When considering machining and milling operations, deciding between a face mill and an end mill can have significant implications. Both tools are commonly used in the metalworking industry for cutting various materials, but they have distinct differences that set them apart.

While the end mill is a versatile tool that can be used for a wide range of applications, the face mill specializes in high-speed, large surface-area cutting. The decision between these two milling tools ultimately depends on the specific needs and requirements of the project. We will delve into the differences between the face mill. So, let’s take a closer look at the face mill vs end mill debate and help you make an informed decision for your milling needs.

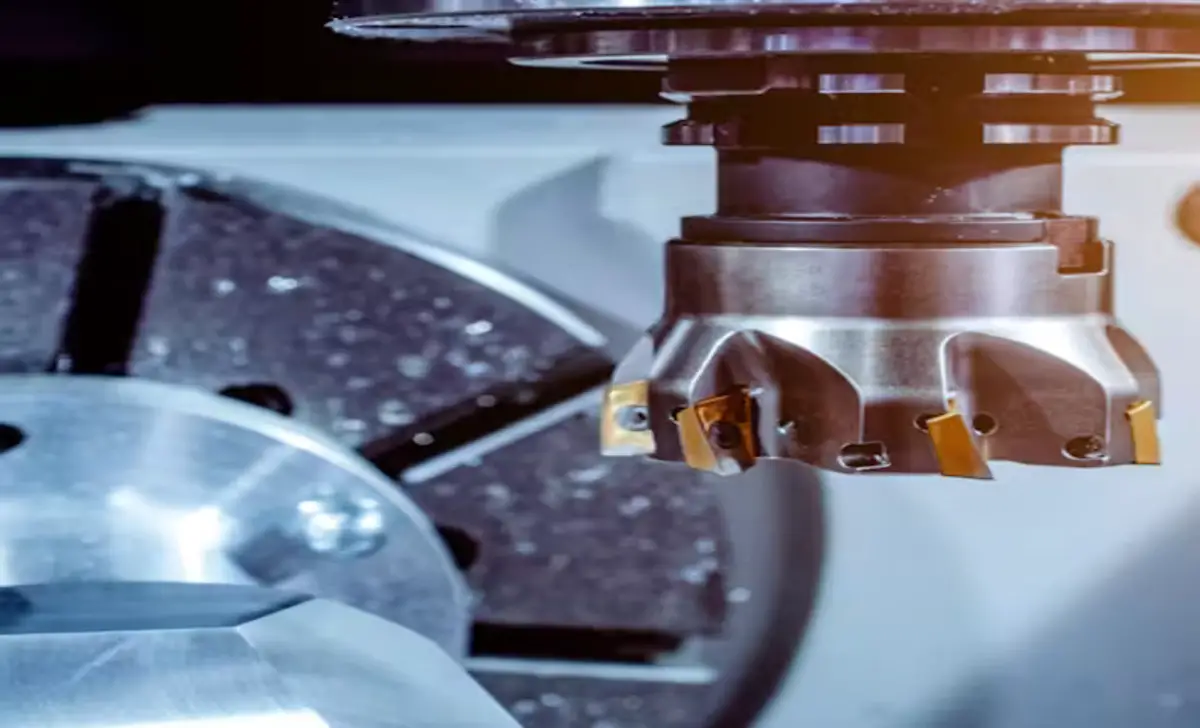

What Is A Face Mill?

a face mill is a milling cutter to create flat surfaces on a workpiece. It consists of multiple cutting edges known as fly cutters, which rotate at high speeds to remove material from the surface. Face milling is commonly used in machining operations to achieve precise feed rates and produce smooth, flat surfaces.

The purpose of a face mill is to efficiently remove material and create a uniform finish on a workpiece, making it an essential tool in various industries such as manufacturing and metalworking.

Pros

- Versatility in machining operations (facing, profiling, contouring)

