Milling machines are vital tools in the world of manufacturing and engineering. These versatile machines shape and cut solid materials, such as metal, wood, and plastic, into various shapes and sizes. Invented in the 19th century, milling machines have become integral to modern manufacturing, revolutionizing how products are made.

From large-scale industrial production to small workshops, these machines are crucial in creating precise and intricate components used in various applications. But how exactly does a milling machine work? We will delve into how a milling machine works, exploring its overview. So, let’s dive into the world of milling machines and discover the wonders of this remarkable technology.

Basic Components Of A Milling Machine

A milling machine is a powerful tool used in manufacturing processes to shape and cut materials. It consists of various components, including horizontal and vertical milling machines. Horizontal milling machines are ideal for removing material from the workpiece in a side-to-side motion, while vertical milling machines are great for drilling and cutting vertically. These milling machines offer versatility and precision, making them essential in various industries.

- Base: Provides support and stability

- Column: Vertical structure supporting the milling head

- Knee: Adjustable component for vertical movement

- Saddle: Horizontal component supporting the table

- Table: Work surface for securing and moving material

Overview Of Milling Machine

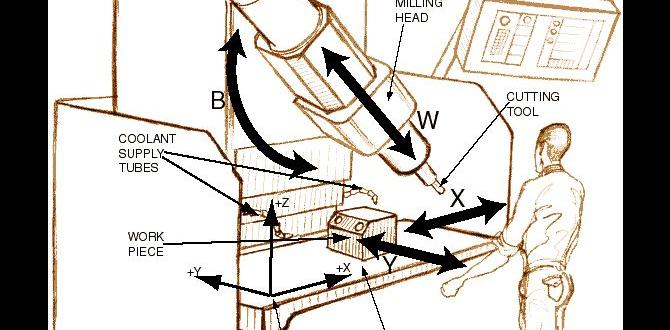

A milling machine is a versatile tool used in machining processes to shape and cut materials. Thanks to various cutting tools, one of its main features is the ability to work with complex shapes. The milling cutter is a rotating tool that removes material from the workpiece. The universal milling machine is particularly noteworthy, as it offers a wide range of operations and can handle horizontal and vertical milling tasks, enhancing its flexibility and efficiency in different applications.

How Does A Milling Machine Work: Explanation

A milling machine is a versatile tool used in machining processes to remove material from a workpiece. It operates by rotating a cutting tool, known as a milling cutter, while the workpiece is held in place on a table. As the cutter moves across the workpiece, it removes material, creating the desired shape or surface.

The machine can perform various operations, such as drilling, slotting, and threading, making it essential in manufacturing industries. It offers precision, efficiency, and the ability to produce complex parts accurately.

How Do You Work With A Milling Machine?

Working with a milling machine involves a series of steps. First, ensure you have the necessary safety equipment, such as goggles and gloves. Next, set up the machine by securing the material to be milled and adjusting the cutting tools.

Then, carefully operate the machine by following the instructions, making precise cuts, and monitoring the progress. Finally, clean up the workspace and maintain the machine for optimal performance. bellow we discuss more how you work with a milling machine

A. Setting Up The Machine

To set up a milling machine, ensure all necessary tools and materials are available. Next, carefully position the machine and secure it in place. Connect the power source and carefully adjust the settings according to the desired specifications. Once everything is properly set up, you can begin working with the milling machine by carefully feeding the material and operating the controls to achieve precise cuts and shapes.

B. Fixturing The Workpiece

Fixturing the workpiece is an essential step in working with a milling machine. Various methods can be handy to ensure precision and stability. One common approach is using clamps or vises to secure the workpiece firmly. Another option is utilizing fixtures specifically designed for milling machines, such as angle plates or rotary tables. Properly fixturing the workpiece allows for accurate machining and reduces the risk of errors or accidents during milling.

