This guide shows you how to build a simple, effective DIY wood lathe dust collection box. It’s an essential upgrade for any workshop, significantly reducing airborne dust and improving your working environment. Learn the easy steps to create your own dust management system and make your turning safer and cleaner.

Working with a wood lathe is incredibly rewarding, letting you shape beautiful pieces from raw wood. But let’s be honest, it can also be messy! Sawdust and wood chips fly everywhere, settling on your tools, your clothes, and most importantly, filling the air you breathe. This fine dust isn’t just a nuisance; it can be a health hazard. Thankfully, managing this airborne mess doesn’t have to be complicated or expensive. This guide will walk you through building a proven, essential DIY wood lathe dust collection box. You’ll learn exactly what you need and how to put it together step-by-step, transforming your dusty workspace into a cleaner, safer, and more enjoyable turning haven.

There’s a real satisfaction in crafting something with your own hands, and that extends to improving your workshop. A good dust collection system is often seen as a big, complex investment, but it doesn’t have to be. We’re going to focus on a simple, highly effective DIY wood lathe dust collection box. This project is designed for beginners, using readily available materials and straightforward assembly. By the end, you’ll have a functional setup that makes a noticeable difference.

—

Why a Wood Lathe Dust Collection Box is Essential

The wood chips and fine dust generated by a lathe can quickly accumulate. If you’re turning green wood or working with denser hardwoods, the volume of material expelled can be significant. This dust isn’t just unsightly; it impacts your health and the longevity of your equipment.

Here’s why a DIY wood lathe dust collection box is more than just a nice-to-have:

- Health Benefits: Inhaling fine wood dust over time can lead to respiratory problems. A dust collection system captures a large percentage of this airborne particulate, protecting your lungs. The U.S. Occupational Safety and Health Administration (OSHA) has standards for air contaminants, and wood dust is a common concern in woodworking environments.

- Workshop Cleanliness: Less dust means less time spent cleaning up. It keeps your tools cleaner, preventing buildup that can affect their performance and lifespan.

- Improved Air Quality: Beyond direct health risks, fine dust can irritate eyes and skin. Cleaner air makes your workshop a more pleasant place to be for extended periods.

- Reduced Fire Hazard: Accumulations of fine, dry sawdust can be a fire hazard in a workshop. Effective dust collection helps mitigate this risk.

- Environmental Control: Capturing dust at the source prevents it from spreading throughout your workshop and potentially outside.

While professional dust collection systems exist, a well-made DIY box is a fantastic and cost-effective alternative, especially for hobbyists. It provides targeted collection right where the dust is created.

—

Understanding the Basics of Lathe Dust Collection

A wood lathe dust collection box works on a simple principle: capturing dust and chips at their point of origin. Most lathe dust collection setups involve some form of enclosure and a way to draw the debris away. For a DIY box, we’ll be creating a physical barrier around the headstock and tool rest area, combined with a connection point for a shop vacuum or a dedicated dust collector.

The goal is to funnel the expelled material into a manageable collection point, rather than letting it disperse into the air. This requires strategic placement and a good seal where possible.

Key components to consider for any dust collection system, including a DIY box, are:

- Enclosure: A physical barrier to contain the dust.

- Airflow: A method (like a shop vacuum) to move air and dust out of the enclosure.

- Collection Point: Where the dust and chips are deposited (e.g., a vacuum bag, bin, or filter).

- Sealing: Minimizing air leaks to maximize collection efficiency.

Our DIY project will focus on creating an effective and affordable enclosure that can be integrated with your existing shop vacuum.

—

Project Overview: Your DIY Wood Lathe Dust Collection Box

This project involves building a custom-fit enclosure for your lathe’s working area. We’ll use common materials like plywood, some fasteners, and a piece of flexible ducting or hose. The beauty of this DIY approach is that you can tailor the box to your specific lathe model, ensuring a snug fit.

We will construct a box that attaches around the headstock and tool rest area. It will have an opening at the back to connect your shop vacuum hose. This creates a “hood” that catches the majority of flying debris.

Materials You’ll Need:

Gathering your materials beforehand makes the building process smooth. Here’s what you should look for:

- Plywood: 1/2 inch or 3/4 inch thickness is ideal. Scraps are often perfect for this project.

- Fasteners: Wood screws (e.g., 1 1/4 inch) for joining the plywood.

- Hinges (Optional): Small hinges if you want an access door.

- Clamps: Several workshop clamps to hold pieces while assembling and screwing.

- Dust Collection Port: A PVC pipe fitting (like a 4-inch diameter reducer) or a dedicated dust collection port fitting.

- Shop Vacuum Hose: The hose from your shop vacuum.

- Flexible Ducting/Hose (Optional but Recommended): A short length of flexible hose to connect the port to the vacuum.

- Sandpaper: Medium grit (e.g., 120-grit) for smoothing edges.

- Wood Glue: For added strength at the joints.