- Efficient material removal, reducing machining time

- Smooth surface finish on workpiece

- Cost-effective tool for multiple applications

Cons

- Limited depth of cut compared to other milling tools

- Higher power consumption due to aggressive cutting action

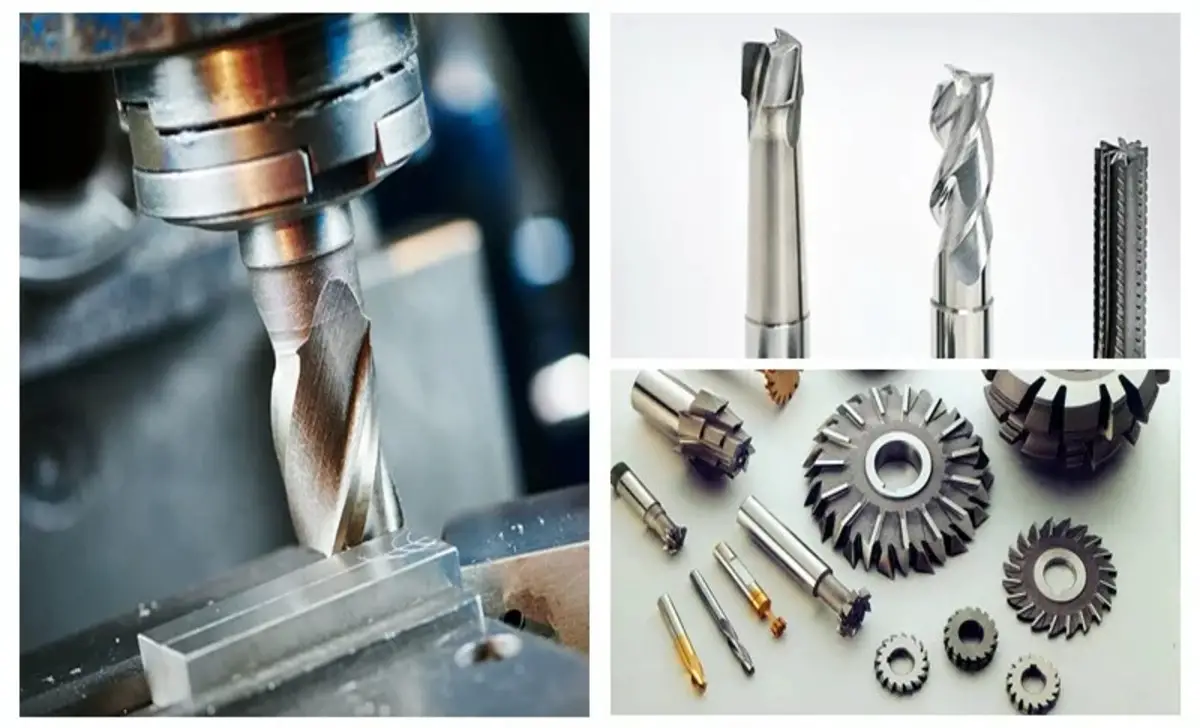

What Is An End Mill?

An end mill is a cutting tool used in machining, specifically in peripheral milling operations. It has specific designs to remove material from a workpiece, particularly softer materials, by rotating and cutting with multiple flutes. The end mill’s outer edge, which contains the cutting edges, is crucial in achieving precise and accurate cuts. Its purpose is to shape, contour, and create various features on the workpiece, making it an essential tool in the manufacturing industry.

Pros

- Versatility: End mills can be handy

- Precision: They offer high precision and accuracy in cutting

- Efficiency: End mills have specific designs

- Durability: Made from durable materials, end mills are built

Cons

- Cost: End mills can be relatively expensive

- Limited Reach: Depending on the tool design

Comparison Between Face Mill And End Mill

In milling operations, the face and end mill are commonly handy tools. While both tools are handy for material removal, their distinct differences make them suitable for specific applications. While the face and end mill are milling tools, they serve different purposes.

The face mill is ideal for milling flat surfaces at high material removal rates, while the end mill is more versatile and can be handy for a wider range of milling operations. Understanding the differences between these tools is crucial in selecting the appropriate tool for specific machining requirements. Below, we will discuss the differences between a face mill and an end mill.

1.Cutting Capabilities

There is a noticeable difference in cutting capabilities between the Face Mill and the End Mill. The Face Mill, equipped with cutting-edge technology, offers efficient milling with larger diameters, making it ideal for removing large amounts of material. On the other hand, the End Mill specializes in precision milling with smaller diameters, using plain milling cutters to achieve intricate and detailed results. Both tools have their unique advantages, providing versatility for various machining tasks.

2.Surface Finish Quality

When achieving a high-quality surface finish, considering the type of milling cutter used is essential. One popular option is the face mill, known for its ability to perform slab milling. This technique removes material from a large surface area, resulting in a smoother finish. On the other hand, machinists often prefer the end mill for more precise milling tasks. By understanding the different types of milling cutters available, manufacturers can select the most suitable tool for their specific surface finish requirements.

3.Material Suitability

When considering the material suitability for manual face milling and the use of milling bits, it is important to compare face mills and end mills. Face mills are suitable for larger surfaces and are ideal for achieving flat finishes. They excel in removing material quickly and efficiently.

On the other hand, end mills are more versatile and can handle various contours and profiles. They are commonly handy for precision work and intricate machining tasks. Ultimately, the choice between face mills and end mills depends on the specific requirements of the project and the desired outcome.

4.Speed And Feed Requirements

It is important to compare face and end mills’ performance when considering speed and feed requirements. Face mills are typically handy for large cutting diameters and can remove material quickly due to their multiple inserts.

On the other hand, end mills are more versatile and can be handy for various cutting operations, including slotting and contouring. The choice between the two depends on the desired surface finish, machining material, and specific application requirements. Overall, understanding the differences between face and end mills is essential in determining the most efficient and effective tool for the job.

