Have you ever wondered how something as small as a compact metal lathe can be both powerful and dangerous? When used correctly, these machines can create amazing projects. But safety should always come first.

Imagine a young inventor working on a cool gadget in their garage. They have a shiny compact metal lathe in front of them. Excitement fills the air, but so does the risk of injury. This is where safety steps in.

Using a compact metal lathe safely means knowing the right tricks. It’s not just about spinning metal; it’s about keeping hands and eyes safe. Did you know that many accidents happen because of simple mistakes? Students and hobbyists alike must learn how to protect themselves while they create.

As we explore the world of compact metal lathe safety, we will share tips and best practices. Together, we can make sure that every project is fun and safe!

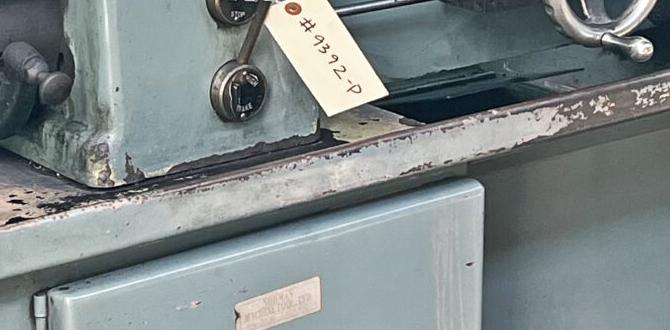

Compact Metal Lathe Safety: Essential Tips For Safe Operation When It Comes To Using A Compact Metal Lathe, Safety Should Always Be The Top Priority. These Machines, Although Incredibly Useful For Precision Work, Can Pose Significant Risks If Not Used Correctly. Here’S A Detailed Guide To Ensure Safe Operation And Minimize The Chances Of Accidents In The Workshop. Understanding Your Compact Metal Lathe Before Delving Into Safety Tips, It’S Essential To Understand What A Compact Metal Lathe Is. Commonly Used In Small Workshops Or For Hobby Projects, These Lathes Are Designed For Turning Metal And Producing Precise Parts. However, Their Power And Speed Necessitate Strict Adherence To Safety Practices. Key Safety Tips For Operating A Compact Metal Lathe 1. **Wear Appropriate Personal Protective Equipment (Ppe):** Always Wear Safety Goggles To Protect Your Eyes From Metal Shavings And Debris. Additionally, Consider Using Gloves Specifically Designed For Machine Work, And Avoid Loose Clothing That Can Get Caught In Moving Parts. 2. **Keep The Work Area Clean And Organized:** A Cluttered Workspace Can Lead To Accidents. Ensure That Your Work Area Is Tidy And Free Of Obstacles That Can Cause Trips Or Falls. 3. **Inspect Your Machinery Before Use:** Regularly Check The Lathe For Any Signs Of Wear Or Damage. Look For Loose Parts, And Make Sure All Guards Are In Place And Functional. If You Find Any Issues, Address Them Before Starting Work. 4. **Understand The Operating Manual:** Familiarize Yourself With The Manufacturer’S Operating Manual. Understanding The Controls And Specific Safety Features Of Your Compact Metal Lathe Will Help Prevent Misuse. 5. **Use Proper Techniques For Setup:** Securely Mount Your Workpiece And Ensure That Tools Are Appropriately Positioned. Always Double-Check For Tightness And Security Before Powering On The Lathe. 6. **Monitor Machine Speed And Feed Rate:** Adjust The Speed And Feed Rate According To The Material You Are Working With. Operating At Incorrect Speeds Can Lead To Breakage Or Injury. 7. **Stay Focused And Avoid Distractions:** Concentration Is Critical. Avoid Multitasking Or Engaging In Conversations While Operating The Lathe. A Momentary Lapse In Focus Can Lead To Severe Accidents. 8. **Know Emergency Procedures:** Familiarize Yourself With Emergency Shutdown Procedures Specific To Your Lathe. Ensure That Emergency Stop Buttons Are Easily Accessible And Functional. 9. **Practice Regular Maintenance:** Regularly Clean And Maintain Your Lathe To Prolong Its Life And Ensure Safety. Lubricate Moving Parts And Check For Any Wear That May Pose A Risk During Operation. 10. **Seek Training And Guidance:** If You’Re New To Operating A Lathe, Consider Seeking Training From A Qualified Professional. Knowledgeable Supervision Can Significantly Enhance Safety And Skill Development. Conclusion Compact Metal Lathe Safety Is Crucial For Anyone Utilizing This Powerful Tool. By Following These Essential Tips, You Can Mitigate Risks And Create A Safer Working Environment. Always Prioritize Safety, Stay Informed, And Respect Your Equipment—Doing So Will Lead To Successful And Safe Metalworking Endeavors.

