Have you ever wondered how metal objects are made? They often start their journey on a machine called a lathe. A **DIY metal lathe** can be an exciting project. It opens up a world of possibilities for crafting and building. Imagine spinning metal and shaping it with your own hands!

Many people think crafting with metal requires special skills. But, with a little knowledge, anyone can learn. DIY metal lathe operations let you create unique pieces, from simple to intricate designs. Plus, you’ll feel proud seeing your hard work come to life.

Did you know that lathes have been around for thousands of years? They first appeared in ancient Egypt, and today, they are still vital in labs and workshops. With a DIY metal lathe, you don’t just get tools; you gain a new hobby that could lead to endless creativity!

Are you ready to dive into the exciting world of metalworking? Let’s explore the basics of DIY metal lathe operations together!

Mastering Diy Metal Lathe Operations: Tips And Techniques

Creating parts with a DIY metal lathe can be exciting. You can learn how to shape metal and make unique projects at home. Key skills include understanding lathe components, choosing the right tools, and mastering techniques for cutting. Have you ever wanted to craft custom pieces? With a little practice, you can turn metal into art or functional items. Plus, exploring lathe operations boosts problem-solving and creativity. Get ready to dive into this hands-on adventure!

Understanding Metal Lathes

Definition and purpose of a metal lathe. Key components and their functions.

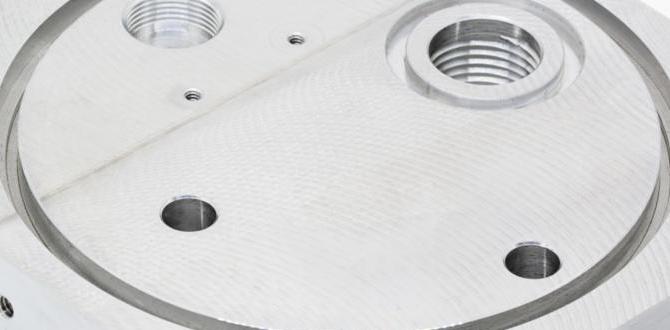

A metal lathe is a machine that shapes metal. It spins a piece of metal and cuts it into the right shape. This process helps make tools, parts, and other objects. Key parts of a lathe include:

- Bed: This is the base that holds everything.

- Headstock: It holds the spindle, which spins the metal piece.

- Tailstock: This part supports the other end of the metal.

- Carriage: It moves the cutting tool to shape the metal.

Using a lathe can help create many useful things. Knowing how each part works makes it easier to use.

What are the key functions of a metal lathe?

A metal lathe shapes and cuts metal into specific forms. It is essential for creating parts in machines or tools.

Essential Tools and Materials

List of necessary tools for metal lathe operations. Recommended materials for DIY metalworking projects.

Every successful metal lathe project needs the right tools and materials. Think of tools as your trusty sidekicks. You can’t fight crime without Batman and Robin! For metal lathe operations, you’ll need a few essentials. First, grab a good quality lathe, of course. Then, keep a collection of cutting tools handy. Don’t forget a nice set of calipers for measuring! Finally, stock up on materials like aluminum and steel for your DIY projects. The better the materials, the cooler the results!

| Tools | Materials |

|---|---|

| Metal Lathe | Aluminum |

| Cutting Tools | Steel |

| Calipers | Copper |

| Chucks | Brass |

With this setup, you’ll be creating fantastic metal masterpieces in no time! Remember, a happy tool is a productive tool. So, keep them sharp and in good mood!

Setting Up Your DIY Metal Lathe

Stepbystep instructions for setting up a metal lathe. Safety precautions to consider during setup.

Setting up a metal lathe needs careful steps. Follow these simple instructions for a smooth setup:

- Choose a strong table for your lathe.

- Make sure the lathe is level and secure.

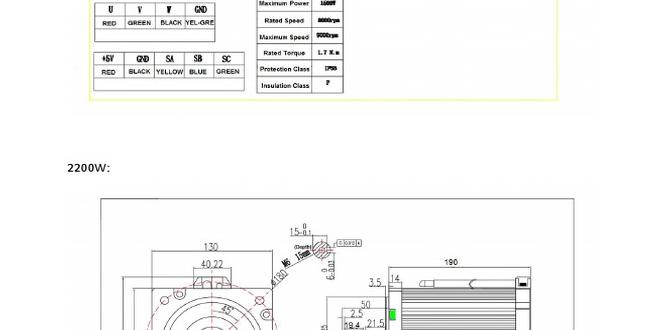

- Install the drive motor properly.

- Check alignment of the tailstock and headstock.

Also, remember safety first:

- Wear safety glasses to protect your eyes.

- Keep long hair tied back.

- Don’t wear loose clothes near the machine.

Taking these steps makes your workspace safe and ready for diy metal lathe operations.

What can go wrong during setup?

Improper setup can lead to damage. Always check level and alignment. Misalignment can cause accidents or broken tools.

Basic Operations and Techniques

Fundamental turning techniques (facing, boring, tapering). Tool selection and usage for different operations.

When using a DIY metal lathe, fundamental turning techniques are essential. You will often need to perform basic operations like:

- Facing: This makes a smooth, flat end on your workpiece.

- Boring: Here, you enlarge a hole precisely.

- Tapering: This creates a gradual slant on the piece.

Choosing the right tool for each job is crucial. For instance, use a sharp cutting tool for facing. A boring bar works best for boring. Remember, the correct tool enhances the quality of your work.

How do I choose the right tool for metal lathe operations?

