Have you ever seen a metal lathe at work? It’s amazing how these machines can shape metal into various forms. But, where do you put a metal lathe? That’s where a compact metal lathe stand comes in!

A good stand makes all the difference. It keeps your lathe steady and safe. Imagine trying to work on a wobbly table. Frustrating, right? A strong, compact stand ensures you can do your best work without worrying about your machine falling over.

Did you know that a well-designed stand can save you space too? In small workshops or garages, every inch counts. A compact metal lathe stand fits easily into tight spots, letting you maximize your workspace without sacrificing stability.

In this article, we’ll explore the benefits of these stands and how to choose the right one for your needs. Ready to learn more? Let’s dive in!

Essential Guide To Choosing A Compact Metal Lathe Stand

Compact Metal Lathe Stand: Key Insights

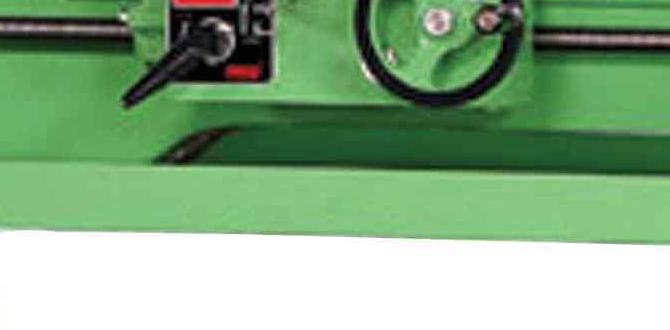

Are you looking for a sturdy and space-saving solution for your workshop? A compact metal lathe stand might be the answer. This type of stand provides stability, allowing for precise machining tasks. Many come with adjustable heights for user comfort. Did you know that using a metal stand can improve your lathe’s performance? It’s a smart choice for hobbyists and professionals alike, making your workspace more efficient and organized. Plus, it saves valuable floor space!Understanding the Compact Metal Lathe

Key features of compact metal lathes. Benefits of using a compact lathe in smaller workshops.A compact metal lathe is like a Swiss Army knife for metalworking. It’s small but mighty, perfect for tight spaces. Key features include adjustable speed, easy control, and durable materials that can handle any job. These lathes help hobbyists and professionals create parts without taking over the workshop. Picture a tiny giant that fits on a desk; you can turn metal into masterpieces while sipping coffee! Why not keep your workspace organized and your projects flowing?

| Key Features | Benefits |

|---|---|

| Space-saving design | Perfect for small workshops |

| Easy-to-use controls | Great for beginners |

| Variable speed settings | Versatile for different tasks |

Importance of a Dedicated Stand for Your Lathe

Stability and safety considerations. Impact on precision and accuracy while working.Having a stand for your lathe is very important. A strong, dedicated stand keeps the lathe stable. This means it won’t shake or tip over while you work. Stability helps you stay safe while creating your projects. It also improves your precision and accuracy. When the lathe doesn’t move, you can make better cuts. A good stand can make your work much easier and fun.

Why is a metal lathe stand important?

A metal lathe stand helps keep your work area safe and organized. Strong stands can prevent accidents and help you work better.

Key benefits of a dedicated stand

- Enhances stability

- Improves safety

- Increases precision

- Boosts accuracy

Materials Needed for Building a Metal Lathe Stand

Recommended materials for construction (wood, metal, etc.). Tools required for assembling the lathe stand.Building a sturdy lathe stand requires thoughtful choices in materials. For a solid base, wood or metal works well—pick your favorite! Wood is cheaper and easy to work with, while metal offers strength. Gather tools like a drill, screws, and a saw, and you’re ready to roll. A little humor goes a long way—just remember, woodworking doesn’t require a magic wand, just a bit of elbow grease! Here’s a table of suggested materials and tools:

| Materials | Tools |

|---|---|

| Wood (Plywood or 2x4s) | Drill |

| Metal sheets | Saw |

| Fasteners (screws, bolts) | Screwdriver |

| Paint or sealant | Measuring tape |

With the right materials and tools, building your compact metal lathe stand can be a fun adventure. Get ready to create something awesome!

Design Options for Compact Metal Lathe Stands

Different stand designs to consider (fixed, adjustable, etc.). Customization ideas for ergonomics and space efficiency.When choosing a stand, there are multiple designs to explore. Fixed stands stay in one spot and provide sturdy support. Adjustable stands can raise or lower, allowing for comfort at different heights. Fun fact: the right height can prevent backaches, making you more of a woodworking superhero!

Customization is key for both comfort and space. Think about adding shelves for tools or wheels for easy movement. Can you imagine a lathe that rolls around like a shopping cart? Now that’s efficiency! Whether you’re tall or short, fit your stand to your needs for the best experience.

| Stand Type | Benefits |

|---|---|

| Fixed | Sturdy and reliable. |

| Adjustable | Height can change for comfort. |

| Custom Shelves | Extra storage for tools. |

| Wheeled | Easy to move and reposition. |

Step-by-Step Guide to Constructing Your Lathe Stand

Detailed instructions for assembly. Tips for ensuring durability and stability.Building a lathe stand can be quite fun, like building with LEGO but for grown-ups! First, gather your materials. You’ll need sturdy wood or metal, screws, and tools. Assemble the frame by connecting the pieces securely. Remember, a wobbly stand is like a dancing tree – not good for your lathe! For stability, use cross bracing to keep everything steady. Tighten all screws and check for balance. If it wobbles, you might end up with a very “artistic” lathe project!