Compact Metal Lathe Safety

Using a compact metal lathe can be exciting, but safety must always come first. Wear protective gear like goggles and gloves to keep yourself safe. Did you know that most accidents happen due to distractions? Staying focused is crucial! Ensure all tools are secure and hands are clear from moving parts. Regularly check for loose screws or dangerous wear. Remember, a little caution can prevent serious injuries. Stay safe, and enjoy your lathe work!Understanding Compact Metal Lathes

Definition and typical uses of compact metal lathes. Importance of safety in operation.Compact metal lathes are handy machines used to shape metal into various parts. They can make things like screws and small brackets. Using a compact metal lathe is fun, but safety comes first! Accidents can happen, and no one wants a trip to the hospital instead of making cool stuff. Remember to wear safety goggles and keep long hair tied back. Safety first, fun later!

| Safety Tips | Description |

|---|---|

| Wear Goggles | Protect your eyes from flying debris. |

| Keep Hair Secure | Avoid tangling in moving parts. |

| Read the Manual | Know your machine to avoid mishaps. |

Personal Protective Equipment (PPE) for Lathe Operators

Essential PPE items for working with metal lathes. Proper use and maintenance of PPE.Working near metal lathes requires special safety gear. Always wear goggles to protect your eyes from flying metal shavings. A snug-fitting face shield can guard against bigger debris. Don’t forget earplugs; lathes can get loud enough to make you feel like you’re at a rock concert! Sturdy steel-toed boots keep your feet safe from falling parts. And remember, using your PPE correctly is key. Keep it clean and in good shape. Just like your favorite superhero, it needs to be ready for action!

| PPE Item | Purpose |

|---|---|

| Goggles | Eye protection from shavings |

| Face Shield | Protection from large debris |

| Earplugs | Hearing protection from noise |

| Steel-Toed Boots | Foot protection from heavy falls |

Pre-Operation Safety Checks

Comprehensive checklist before operating the lathe. Importance of inspecting tools and workspaces.Before you dive into using the lathe, it’s crucial to run through a quick safety checklist. This isn’t just for fun; it helps keep you safe and your workspace tidy. You wouldn’t want to trip over a rogue tool or accidentally use a faulty one! Here’s a handy checklist to help you:

| Task | Check Status |

|---|---|

| Inspect the lathe | ✔️ |

| Check tools for damage | ✔️ |

| Clear workspace | ✔️ |

| Wear safety gear | ✔️ |

Inspecting your tools and workspace can save you from a trip to the emergency room, which beats another trip to the doctor any day! An organized workspace leads to a fun and smooth experience. Remember, a safe lathe operator is a happy lathe operator!

Safe Operating Procedures

Stepbystep guide on safe lathe operation. Tips for maintaining control and workpiece stability.Using a lathe can be fun and rewarding, but safety is key. Follow these steps for safe operation:

- Always wear safety goggles to protect your eyes.

- Keep hands and clothing away from moving parts.

- Secure your workpiece tightly in the lathe.

- Adjust the speed appropriately before starting.

- Stay focused on your task and avoid distractions.

For control and stability, use both hands for better grip. Always check your setup before turning on the machine. This will keep you safe and make your work easier!

