Imagine creating something amazing with a metal lathe. You could make beautiful parts for models or even furniture. But, do you know what makes it all work smoothly? That’s right! It’s the heavy duty metal lathe controller board. This little gadget controls everything, making the lathe function just right.

Have you ever watched a lathe in action? It spins metal like magic! The controller board plays a huge role in this process. Without it, your dreams of building cool projects would be much harder to achieve. Choosing the right controller board can change your entire experience.

Here’s a fun fact: many skilled makers have built their own controller boards. They wanted more power and control. This shows how important the right board really is. It can enhance your skills and creativity in ways you never thought possible.

So, why should you care about a heavy duty metal lathe controller board? Let’s dive in and discover how it can help bring your metalworking projects to life!

Heavy Duty Metal Lathe Controller Board: Essential Insights

Understanding Heavy Duty Metal Lathe Controller Boards

Heavy duty metal lathe controller boards are essential for precise machining tasks. They help control the lathe’s movements, making sure everything is accurate. Imagine trying to carve a block of wood without a guide—chaotic, right? These boards offer just that guidance. They enhance speed and efficiency, allowing the machine to work faster without sacrificing quality. Curious about how they can improve your projects? Learning about these tools opens a world of possibilities in metalworking.What is a Heavy Duty Metal Lathe Controller Board?

Definition and purpose of a controller board in metal lathes. Key features that distinguish heavyduty models from standard ones.A controller board in a metal lathe is like the brain of the operation. It tells the lathe how fast to spin and how deep to cut. In heavy-duty models, this board is designed to manage tougher tasks. It can handle higher loads and work with stronger materials.

Key features that set heavy-duty boards apart include:

| Feature | Heavy-Duty Model | Standard Model |

|---|---|---|

| Power Capacity | Higher wattage | Lower wattage |

| Material Compatibility | Harder metals | Soft metals |

| Durability | More robust | Less robust |

Overall, a heavy-duty metal lathe controller board is essential for anyone who wants to turn out serious work in their workshop. Remember, if it can handle tough jobs, it’s definitely a winner!

Benefits of Using a Heavy Duty Metal Lathe Controller Board

Enhanced precision and control in machining operations. Improved efficiency and productivity in workshops.A heavy duty metal lathe controller board improves how machines work. This board gives better precision during machining. Users can make exact cuts and shapes more easily. It helps avoid mistakes that waste materials. Also, it speeds up work in shops. Workers can finish jobs quicker, leading to higher productivity. This means they can take on more projects. As a result, businesses can earn more money while keeping quality high.

What are the main benefits of using this technology?

Using a heavy duty metal lathe controller board can lead to better quality, faster work, and increased profits.

Key Benefits:

- Enhanced precision for accurate cuts

- Improved efficiency saves time

- Higher productivity means more jobs

Key Specifications to Look For

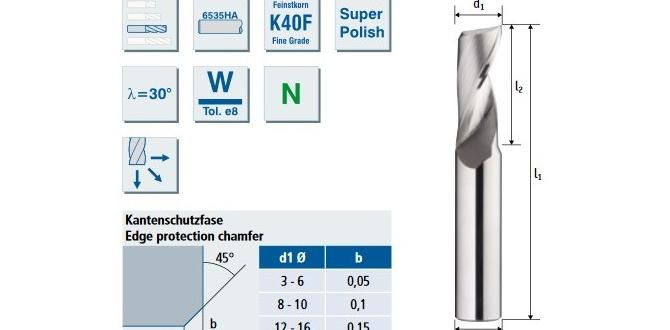

Motor compatibility and power ratings. Control interfaces and software compatibility.Choosing the right controller board is key for a heavy duty metal lathe. Here are important features to consider:

- Motor Compatibility: Ensure the board works with your motor type. Check power ratings, as they affect performance.

- Control Interfaces: Look for USB or serial connections. This simplifies software linking.

- Software Compatibility: Make sure it supports popular programs for easy use.

What motor power ratings are important?

Higher power ratings allow for bigger workloads. Choose a board that can handle the motor’s power needs for better efficiency.

What control interfaces should I consider?

Look for simple options. USB ports make connecting to your computer easier. More options mean more flexibility!

Installation and Setup Guidelines

Stepbystep instructions for installation. Essential tools and safety precautions.Installing a heavy-duty metal lathe controller board can feel like assembling a puzzle, minus the cat trying to help. Start by gathering your tools: a screwdriver, wire cutters, and, of course, safety glasses—because who wants to be a pirate with an eye patch? Follow these basic steps:

| Step | Action |

|---|---|

| 1 | Turn off all power sources. |

| 2 | Fix the controller board to its designated spot. |

| 3 | Connect the wires carefully. (No spaghetti mess, please!) |

| 4 | Double-check your connections. |

| 5 | Power it up and do a happy dance! |

Remember, safety first! Always work in a well-lit area and keep those hands clean. After all, nobody likes a greasy toolkit! Follow these tips, and you’ll be spinning that metal like a pro in no time!

Troubleshooting Common Issues

Identifying and resolving typical problems encountered. Maintenance tips to keep the controller board functional.Troubleshooting is like being a detective for your heavy-duty metal lathe controller board! Sometimes, it may not work properly, and that can be frustrating. A quick check on connections can fix many issues. Look out for loose wires; they can cause chaos. For maintenance, keep it clean and dust-free. Remember, a clean board is a happy board! Also, using it regularly helps keep it in tip-top shape.

| Common Issue | Solution |

|---|---|

| Poor Performance | Check connections and clean the board. |

| Unresponsive Buttons | Look for dirt or wear on buttons. |

| Overheating | Ensure proper ventilation around the board. |

Upgrading Your Existing Lathe with a Controller Board

Factors to consider before upgrading. Recommended upgrades for specific lathe models.Upgrading a lathe can be exciting. Many factors are important to consider. First, think about your current lathe model and its compatibility with a new controller board. Check if you have enough power supply for the upgrade.