- Measuring Tape and Pencil

- Safety Glasses and Hearing Protection

Tools You’ll Need:

The tools required are fairly standard for a home workshop.

- Circular Saw or Table Saw: For cutting plywood sheets.

- Jigsaw: For cutting curves and opening for the dust port.

- Drill/Driver: For pre-drilling holes and driving screws.

- Drill Bits: Including a bit for pilot holes and a spade bit or hole saw for the dust port opening.

- Screwdriver Bits

- Optional: Router with a round-over bit for softer edges.

Before we start cutting, let’s look at measuring and planning. This is the most crucial part for ensuring your box fits your lathe perfectly.

—

Step-by-Step Guide: Building Your DIY Wood Lathe Dust Collection Box

This project is broken down into manageable steps. The key is careful measuring and precise cutting. Remember to always prioritize safety.

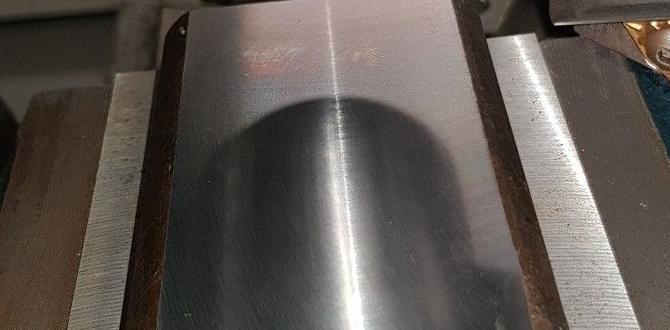

Step 1: Measure Your Lathe

This is where we measure your lathe’s critical dimensions. You need to determine how large your dust collection box needs to be to effectively cover the working area.

- Height: Measure the vertical distance from the lathe bed, where the tool rest sits, up to the anticipated highest point of your work. You want the box to extend above the center line of your workpiece. A good starting point is usually around 8-12 inches.

- Depth: Measure the distance from the front of the headstock (where the chuck mounts) to the back of the lathe bed, behind the tool rest. You want enough depth to capture chips that are thrown backward.

- Width: Measure the overall width of the area you want to enclose. This typically includes the headstock, the tool rest assembly, and a little extra clearance.

- Tool Rest Clearance: Ensure there’s enough space for your tool rest to move up and down and side-to-side without hitting the box walls.

- Spindle Access: You’ll need to be able to access the spindle for chuck mounting and removal. Consider adding a hinged door or planning your box dimensions to allow for easy hand access near the headstock.

Tip: Use a piece of cardboard or a large sheet of paper to sketch out your measurements. You can even cut a template from cardboard the size of your box walls before committing to plywood. This helps visualize fit and clearance.

Step 2: Design and Cut Your Plywood Panels

Based on your measurements, you’ll cut the pieces for your dust collection box. A simple box design will have a back panel, two side panels, and a top panel. The front will remain largely open, with a cut-out to accommodate the lathe’s spindle and a place for the tool rest to poke through.

- Back Panel: Cut one piece of plywood to your measured width and height.

- Side Panels: Cut two pieces of plywood to your measured depth and height.

- Top Panel: Cut one piece of plywood to your measured width and depth.

Example Dimensions (Adjust to your lathe):

Let’s say your measurements result in a box that needs to be 18 inches wide, 10 inches tall, and 12 inches deep.

- Back Panel: 18″ W x 10″ H

- Side Panels (x2): 12″ D x 10″ H

- Top Panel: 18″ W x 12″ D

Cutting Layout: Plan your cuts on your plywood sheets to maximize material usage and minimize waste. It’s often efficient to cut the back and top panels side-by-side if your width and depth allow.

Step 3: Cut Out Access and Dust Port Openings

Now we create the openings necessary for operation and dust extraction.

- Headstock/Spindle Opening: On the back panel and/or side panels, plan where your headstock and spindle are. You’ll need to cut a large opening here to allow for chuck mounting and access. This can be a simple vertical slot or a more complex shape depending on your lathe. Ensure you can comfortably get your hands and chuck key in there.

- Tool Rest Slot: On the front edge of the side panels, you might need to cut horizontal slots where the tool rest will be positioned. This allows the tool rest to be adjusted for different turning diameters. Alternatively, if the box is tall enough, you might just need a wider opening at the bottom front.

- Dust Port Hole: On one of the side panels or the back panel (where it’s most convenient to connect your vacuum hose), drill a hole sized for your chosen dust collection port fitting. Use a spade bit or hole saw for a clean circular cut. For a 4-inch dust port:

- Measure the outer diameter of your chosen PVC fitting or dust port.

- Select a drill bit or hole saw that is slightly smaller than this diameter so the fitting will create a snug friction fit, or exactly the size if you plan to glue or screw it in.

- Optional Door: If you prefer a hinged access door rather than cutting large openings, you can create one side or the front panel as a separate piece, attach it with hinges, and add a simple latch.

