Do you ever wonder how to make great projects with metal? A compact metal lathe is one tool that can help you. It’s like a magic wand for metalworkers. With the right parts, this tool can create amazing shapes from solid metal.

One key part of a metal lathe is the tailstock. It assists in holding and supporting long pieces of metal. Imagine you want to create a beautiful lamp or a model car. The tailstock keeps everything steady so you can work without trouble.

Have you ever tried to build something and had it wobble? That can be very frustrating! A good tailstock can prevent that. It ensures your work stays in place, making it easier to design and shape the metal just how you want.

In this article, we will explore the wonders of a compact metal lathe tailstock. You will learn why it matters and how it can make your projects shine. Are you ready to dive in and discover new possibilities?

Compact Metal Lathe Tailstock: Enhancing Precision Machining

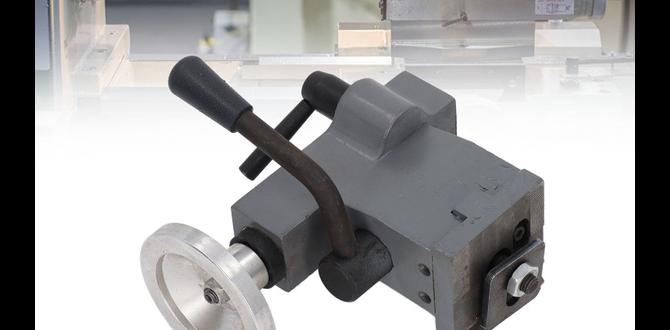

Compact Metal Lathe Tailstock

The compact metal lathe tailstock holds a vital role in metalworking. It supports tools and helps create precise cuts. Imagine trying to carve a perfect shape, but your tool keeps slipping! That’s where a sturdy tailstock comes in. This piece not only stabilizes the workpiece but also allows easy adjustments. Good tailstocks improve your craft by enhancing accuracy. A surprising fact? Smaller sizes often pack just as much power as larger models!Understanding the Basics of Metal Lathe Tailstocks

Definition and function of a tailstock in metal lathes. Importance of a quality tailstock for precision work.A tailstock is a key part of metal lathes. It sits opposite the headstock and holds the end of the workpiece. This support helps with stability during machining. A good quality tailstock ensures precise work. Without it, cuts can be wobbly, leading to mistakes. Think of it like trying to balance a pencil on your nose. If it’s off, it might fall! Always make sure your tailstock is strong and well-aligned to keep everything in check.

| Feature | Importance |

|---|---|

| Stability | Prevents wobbling |

| Alignment | Ensures flat cuts |

| Quality | Leads to precision |

Key Features to Consider When Selecting a Tailstock

Tailstock capacity and alignment. Build quality and materials used. Adjustability and ease of use.Choosing the right tailstock isn’t just about picking a pretty face; it’s about being smart! First, think about tailstock capacity and alignment. The better the alignment, the smoother your work. Next, consider the build quality and materials. A solid tailstock lasts longer—no one wants a wobbly companion! Lastly, look for adjustability and ease of use. If it takes you longer to adjust it than to use it, that’s just silly!

| Feature | Why It Matters |

|---|---|

| Capacity & Alignment | A smooth, straight cut makes life easier. |

| Build Quality | Durable materials mean less repair time! |

| Adjustability | Simple adjustments save you time and headaches. |

Common Brands and Models of Compact Metal Lathe Tailstocks

Review of popular brands and their features. Pros and cons of toprated models.Several brands make great compact metal lathe tailstocks. Popular examples are Grizzly, Jet, and Sherline. Each brand has unique features. For instance, Grizzly tailstocks are known for their strength. Jet models offer easy adjustments. Sherline’s tailstocks are very compact and perfect for small projects.

Here’s a quick look at pros and cons:

- Grizzly: Durable but heavier to move.

- Jet: Easy to use but more expensive.

- Sherline: Very compact but less power.

What should I consider when choosing a tailstock?

