Have you ever wondered how metal parts are made? It’s a fascinating process that involves powerful machines. One of these machines is the CNC metal lathe. It plays a crucial role in shaping metal pieces with amazing precision.

CNC stands for Computer Numerical Control. This means that computers guide the machines, making them very accurate. But what are the actual parts of a CNC metal lathe? Each part works together like a team to create beautiful shapes and designs. From the bed to the spindle, every piece is important.

Imagine a world without these machines. How would cars, airplanes, or even toys be made? They all rely on CNC metal lathe parts. This technology has changed how we create products, making it faster and better.

In the following sections, we’ll explore some of these parts. We’ll learn what they do and why they matter. By the end, you’ll have a better understanding of how CNC metal lathes shape the world around us.

Cnc Metal Lathe Parts: Exploring Their Importance And Types

CNC metal lathe parts play a crucial role in modern machining. They help shape metal into precise items. Have you ever wondered how toys or car parts are made? That’s where CNC lathes shine! These machines use computer control to cut and carve metal accurately. Key components include spindles, tool holders, and chucks. Understanding these parts can enhance your machining skills and prepare you for exciting projects. Get ready to dive into the world of CNC machining!

Materials Used in CNC Metal Lathe Parts

Discussion of materials like steel, aluminum, and plastics used in manufacturing lathe parts.. Impact of material choice on durability and machining performance..

Strong materials make better cnc metal lathe parts. Steel is tough and lasts a long time. Aluminum is lightweight and easy to shape. Plastics are flexible and often cheaper. Choosing the right material affects how long parts last and how well they work. A good material choice can create strong, precise parts for various projects.

Why is material choice important for cnc metal lathe parts?

The right material improves durability and machining performance. Strong materials can handle more stress. This means they won’t break or wear down quickly. Using lightweight materials can speed up finishing. The success of the lathe parts often depends on what they are made from.

- Steel: Durable and strong.

- Aluminum: Light and easy to machine.

- Plastics: Flexible and cost-effective.

Manufacturing Process of CNC Metal Lathe Parts

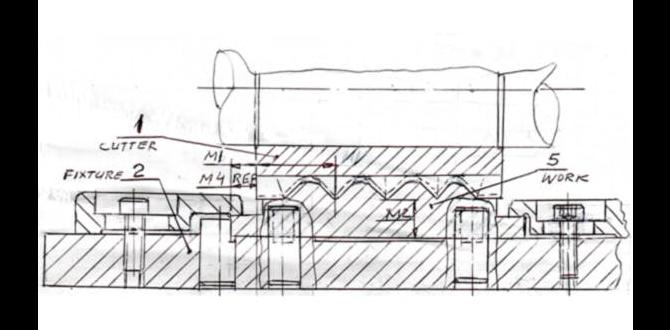

Stepbystep explanation of how CNC metal lathe parts are produced.. Importance of precision engineering in the manufacturing process..

CNC metal lathe parts are made through a careful process. First, a design is created on a computer. Then, the CNC machine cuts the metal. This ensures precise shapes and sizes. The steps include:

- **Design Phase:** Create a detailed drawing using software.

- **Setup Machine:** Load the metal and program the CNC lathe.

- **Machining:** The lathe spins, cutting the metal into the desired form.

- **Finishing Touches:** Smooth any rough edges for a clean finish.

Precision is very important in this process. It makes sure each part fits perfectly. Even a tiny mistake can cause big problems. This level of detail helps industries build safe and reliable products.

Why Is Precision Engineering Important?

Precision engineering is crucial because it ensures high-quality parts that work well together. Machines that fit together correctly run better and last longer. Inaccurate parts can lead to breakdowns and costly repairs.

CNC Metal Lathe Parts Maintenance

Tips and best practices for maintaining CNC lathe components for longevity.. Common issues associated with poor maintenance and how to avoid them..

Keeping CNC metal lathe parts in good shape is vital. Regular checks can save money and time. Here are some helpful tips:

- Clean parts after each use.

- Check for wear and tear often.

- Lubricate moving parts regularly.

- Store tools in a dry, safe place.

Poor maintenance can lead to serious problems. This may cause parts to break, or the machine to work less effectively. Avoid these issues by sticking to a routine.

What are common issues with poor maintenance?

Common problems include rust, overheating, and misalignment. These can all shorten the machine’s life. Regular upkeep helps keep everything running smoothly.

Applications of CNC Metal Lathe Parts

Exploration of industries that utilize CNC lathe components (e.g., automotive, aerospace, medical).. Examples of specific applications and their requirements in various sectors..