C. Selecting The Appropriate Cutter

When selecting a cutter for a milling machine, several factors must be considered. Firstly, you must determine the material you will be working with, as different cutters have specific designs for specific materials. Next, consider the cut you want to achieve – roughing, finishing, or specialized profiles. The speed and feed rate should also be considered to ensure optimal performance. By carefully evaluating these factors, you can choose the right cutter for your milling machine and achieve the desired results.

D. Adjusting The Cutting Parameters

Familiarize yourself with the machine’s manual and understand the different controls. Next, determine the type of material you will be working with and select the appropriate cutting tools. Adjust the spindle speed and feed rate to optimize efficiency and achieve desired results. Finally, ensure proper coolant flow and monitor the process closely for any necessary adjustments.

E. Executing The Milling Operation

Ensure the machine is properly set up and secured. Position the workpiece correctly and adjust the cutting tools accordingly. Next, carefully feed the workpiece into the rotating cutter, making precise and controlled movements. Monitor the machine’s speed and feed rate to achieve the desired results. Regularly check the progress and make any necessary adjustments. Finally, once the milling operation is complete, remove the workpiece and clean the machine for future use.

F. Inspecting The Final Product

Inspecting the final product is an essential step in ensuring its quality. When working with a milling machine, there are several aspects to consider. Firstly, carefully examine the surface finish, checking for any irregularities or defects. Next, verify the dimensional accuracy using precision measuring tools.

Additionally, assess the overall functionality and performance of the machine, ensuring it operates smoothly and efficiently. By meticulously inspecting the final product, you can guarantee its adherence to the required standards and specifications.

Safety Considerations

When operating a milling machine, safety considerations are crucial. First and foremost, ensure proper use of personal protective equipment (PPE) such as safety glasses, gloves, and ear protection. Additionally, machine guarding must be in place to prevent accidental contact with moving parts.

Familiarize yourself with safe operating procedures, including correctly using cutting tools, such as rotary cutting tools, and understanding the cutting process. Lastly, be aware of emergency shutdown procedures and how to stop the machine quickly in case of unforeseen issues.

Pros And Cons Of Milling Machine

Manual milling machines, also known as conventional milling machines, offer a range of pros and cons. One advantage is their versatility, allowing for different milling operations, such as peripheral milling. They also provide the option to use various types of milling cutters, which can be beneficial for achieving different cutting requirements. However, manual operation may require more skill and time than automated milling machines. It is important to weigh these factors when considering manual milling machines.

Pros:

- High precision and accuracy in cutting and shaping materials

- Versatile with a wide range of materials

- Performs complex operations like drilling, boring, and slotting

- Boosts productivity and efficiency in manufacturing processes

cons

- Expensive initial investment and maintenance costs

Conclusion:

The milling machine is a versatile and essential tool in the manufacturing industry. Its ability to cut and shape various materials precisely makes it a valuable asset for any production process. However, these machines have undergone significant advancements with new technologies and innovations, making them even more efficient and precise.

By understanding the mechanics and functions of this machine, we can appreciate the complexity and precision involved in creating the everyday objects we use. With technological advancements, the milling machine continues to evolve and improve, further solidifying its role as a crucial component in modern manufacturing.

FAQ:

1.Why Is Milling Important?

Milling is important because it is a crucial process in various industries, such as manufacturing, construction, and agriculture. It involves the removal of material from a workpiece using rotating cutting tools, resulting in the desired shape, size, and surface finish.

2.What Is High-Efficiency Milling?

High-efficiency milling (HEM) is a machining technique that involves removing material at high speeds and feed rates while using a smaller and higher axial depth of cut.

3.What Is RPM In Milling?

RPM stands for revolutions per minute and refers to the rotational speed of the milling tool or spindle in a milling machine. It is a crucial parameter in milling as it determines the cutting speed and feed rate.

4.What Format Is A CNC Mill?

CNC mills typically use a G-code format, a programming language that controls the movements and operations of the machine.

5.What Is The Basic Milling Process?

The basic milling process involves the removal of material from a workpiece using rotary cutters to create a desired shape or dimension. The workpiece is secured to a milling machine table and the cutting tools.