Have you ever watched a metal lathe in action? It’s fascinating how it shapes metal into useful parts. But did you know that designing these machines can be done with CAD software? It’s called comparison metal lathe CAD design, and it’s changing how we create tools.

Imagine being able to see your ideas come to life on a computer screen before they are even built. With CAD, designers can compare different lathe designs quickly. This means less trial and error in real life. It’s like having a magical toolbox right at your fingertips.

Many people are surprised to learn how much easier CAD makes this process. You can think of it like playing a video game but instead, you are creating real machines! Each design helps engineers improve their work. So, why not dive deeper into how comparison metal lathe CAD design can transform the way we make things?

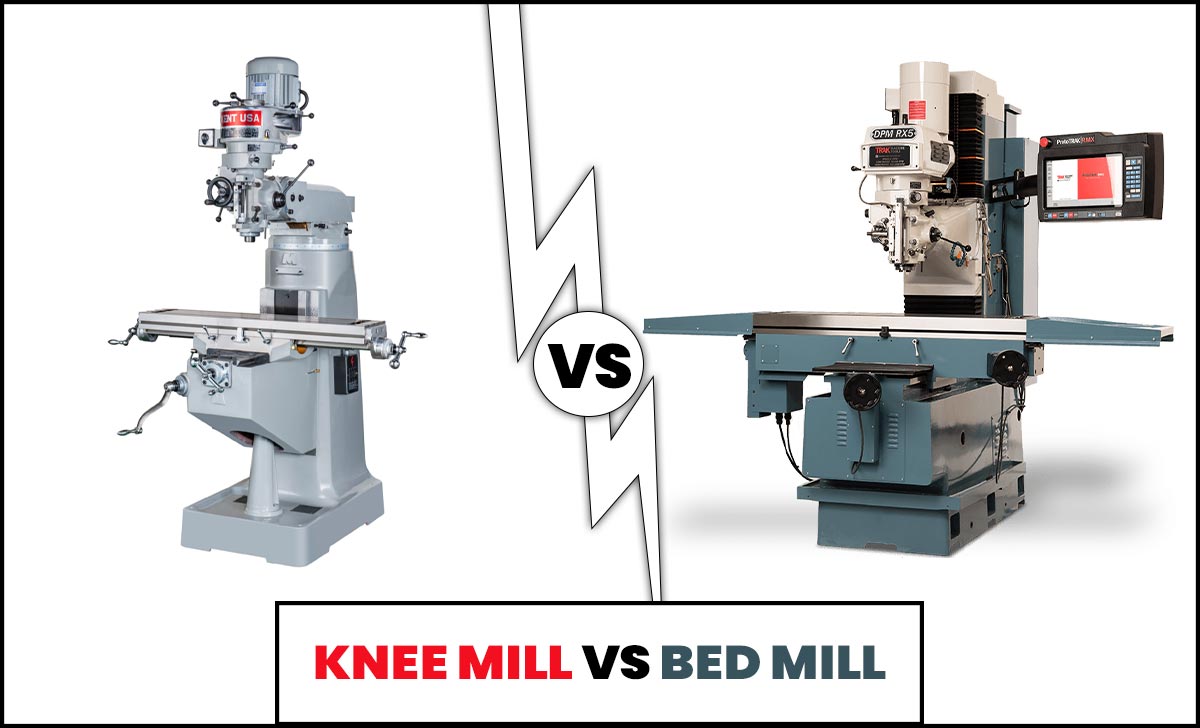

Comparison Metal Lathe Cad Design: Choosing The Right Tool

Comparison Metal Lathe CAD Design

Metal lathes are essential for creating precise parts. In CAD design, comparing different lathes helps to find the best fit for your project. You will learn how design features impact performance. Understanding the specifications of each lathe, like speed and tooling options, is crucial. Did you know some lathes can automatically change tools? This feature saves time and boosts efficiency. Exploring these comparisons makes choosing the right metal lathe easier and more informed!Understanding Metal Lathe Basics

Definition and function of a metal lathe. Common types of metal lathes used in workshops.A metal lathe is a machine that shapes metal into different forms. It spins metal pieces while cutting tools mold them into shape. Think of it as a giant pencil sharpener for metal! There are several common types of metal lathes found in workshops:

| Type of Lathe | Description |

|---|---|

| Engine Lathe | Versatile and used for a variety of tasks. |

| Bench Lathe | Smaller, ideal for home projects. |

| CNC Lathe | Computer-controlled for precision work. |

Understanding these basics makes metalworking less of a mystery. Just remember, a lathe is your best buddy if you want to create cool metal shapes!