5.Tool Life And Maintenance

Several factors come into play when comparing the tool life and maintenance of face and end mills. Face mills, commonly used for larger surface cutting, tend to have longer tool life due to their multiple cutting edges.

However, they require more frequent maintenance and tool changes. On the other hand, end mills, designed for more precise and intricate cutting, may have shorter tool life but require less frequent maintenance. Ultimately, the choice between the two depends on the specific application and desired outcomes.

6.Cost Considerations

The average price of a face mill is typically higher than an end mill’s. Face mills are larger and specialized tools for milling flat surfaces, while end mills are smaller and used for milling contours and slots. The cost of face mills can vary depending on the brand, size, and material, but they generally range from $50 to $200 or more. Purchase face mills from reputable tool suppliers or manufacturers such as MSC Industrial Supply, Grainger, or Amazon.

Choosing The Right Tool For Your Milling Needs

Regarding choosing the right tool for your milling needs, there are two main options: face and end mills. To make an informed decision, it is crucial to consider several factors. Firstly, the machined material type plays a significant role in determining which tool is most suitable.

The specific operation type, roughing or finishing, must also be considered. The desired surface finish and the machine’s handy capabilities should also be considered. You can confidently select the perfect tool for your milling requirements by carefully evaluating these guidelines and considerations.

Applications And Best Practices

Face milling applications are commonly handy in various industries for tasks such as creating flat surfaces, milling large areas, and removing material quickly. This technique is ideal for producing smooth finishes and achieving high accuracy. On the other hand, people typically employ end milling applications for tasks like drilling holes, creating slots, and producing complex shapes.

End mills are versatile tools that can be handy for roughing and finishing operations, making them a popular choice in machining processes. Both face and end milling have unique advantages and best practices, and understanding their differences can help determine the most suitable technique for specific machining requirements.

Factors To Consider When Choosing Between Face Mill And End Mill

There are multiple factors when considering a face mill and an end mill. Face mills are typically handy for larger surfaces and offer a wide cutting diameter, making them suitable for high material removal rates. On the other hand, end mills are more versatile and can be handy for various applications, such as contouring, slotting, and profiling. Additionally, end mills provide better precision and accuracy for intricate machining tasks. Understanding the differences between these two milling tools is crucial in determining the most suitable option for your specific machining needs.

- Material: Consider different cutting tools based on material characteristics.

- Cutting Speed And Feed Rate: Use face mills for heavy cuts and highspeed machining, end mills

- Surface Finish: End mills for finer finishes; face mills may leave slightly rougher surfaces.

- Depth Of Cut: Face mills are suitable for deeper cuts compared

- Tool Geometry: Choose cutting tool shape and design based on specific machining needs.

- Cost And Availability: Evaluate the cost and availability of face and end mills.

- Machine Capabilities: Ensure the machine has appropriate spindle speed, power, and rigidity for selected cutting tools.

Case Studies And Examples

When comparing face and end mills, it is important to consider real-life examples showcasing their applications. For instance, face mills are commonly handy in industries such as automotive manufacturing, where they are employed to achieve high precision and smooth finishes on large, flat surfaces.

On the other hand, end mills find extensive use in producing intricate details and contours, as seen in the aerospace industry for machining complex parts. These case studies highlight the versatility and effectiveness of both tools in different machining scenarios.

Conclusion

The decision to use a face or end mill depends on your project’s requirements. While face mills are ideal for larger surface area milling, end mills offer more versatility and precision for intricate designs. These machines are crucial in creating precise and accurate cuts on various materials, from metal to wood to plastic

However, with the wide array of milling tools available, it can be challenging to determine which one is the best fit for your project. It is important to consider your project’s material, size, and complexity carefully before selecting the appropriate tool. Ultimately, both face and end mills have advantages and should be utilized accordingly to achieve the best results. With the right tools and techniques, you can achieve high-quality and efficient results in your milling projects.

FAQ

1.What Is An End Mill Used For?

An end mill is a cutting tool used in milling machines to remove material from a workpiece. It has a cylindrical shape with cutting edges on both the end and the sides.

2.What Is The End Milling Process?

End milling is a machining process to cut or shape materials using a rotating milling cutter. The milling cutter has multiple teeth and mounts on the end of a spindle, hence called “end milling.”

3.What Is The Best Rpm For Milling?

Generally, a higher RPM is preferred for smaller cutter diameters and softer materials, while a lower RPM is more suitable for larger cutter diameters and harder materials.

4.What Are The Most Used End Mills?

The most commonly used end mills include square end mills, ball nose end mills, and corner radius end mills. These end mills are versatile and can be handy for various milling operations, such as contouring, slotting, and profiling.

5.What Is A Face Mill Arbor?

A face mill arbor is handy in machining to secure a face mill cutter to a milling machine. It is esigned to fit into the machine’s spindle and holds the cutter in place while it rotates.