Have you ever wondered how to stay safe while using metal lathes? These machines play a vital role in shaping metal for various projects. However, safety must always come first. Many people overlook the dangers involved with metal lathes. That’s a mistake! Knowing how to operate them safely is crucial for everyone.

Imagine working on an exciting project. You’re focused, and the lathe is humming along. Suddenly, you realize you didn’t follow a safety step. Panic sets in, right? Avoiding accidents starts with understanding safety measures. By comparing safety practices, we can uncover the best ways to protect ourselves while using metal lathes.

In this article, we will explore the safety aspects of metal lathes. We’ll compare different safety measures and tips. Together, let’s ensure that using metal lathes is not only fun but also safe!

Comparison Metal Lathe Safety: Key Considerations And Tips

Comparison Metal Lathe Safety

Safety is crucial when using a metal lathe. Learning how to operate it safely helps prevent accidents. Always wear safety goggles and keep loose clothing away from the machine. Did you know that most accidents happen because of carelessness? Regular maintenance also keeps the lathe in good shape. Understanding safety features can save lives. So, how prepared are you for a safe experience at the lathe? Remember, safety first leads to great results!Essential Safety Equipment for Metal Lathe Operators

Description of required personal protective equipment (PPE). Explanation of additional safety tools and their purposes.Working with a metal lathe can be exciting, but safety is key! First, wear gloves to protect your hands, and goggles for your eyes. A dust mask helps you breathe better, keeping those tiny metal bits out of your lungs. Also, steel-toed boots are great for keeping your toes safe if you drop something heavy. Let’s not forget ear protection! Lathes can be noisy; you don’t want your ears ringing like a bell!

| Safety Equipment | Purpose |

|---|---|

| Gloves | Protects hands from sharp edges |

| Goggles | Shields eyes from flying debris |

| Dust Mask | Keeps lungs clear of metal particles |

| Steel-Toed Boots | Protects feet from falling objects |

| Ear Protection | Reduces noise levels |

Additional tools like a fire extinguisher and a first aid kit are also smart to have nearby. Better safe than sorry! Remember, safety isn’t just a slogan; it’s a lifestyle!

Safe Operating Procedures for Metal Lathes

Stepbystep guidance on proper startup and shutdown procedures. Importance of maintaining a clean and organized workspace.Starting and stopping a metal lathe safely is important. Follow these steps:

- Check all parts for safety.

- Make sure the area is clean. Remove tools and debris.

- Turn on the machine only after everything is ready.

- Stop the lathe properly by following the shutdown steps.

A clean workspace helps prevent accidents. An organized area makes it easy to find tools and keeps everyone safe. Keep it neat for the best results!

How can I ensure safety while using a metal lathe?

Follow safety rules strictly. Always wear safety gear, and be aware of your surroundings. Make sure the tools are in good shape, too.

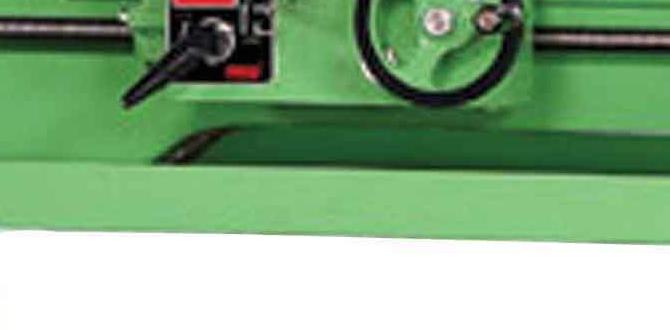

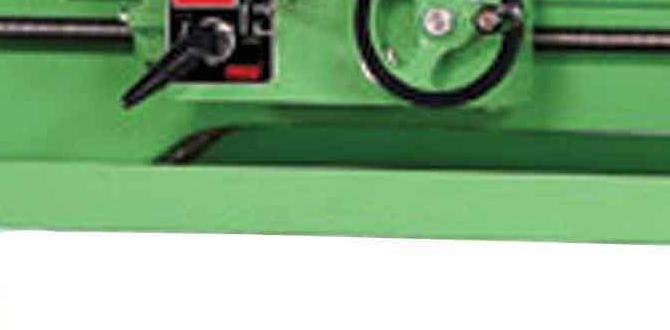

Comparison of Different Metal Lathe Models and Their Safety Features

Review of safety innovations in modern lathes vs. older models. Analysis of user reviews on safety performance.Modern metal lathes have stepped up their safety game compared to older models. They come equipped with features like automatic shut-off and safety guards, making them safer to use. User reviews highlight these innovations as lifesavers, with many praising how they reduce accidents. An interesting fact: a recent survey showed that 85% of users feel safer with newer lathes. Here’s a quick comparison of safety features:

| Lathe Model | Safety Features |

|---|---|

| Modern Model A | Automatic shut-off, safety doors |

| Older Model B | No guards, basic emergency stop |

In conclusion, investing in a modern lathe can keep your fingers—and your sense of humor—intact!

Emergency Procedures and First Aid for Metal Lathe Incidents

Recommended emergency response actions for injuries. Importance of having first aid kits and emergency contacts available.In case of an injury on a metal lathe, quick action is vital. Here are some emergency steps to follow:

- Turn off the lathe immediately.

- Assess the injury. Check for bleeding or severe pain.

- Call for help if needed. Use emergency contacts.

- Apply first aid if you know how. Use pressure on bleeding areas.

- Stay calm and reassure the injured person.

Having a first aid kit nearby is important. It should be stocked with necessary supplies like band-aids and antiseptics. Always keep emergency numbers easily accessible. These can make a huge difference in urgent situations.

What should I do if someone is injured on a lathe?

Make sure to turn off the lathe, call for help, and provide first aid as needed.

