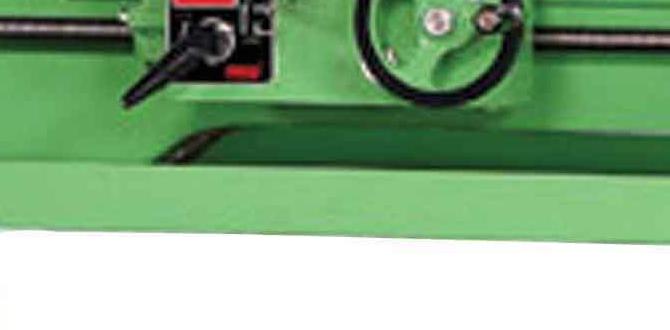

Have you ever wondered how machine shops get such precision in their work? One key tool that helps with this is the metal lathe chuck. A metal lathe chuck holds material in place so workers can shape it accurately. Choosing the right chuck can make a big difference in your projects.

Imagine you’re in a workshop. You see a busy mechanic turning metal effortlessly. The lathe spins, and the chuck keeps everything steady. This setup is crucial for creating parts that fit perfectly. But how do you know which metal lathe chuck is best for your needs?

In this article, we will dive into the world of metal lathe chucks. We will explore the differences between them and what to look for. You might be surprised at how a small part like a chuck can affect the final product. By the end, you’ll have a better understanding of your options. Let’s get started!

A Comprehensive Comparison Of Metal Lathe Chucks

Comparison of Metal Lathe Chucks

Metal lathe chucks play a crucial role in shaping various materials. They come in different types, like three-jaw and four-jaw chucks. Each type has unique advantages. For instance, three-jaw chucks make clamping easy and quick. Conversely, four-jaw chucks provide better accuracy for odd-shaped items. Choosing the right chuck can significantly improve your project quality. Did you know a simple adjustment can save you hours of work? Understanding these differences is key for every metalworking enthusiast.Key Features to Consider

Explanation of gripping strength and precision.. Importance of chuck size and compatibility with different lathes..Think of gripping strength as a superhero power for your lathe chuck. It holds your workpiece tight, preventing any mishaps! Precision is equally important. A good chuck makes sure your project is smooth and accurate, just like a perfectly thrown pizza dough.

Size matters! If your chuck doesn’t fit your lathe, it’s like wearing shoes two sizes too small—very uncomfortable. Check the compatibility before buying to save yourself from future headaches. Remember, a great chuck can make all the difference between a masterpiece and a messy project!

| Feature | Importance |

|---|---|

| Gripping Strength | Prevents slipping and ensures safety! |

| Precision | Delivers accurate results for your projects. |

| Chuck Size | Must match your lathe for a snug fit. |

Material and Build Quality

Comparison of materials used in chuck construction (steel, cast iron, etc.).. How build quality affects durability and performance..When choosing a metal lathe chuck, the materials matter a lot. Chucks are often made of steel or cast iron. Steel is strong and often lasts longer. Cast iron is heavy but can crack under stress. The build quality affects how well the chuck performs. A well-made chuck stays tight and gives better results. Poor quality can lead to wobbling or breaking.

What materials are best for a lathe chuck?

Steel and cast iron are the most common. They each have their pros and cons, but steel usually wins for durability.

Pros and Cons

- Steel: Strong and durable.

- Cast Iron: Heavy but may crack.

Building a metal lathe chuck with high-quality materials ensures long-lasting performance. A good chuck can last for years, making your work smoother and easier.

Brand Comparisons

Analysis of leading brands in the metal lathe chuck market.. Performance comparison based on customer reviews and industry standards..Different brands offer various metal lathe chucks. Each one has unique features, which can affect performance. Customers share their thoughts through reviews, helping us compare them.

- Brand A: Known for its durability and smooth operation.

- Brand B: Offers excellent price and reliability, though slightly heavier.

- Brand C: Features advanced tech but can be tricky to use initially.

Overall, finding the right brand depends on your needs and preferences. Consider customer feedback as a guide. It can help you choose wisely!

Which brand is best for a metal lathe chuck?

