Have you ever watched a craftsman shape metal into something amazing? A metal lathe lets you do just that from the comfort of your home. With a metal lathe drive system, you can turn raw metal into beautiful parts for your projects. Imagine making your own tools or decorations!

Many people think that metalworking is only for experts. But with the right drive system, anyone can learn. It’s like having a magic wand that helps you create. Picture yourself working in your garage, seeing metal come to life under your hands. Isn’t that exciting?

Did you know that the first lathes were used more than 5,000 years ago? It’s true! These machines have come a long way. Today, a for home use metal lathe drive system gives you the power to do amazing things. Are you ready to explore how to make your own creations? Let’s dive in!

For Home Use Metal Lathe Drive System: A Comprehensive Guide

For Home Use Metal Lathe Drive System

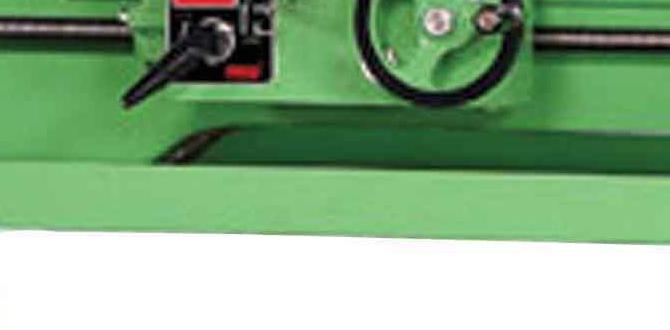

Looking to create precision parts at home? A metal lathe drive system might be your best tool. This system allows you to shape and cut metal efficiently. Did you know that using a metal lathe can help you craft everything from machinery parts to artistic sculptures? With various drive options, you’ll find one that fits your needs. Choosing the right drive system can enhance your projects and simplify your experience. Explore how this fascinating tool can unleash your creativity!Factors to Consider When Selecting a Drive System

Importance of motor power and speed control options.. Assessment of torque requirements for different metalworking tasks..Choosing the right drive system can be a bit like picking the right ice cream flavor—so many choices! First, think about motor power. More power means smoother cuts, especially for tough metal. Speed control is key, too; it helps you adjust for different tasks. You don’t want your lathe zooming off like it’s in a race! Then, consider torque. It’s what gets the job done, and different tasks need different amounts. Check out the table below for some tips:

| Task | Recommended Torque |

|---|---|

| Turning | Medium |

| Drilling | High |

| Facing | Low to Medium |

Remember, picking a drive system is crucial for metalworking. Choose wisely and make your lathe sing like a showbiz star!

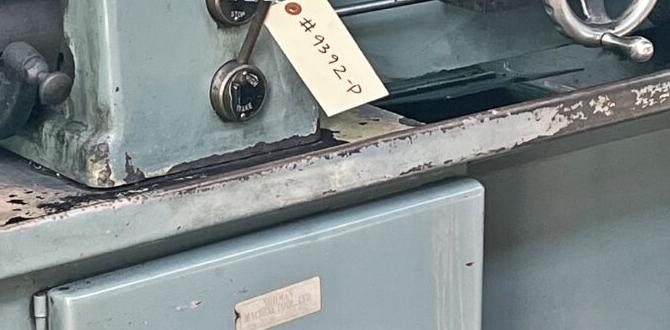

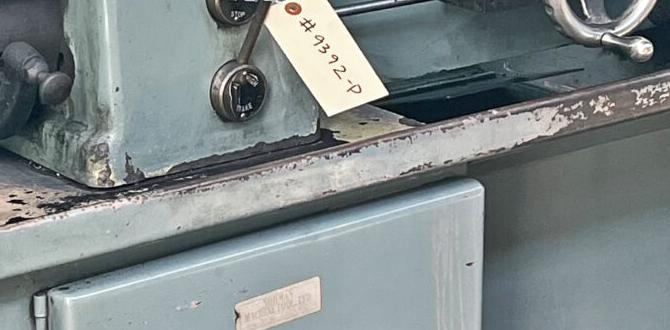

Top Brands and Models for Home Use

Review of popular drive systems in the market for home metal lathes.. Comparison of features, pricing, and customer feedback..Many folks enjoy working with metal lathes at home, and several brands stand out in the crowd. For starters, there’s Precision Mathews, known for its sturdy machines that make threading easy. Then we have Grizzly, which offers great value with lots of features. Customer reviews often praise both for reliability but watch out for long shipping times! Below is a simple comparison of some popular models:

| Brand | Model | Price | Rating |

|---|---|---|---|

| Precision Mathews | PM-1228VF | $1,899 | 4.8/5 |

| Grizzly | G4003G | $1,545 | 4.5/5 |

| Jet | JWL-1442 | $1,299 | 4.6/5 |

Choosing a metal lathe isn’t rocket science, but do pick one that fits your needs. Happy turning, and may your projects be as smooth as butter!

