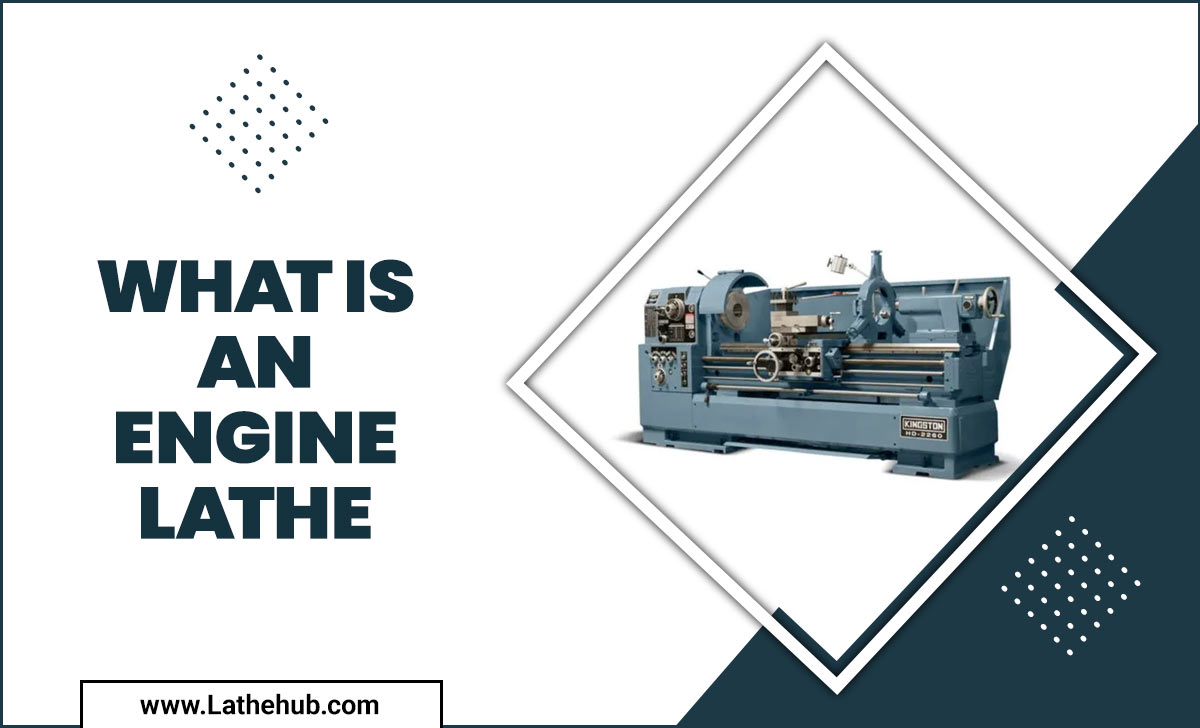

Have you ever wondered how metal lathes work? These machines shape metal into amazing parts. One key piece in that process is the pulley. A metal lathe pulley helps control the machine’s speed and power. Without it, the lathe wouldn’t perform efficiently.

Imagine you’re building a model airplane. You need precise and strong parts. A metal lathe can make these parts, but how does the pulley fit into the picture? Comparing different metal lathe pulleys can help you find the best one for your project.

Did you know that the right pulley can make your lathe run smoother? It can even extend its life. Discovering how different pulleys stack up against each other could change the way you think about metal lathes. Let’s dive into the world of comparison metal lathe pulley and see how they can make your next project a breeze!

Comparison Of Metal Lathe Pulley Systems And Their Benefits

Comparison Metal Lathe Pulley

When choosing a metal lathe pulley, consider size and durability. A stronger pulley can handle heavy workloads better. Do you know that using the right pulley can improve your machine’s performance? It can also save time and effort. Some pulleys are made from steel, while others use aluminum. Each material has its benefits. Check the specifications carefully. The right choice makes a big difference in your projects, ensuring smoother operation and lasting results.Understanding Metal Lathe Pulley Systems

Definition and function of pulley systems in metal lathes. Importance of pulley systems in enhancing machining capabilities.Pulleys are simple yet powerful tools in metal lathes. They help transfer power from the motor to the lathe itself, making your work smoother. The pulley system allows you to change the speed of the lathe easily, giving you more control over your machining tasks. Think of it as a traffic light for turning metal—directing power where it needs to go!

The importance of these systems can’t be overstated. Without them, machining would be a bit like trying to ride a bike with flat tires—frustrating and slow. A good pulley system enhances your machine’s capabilities, letting you tackle different projects with ease.

| Function | Benefit |

|---|---|

| Speed Control | Precision machining |

| Power Transfer | Efficiency |

| Durability | Longer Machine Life |

Key Features to Consider in Metal Lathe Pulleys

Material and construction quality: Factors affecting durability and performance. Size and diameter specifications: Impact on torque and speed.Choosing the right pulley for your metal lathe can be a bit tricky. Material plays a huge role in how long your pulley lasts and how well it performs. A sturdy metal ensures durability, while flimsy ones might lead to sad, squeaky noises. Size matters too! The diameter of the pulley affects torque and speed—bigger might be better if you want to zoom through your projects. Let’s compare some specs:

| Feature | Effect |

|---|---|

| Material | Durability and Performance |

| Diameter | Torque and Speed |

In the end, think of your lathe as a car. A strong pulley is like a good engine—it helps you go the distance without stalling! Who wants a car that just makes noise? Not us!