CNC metal lathe parts play a big role in many industries. They help create precise components used in cars, planes, and medical devices. For example:

- Automotive: Parts like gears and shafts are made for engines.

- Aerospace: Lightweight components ensure planes fly safely.

- Medical: Unique tools are crafted for surgeries.

These parts need to be accurate and strong. Each industry uses CNC lathe parts to meet special needs, ensuring safety and performance.

Why are CNC metal lathe parts important?

CNC metal lathe parts help industries create important items safely and accurately. For example, in the automotive field, they make engine components that power vehicles. In aerospace, they ensure aircraft function correctly. In the medical field, these parts enable reliable tools for doctors.

Choosing the Right CNC Metal Lathe Parts

Factors to consider when selecting parts for specific CNC lathe machines.. Comparison of brands and manufacturers in the market for CNC lathe parts..

Finding the best parts for your CNC lathe can feel like a treasure hunt. First, think about compatibility. Each machine has specific requirements, so check your manual like it’s the last slice of pizza at a party. Next, compare brands and manufacturers. Some are like the superheroes of the CNC world, offering great quality and support, while others are more like sidekicks. You want the heroes, not the sidekicks!

| Brand | Quality | Support |

|---|---|---|

| Brand A | ⭐️⭐️⭐️⭐️⭐️ | Excellent |

| Brand B | ⭐️⭐️⭐️⭐️ | Good |

| Brand C | ⭐️⭐️⭐️ | Fair |

Choosing the right parts means balancing quality and price. Look for reviews and expert opinions; they can be a lifesaver! Remember, the best part is the one that keeps your lathe running smoothly, not the one that breaks down faster than a toy on Christmas morning!

Future Trends in CNC Metal Lathe Parts

Emerging technologies and innovations affecting CNC metal lathe parts.. Predictions for the future of CNC machining and potential advancements..

New technologies are changing how we make cnc metal lathe parts. 3D printing is gaining popularity. It can create complex shapes quickly. AI helps machines learn and improve. This makes CNC machining faster and more accurate. We can expect more smart machines in the future. These machines will help reduce waste and speed up production.

- 3D printing will grow in use.

- AI will enhance machine learning.

- Automation will increase efficiency.

What innovations impact CNC lathe parts?

Innovations like 3D printing and AI are key. They allow for better designs and faster production. These changes promise a bright future for CNC machining.

Conclusion

In conclusion, CNC metal lathe parts are essential for precision in machining. These parts help create accurate shapes and sizes in metalwork. Understanding them can improve your projects. If you’re interested in machining, consider researching specific parts and their functions further. This knowledge will boost your skills and confidence. Start exploring today!

FAQs

What Are The Key Components Of A Cnc Metal Lathe, And How Do They Function Together To Facilitate Precision Machining?

A CNC metal lathe has a few key parts. There is a motor that spins the metal. We also have a tool that cuts the metal into shape. The computer controls everything so it cuts very accurately. Together, these parts help us make precise and smooth metal pieces.

How Do Different Types Of Cnc Metal Lathe Tools, Such As Turning Tools And Threading Tools, Impact The Quality Of The Finished Product?

Different types of CNC metal lathe tools change how well a finished product looks and works. Turning tools help make smooth, round shapes. Threading tools create spirals for screws and bolts. If we use the right tool, our product will be strong and precise. This way, we get better quality items that are fun to use!

What Materials Are Commonly Used In Manufacturing Cnc Metal Lathe Parts, And How Do Their Properties Affect Machining Performance?

CNC metal lathes make parts using materials like steel, aluminum, and brass. Steel is strong and lasts a long time. Aluminum is light and easy to shape. Brass is shiny and doesn’t rust. Each material has different properties, which can help or make it harder to machine them into parts.

How Does The Cnc Control System Influence The Operation And Accuracy Of A Metal Lathe?

The CNC control system helps us run the metal lathe precisely. It tells the machine exactly how to move. This means we can make parts that fit together perfectly. Because of the CNC, we can repeat the same shapes over and over without mistakes. This makes our work faster and better!

What Are The Common Maintenance Practices For Ensuring The Longevity And Optimal Performance Of Cnc Metal Lathe Parts?

To keep CNC metal lathe parts working well, you should clean them regularly. Check for any loose screws and tighten them. Lubricate the moving parts with oil to help them move smoothly. Also, always follow the user manual for special care tips. Finally, store the lathe in a dry place to avoid rust.