Tip: When cutting large openings, it’s often easier to drill a starting hole with a regular drill bit, then use a jigsaw to complete the cut. This prevents the jigsaw blade from wandering at the start.

Step 4: Assemble the Box

With all your pieces cut, it’s time to put the box together.

- Dry Fit: Before applying glue or screws, hold the pieces together to ensure everything aligns correctly. Make any necessary adjustments now.

- Apply Glue: Apply a thin bead of wood glue to the edges where the panels will meet. This adds significant strength and helps seal the joints.

- Attach Side Panels to Back Panel: Position the side panels against the edges of the back panel. Clamp them securely. Pre-drill pilot holes through the side panels into the edge of the back panel to prevent the wood from splitting. Drive your wood screws.

- Attach Top Panel: Place the top panel onto the assembled back and side panels. Clamp it in place. Pre-drill pilot holes through the top panel into the edges of the back and side panels. Drive your wood screws.

- Install Dust Port: Insert your PVC fitting or dust port into the hole you drilled. If it’s a tight friction fit, it might stay in place on its own. For added security, you can apply a ring of wood glue around the outside of the fitting before inserting it or use small screws to secure it to the plywood.

Tip: If you have a router, you can use a round-over bit on all exterior edges to create a smoother, more professional finish and reduce sharp corners.

Step 5: Finishing Touches

Before mounting the box, sand any rough edges and consider how you’ll attach it to your lathe.

- Sand Edges: Use medium-grit sandpaper to smooth any sharp edges or minor imperfections on the inside and outside of the box.

- Test Fit: Place the box onto your lathe to check the fit around the headstock, tool rest, and bed. Ensure it doesn’t obstruct any necessary functions.

- Attachment Method: How will you secure the box?

- Clamps: You can use large C-clamps or bar clamps to temporarily or semi-permanently attach the box to the lathe bed.

- Brackets: Custom metal or wood brackets can be fabricated to bolt to the lathe somehow and then to the box.

- Friction Fit/Balancing: For some lathes, a well-designed box might simply rest securely without formal attachment. This is the least secure method.

Important: For safety, ensure the box is securely attached or positioned so it cannot tip or fall off during operation. A falling object in a workshop is a serious hazard.

—

Integrating with Your Shop Vacuum

The effectiveness of your DIY wood lathe dust collection box hinges on how well it connects to an air-moving device. A shop vacuum is usually the most accessible option for DIY projects.

Connecting the Hose:

- Attach one end of your flexible ducting or hose to the dust port fitting on your box.

- Connect the other end of the ducting or hose to your shop vacuum hose. Use a hose clamp if the connection feels loose to ensure a good seal. A good seal is vital for efficient dust collection.

- Ensure your shop vacuum is turned on and running before you start turning.

Vacuum Performance:

The suction power of your shop vacuum will directly impact how much dust is captured. For best results:

- Check Vacuum Filter: A clogged filter will significantly reduce airflow. Clean or replace your vacuum filter regularly.

- Empty the Vacuum Canister: Don’t let the collected debris fill the vacuum’s bin more than halfway. This also impacts airflow.

- Consider a Dust Deputy or Cyclone Separator: If you use your lathe frequently, investing in a small cyclone separator (like a Dust Deputy) that attaches between the box and your vacuum can dramatically improve collection efficiency and prolong the life of your vacuum’s filter. It separates the bulk of the debris into a separate container. You can find these at most woodworking stores.

External Resource: For more detailed information on shop vacuum types and dust collection principles, consult resources from the U.S. Environmental Protection Agency (EPA) on indoor air quality and dust control in workshops.

—

Alternative Designs and Enhancements

While the basic box design is highly effective, you can customize it further.

Considerations for Specific Lathes

Different lathes have different layouts. Some are more compact, while others have larger headstocks.

- Dormer Lathes: Often have a more integrated headstock that might require a box that wraps more closely around it.

- South Bend Lathes: These are classic machines where a well-fitted box can significantly improve the environment.

- Wood Lathes: Generally have more open frames, allowing for easier box placement but also more potential for dust escape if the box isn’t well-sealed.

Enhancements:

- Hinged Lid/Door: For easier access to the chuck and spindle, a hinged front or side panel can be a great addition. Use small, sturdy hinges and a simple latch.

- Clear Panels: Incorporating a piece of clear acrylic or polycarbonate on the front or side can allow you to see your work while maintaining containment. This requires careful cutting and sealing.

- Internal Baffles: Sometimes, adding small internal baffles can help direct airflow more efficiently towards the vacuum port. This is more advanced and might not be necessary for a beginner’s setup.

- Wheels or Casters: If you need to move the box around, consider adding small casters.

Table: Pros and Cons of Different DIY Box Designs

| Design Type | Pros | Cons | Best For |

|---|---|---|---|

| Simple Box (No Door) | Easiest and quickest

|