You should match the tool to the task. For example, use a parting tool for making deep cuts. A tool for boring should be sturdy and straight.

Advanced DIY Metal Lathe Projects

Ideas for creative and functional projects (custom parts, tools, etc.). Tips for enhancing project complexity and creativity.

Looking for some fun projects to tackle with your metal lathe? Why not create custom parts, cool tools, or even quirky gadgets? These projects not only spark creativity, but they are also useful! Start with simple designs and gradually increase complexity to challenge yourself. How about making a unique pen holder or a toy car? The possibilities are endless!

| Project Type | Description | Complexity Level |

|---|---|---|

| Custom Handles | Create unique, ergonomic handles for tools. | Medium |

| Parts for Hobbies | Make specific parts for model building or RC cars. | High |

| Funny Gadgets | Invent silly items like a wobbly desk toy. | Low |

Remember, the best projects are the ones that make you smile. So, let your imagination run wild and get crafting!

Troubleshooting Common Problems

Common issues faced while using metal lathes. Solutions and preventive measures for these problems.

Metal lathes can have issues like tool chatter, uneven cuts, and tool wear. These problems can make your work difficult. Fortunately, there are easy fixes:

- Check the tool sharpness for clean cuts.

- Adjust the speed to reduce tool chatter.

- Ensure your workpiece is secure and aligned.

Regular maintenance helps prevent issues too. Clean your lathe often and lubricate the moving parts. This keeps everything running smoothly. If you face a problem, don’t worry. Solutions are simple and effective!

What are some common issues when using a metal lathe?

Common issues include tool wear, vibration, and inaccurate cuts. Check your setup to solve these quickly. Fixes are usually easy and keep your projects on track!

Maintaining Your Metal Lathe

Routine maintenance tasks to keep your lathe in good condition. Tips for extending the lifespan of your lathe equipment.

To keep your metal lathe running smoothly, it’s important to perform regular maintenance. This includes cleaning the machine and checking for any loose parts. Always lubricate moving areas to prevent rust and wear. Want your lathe to last longer? Use it wisely! Avoid overloading it, and give it breaks, just like you would after a big lunch! Here’s a quick table with essential tasks:

| Maintenance Task | Frequency |

|---|---|

| Cleaning | After every use |

| Lubrication | Weekly |

| Check belts | Monthly |

| Tighten screws | Every 3 months |

Following these steps can help you get the most out of your lathe, making it happy and healthy. A well-kept lathe is like a cat—purring and ready to work!

Resources for Further Learning

Recommended books, websites, and forums for DIY metal lathe enthusiasts. Online courses and tutorials for skill improvement.

If you’re diving into DIY metal lathe operations, many resources can help you grow. Books offer great tips and tricks for beginners and experts alike. Websites and forums let you connect with other enthusiasts. Online courses and tutorials boost your skills.

- Books: Check out titles like “Lathe Work” and “Metalworking for Beginners.”

- Websites: Great choices include “The Home Machinist” and “Machinery’s Handbook.”

- Forums: Join communities like “Reddit’s Machinists” for advice and sharing experiences.

- Online Courses: Websites like Udemy and Coursera offer useful lessons.

Exploring these resources can help you become a better metal lathe operator.

What are the best resources for DIY metal lathe enthusiasts?

Books, websites, forums, and online courses are top resources for DIY metal lathe fans. They offer knowledge, tips, and community support to help improve your skills.

Conclusion

In conclusion, DIY metal lathe operations let you create amazing projects at home. You can build parts, tools, and art. Remember to practice safety and understand your equipment. Start simple and gradually take on bigger tasks. Try reading more guides or watching videos to learn new techniques. Get hands-on, and have fun turning metal into something special!

FAQs

What Are The Essential Components Needed To Build A Diy Metal Lathe, And How Do They Function Together?

To build a DIY metal lathe, you need a few important parts. First, you need a sturdy base to hold everything steady. Next, you need a spindle that spins the metal piece you will work on. You also need a cutting tool that shapes the metal as it spins. Finally, some handles let you move the cutting tool closer or further away from the spinning metal. All these parts work together to shape metal into the shapes you want!

What Safety Precautions Should Be Taken When Operating A Diy Metal Lathe?

When using a DIY metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear snug clothing to avoid getting caught in the machine. Make sure to use gloves if needed, but not for moving parts. Always keep your hands away from the spinning metal. Finally, read the instruction manual before starting, so you know how to use it safely.

How Can One Achieve Accurate Measurements And Tolerances When Machining Parts On A Diy Metal Lathe?

To get accurate measurements when using a DIY metal lathe, you should start by using good measuring tools like calipers or rulers. Always measure your parts before and after cutting. Keep your lathe clean and well-maintained to work smoothly. Make sure you set the right speed and pressure while cutting. Lastly, take your time and double-check your work to avoid mistakes.

What Materials Are Recommended For Constructing Different Parts Of A Diy Metal Lathe, And Why?

To build a DIY metal lathe, you can use strong metals like steel or aluminum. Steel is tough and lasts a long time. Aluminum is lighter and easier to work with. For parts that move, use ball bearings because they help things spin smoothly. You can use wood for the base, as it holds everything steady.

What Are Some Common Troubleshooting Tips For Issues That May Arise During Diy Metal Lathe Operations?

If your metal lathe isn’t working right, here are some tips. First, check if the machine is plugged in and turned on. Next, make sure the tools are sharp and correctly attached. If your metal is getting stuck, try adjusting the speed. Lastly, keep everything clean to help the machine work better.