Have you ever wondered how a metal lathe works? Imagine creating your own tools at home! A DIY metal lathe motor can help turn that dream into reality.

Building your own metal lathe is not just fun; it can save you money too. A lot of people think it’s too hard, but it’s easier than you think. With the right materials and some basic skills, you can make a fantastic machine.

Did you know that many professional machinists started with DIY projects? They learned skills that helped them in their careers. By making a metal lathe motor, you gain valuable experience while enjoying a great hobby.

So, are you ready to learn how to create your own DIY metal lathe motor? Let’s dive into the exciting world of metalworking!

Diy Metal Lathe Motor: Tips For Your Own Project Setup

Building a DIY metal lathe motor can be a fun and rewarding project. You’ll learn about motor types, power requirements, and how to properly assemble components. This guide helps you understand the tools needed and the steps involved, even if you are a beginner. Imagine creating custom parts for your hobbies! With some creativity and basic knowledge, you can turn everyday materials into a powerful lathe motor. Ready to get started?

Understanding DIY Metal Lathe Motors

Explanation of what metal lathe motors are. Importance of choosing the right motor for your projects.

In simple terms, a metal lathe motor helps machines shape metal. It spins tools that cut, shape, or drill metal pieces. Choosing the right motor is key for any metalworking project. A good motor makes your work smoother and more precise. If you pick the wrong one, your project may not go as planned.

- Power: The motor needs enough power for tough jobs.

- Speed: Different tasks need different speeds for best results.

- Size: The size of your motor should match your workspace.

Why is a good motor important?

A good motor ensures safety and efficiency. It can save time and reduce mistakes, helping you build better projects.

How to Choose the Right Motor for Your DIY Metal Lathe

Key factors to consider: torque, speed, and power requirements. Assessing the specific needs of your lathe project.

Choosing the right motor for your project is like picking the perfect ice cream flavor. You need to consider torque, speed, and power requirements. More torque means better cutting power, while speed lets you choose how fast to work. Make sure to match the motor to your lathe’s needs. Here’s a simple table to help you decide:

| Factor | Consideration |

|---|---|

| Torque | High torque is best for tough materials. |

| Speed | Adjustable speed for different tasks is a lifesaver. |

| Power | Check your lathe’s power supply limits! |

Getting these right ensures your lathe runs smoothly, and you won’t have to fix a disco-dancing machine instead of a metal lathe!

Installation Guide for DIY Metal Lathe Motors

Stepbystep instructions on installing a lathe motor. Common mistakes to avoid during installation.

Installing a lathe motor can be simple if you follow these steps: First, secure the motor to the lathe’s base. Next, connect the power supply carefully. Make sure the motor aligns with the drive belt. Check for tightness and correct positioning. Avoid common mistakes, such as incorrect wiring and loose connections. Double-check your work to ensure safety.

What are common mistakes to avoid during installation?

One mistake is not securing the motor tightly. Another is wrong wiring connections. Both can cause problems later.Always double-check your motor setup for safety and performance.

- Secure the motor properly.

- Ensure the wiring is correct.

- Check that connections are tight.

Upgrading Your Existing Metal Lathe Motor

Signs that indicate you need an upgrade. Benefits of upgrading to a more powerful motor.

Have you noticed your lathe struggling to keep up? Signs like slow speeds, odd noises, or overheating mean it’s time for an upgrade. A stronger motor can make turning metal easier and faster, giving your projects a big boost. Plus, think of all the extra fun! A new motor means less frustration and more creative time. So, don’t let your lathe be a couch potato. Get it pumping!

| Signs You Need an Upgrade | Benefits of Upgrading |

|---|---|

| Slow cutting speeds | Increased efficiency |

| Strange noises | More torque for tough materials |

| Overheating | Longer lifespan of your machine |

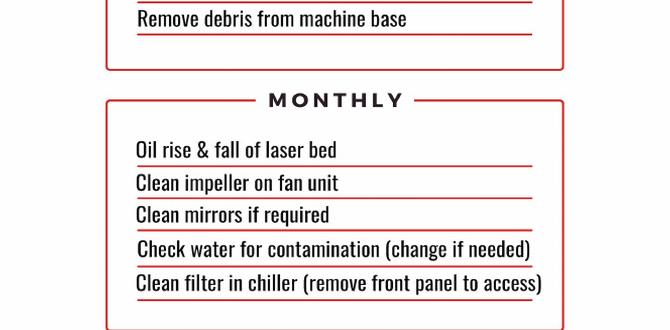

Maintenance Tips for DIY Metal Lathe Motors

Regular maintenance practices to extend motor life. Troubleshooting common motor issues.