Installation and Setup Guidelines

Stepbystep instructions for installing the drive system.. Tips for aligning and calibrating the lathe after installation..Installing your drive system is key to a smooth-running lathe. Follow these easy steps:

- Gather all parts and tools needed.

- Secure the lathe on a flat, sturdy surface.

- Attach the drive system according to the manual.

- Check all connections carefully.

After installation, alignment and calibration are important:

- Use a level to ensure your lathe is even.

- Spin the lathe to check for any wobble.

- Adjust the belts for proper tension.

Following these steps will help you set up your metal lathe effectively. Have fun creating!

What should I know about installing a home lathe drive system?

Measure twice, cut once! Follow the manual closely for accurate assembly. Proper installation ensures safety and efficiency.

Maintenance and Troubleshooting Tips

Routine maintenance practices to extend the lifespan of the drive system.. Common issues and how to troubleshoot them effectively..Keeping your metal lathe drive system in good shape is key to its performance. Regular maintenance can make it last longer and work better. Here are some simple tips:

- Clean dust and chips often.

- Check for loose screws or bolts.

- Lubricate moving parts regularly.

If you face common problems, here’s how to fix them:

- For strange noises, check for misalignments.

- If the motor doesn’t start, inspect the power supply.

- For stalling, ensure that your tools are sharp and correctly set.

These tips can help keep your drive system running smoothly.

What should I do if my drive system gets loud?

Check for any loose parts and make sure everything is aligned properly. If the problem continues, consider consulting a professional.

Enhancing Performance with Upgrades

Discussion on potential upgrades for better efficiency.. Recommendations for accessories that improve functionality..Upgrading your metal lathe can make a big difference in its performance. Small changes can lead to better results. For example, consider these upgrades:

- **Enhanced motor:** A stronger motor gives you more power.

- **Better gears:** High-quality gears improve speed and accuracy.

- **Upgraded tools:** Sharp and durable tools work faster.

- **Coolant systems:** These keep the machine at a good temperature.

Adding these accessories can improve your work routine. They can help you finish projects more efficiently and with high quality. So, think about these options for a smoother experience!

What upgrades can enhance my metal lathe’s performance?

Upgrades like a stronger motor and better gears can boost your metal lathe’s performance. These changes can make your tasks quicker and more accurate. Consider tools and coolant systems to further enhance efficiency.

Conclusion

In summary, a metal lathe drive system for home use is important for precision work. It helps you create various projects with ease. Choosing the right system can improve your skills and efficiency. Explore different options, and consider factors like power and size. Start your journey into metalworking today and learn more to enhance your projects!FAQs

What Are The Key Components Of A Metal Lathe Drive System For Home Use, And How Do They Work Together To Achieve Precision Machining?A metal lathe drive system has a few important parts. First, there’s the motor, which gives power to the machine. Next, we have gears that help control how fast the lathe turns. There’s also a spindle, which holds the metal piece you want to shape. Together, these parts let you cut and shape metal very accurately.

How Do Different Types Of Drive Systems (Belt Drive Vs. Direct Drive) Affect The Performance And Maintenance Of A Home Metal Lathe?Belt drive systems use a belt to connect the motor to the lathe. They can be quieter and easier to fix. However, they can slip, which might make cutting less accurate. Direct drive systems connect the motor directly to the lathe. They offer better power and accuracy but can be harder to repair if something breaks.

What Factors Should Be Considered When Selecting A Motor For A Home Metal Lathe Drive System?When picking a motor for a metal lathe, you should think about power, speed, and size. The motor needs enough strength to turn the lathe properly. You also want it to go fast enough for the work you do. Finally, make sure it fits in the space where you’ll use it. Always check if it’s easy to connect and use too!

How Can One Troubleshoot Common Issues Related To The Drive System Of A Home Metal Lathe?To troubleshoot problems with the drive system of a home metal lathe, start by checking the power source. Make sure it’s plugged in and turned on. Next, look for any loose or broken parts in the belt or gears. If the lathe makes strange noises, stop it and check for any stuck pieces. Finally, consult the manual for help or ask someone who knows about lathes.

What Are The Advantages And Disadvantages Of Using Variable Speed Drives In Home Metal Lathe Applications?Using variable speed drives (VSDs) on home metal lathes has good and bad sides. One advantage is you can change the speed easily, which helps you make better cuts. This means you can work on different types of metal without trouble. However, a downside is that VSDs can be more expensive and harder to fix if they break. So, you need to think about the costs and your skill level before deciding.