Look for features like ease of use, size, and cost.

Setting Up Your Compact Metal Lathe Tailstock

Stepbystep installation guide. Tips for ensuring proper alignment and functionality.Setting up your compact metal lathe tailstock is like assembling a puzzle. First, gather your tools: a wrench and some patience. Start by attaching it to the lathe bed, making sure everything lines up just right—like trying to put a square peg in a round hole, only less frustrating! Use a level to check if it’s straight. Don’t forget to tighten the screws well, or you might have a tailstock that plays hide and seek. Here’s a quick table with tips:

| Step | Tip |

|---|---|

| 1 | Align the tailstock with the lathe bed. |

| 2 | Use a level to check for evenness. |

| 3 | Tighten screws securely. |

| 4 | Test movement for smooth operation. |

Following these steps will help you avoid mishaps. A well-aligned tailstock can make your projects smoother than a buttered slide!

Maintenance and Care for Longevity

Essential maintenance practices. Troubleshooting common issues.Keeping your tools in great shape helps them last longer. Regular cleaning is key for any compact metal lathe tailstock. Remove dust and chips after each use. Lubricating moving parts is essential too; it helps them run smoothly. If something goes wrong, here are easy fixes:

- Check the alignment if parts aren’t fitting right.

- Look for any wear or damage on the components.

- Ensure that your lathe is level on the workbench.

By doing these simple tasks, you can enjoy working with your tailstock for years!

How can I troubleshoot my compact metal lathe tailstock?

For quick fixes, check the clamping mechanism and ensure it’s tightened. If the tailstock won’t move, clean the ways and check for rust. Regular maintenance prevents most issues.

Applications of Compact Metal Lathe Tailstocks

Typical projects and tasks utilizing tailstocks. How tailstocks enhance precision and productivity in various applications.Compact metal lathe tailstocks are essential tools in many projects. They help hold workpieces securely during machining. The tailstock improves precision in tasks like drilling and tapering. This leads to better results and time savings. Common uses include:

- Drilling holes in metal.

- Taper turning for shape creation.

- Supporting long workpieces when cutting.

With a tailstock, operators can work efficiently and achieve high-quality outcomes. It enhances both precision and productivity, which is key in metalworking.

What are common tasks with a tailstock?

People often use tailstocks for tasks like drilling holes, shaping metal, and supporting long pieces. These tasks need steady support for the best results.

Upgrading Your Tailstock: When and Why

Signs that it’s time for an upgrade. Benefits of investing in a higherquality tailstock.Are you struggling with your lathe and feeling like you’re missing the mark? It’s probably time for an upgrade! Look for signs like inconsistent accuracy or a tailstock that just won’t hold your workpiece straight. If your tailstock wobbles more than a toddler on roller skates, it’s time to go shopping!

Investing in a high-quality tailstock can be a game-changer. You’ll enjoy better precision and save time, which, as we know, is worth gold in the workshop. Plus, upgraded models often come with nifty features that make your life easier. Why not treat your lathe—and yourself—to an upgrade? After all, even tools deserve a little TLC!

| Signs It’s Time to Upgrade | Benefits of Upgrading |

|---|---|

| Inaccurate adjustments | Improved accuracy |

| Frequent slippage | Enhanced stability |

| Wear and tear | Time-saving features |

Conclusion

In summary, a compact metal lathe tailstock is essential for accuracy in metalworking. It supports your workpiece and helps you drill holes precisely. Choosing the right tailstock improves your projects significantly. To learn more, check out guides and videos on metal lathe use. With practice, you’ll master your skills and enhance your creations. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Compact Metal Lathe Tailstocks:Sure! A compact metal lathe tailstock is an important part of a lathe machine. It helps support the other end of the metal you’re working on. You can move it up and down to fit different pieces. Using it makes your work more accurate and safe. Always check it is tight before you start!

Sure! What question would you like me to answer?