Brand A is highly rated for its durability and performance. Customer reviews often praise its smooth operation. It’s a favorite among both beginners and experts.

Price vs. Performance

Breakdown of price ranges for various types of chucks.. Evaluation of whether higherpriced options offer proportional performance benefits..The price of chuck systems varies widely based on type and features. Basic chucks can start around $30, while high-quality options may reach $300 or more. It’s vital to weigh performance against price. Higher-priced chucks often have better grip and durability. However, this does not always guarantee more efficiency for your specific needs.

- Basic chucks: $30 – $60

- Mid-range chucks: $60 – $150

- Premium chucks: $150 – $300+

In many cases, a good mid-range chuck offers solid performance without breaking the bank. So, is spending more always better? Not necessarily!

Do expensive chucks provide better performance?

Not always! Sometimes, a well-designed mid-range chuck can perform just as well, making it a smart choice for most users.

Maintenance and Lifespan

Best practices for maintaining metal lathe chucks.. Average lifespan and factors that influence longevity..Taking care of a metal lathe chuck is important for its lifespan. Regular cleaning keeps it free from dirt and debris. Check the jaws and align them straight. Use lubricants when needed. Remember, a well-maintained chuck works better and lasts longer. Factors like usage frequency and material type can affect how long it lasts. With proper care, a metal lathe chuck can last many years, even up to 15 to 20 years!

What are the best practices for maintaining metal lathe chucks?

Keep it clean, check alignment, and use lubricants regularly.Key tips for care:

- Clean after each use

- Check for wear and tear

- Lubricate moving parts

- Store in a dry place

Real User Experiences

Case studies or testimonials from users of different types of chucks.. Examples of projects that highlight the performance of various chucks..Users share some funny and helpful stories about their metal lathe chucks. One woodworker said, “My chuck held the wood tighter than my grandma hugs!” This is a good sign for projects. Different chucks shine in various tasks. For example, a 3-jaw chuck was perfect for making wooden bowls, while a 4-jaw chuck excelled at holding odd shapes. Here’s a peek into user experiences:

| Chuck Type | User Experience | Project Example |

|---|---|---|

| 3-Jaw Chuck | Secure grip for smooth cuts | Wooden bowls |

| 4-Jaw Chuck | Great for holding unique shapes | Custom pen turning |

| Collet Chuck | Perfect for tiny details | Miniature models |

These stories and projects show how the right chuck can make work easier and more fun.

Recommendations for Specific Applications

Suggested chucks for beginners vs. advanced users.. Recommendations based on specific machining tasks or materials..For newcomers, a three-jaw chuck is often the best choice. It holds round pieces firmly and allows for quick setups. Advanced users may prefer a four-jaw chuck. This tool can grip irregular shapes or things that look like they got into a wrestling match! For specific tasks, like wood turning, a scroll chuck works wonders to handle various materials easily.

| User Level | Recommended Chuck | Best Applications |

|---|---|---|

| Beginner | Three-Jaw Chuck | Basic turning tasks |

| Advanced | Four-Jaw Chuck | Complex shapes & precision jobs |

| Wood Turner | Scroll Chuck | Wood and softer materials |

Choosing the right chuck allows you to work better and faster. Remember, the right tool can make you feel like a wizard in your workshop!

Conclusion

In conclusion, choosing the right metal lathe chuck is essential for your projects. Consider factors like size, type, and material for the best fit. We’ve discussed how different chucks affect precision and stability. Now, it’s time to explore your options. Check online reviews or visit local shops to find the best chuck for your needs. Happy crafting!FAQs

Here Are Five Related Questions On The Topic Of Comparing Metal Lathe Chucks:Sure! When you compare metal lathe chucks, you look at their size, grip, and strength. Some chucks hold pieces tightly, while others are easier to use. You want one that matches your lathe and your projects. Checking reviews can help you choose the best one for your needs. Let’s make sure you pick a good chuck!

Sure! Please give me the question you want answered, and I will help you with it.