Importance of CAD Design in Metal Lathes

Benefits of using CAD design for metal lathe projects. How CAD improves precision and efficiency in machining.Using CAD design for metal lathe projects is like having a magic wand! It brings many benefits, such as better precision and speed in your work. With CAD, you can create detailed designs that ensure every cut and shape is perfect. This minimizes mistakes and saves time. Think of it as giving your metal lathe superpowers! Plus, no more guesswork means fewer surprises, kind of like realizing your ice cream cone doesn’t have a hole at the bottom!

| Benefits of CAD Design | Description |

|---|---|

| Precision | CAD designs help achieve accurate measurements and shapes. |

| Efficiency | With better planning, projects take less time to complete. |

| Less Waste | Fewer errors mean less material waste. Hooray for saving! |

Key Features to Compare in Metal Lathes

Size and capacity: What to consider for your projects. Speed and torque specifications: Importance for various materials.Choosing the right metal lathe is important for your projects. First, think about the size and capacity you need. Think about what you will make. Larger projects need bigger lathes. Next, check the speed and torque specifications. Different materials need different speeds. For example, soft metals can work well at high speed. Hard metals need more torque to cut properly. Pay attention to these features to make the best choice.

What size lathe do I need?

It’s best to choose a lathe that fits your project size. Smaller projects can use smaller lathes, while larger projects need bigger machines.

How important is speed and torque?

- Speed is key for softer materials.

- More torque helps with harder materials.

Cost Analysis of Metal Lathes and CAD Software

Price range for different types of lathes. Cost vs. value: Investing in quality CAD software.Buying a metal lathe can be tricky. Prices for lathes can start at $1,000 for small models and go up to $10,000 for high-end machines. Investing in a good CAD software brings value too. Good software costs between $300 to $2,000 but helps in designing better projects. This makes it easier to work with different materials and achieve great results. Think of it this way: paying a little more for quality can save you time and trouble later.

What is the typical cost of metal lathes?

The typical cost of metal lathes ranges from $1,000 to $10,000, depending on size and features.

Cost vs. Value of CAD Software

- Basic Software: $300 – $600

- Mid-Range Software: $600 – $1,200

- Advanced Software: $1,200 – $2,000

User Experience and Support Options

Importance of user community and support for new lathe users. Comparing customer service quality of different metal lathe brands.Getting help and advice about metal lathes is very important for new users. A strong user community can share tips and tricks that make using a lathe easier. Customer service quality varies between brands. Some companies provide fast response times, while others may take longer to help.

- Quick Replies: Some brands answer questions fast.

- Helpful Guides: Good companies offer clear instructions.

- Online Groups: Many lathe users make online forums to share advice.

Finding a brand with strong user support will help you feel confident as you learn.

Why is support important for new lathe users?

Support helps beginners learn quickly and fix problems easily. Getting answers and advice can make using a lathe a fun experience!

Key Support Features:

- Live chat options

- Email assistance

- Video tutorials

Real-World Applications of CAD Designed Metal Lathe Projects

Examples of successful projects using CAD design with metal lathes. Industries that benefit the most from CADdesigned metal lathe components.Have you ever wondered where all those cool metal parts come from? From car engines to fancy gadgets, CAD-designed metal lathe projects are everywhere! Industries like automotive and aerospace love using these designs because they create precise parts quickly. For example, one company recently made a component that reduced engine weight by 20%. That’s like losing your lunchbox on a diet! It’s clear that CAD designs are a game changer in making things better and lighter.

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Engine components | Improved fuel efficiency |

| Aerospace | Aircraft parts | Weight reduction |

| Manufacturing | Custom tools | Precision and time-saving |

In real life, these projects help create wonders that benefit everyone. So, next time you see a shiny part, remember there’s a metal lathe and some clever design behind it!