Keeping your DIY metal lathe motor in top shape is like keeping your pet goldfish happy. Feed it, clean its bowl, and it’ll swim happily! Regular maintenance helps it last longer. Check for dust, tighten loose parts, and oil the bearings. Trust me, a well-oiled machine is a happy machine!

Got a hiccup? Don’t worry! Most common issues are simple. If it stops suddenly, check the power supply first. If it hums but won’t spin, you might need to replace the capacitor. It’s like giving your motor a little pep talk: “You can do this!” Follow these tips, and your lathe motor will keep on spinning!

| Maintenance Tips | Troubleshooting Issues |

|---|---|

| Clean regularly | Check power supply |

| Oil moving parts | Inspect for loose wires |

| Tighten bolts | Replace capacitor if needed |

Safety Considerations When Using Metal Lathe Motors

Essential safety equipment and precautions. Best practices for safe operation.

Using a metal lathe motor can be fun, but safety is key! Always wear essential gear like goggles, gloves, and ear protection. This keeps you safe from flying debris and loud noises. Next, keep your workspace clean. A cluttered area is like a messy kitchen—easy to trip on a stray tool! Follow proper techniques. This means using the right speed and feed rates for your materials.

| Essential Safety Gear | Best Practices |

|---|---|

| Goggles | Keep hands clear of moving parts. |

| Gloves | Check for loose clothing before starting. |

| Ear Protection | Always follow the manual guidelines. |

Oh, and don’t forget to unplug it when changing tools. Remember, safety first, fun second!

Resources and Tools for DIY Metal Lathe Motor Projects

Recommended tools and materials for motor projects. Useful online resources and forums for DIY enthusiasts.

Starting a DIY metal lathe motor project is exciting! You’ll need some essential tools and materials. Here are a few recommendations:

- Motor: Choose a reliable electric motor for power.

- Lathe Bed: Make or buy a sturdy lathe bed.

- Tools: Have wrenches, pliers, and a drill handy.

Many online resources can help you, like forums and websites full of tips. Check out:

- Instructables.com for step-by-step guides.

- Reddit’s DIY community for sharing ideas.

- YouTube channels that demonstrate DIY projects.

These resources make learning easier and more fun!

What tools are important for a DIY metal lathe motor?

Key tools include a sturdy motor, lathe bed, and basic hand tools like wrenches and drills. They help you build and use your lathe properly.

Conclusion

In conclusion, a DIY metal lathe motor can enhance your projects significantly. You can customize it to fit your needs and save money. Remember to research materials and safety tips before starting. If you want to learn more, check out online guides and videos. Let’s get started on your metalworking journey!

FAQs

What Type Of Motor Is Most Suitable For A Diy Metal Lathe Project: Ac Or Dc, And Why?

For a DIY metal lathe, a DC motor is often better. DC stands for direct current. It gives you more control over speed. You can easily adjust how fast the lathe turns. This helps you make precise cuts on your metal projects.

How Do You Calculate The Necessary Torque For A Metal Lathe Motor To Ensure Efficient Cutting?

To find the right torque for a metal lathe motor, you need to know a few things. First, measure the cutting force needed for your job. Then, check the speed the lathe will run at. We can use the formula: Torque = Force x Distance. This means you multiply the force by how far the cutting tool is from the center. That gives you the torque you need!

What Are The Steps Involved In Mounting A Motor To A Diy Metal Lathe Frame?

To mount a motor to your DIY metal lathe frame, first gather your tools. Next, find a good spot on the frame for the motor. Then, use screws to attach the motor firmly. After that, connect the motor to the power supply. Finally, test it to make sure everything works well.

How Can You Control The Speed And Torque Of A Diy Metal Lathe Motor For Different Machining Operations?

You can control the speed and torque of a DIY metal lathe motor by using a variable speed controller. This device lets you change how fast the motor spins. If you need more power for tough materials, you can lower the speed and increase the torque. For softer materials, you can speed it up to make the job quicker. Always adjust carefully to match the type of work you’re doing!

What Safety Precautions Should Be Taken When Working With Motors And Electrical Components In A Diy Lathe Setup?

When working with motors and electrical parts, always unplug the machine before touching it. Use safety glasses to protect your eyes. Keep your hands dry and don’t work in wet areas. Make sure to use the right tools for the job. Finally, never touch wires with bare hands; always use insulated tools.