Some recommended upgrades include:

- CNC Lathe: Consider a simple interfaz board.

- Mini Lathe: Look for a compact, user-friendly controller.

- Heavy Duty Lathe: Focus on high-capacity boards for better control.

Research helps you choose the right upgrade.

What should I consider before upgrading my lathe?

Check compatibility, user needs, and power requirements.

Key Tips:

- Ask for expert advice.

- Read reviews for the controller board.

Understanding these factors can make your upgrade process smooth and successful!

Real-World Applications and Case Studies

Industries that benefit from heavyduty lathe controller boards. Success stories of workshops that improved productivity.Many industries use heavy duty metal lathe controller boards. These tools help make precise parts quickly and easily. Some industries that benefit include:

- Automotive: They create engine parts and wheels.

- Aerospace: They make lightweight and strong components.

- Manufacturing: They produce items like tools and machines.

Some workshops have shared their success stories. By using these boards, they improved their productivity by as much as 30%. Workers spend less time fixing mistakes and more time creating. This means happy workers and happy customers. Isn’t that awesome?

Frequently Asked Questions (FAQs)

Addressing common queries and concerns regarding usage. Tips for choosing the right controller board for specific needs.Many people wonder how to use a heavy duty metal lathe controller board. It’s like asking how to ride a bike. Start with the basics. Read the manual and get familiar with the buttons and settings. Then, you’ll be ready to create amazing parts!

Need help deciding which board is right for you? Here are some key tips:

| Tip | Description |

|---|---|

| Compatibility | Make sure it works with your lathe model. |

| Features | Look for good speed control and easy programming. |

| Support | Check if there is help available when things go wrong. |

Choosing the right controller can make your projects smoother. Remember, it’s all about finding the best fit. Happy turning!

Conclusion

In summary, a heavy-duty metal lathe controller board is essential for precision and control in machining. It enhances your projects’ quality and efficiency. If you’re interested in upgrading your workshop, consider exploring different models and features. We encourage you to read more about specifications and user experiences to find the perfect fit for your needs. Happy machining!FAQs

What Are The Key Features To Look For In A Heavy Duty Metal Lathe Controller Board?When choosing a heavy-duty metal lathe controller board, look for a few important features. First, make sure it has good power handling. This helps the lathe work harder without breaking. Next, check if it has easy controls. You want to adjust settings without trouble. Lastly, think about the software. It should be user-friendly and help you program different tasks easily.

How Does The Controller Board Impact The Precision And Efficiency Of A Heavy Duty Metal Lathe?The controller board is like the brain of the metal lathe. It helps control how fast and how carefully the machine works. With a good controller, the lathe cuts metal more accurately and saves time. This means you get better metal pieces and finish your work faster.

What Types Of Motors Can Be Effectively Controlled By A Heavy Duty Metal Lathe Controller Board?A heavy-duty metal lathe controller board can control different types of motors. You can use it for stepper motors, which move in small steps. It also works with DC motors, which spin smoothly. Lastly, you can control servo motors, which can move to specific positions. These motors help the lathe spin and cut materials.

How Can One Troubleshoot Common Issues With A Heavy Duty Metal Lathe Controller Board?To troubleshoot problems with a heavy-duty metal lathe controller board, first, check the power supply. Make sure everything is plugged in and working. Next, look for loose wires or connections that might be causing issues. If you see any error messages, write them down and check the manual for help. Lastly, reset the controller board to see if that fixes the problem.

What Are The Differences Between Analog And Digital Controller Boards For Heavy Duty Metal Lathes?Analog controller boards use simple electrical signals to control the lathe. They are easy to understand and use. Digital controller boards use computers and codes to manage the lathe. They can be more precise and have more features. So, analog is basic, while digital is advanced and often smarter.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Heavy Duty Metal Lathe Controller Board? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a heavy-duty metal lathe controller board, look for a few important features. First, make sure it has good power handling. This helps the lathe work harder without breaking. Next, check if it has easy controls. You want to adjust settings without trouble. Lastly, think about the software. It should be user-friendly and help you program different tasks easily.”}},{“@type”: “Question”,”name”: “How Does The Controller Board Impact The Precision And Efficiency Of A Heavy Duty Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The controller board is like the brain of the metal lathe. It helps control how fast and how carefully the machine works. With a good controller, the lathe cuts metal more accurately and saves time. This means you get better metal pieces and finish your work faster.”}},{“@type”: “Question”,”name”: “What Types Of Motors Can Be Effectively Controlled By A Heavy Duty Metal Lathe Controller Board? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A heavy-duty metal lathe controller board can control different types of motors. You can use it for stepper motors, which move in small steps. It also works with DC motors, which spin smoothly. Lastly, you can control servo motors, which can move to specific positions. These motors help the lathe spin and cut materials.”}},{“@type”: “Question”,”name”: “How Can One Troubleshoot Common Issues With A Heavy Duty Metal Lathe Controller Board? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot problems with a heavy-duty metal lathe controller board, first, check the power supply. Make sure everything is plugged in and working. Next, look for loose wires or connections that might be causing issues. If you see any error messages, write them down and check the manual for help. Lastly, reset the controller board to see if that fixes the problem.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Analog And Digital Controller Boards For Heavy Duty Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Analog controller boards use simple electrical signals to control the lathe. They are easy to understand and use. Digital controller boards use computers and codes to manage the lathe. They can be more precise and have more features. So, analog is basic, while digital is advanced and often smarter.”}}]}