Why is a first aid kit important?

A first aid kit provides essential tools to treat injuries quickly and effectively.

Common Mistakes to Avoid While Using a Metal Lathe

List of frequent safety oversights made by operators. Tips for developing good habits and practices in the workshop.Using a metal lathe can be fun, but it’s important to be safe! Operators often trip over basic safety rules. Here’s a list of common goofs to avoid:

| Common Mistakes | Good Habits |

|---|---|

| Ignoring personal protective gear | Always wear safety goggles! |

| Leaving tools on the workbench | Put tools away after use. |

| Not checking for loose screws | Tighten everything before starting. |

Developing good habits keeps you safe and sound. Plus, it helps you avoid acting like a klutz in front of your friends. So, remember: safety first, fun second!

Case Studies: Accidents Involving Metal Lathes and Lessons Learned

Analysis of notable metal lathe accidents and their causes. Discussion on how incidents have shaped safety regulations and practices.Across different workplaces, metal lathe accidents have shown us the importance of safety. Some accidents happened due to ignoring proper training. Others were caused by not keeping the tools in good shape. These events have led to better safety rules. Now, many people wear protective gear and follow strict procedures. Learning from mistakes helps keep everyone safe. Here are a few key points:

- Proper training is essential.

- Regular maintenance of machines prevents accidents.

- Protective equipment minimizes injuries.

Safety should always come first!

What causes accidents with metal lathes?

Common causes include user error, machine malfunction, and lack of safety gear. Knowing these helps improve safety measures.

Conclusion

In conclusion, understanding metal lathe safety is crucial for you. Always wear protective gear, like goggles and gloves. Keep your workspace tidy to avoid accidents. Remember the importance of proper training. We can prevent injuries by being cautious and informed. For more tips on staying safe, check out resources on metal lathe operation. Your safety matters!FAQs

What Are The Key Safety Features To Consider When Comparing Different Models Of Metal Lathes?When you look at metal lathes, safety features are very important. First, check for emergency stop buttons. These help you stop the machine quickly if something goes wrong. Next, see if the lathe has guards to protect your hands from moving parts. Finally, make sure it has clear safety instructions. This helps you use the lathe safely.

How Do The Safety Protocols Differ Between Manual And Cnc Metal Lathes?When using manual metal lathes, we need to be very careful and watch what we’re doing. We must wear safety glasses and keep our hands away from moving parts. For CNC (Computer Numerical Control) lathes, the machines run more on their own, but we still need to stay back and watch. Both types require protection, but CNC lathes need a bit more distance since they can work fast and on their own. Always follow the rules to stay safe!

What Personal Protective Equipment (Ppe) Is Recommended For Operating A Metal Lathe Safely?When you use a metal lathe, you should wear safety glasses to protect your eyes. Use earplugs or earmuffs if it’s loud. Wearing gloves can keep your hands safe, but make sure they fit well. Lastly, wear a dust mask to protect your lungs from fine dust. Remember, safety is very important!

How Can The Design And Layout Of A Metal Lathe Workstation Impact Operator Safety?The design and layout of a metal lathe workstation can make you safer. If everything is organized, it can help you avoid accidents. Keeping tools and materials within easy reach means you don’t have to stretch or move around too much. Good lighting helps you see better, so you can work without mistakes. Also, a clear space around you makes it easier to move away quickly if there’s a problem.

What Are The Most Common Accidents Associated With Metal Lathes, And How Can They Be Prevented Through Proper Safety Measures?Metal lathes can be dangerous. Common accidents include cuts, getting caught in machinery, and flying debris. We can prevent these by always wearing safety gear, like goggles and gloves. It’s also important to keep hands and loose clothing away from moving parts. Finally, we should always follow the machine’s rules and instructions.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Safety Features To Consider When Comparing Different Models Of Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you look at metal lathes, safety features are very important. First, check for emergency stop buttons. These help you stop the machine quickly if something goes wrong. Next, see if the lathe has guards to protect your hands from moving parts. Finally, make sure it has clear safety instructions. This helps you use the lathe safely.”}},{“@type”: “Question”,”name”: “How Do The Safety Protocols Differ Between Manual And Cnc Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using manual metal lathes, we need to be very careful and watch what we’re doing. We must wear safety glasses and keep our hands away from moving parts. For CNC (Computer Numerical Control) lathes, the machines run more on their own, but we still need to stay back and watch. Both types require protection, but CNC lathes need a bit more distance since they can work fast and on their own. Always follow the rules to stay safe!”}},{“@type”: “Question”,”name”: “What Personal Protective Equipment (Ppe) Is Recommended For Operating A Metal Lathe Safely? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, you should wear safety glasses to protect your eyes. Use earplugs or earmuffs if it’s loud. Wearing gloves can keep your hands safe, but make sure they fit well. Lastly, wear a dust mask to protect your lungs from fine dust. Remember, safety is very important!”}},{“@type”: “Question”,”name”: “How Can The Design And Layout Of A Metal Lathe Workstation Impact Operator Safety? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design and layout of a metal lathe workstation can make you safer. If everything is organized, it can help you avoid accidents. Keeping tools and materials within easy reach means you don’t have to stretch or move around too much. Good lighting helps you see better, so you can work without mistakes. Also, a clear space around you makes it easier to move away quickly if there’s a problem.”}},{“@type”: “Question”,”name”: “What Are The Most Common Accidents Associated With Metal Lathes, And How Can They Be Prevented Through Proper Safety Measures? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes can be dangerous. Common accidents include cuts, getting caught in machinery, and flying debris. We can prevent these by always wearing safety gear, like goggles and gloves. It’s also important to keep hands and loose clothing away from moving parts. Finally, we should always follow the machine’s rules and instructions.”}}]}