Why is maintaining control important?

Maintaining control helps prevent accidents. A stable workpiece ensures clean cuts, leading to better results.

Emergency Procedures and First Aid

Emergency response plan for accidents occurring during operation. Basic first aid measures for typical latherelated injuries.Accidents can happen, even when using a compact metal lathe. Having a solid plan is essential. First, everyone should know where the emergency stops are located. If an accident occurs, call for help immediately. Remember, time is crucial! For small injuries, here are some basic first-aid tips:

| Injury Type | First Aid Procedure |

|---|---|

| Minor Cuts | Wash with soap, apply antiseptic, and cover with a bandage. |

| Burns | Cool the burn under running water for 10-20 minutes. |

| Pinched Fingers | Check for swelling, ice if needed, and keep it elevated. |

Stay calm during emergencies. Laughter can help too! As they say, “If you can laugh at it, you can survive it!”

Regular Maintenance and Safety Audits

Importance of routine maintenance for safety. Schedule and checklist for safety audits.Keeping machines in top shape is key for a safe working environment. Regular maintenance helps spot issues early, preventing accidents. Create a schedule for routine checks. This ensures every part functions well. Use a checklist to remember important tasks. A simple list can include:

- Check all safety guards

- Inspect electrical connections

- Lubricate moving parts

- Test emergency stop buttons

- Review operator training

Staying on top of these tasks keeps everyone safe. Make checks part of your routine. A little effort today can prevent big problems tomorrow.

Why is regular maintenance important for safety?

Regular maintenance helps prevent accidents. It keeps machines working correctly, which lowers the risk of injury. A safe workspace is a happy workspace!

Training and Competence for Lathe Operators

Significance of proper training for safety. Recommendations for training programs and certifications.Proper training for lathe operators is essential for keeping everyone safe in the workshop. Without it, accidents can happen faster than a squirrel on caffeine! It’s important to choose certified training programs that teach the ropes of using a lathe correctly. These programs often include hands-on practice and safety tips. Here’s a handy table with some recommendations:

| Program Name | Certification | Duration |

|---|---|---|

| Machine Operator Basics | Basic Lathe Certification | 2 Weeks |

| Advanced Lathe Techniques | Advanced Certification | 4 Weeks |

| Safety First! | Safety Certification | 1 Week |

Training helps operators develop skills and confidence. Remember, safety is no joke—unless you count “Why did the metal lathe fail?” “It didn’t get enough training!”

Resources for Further Learning

Recommended books, articles, and online courses on lathe safety. Organizations and associations that provide safety guidelines.Learning about compact metal lathe safety is essential. Many resources are available to help you. Here are some great options:

- Books: Look for titles like “Lathe Safety for Beginners” and “Working Safely with Lathes.

- Articles: Many websites offer tips on lathe safety. Search for articles from well-respected metalworking magazines.

- Online Courses: Websites like Udemy and Coursera provide classes. These can teach you safe practices at your own pace.

- Organizations: Groups like OSHA and the American Machinist Association provide safety guidelines. Check their websites for valuable information.

Use these resources to learn more and stay safe! Remember, safety first makes your work enjoyable!

What are some good sources for lathe safety?

Books, articles, and online courses are excellent sources. Organizations like OSHA offer guidelines, making it easier for you to learn!

Conclusion

In conclusion, staying safe with a compact metal lathe is crucial. Always wear safety gear like goggles and gloves. Keep your workspace tidy and never distract others while working. Regularly check your tools and follow instructions carefully. By following these tips, you can enjoy a safe and productive experience. For more guidance, consider reading safety manuals or watching tutorial videos.FAQs

Sure! Here Are Five Related Questions On The Topic Of Compact Metal Lathe Safety:When using a compact metal lathe, safety is very important. Always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothes. Make sure to keep your hands away from moving parts. Finally, always read the manual before you start working!

Sure! Please provide the question you’d like me to answer.

