiny 1/16″ end mill will deflect much more easily than a 1/2″ one.

- Cutting Strategy: How the cutter engages with the material matters. Taking too deep a bite, for example, dramatically increases cutting forces.

- Tool Quality and Condition: Even good carbide tools can deflect if they’re dull, chipped, or simply not designed for the specific material and operation.

Key Strategies for Controlling Deflection

Now for the good stuff! Controlling deflection isn’t about one single trick; it’s a combination of smart choices and techniques. We’ll break these down so they’re easy to follow.

1. Choosing the Right Carbide End Mill for the Job

This is your first line of defense. Not all carbide end mills are created equal. For carbon steel, you want a tool built for the task.

- Number of Flutes: For tougher materials like carbon steel, using end mills with fewer flutes can be beneficial.

- 2-Flute: Offers more chip clearance, which is great for softer materials but can also handle some steels. Good for slotting.

- 3-Flute: A great all-around choice for steels. It offers a good balance between cutting sharpness and strength, and better chip evacuation than 4-flute. Often recommended for general milling of medium-hardness steels.

- 4-Flute: Best for finishing operations and materials that are more prone to vibration or where better surface finish is critical. They provide more rigidity but can clog with chips in softer or stringy materials.

- Coating: Coatings like TiN (Titanium Nitride), TiAlN (Titanium Aluminum Nitride), or ZrN (Zirconium Nitride) can improve tool life and performance by reducing friction and heat. For carbon steel, a TiAlN or ZrN coating is often a good choice as they perform well at higher temperatures.

- Helix Angle: A standard helix angle is around 30 degrees. A higher helix angle (e.g., 45 degrees) can provide a smoother, shearing action which reduces cutting forces and thus deflection. Look for “high helix” end mills if you’re tackling particularly gummy or hard steels.

- End Mill Geometry: Some end mills are designed with specific geometries to help with chip evacuation and rigidity. Look for terms like “form relief” or “corner radius” which can add strength.

- Reach: For carbon steel, try to use the shortest possible reach end mill. A 3/16 inch 8mm shank long reach end mill will deflect significantly more than a standard length one. If you need to reach deep, consider using a larger diameter end mill if the part allows to improve stiffness.

2. Setting Up Your Machine for Success

How you mount your workpiece and the end mill itself plays a crucial role. A solid setup means less unintended movement.

- Rigid Workholding: Ensure your workpiece is clamped down TIGHTLY. Use a stout vise, clamps, or fixture that won’t budge. Any movement here is amplified.

- Secure Tool Holder: Use a high-quality collet chuck or side-lock holder. ER collets are great, but for heavy cuts, a Weldon shank end mill in a side-lock holder provides excellent axial holding and prevents pull-out. Make sure the collet and holder are clean and free of debris.

- Minimize Tool Stick-out: This is HUGE. The less the end mill has to stick out of the collet/holder, the stiffer it will be. Aim to have the cutting edge as close to the holder as possible without the holder crashing into the workpiece.

- Check Spindle Runout: Excessive runout (wobble) in your spindle will worsen deflection. Ensure your spindle is in good condition and your tool holding system is bringing the tool in true.

3. Mastering Speeds and Feeds

This is where many beginners struggle, but it’s critical for controlling deflection. The goal is to find a balance that removes material efficiently without overloading the tool.

Speeds and feeds are a bit of an art, and manufacturers provide starting points. You’ll often see charts that list Surface Feet per Minute (SFM) or Meters per Minute (MPM) for the cutting speed and chip load (how much material each flute takes per revolution).