Performance Comparison of Metal Lathe Pulley Systems

Speed variations and their implications on machining. Torque output comparison among different pulley setups.Different metal lathe pulley systems can really change how your machine works. Speed matters! Faster speeds can help you finish jobs quicker but might also lead to mistakes. Imagine trying to eat spaghetti super fast—sauce everywhere! The amount of torque your system provides is just as important. Some pulleys give more strength, making it easier to handle tough materials without breaking a sweat. Here’s a quick look at how the speed and torque can vary:

| Pulley Type | Speed (RPM) | Torque (Nm) |

|---|---|---|

| Standard | 1200 | 10 |

| High-Torque | 800 | 15 |

| Variable Speed | 600-1800 | 12 |

Choosing the right system is key to your success. If you pick wisely, your projects will be smoother than a butter slide!

Installation and Maintenance of Metal Lathe Pulley Systems

Stepbystep guide to installing pulleys on metal lathes. Tips for maintaining and troubleshooting common pulley issues.Installing pulleys on metal lathes can feel like assembling a puzzle. First, gather your tools: a wrench, screwdriver, and patience. Start with the main drive pulley, placing it securely on the spindle. Tighten it until it can’t go anymore—just don’t overtighten and treat it like your favorite snack! Next, attach the idler pulleys, ensuring they’re aligned. For maintenance, check belts regularly for wear and give everything a good wipe down. If something feels off, it might just need a little love—and a few adjustments!

| Common Issues | Quick Fixes |

|---|---|

| Slip belts | Adjust tension |

| Squeaky noises | Lubricate bearings |

| Pulley misalignment | Realign pulleys |

Cost Analysis of Metal Lathe Pulley Options

Comparison of budgetfriendly vs. premium pulley systems. Longterm savings vs. initial costs and why it matters.When considering pulley systems for your metal lathe, you’ll encounter two main choices: budget-friendly and premium options. While the cheap ones can save you money up front, they might not last as long. Premium pulleys are like fine wine; they age well and can save you money in the long run. Think of it this way: a good pulley can keep your lathe running smoothly, leading to fewer repairs. So, is it worth it to invest more?

| Type | Initial Cost | Long-term Savings |

|---|---|---|

| Budget-friendly | $50 | Lower lifespan |

| Premium | $150 | High durability |

In short, while your wallet might feel lighter with a budget pulley, a premium one could save you time and trouble down the road. Remember, a penny saved today might cost you dollars tomorrow!

Real-World Applications of Metal Lathe Pulley Systems

Industrial uses: What industries rely on specific pulley systems?. Hobbyist applications and recommendations for different skill levels.Many industries rely on metal lathe pulley systems to keep things running smoothly. For example, manufacturing and automotive sectors use pulleys for efficient machinery operations. Hobbyists, such as woodworkers or metalworkers, also find these systems handy. Beginners might choose simpler models, while pros can tackle advanced setups. It’s like choosing between a tricycle and a racing bike! Here’s a quick look at the types of pulleys folks might use:

| Skill Level | Recommended Pulley Type |

|---|---|

| Beginner | Basic Pulley Set |

| Intermediate | Adjustable Pulley System |

| Advanced | High-Precision Pulley Setup |

With the right understanding, anyone can get started on exciting projects!

Conclusion

In conclusion, comparing metal lathe pulleys helps you choose the best one for your project. Look for quality materials and the right size. Understand how pulleys affect speed and torque. By knowing these factors, you can enhance your lathe’s performance. Now, explore different options and see what works best for you. Happy turning!FAQs

Sure! Here Are Five Related Questions Regarding The Comparison Of Metal Lathe Pulleys:Sure! Metal lathe pulleys help machines work better. They come in different sizes and designs. You compare them by looking at how strong they are and how they fit your machine. We can also check how much noise they make. Lastly, think about how much they cost before you choose one!

Sure! Just share the question you want me to answer, and I’ll help you with it.

What Are The Key Differences Between Cast Iron And Aluminum Pulleys Used In Metal Lathes?Cast iron pulleys are heavy and strong. They can handle a lot of work without breaking. Aluminum pulleys are lighter and easier to move. They don’t rust, but they might not be as strong. You can choose one based on your needs!

How Does The Pulley Size And Ratio Impact The Performance And Torque Output Of A Metal Lathe?The size of the pulley affects how fast our metal lathe spins. Bigger pulleys can make it spin quicker, while smaller ones give more power. The pulley ratio tells us how these sizes compare. A higher ratio means more strength to cut through metal, but it can be slower. So, by changing pulley size and ratio, we control speed and power for different jobs.

What Are The Advantages And Disadvantages Of Using V-Belt Pulleys Versus Timing Belt Pulleys In Metal Lathes?V-belt pulleys are great because they are easy to find and usually cheaper. They can handle a lot of power but may slip if they get worn out. Timing belt pulleys are more precise, so they don’t slip and help keep things in sync. However, they can be more expensive and harder to replace. You need to pick the one that works best for your project!

How Do Different Materials Influence The Durability And Noise Levels Of Metal Lathe Pulleys?Different materials can change how strong and noisy metal lathe pulleys are. If we use strong metals, the pulleys last longer and make less noise. Softer materials may wear out quickly and can be louder. So, choosing the right material helps pulleys work better and last a long time.

In What Ways Can The Design And Construction Of Pulleys Affect The Overall Maintenance Requirements Of A Metal Lathe?The design and build of pulleys can change how easy a metal lathe is to take care of. If pulleys are strong and smooth, they help the lathe run better. This means you won’t have to fix or clean them as often. If they’re poorly made, they might break or wear out, needing more repairs. Good pulleys help keep your lathe in good shape for longer!