What Are The Essential Personal Protective Equipment (Ppe) Items Required When Operating A Compact Metal Lathe?When using a compact metal lathe, we need to wear some important safety gear. First, always put on safety goggles to protect your eyes from flying pieces of metal. Next, wear gloves to keep your hands safe while you work. Wearing a mask can help you breathe easier by keeping out dust and tiny particles. Lastly, it’s good to wear sturdy shoes to protect your feet from heavy tools.

How Can Operators Prevent Accidents Caused By Entanglement With Rotating Parts Of The Lathe?To prevent accidents with a lathe, you should always wear tight clothing and keep long hair tied back. Make sure to stand clear of moving parts. Use safety guards that cover the rotating areas. Always pay attention while working, and ask for help if you’re unsure. Safety first keeps everyone safe from getting hurt!

What Safety Measures Should Be Taken To Ensure The Workspace Around The Compact Metal Lathe Is Hazard-Free?To keep the area around the compact metal lathe safe, we should do a few things. First, keep the workspace clean and free of clutter. This helps prevent trips and falls. Second, wear safety gear like goggles and gloves to protect yourself. Lastly, make sure the lathe is turned off when not in use to avoid accidents.

How Often Should Maintenance Checks Be Performed On A Compact Metal Lathe To Ensure Safety And Optimal Performance?You should check your compact metal lathe often, at least once a month. Look for loose parts or rust. Clean it to keep it working well. If you use it a lot, check it more often. This helps keep you safe and makes sure the lathe works great!

What Are The Specific Steps To Follow In Case Of A Malfunction Or Emergency While Operating A Compact Metal Lathe?If the metal lathe stops working or something goes wrong, here’s what you should do. First, turn off the power switch to stop the machine. Next, check the area around the lathe for any problems. If you see something that looks broken or dangerous, tell an adult right away. Finally, never try to fix the lathe yourself; always wait for a teacher or a trained person to help you.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Compact Metal Lathe Safety:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a compact metal lathe, safety is very important. Always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothes. Make sure to keep your hands away from moving parts. Finally, always read the manual before you start working!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Personal Protective Equipment (Ppe) Items Required When Operating A Compact Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a compact metal lathe, we need to wear some important safety gear. First, always put on safety goggles to protect your eyes from flying pieces of metal. Next, wear gloves to keep your hands safe while you work. Wearing a mask can help you breathe easier by keeping out dust and tiny particles. Lastly, it’s good to wear sturdy shoes to protect your feet from heavy tools.”}},{“@type”: “Question”,”name”: “How Can Operators Prevent Accidents Caused By Entanglement With Rotating Parts Of The Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To prevent accidents with a lathe, you should always wear tight clothing and keep long hair tied back. Make sure to stand clear of moving parts. Use safety guards that cover the rotating areas. Always pay attention while working, and ask for help if you’re unsure. Safety first keeps everyone safe from getting hurt!”}},{“@type”: “Question”,”name”: “What Safety Measures Should Be Taken To Ensure The Workspace Around The Compact Metal Lathe Is Hazard-Free?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the area around the compact metal lathe safe, we should do a few things. First, keep the workspace clean and free of clutter. This helps prevent trips and falls. Second, wear safety gear like goggles and gloves to protect yourself. Lastly, make sure the lathe is turned off when not in use to avoid accidents.”}},{“@type”: “Question”,”name”: “How Often Should Maintenance Checks Be Performed On A Compact Metal Lathe To Ensure Safety And Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check your compact metal lathe often, at least once a month. Look for loose parts or rust. Clean it to keep it working well. If you use it a lot, check it more often. This helps keep you safe and makes sure the lathe works great!”}},{“@type”: “Question”,”name”: “What Are The Specific Steps To Follow In Case Of A Malfunction Or Emergency While Operating A Compact Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the metal lathe stops working or something goes wrong, here’s what you should do. First, turn off the power switch to stop the machine. Next, check the area around the lathe for any problems. If you see something that looks broken or dangerous, tell an adult right away. Finally, never try to fix the lathe yourself; always wait for a teacher or a trained person to help you.”}}]}