Surface Speed (SFM/MPM): This is how fast the cutting edge is moving. For carbide in carbon steel, this might range from 200-600 SFM (60-180 MPM), depending on the specific steel and coating. Your spindle’s RPM (Revolutions Per Minute) is calculated from this and the tool diameter. A common formula is:

RPM = (SFM 12) / (π Diameter)

For metric:

RPM = (MPM 1000) / (π Diameter_in_mm)

Chip Load: This is how thick the tiny slice of material is that each cutting edge removes. A common formula for chip load is:

Chip Load (per tooth) = (Desired Chip Thickness) (Tool Diameter) / (Number of Flutes)

A typical recommended chip load for a 3/16″ carbide end mill in carbon steel might be around 0.001″ to 0.003″ per tooth. Crucially, for deflection control, you often want to use a slightly higher chip load and a slightly lower RPM than a generic chart might suggest for softer metals.

Why?

- Higher Chip Load: A thicker chip engages more of the tool and can help “push back,” counteracting some deflection. It also means you’re removing material faster, so the tool is in the cut for less time per pass, reducing heat buildup.

- Lower RPM: This reduces the overall cutting speed and the impact force of the cutting edge, making the tool less prone to chatter and breakage.

Important Note: Always start conservatively, listen to your machine, and watch for chip formation. Refer to tooling manufacturer’s recommendations for starting points. Websites like CarbideProbes or tool manufacturer sites (e.g., Harvey Tool’s Calculators) can be invaluable resources for finding starting speeds and feeds.

4. Strategic Cutting Techniques

How you approach the cut can dramatically affect deflection. Think about how you want the tool to bite into the material.

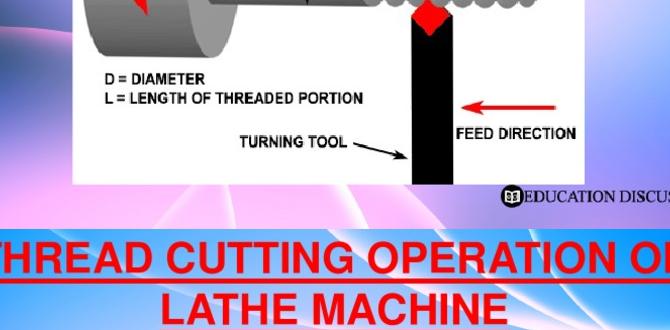

Conventional Milling vs. Climb Milling:

This is a key concept for reducing deflection and improving surface finish.

- Conventional Milling: The cutter rotates against the direction of workpiece feed. The cut starts thin and gets thicker as the tooth goes deeper. This tends to lift the workpiece and put more outward force on the cutter, increasing deflection.

- Climb Milling: The cutter rotates in the same direction as the workpiece feed. The cut starts thick and gets thinner. This pushes the workpiece down onto the table and puts a net downward force on the cutter, significantly reducing deflection and improving surface finish.

Recommendation: For controlling deflection in carbon steel, climb milling is almost always preferred. If your CNC machine supports it, enable climb milling whenever possible. For manual milling, you can achieve a similar effect by carefully coordinating your handwheel movements and using a machine with minimal backlash.

Adaptive/Trochoidal Toolpaths:

If you’re using CNC, “adaptive” or “trochoidal” toolpaths are fantastic for managing cutting forces and deflection. These toolpaths use a high-speed, looping motion that keeps a constant chip load and maintains a consistent, shallow engagement with the material. This reduces heat buildup and deflection, allowing you to take much larger stepovers (sideways movement per pass) and faster feed rates in many cases.

Dressing the Cut:

Think of this as taking a series of light finishing passes rather than one heavy roughing pass. Instead of trying to remove all your material in one go, break it down:

- Shallow Axial Depth of Cut (DOC): Don’t try to cut too deep into the material vertically. A common recommendation for carbide in steel is often 1-2 times the tool diameter for roughing, but for minimizing deflection, you’ll want to stay even shallower, perhaps 0.5x to 1x the tool diameter, or even less.

- Appropriate Radial Depth of Cut (Stepover): This is how much the tool moves sideways with each pass. For roughing, a stepover of 20-50% of the tool diameter is common. For minimizing deflection, start on the lower end (20-30%) and increase if the cut is stable.