| Tip | Description |

|---|---|

| Use Quality Materials | This keeps your stand strong for years. |

| Double-check Measurements | Measure twice before cutting, just like a wise woodcutter. |

Placement and Setup of Your Metal Lathe Stand

Optimal location in your workshop for usability. Considerations for electrical and tool access.Finding the right spot for your metal lathe stand is like picking the best seat at a concert—you want a good view and easy access! First, choose a location that has enough space for you to move around. Think about how close your electrical outlets are. You don’t want to be doing a weird dance while reaching for a socket! Also, keep your tools nearby for quick access. This will make your work smoother and keep you from looking like you’re auditioning for a slapstick comedy show.

| Considerations | Notes |

|---|---|

| Space | Make sure you have enough room to move. |

| Electrical Access | Find a spot closer to outlets. |

| Tool Access | Place tools within easy reach. |

Maintenance Tips for Your Metal Lathe Stand

Routine checks and adjustments to keep your stand in top shape. Common issues and how to troubleshoot them.Keeping your metal lathe stand in great shape is easy with a few simple checks. Regularly inspect for rust or loose screws—don’t let it become a wobbly mess! Adjust the leveling feet so it stands firm, like a superhero ready to tackle any project. If the stand starts to sway, check for wear and tear on the base. Remember, a happy lathe stand means happy machining!

| Common Issues | Solutions |

|---|---|

| Rusty surface | Clean with rust remover and apply protective oil. |

| Loose screws | Tighten screws with the appropriate tool. |

| Unstable base | Adjust leveling feet for stability. |

A little maintenance goes a long way. You don’t want your stand to throw a tantrum during work! Keep it neat, and it will reward you with smooth and safe operations.

Enhancements and Accessories for Your Lathe Stand

Adding storage solutions for tools and materials. Optional upgrades for better performance and user experience.Upgrading your lathe stand can be a game changer! Consider adding storage solutions like shelves or drawers to organize tools and materials. Nothing beats easily finding that tool you need right when you’re about to start making something cool. Optional upgrades, like vibration dampeners, can make your lathe run smoother, turning noise into a gentle hum. And who wouldn’t want their workshop to feel more like a cozy café and less like a rock concert?

| Upgrade | Benefit |

|---|---|

| Tool Storage | Easy Access |

| Dampeners | Less Noise |

| Lighting | Better Visibility |

Comparing Commercial vs. DIY Lathe Stands

Pros and cons of each option. Cost analysis and value for money discussion.Choosing between a store-bought lathe stand and a DIY option can feel like a puzzle. Commercial stands offer reliability and often come ready to use, which is great for those who prefer no fuss. However, they can pinch your wallet a bit more than a home-cooked meal. On the other hand, DIY stands let you flex your creative muscles and can be cheaper, but they require time and some handy skills.

| Option | Pros | Cons | Cost |

|---|---|---|---|

| Commercial | Ready to use, Durable | More expensive | $$$ |

| DIY | Custom design, Cost-effective | Time-consuming, Requires skills | $ |

Ultimately, your choice depends on your needs and budget. If you’re feeling adventurous and can find spare parts lying around, a DIY stand could be your ticket to creativity. But if you want to skip the hassle, a commercial stand will keep you steady, even if it means giving up a few bucks!

Conclusion

In summary, a compact metal lathe stand is essential for a stable workspace. It supports your lathe safely and efficiently. When choosing one, consider size, strength, and adjustability. You can improve your projects with the right stand. Explore different designs online and find one that fits your needs. Get ready to enhance your metalworking experience today!FAQs

What Are The Key Features To Look For In A Compact Metal Lathe Stand?When looking for a compact metal lathe stand, you want it to be strong and sturdy. It should not wobble while you work. Check if it has adjustable legs for uneven floors. Also, make sure it has enough storage for your tools. Finally, look for a stand that is the right height for you to work comfortably.

How Does The Height Of A Compact Metal Lathe Stand Affect User Ergonomics And Comfort During Operation?The height of a compact metal lathe stand is important for your comfort. If it’s too low or too high, you might need to bend or stretch. This can make your back and arms hurt. A good height helps you stand straight, making it easier to work for a long time. You’ll feel better and work better too!

What Materials Are Typically Used To Construct Durable Compact Metal Lathe Stands, And How Do They Influence Stability?Metal lathe stands are usually made from steel or heavy-duty metal. These materials are strong and don’t tip over easily. When we use heavy metal, it helps keep the lathe steady while we work. A stable stand makes it safer and easier to use the lathe.

Can A Compact Metal Lathe Stand Be Customized For Specific Lathes Or Workspaces, And If So, How?Yes, you can customize a compact metal lathe stand. First, measure your lathe and workspace carefully. Then, you can add or remove shelves or adjust the height of the stand. You can also paint it or use different materials to match your workshop. This helps you have a better and more useful space to work in!

What Are Some Recommended Brands Or Models Of Compact Metal Lathe Stands For Hobbyists And Professional Machinists?Some good brands for compact metal lathe stands include Grizzly, Jet, and Smithy. Grizzly stands are sturdy and affordable. Jet offers strong and reliable options for serious users. Smithy is great for beginners who want something easy to use. These stands help keep your lathe steady while you work.