Imagine standing in a workshop filled with machines buzzing and humming. It feels like magic, right? Among these machines, the metal lathe is quite special. This tool shapes metal into awesome parts, like gears and rods. But how does it work so smoothly? The secret often lies in the essential tools metal lathe control panel.

This control panel is like the brain of the lathe. It helps the operator control speed and movement with ease. Ever wonder how a small twist can make such a big difference in cutting metal? That’s the power of the control panel at work.

In this article, we will dive deeper into the essential tools of the metal lathe control panel. We’ll uncover what each tool does and why they are important. Get ready to discover the hidden magic of metalworking!

Essential Tools For Metal Lathe Control Panel Setup

Essential Tools for Metal Lathe Control Panel

Have you ever wondered what makes a metal lathe work so smoothly? The control panel is key! Essential tools include knobs and buttons that let you adjust speed and direction. This helps create precise shapes from metal. A fun fact: many metalworkers upgrade their panels for even better control. With the right tools, new users can produce quality work quickly. Understanding these parts makes metalworking more enjoyable and satisfying for everyone.Understanding Metal Lathe Control Panels

Definition and purpose of metal lathe control panels. Importance in machining processes.Metal lathe control panels are important tools for managing a lathe machine. They help operators control the machine’s speed and movements. This control ensures that parts are shaped accurately and safely. Without these panels, machining would be unsafe and less precise. They play a key role in various tasks:

- Directs machine operations

- Increases safety

- Improves accuracy

These panels make machining easier and help create high-quality products efficiently.

What is the purpose of a metal lathe control panel?

The purpose of a metal lathe control panel is to provide operators with the ability to control the lathe’s functions easily. This includes adjusting speed, direction, and tool changes, ensuring safe and efficient machining processes.

Essential Tools for Operating Metal Lathe Control Panels

List and description of necessary tools (calipers, micrometers, etc.). Importance of maintenance tools (lubricants, cleaning supplies).To operate a metal lathe control panel, you’ll need some handy tools. First up are calipers, perfect for measuring thickness. Then there’s micrometers, which are great for super precise measurements. Don’t forget about maintenance! Keeping your lathe happy means using lubricants and cleaning supplies. A clean lathe is a happy lathe! Here’s a quick table of essential tools:

| Tool | Purpose |

|---|---|

| Calipers | Measure thickness |

| Micrometers | Precise measurements |

| Lubricants | Keep parts moving smoothly |

| Cleaning Supplies | Maintain cleanliness |

So, gear up with these essentials, and your lathe will treat you right! Remember, a clean, well-oiled machine is less likely to complain about those late-night work sessions. Happy turning!

Common Issues and Troubleshooting Tips

Frequent problems encountered with control panels. Stepbystep troubleshooting process.Control panels can have some quirky issues. One common problem is a flickering display—like a disco party gone wrong! This might be due to loose connections or a power supply hiccup. Another issue is unresponsive buttons. If a button feels like it’s on a permanent vacation, it might need a good cleaning or a reset. To troubleshoot, follow this simple guide:

| Issue | Solution |

|---|---|

| Flickering Display | Check connections and power supply. |

| Unresponsive Buttons | Clean panel and reset device. |

| Error Messages | Refer to the user manual for fixes. |

By dealing with these common snags, you’re one step closer to becoming a metal lathe magician!

Upgrading Your Metal Lathe Control Panel

Reasons to upgrade existing systems. Latest advancements in control panel technology.There are many good reasons to upgrade your metal lathe control panel. First, new systems boost accuracy and efficiency. This means you can make those precise cuts while saving time—two birds, one stone! Technology has also made giant leaps. Modern panels now sport cool features like touch screens and smart controls. Imagine running your lathe with a fancy tablet! It’s like trading in your flip phone for a smartphone.

| Feature | Old Panels | New Panels |

|---|---|---|

| Interface | Buttons and knobs | Touch screens |

| Precision | Basic controls | Highly accurate |

| Smart Features | No | Yes, like machine learning! |

Upgrading can make your work feel like magic. Isn’t it time to enjoy the ride?

Expert Recommendations and Resources

Suggestions from experienced machinists. Links to additional learning materials and resources.Experienced machinists offer valuable tips to use your metal lathe control panel better. Here are some recommendations:

- Practice regularly to improve your skills.

- Always read your machine’s manual.

- Keep tools organized for easy access.

- Watch tutorials for visual guidance.

For further learning, check these resources:

What top tips can I follow for using a metal lathe?

Always double-check measurements and enjoy learning from mistakes. Listen to tips from experts to grow your skills.

Conclusion

In summary, a metal lathe control panel is key for precise machining. It includes essential tools like dials and switches that help you operate the lathe. By learning how each tool works, you can improve your projects. Explore the manuals or online resources to get hands-on experience. Start using these tools today and sharpen your skills!FAQs

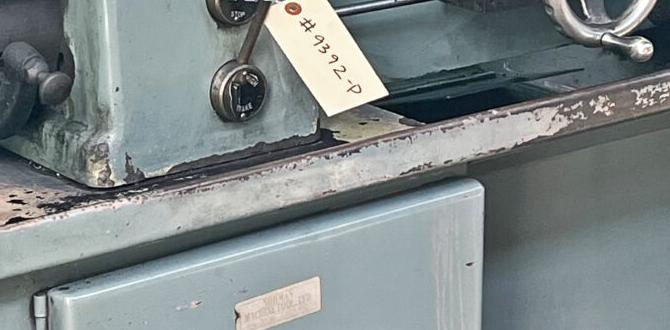

What Are The Key Components Of A Metal Lathe Control Panel And Their Functions?A metal lathe control panel has important parts that help you use the machine. First, there is a power switch to turn it on and off. Then, you will find speed controls to change how fast the lathe spins. There are also buttons for moving the tool in and out. Lastly, there are emergency stop buttons to stop everything quickly if needed.

How Does The User Interface Of A Metal Lathe Control Panel Influence Machining Precision And Efficiency?The user interface on a metal lathe control panel helps us control the machine easily. If buttons are clear and labeled well, we can make quick adjustments. This means we can cut metal more accurately and save time. A good design helps us avoid mistakes, making our work better and faster. Overall, it helps us do our jobs right!

What Safety Features Should Be Integrated Into A Metal Lathe Control Panel To Protect Operators?To keep you safe while using a metal lathe, the control panel should have some important features. First, a big emergency stop button lets you quickly turn off the machine if something goes wrong. Second, we can use clear labels and signs to show how to use the lathe safely. Finally, adding safety guards around moving parts can help prevent accidents while you work.

How Can Programmable Controls On A Metal Lathe Enhance Production Capabilities Compared To Manual Controls?Programmable controls on a metal lathe let you set exact steps for the machine to follow. This means it can work faster and make more pieces without mistakes. You can easily change the settings for different projects. With manual controls, you might make more errors and it takes longer. Programmable controls help you work better and finish projects quickly.

What Are The Best Practices For Maintaining And Troubleshooting Metal Lathe Control Panels?To keep metal lathe control panels working well, check them often for dirt or loose wires. You should clean the buttons and screens gently with a soft cloth. If the panel doesn’t work, make sure it’s plugged in and turned on. If it still has problems, ask an adult for help or read the manual for fixes. Always be careful and follow safety rules when using machines.