What Are The Key Differences Between A Three-Jaw And A Four-Jaw Chuck In Terms Of Versatility And Precision?A three-jaw chuck holds things quickly and is easy to use. It works well for round objects. A four-jaw chuck can hold different shapes better. This makes it more precise, but it takes more time to set up. So, if you want speed, use a three-jaw; for tricky shapes or exact work, choose a four-jaw.

How Do The Materials Used In The Construction Of Metal Lathe Chucks Affect Their Performance And Durability?The materials for metal lathe chucks matter a lot. If they’re made of strong metal, they will last longer and handle more weight. We want them to resist bending or breaking when we use them. Better materials help chucks grip things tightly and work smoothly. Using the right materials means our tools last longer and work better.

What Are The Advantages And Disadvantages Of Using A Quick-Change Chuck Versus A Standard Chuck On A Metal Lathe?A quick-change chuck lets you switch tools fast, which saves time. It’s great when you need to change pieces often. However, it can be more expensive and might be harder to use for beginners. A standard chuck is usually cheaper and easier for new users but takes longer to change tools. So, it’s a trade-off between speed and ease.

In What Scenarios Would A Self-Centering Chuck Be More Beneficial Than A Manual-Adjust Chuck For Metalworking Projects?A self-centering chuck is great when you have many pieces to work on. It automatically holds them tight and straight. This saves you time because you don’t need to adjust it each time. If you’re working on projects that need a lot of pieces, a self-centering chuck makes things easier. It’s perfect for making things like gears or wheels that need to be exact.

How Does The Size And Mounting Type Of A Lathe Chuck Influence Its Compatibility With Different Types Of Lathes?The size of a lathe chuck is important because it needs to fit the lathe properly. If the chuck is too big or too small, it won’t work well. The mounting type is also key because it decides how the chuck attaches to the lathe. Different lathes use different mountings, so you have to match them. This way, your chuck will hold the pieces tightly while you work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Comparing Metal Lathe Chucks:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you compare metal lathe chucks, you look at their size, grip, and strength. Some chucks hold pieces tightly, while others are easier to use. You want one that matches your lathe and your projects. Checking reviews can help you choose the best one for your needs. Let’s make sure you pick a good chuck!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want answered, and I will help you with it.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between A Three-Jaw And A Four-Jaw Chuck In Terms Of Versatility And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A three-jaw chuck holds things quickly and is easy to use. It works well for round objects. A four-jaw chuck can hold different shapes better. This makes it more precise, but it takes more time to set up. So, if you want speed, use a three-jaw; for tricky shapes or exact work, choose a four-jaw.”}},{“@type”: “Question”,”name”: “How Do The Materials Used In The Construction Of Metal Lathe Chucks Affect Their Performance And Durability?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The materials for metal lathe chucks matter a lot. If they’re made of strong metal, they will last longer and handle more weight. We want them to resist bending or breaking when we use them. Better materials help chucks grip things tightly and work smoothly. Using the right materials means our tools last longer and work better.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using A Quick-Change Chuck Versus A Standard Chuck On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A quick-change chuck lets you switch tools fast, which saves time. It’s great when you need to change pieces often. However, it can be more expensive and might be harder to use for beginners. A standard chuck is usually cheaper and easier for new users but takes longer to change tools. So, it’s a trade-off between speed and ease.”}},{“@type”: “Question”,”name”: “In What Scenarios Would A Self-Centering Chuck Be More Beneficial Than A Manual-Adjust Chuck For Metalworking Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A self-centering chuck is great when you have many pieces to work on. It automatically holds them tight and straight. This saves you time because you don’t need to adjust it each time. If you’re working on projects that need a lot of pieces, a self-centering chuck makes things easier. It’s perfect for making things like gears or wheels that need to be exact.”}},{“@type”: “Question”,”name”: “How Does The Size And Mounting Type Of A Lathe Chuck Influence Its Compatibility With Different Types Of Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The size of a lathe chuck is important because it needs to fit the lathe properly. If the chuck is too big or too small, it won’t work well. The mounting type is also key because it decides how the chuck attaches to the lathe. Different lathes use different mountings, so you have to match them. This way, your chuck will hold the pieces tightly while you work.”}}]}