What Are The Key Features To Consider When Selecting A Compact Metal Lathe Tailstock?When choosing a compact metal lathe tailstock, you should think about a few important features. First, check the tailstock’s stability. It should hold your work piece firmly. Next, look at how easy it is to adjust for different sizes. You want something simple to move. Lastly, make sure it’s made of strong metal to last a long time.

How Does The Design Of A Compact Tailstock Impact The Precision And Stability Of Machining Operations?A compact tailstock helps keep machines steady while they work. When it’s small, it takes up less space and can still hold tools tightly. This tight grip means your work is more accurate. If the tailstock is stable, your machining will be smoother and better. So, a good design helps you make precise parts easily.

What Types Of Adjustments And Alignments Can Be Made On A Compact Metal Lathe Tailstock For Improved Performance?You can make a few adjustments to a compact metal lathe tailstock to help it work better. First, check the alignment to make sure it is straight and not tilted. You can adjust the position of the tailstock by loosening screws. Next, you can also adjust the height. This makes sure the tailstock is even with the main part of the lathe. Lastly, clean all parts to help everything slide smoothly.

How Does The Weight And Size Of A Compact Tailstock Affect Its Usability In A Small Workshop Environment?A compact tailstock is smaller and lighter, making it easier to move around. In a small workshop, this saves space and helps you work better. You can quickly adjust it to fit different projects. Plus, it won’t take up too much room, so you can keep your tools organized. Overall, it makes working in a small space more fun and easy!

What Maintenance Practices Are Essential To Prolong The Life And Functionality Of A Compact Metal Lathe Tailstock?To keep your compact metal lathe tailstock working well, you should do a few important things. First, clean it regularly to remove any dust or dirt. Second, oil the moving parts so they work smoothly. You should also check for any loose or broken pieces and fix them right away. Lastly, make sure to store the lathe in a dry place to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Compact Metal Lathe Tailstocks:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A compact metal lathe tailstock is an important part of a lathe machine. It helps support the other end of the metal you’re working on. You can move it up and down to fit different pieces. Using it makes your work more accurate and safe. Always check it is tight before you start!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! What question would you like me to answer?”}},{“@type”: “Question”,”name”: “What Are The Key Features To Consider When Selecting A Compact Metal Lathe Tailstock?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a compact metal lathe tailstock, you should think about a few important features. First, check the tailstock’s stability. It should hold your work piece firmly. Next, look at how easy it is to adjust for different sizes. You want something simple to move. Lastly, make sure it’s made of strong metal to last a long time.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Compact Tailstock Impact The Precision And Stability Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A compact tailstock helps keep machines steady while they work. When it’s small, it takes up less space and can still hold tools tightly. This tight grip means your work is more accurate. If the tailstock is stable, your machining will be smoother and better. So, a good design helps you make precise parts easily.”}},{“@type”: “Question”,”name”: “What Types Of Adjustments And Alignments Can Be Made On A Compact Metal Lathe Tailstock For Improved Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can make a few adjustments to a compact metal lathe tailstock to help it work better. First, check the alignment to make sure it is straight and not tilted. You can adjust the position of the tailstock by loosening screws. Next, you can also adjust the height. This makes sure the tailstock is even with the main part of the lathe. Lastly, clean all parts to help everything slide smoothly.”}},{“@type”: “Question”,”name”: “How Does The Weight And Size Of A Compact Tailstock Affect Its Usability In A Small Workshop Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A compact tailstock is smaller and lighter, making it easier to move around. In a small workshop, this saves space and helps you work better. You can quickly adjust it to fit different projects. Plus, it won’t take up too much room, so you can keep your tools organized. Overall, it makes working in a small space more fun and easy!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential To Prolong The Life And Functionality Of A Compact Metal Lathe Tailstock?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your compact metal lathe tailstock working well, you should do a few important things. First, clean it regularly to remove any dust or dirt. Second, oil the moving parts so they work smoothly. You should also check for any loose or broken pieces and fix them right away. Lastly, make sure to store the lathe in a dry place to prevent rust.”}}]}