- Finishing Pass: Always leave a small amount of material (e.g., 0.005″ – 0.010″) for a final finishing pass. Use a light radial and axial depth of cut at a slightly higher feed rate to get a nice smooth surface.

5. Using Specialized Long Reach End Mills Wisely

You mentioned wanting to know about a “carbide end mill 3/16 inch 8mm shank long reach for carbon steel minimize deflection.” Long reach end mills are great for getting into deep pockets or over raised features, but they are inherently more flexible and prone to deflection.

To minimize deflection with these:

- Shorter Stick-out is Still Key: Even if it’s a “long reach” model, use the shortest possible length necessary for your operation.

- Reduced DOC and Stepover: You MUST use significantly shallower depths of cut (both axial and radial) compared to a standard length end mill.

- Climb Milling: Absolutely essential.

- Lower Spindle Speed: Consider reducing your RPMs.

- Consider Larger Diameter: If your pocket geometry allows, a 1/4″ or 3/8″ standard length end mill will be far stiffer than a 3/16″ long reach.

- Multi-Flute Considerations: For reach, sometimes a 4-flute end mill might offer a bit more rigidity than a 2-flute, though it sacrifices some chip clearance.

- Tooling Material: Ensure it’s solid carbide for the best hardness, and consider a high-performance coating suitable for steel.

Here’s a quick comparison table for stick-out and deflection:

| Tool Stick-out (from holder) | Approximate Deflection Factor | Impact on Accuracy |

|---|---|---|

| 1x Tool Diameter | 1x | Minimal |

| 2x Tool Diameter | 8x | Noticeable/Significant |

| 3x Tool Diameter | 27x | Very Significant/Unacceptable for precision |

| 4x Tool Diameter | 64x | Extreme/Tool Breakage Likely |

Note: This is a simplified model. Actual deflection depends on material, tool diameter, rigidity of the setup, and cutting forces. The key takeaway is how drastically deflection increases with stick-out.

Putting It All Together: A Step-by-Step Approach

Let’s walk through a typical scenario to apply these principles. Suppose you need to mill a slot in a 1018 carbon steel block using a 3/16″ diameter, 4-flute solid carbide end mill with an 8mm shank.

- Tool Selection: You have a 3/16″ (approx 4.76mm) 4-flute carbide end mill. It has an 8mm shank, which is common. For this specific job, assume it’s a standard length end mill, not a long-reach one to minimize deflection from the start. Choose one with a good coating, like TiAlN, for steel.

- Machine Setup:

- Securely clamp the 1018 steel block in a stout vise.

- Insert the end mill into a clean ER-32 collet and then into a rigid tool holder (like an ER collet chuck or a side-lock holder).

- Adjust the tool holder so the end mill sticks out the absolute minimum required to clear the workpiece features. Aim for no more than 1.5x to 2x the tool diameter (so, about 7-10mm stick-out from the holder).

- Determine Speeds and Feeds:

- Target Material: 1018 Carbon Steel.

- Tool: 3/16″ (4.76mm) 4-flute carbide, TiAlN coated.

- Manufacturer Data: Consult a carbide tool manufacturer’s chart. For 1018 steel with a 4-flute carbide tool, a starting SFM might be around 300-400 SFM.

- Calculate RPM: Let’s use 350 SFM and a 2″ effective stick-out for calculation (though we want less!).

RPM = (350 SFM 12) / (3.14159 0.1875 inches) ≈ 7160 RPM

However, to combat deflection, we should reduce RPM. Let’s try 5000 RPM. - Calculate Chip Load: Chip load charts might suggest 0.001″ to 0.002″ per tooth for this size. To reduce deflection and chatter, aim for the higher end. Let’s pick 0.002″ per tooth.

- Calculate Feed Rate: `Feed Rate (IPM) = RPM Chip Load per Tooth Number