Future Trends in Metal Lathes and CAD Design

Innovations in metal lathe technology. The evolving role of CAD in modern machining practices.Metal lathes are getting cooler every day! New designs are popping up, packed with smart tech that makes cutting and shaping metal easier. Picture a robot doing all the heavy lifting while you enjoy a snack. In this tech party, computer-aided design (CAD) is the DJ. CAD lets engineers create super precise models, making machining safer and faster. It’s like having a magic blueprint!Future innovations will keep bringing both metal lathes and CAD into the 21st century. Who knows? One day, you might have a metal lathe that tells jokes!

| Innovation | Description |

|---|---|

| Smart Sensors | Detect problems before they happen. |

| AI Integration | Optimizes machining processes. |

| 3D Printing | Makes metal custom parts quickly. |

Conclusion

In conclusion, comparing metal lathe CAD designs helps you choose the best machine for your projects. We learned that different designs offer unique features and benefits. Understanding these can save you time and money. We encourage you to explore various CAD software options and test designs to see what fits your needs best. Happy designing!FAQs

What Are The Key Differences Between Cad Designs For Manual Lathes And Cnc Lathes In A Metalworking Context?When we design for manual lathes, we focus on simpler shapes. You have to move the tools by hand. This makes it more hands-on, and you can make adjustments easily. With CNC lathes, or Computer Numerical Control lathes, we use computers to control the tools. This allows for more complex shapes and faster work since the machine does the moving for you.

How Can Cad Software Improve The Efficiency And Accuracy Of Metal Lathe Design Compared To Traditional Drawing Methods?CAD software, which stands for Computer-Aided Design, helps us create detailed designs on a computer. This makes it quicker to make changes and see how a metal lathe will look. With CAD, we can also spot mistakes before we build anything. This means our designs are more accurate and we waste less time and materials. Overall, CAD helps us work better and smarter!

What Features Should Be Included In A Cad Design For A Metal Lathe To Accommodate Various Machining Operations?A CAD design for a metal lathe should include a sturdy frame to keep it stable. You should add adjustable speed settings to change how fast the lathe spins. We also need a variety of tool holders, so we can use different tools for different jobs. Including safety guards is important to keep everyone safe while working. Lastly, having clear markers for measurements will help you make accurate cuts.

How Does The Choice Of Materials In Cad Designs For Metal Lathes Affect Their Performance And Longevity?The materials you choose in CAD designs for metal lathes matter a lot. Strong metals last longer and work better. If you use weak materials, the lathe can break easily. Good materials help the lathe perform well for many years. So, picking the right materials is very important!

What Are The Common Challenges Faced When Creating Cad Models For Complex Metal Lathe Parts, And How Can They Be Overcome?When making CAD models for tricky metal lathe parts, you might face some problems. One common issue is getting the shapes just right. We can overcome this by practicing and using good templates as guides. Another challenge is understanding how the parts fit together. To fix this, you can sketch a plan first or use 3D tools in your software.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Differences Between Cad Designs For Manual Lathes And Cnc Lathes In A Metalworking Context? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we design for manual lathes, we focus on simpler shapes. You have to move the tools by hand. This makes it more hands-on, and you can make adjustments easily. With CNC lathes, or Computer Numerical Control lathes, we use computers to control the tools. This allows for more complex shapes and faster work since the machine does the moving for you.”}},{“@type”: “Question”,”name”: “How Can Cad Software Improve The Efficiency And Accuracy Of Metal Lathe Design Compared To Traditional Drawing Methods? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CAD software, which stands for Computer-Aided Design, helps us create detailed designs on a computer. This makes it quicker to make changes and see how a metal lathe will look. With CAD, we can also spot mistakes before we build anything. This means our designs are more accurate and we waste less time and materials. Overall, CAD helps us work better and smarter!”}},{“@type”: “Question”,”name”: “What Features Should Be Included In A Cad Design For A Metal Lathe To Accommodate Various Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A CAD design for a metal lathe should include a sturdy frame to keep it stable. You should add adjustable speed settings to change how fast the lathe spins. We also need a variety of tool holders, so we can use different tools for different jobs. Including safety guards is important to keep everyone safe while working. Lastly, having clear markers for measurements will help you make accurate cuts.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Materials In Cad Designs For Metal Lathes Affect Their Performance And Longevity? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The materials you choose in CAD designs for metal lathes matter a lot. Strong metals last longer and work better. If you use weak materials, the lathe can break easily. Good materials help the lathe perform well for many years. So, picking the right materials is very important!”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced When Creating Cad Models For Complex Metal Lathe Parts, And How Can They Be Overcome? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making CAD models for tricky metal lathe parts, you might face some problems. One common issue is getting the shapes just right. We can overcome this by practicing and using good templates as guides. Another challenge is understanding how the parts fit together. To fix this, you can sketch a plan first or use 3D tools in your software.”}}]}